Cr-Mo Welding Electrodes - ESAB Welding & Cutting Products

Cr-Mo Welding Electrodes - ESAB Welding & Cutting Products

Cr-Mo Welding Electrodes - ESAB Welding & Cutting Products

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

YOUR CHOICE FOR CREEP RESISTANT FILLER METALS<br />

<strong>Cr</strong>-<strong>Mo</strong> <strong>Welding</strong><br />

<strong>Electrodes</strong><br />

for the Power Generating Industry<br />

<strong>ESAB</strong> <strong>Welding</strong> &<br />

<strong>Cutting</strong> <strong>Products</strong><br />

WELDING l CUTTING l FILLER

FOR MORE INFORMATION -<br />

Contact:<br />

<strong>ESAB</strong> <strong>Welding</strong> & <strong>Cutting</strong> <strong>Products</strong><br />

Customer Service Center<br />

P. O. Box 517<br />

801 Wilson Avenue<br />

Hanover, PA 17331<br />

TELEPHONE: 717/637-8911 (General Office)<br />

800/933-7070 (Customer Service - TOLL FREE)<br />

FACSIMILE: 800/444-8911 (Customer Service - TOLL FREE)<br />

The information contained herein is based on data and information<br />

developed in the laboratories of <strong>ESAB</strong> <strong>Welding</strong> & <strong>Cutting</strong> <strong>Products</strong> (“Seller”),<br />

but is presented without guarantee or warranty and the Seller makes no<br />

recommendation for and disclaims any liability incurred from any use<br />

thereof, including without limitation, any use in a commercial process not<br />

controlled by the Seller, and any use in violation of any existing patent,<br />

foreign or domestic, or of applicable laws and regulations.<br />

THE SELLER MAKES NO WARRANTIES, EXPRESS OR IMPLIED,<br />

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF<br />

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,<br />

EXCEPT AS EXPRESSLY STATED IN SELLER’S CONTRACT OR SALES<br />

ACKNOWLEDGMENT FORM.<br />

TABlE of ConTEnTS<br />

PoWEr gEnErATion<br />

Description Page<br />

Process Description ......................................................................................................................1<br />

<strong>Cr</strong>-<strong>Mo</strong> Selection guide ..................................................................................................................2<br />

Product offering<br />

.5% <strong>Mo</strong> ...................................................................................................................................3-5<br />

1.25% <strong>Cr</strong>, .5% <strong>Mo</strong> ..................................................................................................................6-9<br />

2.25% <strong>Cr</strong>, 1% <strong>Mo</strong> ...............................................................................................................10-13<br />

5% <strong>Cr</strong>, .5% <strong>Mo</strong> ...................................................................................................................14-16<br />

9% <strong>Cr</strong> - 1% <strong>Mo</strong> ...................................................................................................................17-18<br />

<strong>Mo</strong>dified 9% <strong>Cr</strong>-<strong>Mo</strong>-V .........................................................................................................19-25<br />

Certified Material Test Report (CMTR)<br />

Atom Arc 9015-B9 ...................................................................................................................26<br />

Atom Arc 9018-B9 ...................................................................................................................27<br />

Dual Shield B9 ........................................................................................................................28<br />

Tigrod ER90S-B9 ....................................................................................................................29<br />

<strong>Cr</strong>eep Data Chart<br />

Atom Arc 9015-B9 ...................................................................................................................30<br />

Atom Arc 9018-B9 ...................................................................................................................30<br />

Dual Shield B9 ........................................................................................................................30<br />

Tigrod ER90S-B9 ....................................................................................................................30<br />

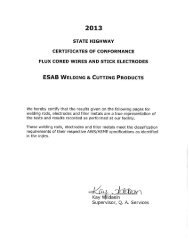

ASME Certificates<br />

Ashtabula, OH facility ..............................................................................................................31<br />

Hanover, PA facility .................................................................................................................32<br />

