TDS-231 Separation of Carbopol® Polymers from ... - Lubrizol

TDS-231 Separation of Carbopol® Polymers from ... - Lubrizol

TDS-231 Separation of Carbopol® Polymers from ... - Lubrizol

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

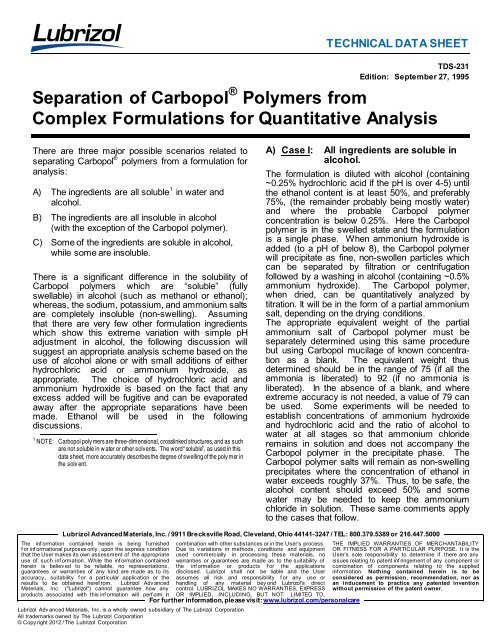

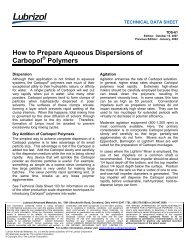

TECHNICAL DATA SHEET<br />

<strong>TDS</strong>-<strong>231</strong><br />

Edition: September 27, 1995<br />

<strong>Separation</strong> <strong>of</strong> Carbopol ® <strong>Polymers</strong> <strong>from</strong><br />

Complex Formulations for Quantitative Analysis<br />

There are three major possible scenarios related to<br />

separating Carbopol ® polymers <strong>from</strong> a formulation for<br />

analysis:<br />

A) The ingredients are all soluble 1 in water and<br />

alcohol.<br />

B) The ingredients are all insoluble in alcohol<br />

(with the exception <strong>of</strong> the Carbopol polymer).<br />

C) Some <strong>of</strong> the ingredients are soluble in alcohol,<br />

while some are insoluble.<br />

There is a significant difference in the solubility <strong>of</strong><br />

Carbopol polymers which are “soluble” (fully<br />

swellable) in alcohol (such as methanol or ethanol);<br />

whereas, the sodium, potassium, and ammonium salts<br />

are completely insoluble (non-swelling). Assuming<br />

that there are very few other formulation ingredients<br />

which show this extreme variation with simple pH<br />

adjustment in alcohol, the following discussion will<br />

suggest an appropriate analysis scheme based on the<br />

use <strong>of</strong> alcohol alone or with small additions <strong>of</strong> either<br />

hydrochloric acid or ammonium hydroxide, as<br />

appropriate. The choice <strong>of</strong> hydrochloric acid and<br />

ammonium hydroxide is based on the fact that any<br />

excess added will be fugitive and can be evaporated<br />

away after the appropriate separations have been<br />

made. Ethanol will be used in the following<br />

discussions.<br />

1 NOTE: Carbopol poly mers are three-dimensional, crosslinked structures, and as such<br />

are not soluble in w ater or other solvents. The word “soluble”, as used in this<br />

data sheet, more accurately describes the degree <strong>of</strong> swelling <strong>of</strong> the poly mer in<br />

the solv ent.<br />

A) Case I: All ingredients are soluble in<br />

alcohol.<br />

The formulation is diluted with alcohol (containing<br />

~0.25% hydrochloric acid if the pH is over 4-5) until<br />

the ethanol content is at least 50%, and preferably<br />

75%, (the remainder probably being mostly water)<br />

and where the probable Carbopol polymer<br />

concentration is below 0.25%. Here the Carbopol<br />

polymer is in the swelled state and the formulation<br />

is a single phase. When ammonium hydroxide is<br />

added (to a pH <strong>of</strong> below 8), the Carbopol polymer<br />

will precipitate as fine, non-swollen particles which<br />

can be separated by filtration or centrifugation<br />

followed by a washing in alcohol (containing ~0.5%<br />

ammonium hydroxide). The Carbopol polymer,<br />

when dried, can be quantitatively analyzed by<br />

titration. It will be in the form <strong>of</strong> a partial ammonium<br />

salt, depending on the drying conditions.<br />

The appropriate equivalent weight <strong>of</strong> the partial<br />

ammonium salt <strong>of</strong> Carbopol polymer must be<br />

separately determined using this same procedure<br />

but using Carbopol mucilage <strong>of</strong> known concentration<br />

as a blank. The equivalent weight thus<br />

determined should be in the range <strong>of</strong> 75 (if all the<br />

ammonia is liberated) to 92 (if no ammonia is<br />

liberated). In the absence <strong>of</strong> a blank, and where<br />

extreme accuracy is not needed, a value <strong>of</strong> 79 can<br />

be used. Some experiments will be needed to<br />

establish concentrations <strong>of</strong> ammonium hydroxide<br />

and hydrochloric acid and the ratio <strong>of</strong> alcohol to<br />

water at all stages so that ammonium chloride<br />

remains in solution and does not accompany the<br />

Carbopol polymer in the precipitate phase. The<br />

Carbopol polymer salts will remain as non-swelling<br />

precipitates where the concentration <strong>of</strong> ethanol in<br />

water exceeds roughly 37%. Thus, to be safe, the<br />

alcohol content should exceed 50% and some<br />

water may be needed to keep the ammonium<br />

chloride in solution. These same comments apply<br />

to the cases that follow.<br />

<strong>Lubrizol</strong> Advanced Materials, Inc. / 9911 Brecksville Road, Cleveland, Ohio 44141-3247 / TEL: 800.379.5389 or 216.447.5000<br />

