Centrifugal Fans direct driven with scroll - Nicotra Gebhardt

Centrifugal Fans direct driven with scroll - Nicotra Gebhardt

Centrifugal Fans direct driven with scroll - Nicotra Gebhardt

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

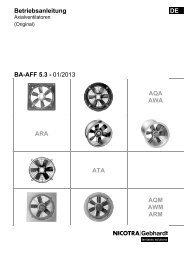

Description<br />

Motors<br />

Electric connection<br />

196<br />

V<br />

400<br />

230<br />

50 87 Hz<br />

Direct <strong>driven</strong> centrifugal fans / RZA / Description<br />

The specially developed integral motors are designated as having protection class<br />

IP54 and heat class F.<br />

They are optimised to a high rate of efficiency, <strong>with</strong> speed that can be adjusted between<br />

0 and 100% via the frequency inverter.<br />

The motors are fitted <strong>with</strong> an easily accessible metal clamping box. To prevent<br />

overloading, PTC are inserted in the windings of the motors. In conjunction <strong>with</strong><br />

PTC release equipment or a frequency inverter <strong>with</strong> PTC connection, effective motor<br />

protection is guaranteed.<br />

The motors ex works are in star connection (Y). When operating <strong>with</strong> a frequency<br />

inverter, the links must be placed in delta connection (D) (see wiring<br />

diagram).<br />

All fans are delivered ready for connection. Electrical connection takes place in<br />

accordance <strong>with</strong> the enclosed operating instructions and observing the relevant<br />

applicable local regulations and <strong>direct</strong>ives. Every fan is accompanied by a connection<br />

circuit diagram. You can also find the relevant circuit diagram online under:<br />

www.nicotra-gebhardt.com.<br />

Frequency inverter operation<br />

Frequency inverter operation <strong>with</strong> a nominal voltage of 400V the edge frequency of<br />

87Hz must be set. The motor must then be delta (D) connected.<br />

The inverter exit voltage is a square function of the frequency and the voltagefrequency-curve<br />

has a corresponding shape. In the case of <strong>direct</strong> mains (400V)<br />

operation the motor should be star (Y) connected.<br />

If frequency inverters are allocated by the customer, then it must be ensured that the<br />

voltage gradient of the frequency inverter does not exceed the figure of 500V/µs and<br />

the maximum peak voltage at the motor terminals is kept to 1200V. Depending on the<br />

frequency inverter employed and the length of cable between the frequency inverter<br />

and the motor, additional units (such as motor choke, active sinus filter, for example)<br />

may be needed to ensure that the limits named above are kept to.<br />

Non-compliance may lead to damage to the motor!