Safety Data Sheets ......................................................................................................................33

making darkness disappear.<br />

WELdINg + CUTTINg + AUTOMATION = POWER gENERATION SOLUTIONS<br />

esabna.com + 1.800.<strong>ESAB</strong>.123<br />

When you use <strong>ESAB</strong> products,<br />

amazing things happen.<br />

In the harsh environments of the power<br />

generation world, even everyday jobs<br />

aren’t simple. Fortunately, your choice<br />

of a welding and cutting manufacturer<br />

is. As the global authority on welding<br />

and cutting, <strong>ESAB</strong> offers the broadest<br />

selection of world-class products<br />

that meet the tough demands of the<br />

industry. From turbine plants to nuclear<br />

containment vessels, choose <strong>ESAB</strong> for<br />

powerful solutions.<br />

Power generation Technology<br />

<strong>Cr</strong>eep resistant steels were originally developed to<br />

provide improved strength at elevated temperatures.<br />

These creep resistant steels were metallurgically<br />

designed with additions of chromium, molybdenum and<br />

other similar alloys to produce the needed strength and<br />

creep resistance required in most steam generating<br />

facilities. Applications include heat exchangers,<br />

header systems, and associated piping within a power<br />

generation facility. Some of the most common grades<br />

of creep resistant steels include P11, P22, P5 and P91.<br />

Each of these grades has a varying amount of <strong>Cr</strong>-<strong>Mo</strong> and<br />

other assorted alloys added.<br />

<strong>Cr</strong>eep resistant steels require the use of comparable filler<br />

metals that perform at the same level as that of the steel.<br />

It is essential that the choice of filler metals complement<br />

the steels while optimizing the creep resistance. In<br />

addition, the mechanical properties of the filler materials<br />

should adequately produce the toughness needed during<br />

the start-up phase of the plant equipment.<br />

PoWEr gEnErATion TEChnology<br />

Because of the wide variety of creep resistant steel types,<br />

the selection of filler materials is also varied. Historically<br />

products such as 1.25% <strong>Cr</strong>, .5% <strong>Mo</strong> or 2.25% <strong>Cr</strong>, 1%<br />

<strong>Mo</strong> would have been used. Today however, due to the<br />

increased demand for energy, utilities are operating their<br />

facilities under peak load conditions causing them to<br />

choose another grade such as P91 over one of the other<br />

creep resistant steels.<br />

The designation most often associated for the applicable<br />

filler metals for welding P91 grade steels is a “B9”. <strong>ESAB</strong><br />

offers a complete line of “B9” filler metals for the SMAW,<br />

GTAW, FCAW and SAW processes. Each of these<br />

products is tested in accordance to the respective AWS<br />

specification and can be certified to the respective ASME<br />

specification, if need be. Each lot of material is lot tested<br />

and certified prior to the sale. If additional testing is<br />

required, <strong>ESAB</strong> can accommodate such testing.<br />

Throughout the years, the Atom Arc ® , Arcaloy ® and Dual<br />

Shield ® brand names have been synonymous with<br />

both fossil fuel facilities and nuclear power plants. The<br />

engineering design built into these products has provided<br />

fabricators with the highest level of reliability possible.<br />

The technical information contained within this catalog<br />

provides the supporting data to substantiate our vast<br />

knowledge and experience in the development of<br />

products to support the power generation industry. Since<br />

all such product is produced in accordance with the<br />

ASME Quality Assurance System, customers can take<br />

comfort in the fact that these products meet or exceed<br />

their most stringent specifications. Feel free to contact us<br />

for further information or to discuss a specific application.<br />

1

<strong>ESAB</strong> Product reference Chart<br />

Type of Steel Grade<br />

<strong>Cr</strong>-<strong>Mo</strong> Alloy<br />

SElECTion guiDE<br />

ASME<br />

Section<br />

IX SMAW GMAW/GTAW SAW/Flux FCAW MCAW<br />

1/2 % <strong>Mo</strong> 2 P#3 Atom Arc 7018-<strong>Mo</strong> Spoolarc 83<br />

