Lisø PhD Dissertation Manuscript - NTNU

Lisø PhD Dissertation Manuscript - NTNU

Lisø PhD Dissertation Manuscript - NTNU

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Typical problem areas and<br />

recommended solutions<br />

Introduction<br />

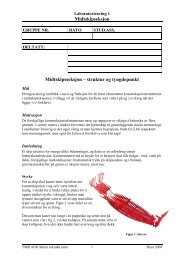

This section presents examples of typical problem areas<br />

and causes of damage regarding weather-protective<br />

flashing, based on the results from the investigation<br />

of building damage assignment reports in NBI’s<br />

project archives (Tables 1 and 2). Examples of ideal<br />

high-performance model solutions for harsh climates<br />

are also provided, based on the performance requirements<br />

for flashings summarized below.<br />

Weather-protective flashings should do the following:<br />

. ensure that a negligible amount of precipitation<br />

penetrates as far as the wind barrier behind<br />

. direct water away from the facade<br />

. allow airflow for appropriate ventilation of cavities<br />

and air gaps<br />

. resist the climatic and mechanical loads to which<br />

they are exposed<br />

. be designed and fastened so that they do not<br />

damage, or become damaged by, the materials in<br />

the adjacent building structures<br />

Experience from other Nordic countries is used (e.g.<br />

Pla˚tslageriernas Riksförbund, 2002). Typical problem<br />

areas and recommended solutions are presented in<br />

more detail by Kvande and <strong>Lisø</strong> (2002). In this overview<br />

of problem areas and causes of damage, the<br />

names of the flashing variants adhere mainly to the<br />

terms and definitions given in Norwegian Standard<br />

3420-S4 (1999). For corresponding English equivalents,<br />

see the Appendix.<br />

Jointing and fastening<br />

The use of folded welts (or seams) is far preferable to,<br />

for example, welding or gluing when jointing extended<br />

lengths of flashing. Sealant should always be used when<br />

fastening flashings in connection with sheet-metal<br />

roofing. Folded welts can give leakage points at bends<br />

in the flashing when poorly executed (Figure 1). It is<br />

often found that attempts have been made to seal<br />

leaks in flashing joints and transitions by using extra<br />

screws or some sort of mastic. Using screws normally<br />

makes matters worse. The use of mastic as a sealant<br />

in connection with jointing is common practice, but<br />

such sealing has only a short life span due to thermal<br />

expansion/contraction of the sheet metal.<br />

Folded welts facilitate the absorption of thermal expansion/contraction.<br />

In order for the folded welt to absorb<br />

temperature-induced movement, the spacing between<br />

joints should not be too large (recommended lengths<br />

High-performance weather-protective £ashings<br />

Figure 1 Poorly executed folded welt on parapet £ashing. The<br />

under-£ashing is missing. Source: Norwegian Building Research<br />

Institute,Oslo<br />

are given in Norwegian Standard 3420, 1999). The<br />

use of overlap jointing is generally not advisable.<br />

The strength of the flashing’s fastening must be sufficient<br />

to prevent it from being blown off by locally<br />

encountered wind forces. When securing flashing with<br />

screws or nails, it is essential that fastening points<br />

be positioned where the structure will not be exposed<br />

to water pressure. Welted flashing (joints) should be<br />

recommended as a principal rule. By anchoring the<br />

flashing via the folded welts, perforation is avoided.<br />

When using screws, one must always choose screws<br />

with rubber washers to ensure that the seal will last<br />

for as long as possible. Unless exposed nail heads are<br />

suitably covered, the use of nails offers a very vulnerable<br />

solution in relation to water penetration.<br />

Flashing edge<br />

Open-ended flashing edges, among other features,<br />

must have a wrap-over to prevent corrosion. Besides<br />

which, finishing off without a wrap-over leaves a<br />

sharp edge that can cause personal injury. To lead<br />

water from the flashing away from the facade, the<br />

finished edge of the flashing must be given a drip<br />

edge. Figure 2a shows examples of flashing edge<br />

designs where the drip edge has been omitted and<br />

where water is being directed to places where it is<br />

unwanted. Recommended solutions are shown in<br />

Figure 2b. Flashing edges lacking support or reinforcement<br />

are also prone to damage when exposed to wind<br />

loads or to possible mechanical loads.<br />

Windowsill and weatherboard £ashing<br />

In contrast to most other types of flashing, windowsill<br />

flashings are generally installed with flashing as<br />

45

![Diagnosis and FTC by Prof. Blanke [pdf] - NTNU](https://img.yumpu.com/12483948/1/190x245/diagnosis-and-ftc-by-prof-blanke-pdf-ntnu.jpg?quality=85)