The inf ormation contained herein is being f urnished combination with other substances or in the User’s process.<br />

f or inf ormational purposes only , upon the express condition Due to v ariations in methods, conditions and equipment<br />

THE IMPLIED WARRANTIES OF MERCHANTABILITY<br />

OR FITNESS FOR A PARTICULAR PURPOSE. It is the<br />

that the User makes its own assessment <strong>of</strong> the appropriate used commercially in processing these materials, no User’s sole responsibility to determine if there are any<br />

use <strong>of</strong> such inf ormation. While the inf ormation contained warranties or guarantees are made as to the suitability <strong>of</strong> issues relating to patent inf ringement <strong>of</strong> any component or<br />

herein is believ ed to be reliable, no representations,<br />

guarantees or warranties <strong>of</strong> any kind are made as to its<br />

the inf ormation or products f or the applications combination <strong>of</strong> components relating to the supplied<br />

disclosed. <strong>Lubrizol</strong> shall not be liable and the User inf ormation. Nothing contained herein is to be<br />

accuracy , suitability f or a particular application or the assumes all risk and responsibility f or any use or considered as permission, recommendation, nor as<br />

results to be obtained heref rom. <strong>Lubrizol</strong> Adv anced handling <strong>of</strong> any material bey ond <strong>Lubrizol</strong>'s direct an inducement to practice any patented invention<br />

Materials, Inc. ("<strong>Lubrizol</strong>") cannot guarantee how any control. LUBRIZOL MAKES NO WARRANTIES, EXPRESS without permission <strong>of</strong> the patent owner.<br />

products associated with this inf ormation will perf orm in OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,<br />

For further information, please visit: www.lubrizol.com/personalcare<br />

<strong>Lubrizol</strong> Adv anced Materials, Inc. is a wholly owned subsidiary <strong>of</strong> The <strong>Lubrizol</strong> Corporation<br />

All trademarks owned by The <strong>Lubrizol</strong> Corporation<br />

© Copy right 2012 / The <strong>Lubrizol</strong> Corporation

B) Case II: All ingredients (except<br />

Carbopol polymer) are alcohol<br />

insoluble.<br />

A large excess <strong>of</strong> alcohol is added to the<br />

formulation so that the Carbopol polymer<br />

concentration is less than 0.25% and the other<br />

ingredients are insoluble. To insure that the<br />

Carbopol polymer is fully swellable, the alcohol<br />

used contains about 0.25% hydrochloric acid. The<br />

insoluble formulation ingredients are separated out<br />

by filtration or centrifugation. The dilute solution is<br />

stirred while about 0.5% ammonium hydroxide is<br />

added to the system (addition as a water solution is<br />

permissible). The Carbopol polymer will precipitate<br />

as fine white particles that can be separated and<br />

treated as in Case I above.<br />

C) Case III: Some formulation ingredients<br />

are alcohol soluble while<br />

others are not.<br />

This situation may represent the majority <strong>of</strong> cases<br />

and will require an additional step. Here we assure<br />

that the Carbopol polymer is initially fully alcohol<br />

swellable by adding hydrochloric acid to reduce the<br />

pH below 3 and adding alcohol until 50% (or<br />

preferably 75%) concentration is reached and the<br />

concentration <strong>of</strong> Carbopol polymer is below 0.25%.<br />

The diluted formulation is then centrifuged or<br />

filtered to effect separation <strong>of</strong> the insoluble<br />

ingredients followed by washing, etc. The diluted<br />

solution phase (including the washing) contains<br />

alcohol soluble ingredients and swelled Carbopol<br />

polymer. It should then be treated by adding<br />

ammonium hydroxide to the system and<br />

proceeding as in Case I.<br />

<strong>TDS</strong>-<strong>231</strong><br />

<strong>Separation</strong> <strong>of</strong> Carbopol ® <strong>Polymers</strong> <strong>from</strong> Complex<br />

Formulations for Quantitative Analysis<br />

Page 2 <strong>of</strong> 3

<strong>TDS</strong>-<strong>231</strong><br />

<strong>Separation</strong> <strong>of</strong> Carbopol ® <strong>Polymers</strong> <strong>from</strong> Complex<br />

Formulations for Quantitative Analysis<br />

Page 3 <strong>of</strong> 3<br />

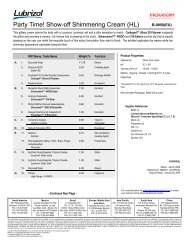

<strong>Separation</strong> <strong>of</strong> Carbopol ® <strong>Polymers</strong> <strong>from</strong> Complex<br />

Formulations for Quantitative Analysis (Flow Chart)<br />

Formulation Ingredients<br />

Soluble in water and alcohol Insoluble in alcohol*<br />

(*Note: Carbopol ® polymer is<br />

soluble)<br />

Dilute with excess alcohol<br />

(50-75%) (~pH 3-4)<br />

[Carbopol ® polymer<br />

concentration