1/2%<strong>Cr</strong>-1/2% <strong>Mo</strong> 11 P#3<br />

1-1/4% <strong>Cr</strong>-1/2% <strong>Mo</strong> 11 P#4<br />

2-1/4% <strong>Cr</strong>-1% <strong>Mo</strong> 22 P#5A<br />

3% <strong>Cr</strong>-1% <strong>Mo</strong> 21 P#5A<br />

5% <strong>Cr</strong>-1/2% <strong>Mo</strong> 5 P#5B<br />

Atom Arc 8018-CM<br />

Atom Arc 7018-B2L<br />

Atom Arc 8018-CM<br />

Atom Arc 7018-B2L<br />

Atom Arc 9018-CM<br />

Atom Arc 8018-B3L<br />

Atom Arc 8018-B6<br />

Atom Arc 8018-B6L<br />

Atom Arc 8018-B6<br />

Atom Arc 8018-B6L<br />

Tigrod ER80S-B2<br />

Tigrod ER80S-B2<br />

Tigrod ER90S-B3<br />

9% <strong>Cr</strong>-1% <strong>Mo</strong> 9 P#5B Atom Arc 8018-B8 Tigrod ER80S-B8<br />

9% <strong>Cr</strong>-1% <strong>Mo</strong>-V-Nb-N 91 P#5B<br />

Atom Arc 9015-B9<br />

Atom Arc 9018-B9<br />

OK Flux 10.62/<br />

Spoolarc 40B<br />

OK Flux 10.62/<br />

Spoolarc U515<br />

OK Flux 10.63/<br />

Spoolarc U515<br />

OK Flux 10.62/<br />

Spoolarc U515<br />

OK Flux 10.63/<br />

Spoolarc U515<br />

OK Flux 10.62/<br />

OK Autrod 13.20SC<br />

OK Flux 10.63/<br />

OK Autrod 13.20SC<br />

Dual Shield 7000-A1 Coreweld 80-D2<br />

Dual Shield 8000-B2<br />

Dual Shield 8000-B2L<br />

Dual Shield 8000-B2<br />

Dual Shield 8000-B2L<br />

Dual Shield 9000-B3<br />

Tigrod ER80S-B6 Dual Shield B6<br />

Tigrod ER80S-B6 Dual Shield B6<br />

Tigrod ER90S-B9 Dual Shield B9<br />

NOTES<br />

+ These creep resistant alloys are used in high temperature service used in hydrocarbon power generation facilites<br />

+ Customer applications may require additional mechanical testing in accordance to ASME or a one-of-a-kind customer specification<br />

+ X-Factor values (< 15) are provided on most of the products listed above<br />

+ Both <strong>ESAB</strong> Hanover and Ashtabula are currently ASME facilities<br />

+ Some diameters and packages may be special order items. Consult Order Entry Department for product availability<br />

Coreweld 80-B2<br />

Coreweld 80-B2<br />

Coreweld 90-B3<br />

Atom Arc 7018-<strong>Mo</strong> electrodes contain 0.5% <strong>Mo</strong> as alloy<br />

addition. They are recommended for welding low-alloy, high<br />

tensile steels of 50 ksi (345 MPa) minimum yield strength and<br />

0.5% molybdenum steels and pipes. They are widely employed<br />

in the fabrication and erection of boilers, pressure piping and<br />

tubing, and other pressure vessel applications.<br />

Classification and Approvals<br />

MIL-E-0022200/7 MIL-7018-A1<br />

A.B.S.- AWS A5.5: E7018-A1<br />

AWS/ASME SFA 5.5: E7018-A1H4R<br />

Complimentary <strong>Products</strong><br />

GTAW (Spoolarc 83)<br />

FCAW (Dual Shield 7000-A1)<br />

SAW (Spoolarc 40B)<br />

Preheat information<br />

Preheat should be used on hardenable steels to prevent the<br />

formation of a hard heat-affected zone. Preheat may also be<br />

required in welding heavy sections.<br />

Electrode imprint Marking<br />

7018-A1H4R<br />

Typical Mechanical Properties<br />

As Welded<br />

AToM ArC ® 7018-<strong>Mo</strong><br />

2 3<br />

ksi MPa<br />

Yield Strength 77 531<br />

Tensile Strength 87 600<br />

Elongation % in 2" 27%<br />

Stress Relieved 1 hr. @ 1150 o F (620 o C)<br />

ksi MPa<br />

Yield Strength 75 518<br />

Tensile Strength 88 607<br />

Elongation % in 2" 29%<br />

Stress Relieved 8 hr. @ 1150 o F (620 o C)<br />

ksi MPa<br />

Yield Strength 76 524<br />

Tensile Strength 88 607<br />

Elongation % in 2" 28%<br />

Stress Relieved 20 hr. @ 1150 o F (620 o C)<br />

ksi MPa<br />

Yield Strength 73 504<br />

Tensile Strength 85 587<br />

Elongation % in 2" 29%<br />

Typical Charpy V-notch<br />

impact Properties<br />

Testing<br />

Temperature Condition Ft.-lbs J<br />

-20ºF (-30ºC)<br />

30ºF (0ºC)<br />

10ºF (-10ºC)<br />

60ºF (15ºC)<br />

Stress Relieved<br />

8 hr. @ 1150 o F (620 o C)<br />

Stress Relieved<br />

8 hr. @ 1150 o F (620 o C)<br />

Stress Relieved<br />

13 hr. @ 1150 o F (620 o C)<br />

Stress Relieved<br />

20 hr. @ 1150 o F (620 o C)<br />

69 94<br />

108 146<br />

135 183<br />

150 203<br />

Typical undiluted Weld Metal Analysis<br />

C Mn Si P S <strong>Mo</strong><br />

0.04% 0.8% 0.4% 0.012% 0.01% 0.55%<br />

Storage and reconditioning<br />

Store open electrodes at 225 o F (107 o C) to 300 o F (150 o C)<br />

Recondition electrodes at 700 o F (370 o C) for 1 hour<br />

ordering information<br />

AA 7018-<strong>Mo</strong> 1/4X18X50#HS .....................................255021412<br />

AA 7018-<strong>Mo</strong> 1/8X14X50#HS .....................................255021818<br />

AA 7018-<strong>Mo</strong> 3/16X14X50#HS ....................................255023111<br />

AA 7018-<strong>Mo</strong> 3/32X14X50#HS ...................................255023319<br />

AA 7018-<strong>Mo</strong> 5/32X14X50#HS ...................................255025314<br />

AA 7018-<strong>Mo</strong> 7/32X18X50#HS ...................................255027310<br />

AA 7018-<strong>Mo</strong> 1/8X14X10#HS .....................................255021826<br />

AA 7018-<strong>Mo</strong> 3/16X14X10#HS ...................................255023129<br />

AA 7018-<strong>Mo</strong> 3/32X14X10#HS ...................................255023327<br />

AA 7018-<strong>Mo</strong> 5/32X14X10#HS ...................................255025322<br />

Product Data Sheet ................................... SSP-1018

Dual Shield 7000-A1 is an all-position flux cored electrode<br />

recommended for 0.5% <strong>Mo</strong> steels. It is used in the<br />

fabrication and erection of boilers, pressure piping and<br />

tubing, and other pressure vessel applications. Shielding<br />

gas of 100% CO 2 and 75% Ar, remainder CO 2 may be used.<br />

A 75% Ar/25% CO 2 shielding gas mixture is recommended<br />

to improve arc characteristics, increase wetting action,<br />

decrease penetration, and provide easier arc control for outof-position<br />

welding. The weld metal analysis is similar to an<br />

E7018-A1 low hydrogen electrode.<br />

Classification and Approvals<br />

AWS/ASME SFA 5.29: E81T1-A1C/A1M<br />

Shielding gas<br />

100% CO 2 and Argon - CO 2 mixtures up to 75% Argon<br />

Complimentary <strong>Products</strong><br />

GTAW (Spoolarc 83)<br />

SMAW (Atom Arc 7018-<strong>Mo</strong>)<br />

SAW (Spoolarc 40B)<br />

Typical Mechanical Properties<br />

As Welded, Co 2<br />

ksi MPa<br />

Yield Strength 82 566<br />

Tensile Strength 92 635<br />

Elongation % in 2" 22%<br />

Stress Relieved 1 hr. @ 1150 o F (620 o C), CO 2<br />

ksi MPa<br />

Yield Strength 82 566<br />

Tensile Strength 93 645<br />

Elongation % in 2" 26%<br />

Product Data Sheet ...................................COR-1061<br />

Typical Charpy V-notch<br />

impact Properties<br />

DuAl ShiElD ® 7000-A1<br />

Testing<br />

Temperature Condition Ft.-lbs J<br />

72ºF (22ºC) As Welded, CO 2 43 58<br />

0ºF (-18ºC) As Welded, CO 2 20 27<br />

Typical undiluted Weld Metal Analysis, Co 2<br />

C Mn Si P S <strong>Mo</strong><br />

0.05% 0.09% 0.6% 0.01% 0.008% 0.55%<br />

Storage and reconditioning*<br />

Store open electrodes at 300 o F (150 o C)<br />

Recondition electrodes at 300 o F (150 o C) for 6 to 8 hours<br />

*Note: If packaged on a plastic spool, remove spool from plastic<br />

bag before placing in oven. Store at 125ºF (52ºC).<br />

ordering information<br />

DS 7000-A1 045X33#AWS ........................................245012521<br />

Spoolarc 40B is a single or multipass welding wire for carbon<br />

and low alloy steels. Product produces good as welded and<br />

stress relieved impact toughness. Weld metal tensile strength<br />

is in excess of 70 ksi (483 MPa).<br />

Applications include pressure vessel fabrication and other<br />

similar welds which require postweld heat treatment.<br />

Classification and Approvals<br />

AWS/ASME SFA 5.23: EA2<br />

Complimentary <strong>Products</strong><br />

GTAW (Spoolarc 83)<br />

SMAW (Atom Arc 7018-<strong>Mo</strong>)<br />

FCAW (Dual Shield 7000-A1)<br />

Typical Mechanical Properties<br />

w/ <strong>ESAB</strong> OK Flux 10.62<br />

Stress relieved 1hr. @ 1150°F (620°C)<br />

SPoolArC ® 40B<br />

4 5<br />

ksi MPa<br />

Yield Strength 80 552<br />

Tensile Strength 91 628<br />

Elongation % in 2" 28%<br />

Typical Charpy V-notch<br />

impact Properties<br />

Testing<br />

Temperature Condition Ft.-lbs J<br />

-50ºF (-46ºC)<br />

Stress relieved<br />

1hr. @ 1150°F (620°C)<br />

40 54<br />

Typical Wire Chemistry<br />

C Mn Si S P <strong>Mo</strong><br />

0.13% 1.2% .03% .019% .009% .54%<br />

Typical undiluted Weld Metal Analysis<br />

OK Flux 10.62<br />

C Mn Si P S <strong>Mo</strong><br />

0.10% 1.1% 0.2% 0.017% 0.010% 0.50%<br />

ordering information<br />

40B 3/32x65#CL ............................................................ 1184F30<br />

40B 1/8x150#CL ............................................................ 1185F12<br />

40B 1/8x65#CL .............................................................. 1184F32<br />

40B 1/8x800#DR ............................................................ 1186F12<br />

40B 5/32x150#CL .......................................................... 1185F14<br />

40B 5/32x65#CL ............................................................ 1184F34<br />

40B 5/32x800#DR .......................................................... 1186F14<br />

40B 3/16x65#CL ............................................................ 1184F35<br />

40B 3/16x800#DR .......................................................... 1186F15<br />

40B 1/4x800#DR ...........................................................118EFLW<br />

Product Data Sheet ...................................COR-1072

Atom Arc 8018-CM electrodes contain 1.25% <strong>Cr</strong> and <strong>Mo</strong><br />

as alloy addition. They are used for the welding of such<br />

steels as 0.5% <strong>Cr</strong> - 0.5% <strong>Mo</strong>, 1% <strong>Cr</strong> - 0.5% <strong>Mo</strong>, and<br />

1.25% <strong>Cr</strong> - 0.5% <strong>Mo</strong>, which are used principally in power<br />

piping and boiler work for the fabrication of plates, pipes,<br />

tubes, castings, and forgings.<br />

Classification and Approvals<br />

MILITARY-MIL-E-22200/8: MIL-8018-B2<br />

A.B.S.- AWS A5.5: E8018-B2<br />

AWS/ASME SFA 5.5: E8018-B2H4R<br />

Application<br />

This electrode is designed to meet the most stringent standards<br />

for welding 1.25% <strong>Cr</strong> - 0.5% <strong>Mo</strong> steels while producing an<br />

X-Factor

TIGROD ER80S-B2 is a chrome-moly Tigrod used for<br />

joining creep resistant steels of the 0.5% <strong>Cr</strong> - 0.5% <strong>Mo</strong>,<br />

1% <strong>Cr</strong> - 0.5% <strong>Mo</strong>, and 1.25% <strong>Cr</strong> - 0.5% <strong>Mo</strong> grades. These<br />

copper-coated rods are primarily used to fabricate and repair<br />

power piping and boilers in the power generation industry.<br />

TIGROD ER80S-B2 is embossed on both ends with the<br />

alloy identification.<br />

Classification and Approvals<br />

AWS/SFA 5.28: ER80S-B2<br />

Shielding gas<br />

100% Argon<br />

Complimentary <strong>Products</strong><br />

SMAW (Atom Arc 8018-CM)<br />

FCAW (Dual Shield 8000-B2)<br />

SAW (Spoolarc U515 w/ OK Flux 10.62)<br />

Typical Mechanical Properties<br />

Stress Relieved 1hr. @ 1150°F (620°C)<br />

TigroD ® ER80S-B2<br />

ksi MPa<br />

Yield Strength 81 559<br />

Tensile Strength 95 655<br />

Elongation % in 2" 29%<br />

Stress Relieved 1hr. @ 1350°F (732°C)<br />

ksi MPa<br />

Yield Strength 82 566<br />

Tensile Strength 95 655<br />

Elongation % in 2" 24%<br />

Stress Relieved 1hr. @ 1375°F (746°C)<br />

ksi MPa<br />

Yield Strength 80 552<br />

Tensile Strength 93 642<br />

Elongation % in 2" 26%<br />

Typical undiluted Weld Metal Analysis<br />

C Mn Si P S <strong>Cr</strong> <strong>Mo</strong> X-Factor<br />

0.08% 0.5% 0.4% 0.007% 0.01% 5.8% 0.5%

Atom Arc 9018-CM is an all-position low hydrogen electrode<br />

designed for welding 2.5% <strong>Cr</strong> - 1% <strong>Mo</strong> steels commonly<br />

used in pressure vessels, heat exchangers and related<br />

components.<br />

Classification and Approvals<br />

MILITARY-MIL-E-0022200/8: MIL-9018-B3<br />

A.B.S.- AWS A5.5: E9018-B3<br />

AWS/ASME SFA 5.5: E9018-B3H4R<br />

Application<br />

This electrode is designed to meet the most stringent<br />

standards for welding 1.25% <strong>Cr</strong> - 0.5% <strong>Mo</strong> steels while<br />

producing an X-Factor

TIGROD ER90S-B3 is a chrome-moly Tigrod used for<br />

joining 2.5% <strong>Cr</strong> - 1% <strong>Mo</strong> creep resistant steels. These<br />

copper-coated rods are primarily used to fabricate and repair<br />

power piping, pressure vessels, heat exchangers and boilers<br />

in the power generation industry.<br />

TIGROD ER90S-B3 is embossed on both ends with alloy<br />

identification.<br />

Classification and Approvals<br />

AWS/SFA 5.28: ER90S-B3<br />

Shielding gas<br />

100% Argon<br />

Complimentary <strong>Products</strong><br />

SMAW (Atom Arc 9018-CM)<br />

FCAW (Dual Shield 9000-B3)<br />

SAW (Autrod 13.20SC w/ OK Flux 10.62 or 10.63)<br />

Typical Mechanical Properties<br />

Stress Relieved 1 hr. @ 1275 o F (690 o C)<br />

TigroD ® ER90S-B3<br />

ksi MPa<br />

Yield Strength 79 545<br />

Tensile Strength 94 649<br />

Elongation % in 2" 27%<br />

Stress Relieved 1 hr. @ 1300 o F (704 o C)<br />

ksi MPa<br />

Yield Strength 76 524<br />

Tensile Strength 93 642<br />

Elongation % in 2" 25%<br />

Typical undiluted Weld Metal Analysis<br />

C Mn Si P S <strong>Cr</strong> <strong>Mo</strong> X-Factor<br />

0.08% 0.6% 0.5% 0.009% 0.009% 2.4% 0.9%

Atom Arc 8018-B6 is designed to weld 5% <strong>Cr</strong> - 0.5%<br />

<strong>Mo</strong> creep resistant steels such as ASTM A387 Grade 5,<br />

A213-T5 and A335-P5. These steels are normally used in<br />

pressure vessels and piping for high temperature service.<br />

Classification and Approvals<br />

AWS/ASME SFA 5.5: E8018-B6H4R<br />

Application<br />

This electrode is designed to meet the most stringent standards<br />

for welding 5% <strong>Cr</strong> - 0.5% <strong>Mo</strong> steels while producing an X-Factor<br />

TIGROD ER80S-B6 is a Chrome-<strong>Mo</strong>ly Tigrod for joining<br />

5% <strong>Cr</strong> - 0.5% <strong>Mo</strong> steels such as ASTM A200-T5, A335-P5<br />

and A387-Gr5. These copper coated rods are primarily<br />

used to fabricate and repair power piping, pressure vessels,<br />

heat exchangers and boilers used in the power generation<br />

industry.<br />

TIGROD ER80S-B6 is embossed on both ends with the<br />

alloy identification.<br />

Classification and Approvals<br />

AWS A5.28: ER80S-B6<br />

Shielding gas<br />

100% Argon<br />

Complimentary <strong>Products</strong><br />

SMAW (Atom Arc 8018-B6)<br />

FCAW (Dual Shield B6)<br />

Typical Mechanical Properties<br />

Stress Relieved 1 hr. @ 1350 o F (732 o C)<br />

TigroD ® ER80S-B6<br />

ksi MPa<br />

Yield Strength 82 566<br />

Tensile Strength 95 656<br />

Elongation % in 2" 24%<br />

Stress Relieved 1 hr. @ 1375 o F (746 o C)<br />

Shielded Gas: 100% Ar ksi MPa<br />

Yield Strength 80 552<br />

Tensile Strength 93 642<br />

Elongation % in 2" 26%<br />

Typical undiluted Weld Metal Analysis<br />

C Mn Si P S <strong>Cr</strong> <strong>Mo</strong> X-Factor<br />

0.08% 0.5% 0.4% 0.007% 0.01% 5.8% 0.5%

TIGROD ER80S-B8 is a solid wire for TIG welding requiring<br />

creep strength. This 9% <strong>Cr</strong> - 1% <strong>Mo</strong> Tigrod is used to weld<br />

9% chromium - 1% <strong>Mo</strong>lybdenum steels (ASTM Section IX,<br />

P No 5B, Group 1) such as ASTM A335 Grade P9 or ASTM<br />

A213 Grade T9.<br />

TIGROD ER80S-B8 is embossed on both ends with the<br />

alloy identification.<br />

Classification and Approvals<br />

AWS A5.28: ER80S-B8<br />

Shielding gas<br />

100% Argon<br />

Complimentary <strong>Products</strong><br />

SMAW (Atom Arc 8018-B8)<br />

FCAW (Dual Shield B8)<br />

Typical Mechanical Properties<br />

Stress Relieved 1 hr. @ 1375 o F (746 o C)<br />

TigroD ® Er80S-B8<br />

Shielded Gas: 100% Ar ksi MPa<br />

Yield Strength 78 538<br />

Tensile Strength 97 670<br />

Elongation % in 2" 24%<br />

Typical undiluted Weld Metal Analysis<br />

C Mn Si P S <strong>Cr</strong> <strong>Mo</strong> X-Factor<br />

0.07% 0.50% 0.40% 0.005% 0.003% 9% 1%

Actual Mechanical Analysis**<br />

Mechanical Analysis<br />

1400 o F (760 o C)<br />

@ 2 hrs.<br />

Chemical<br />

Analysis<br />

AToM ArC ® 9015-B9<br />

hiSToriCAl DATA<br />

Actual Chemical Analysis*<br />

Min Median Max<br />

C 0.080 0.099 0.124<br />

Mn 0.59 0.85 0.99<br />

Si 0.12 0.19 0.30<br />

P 0.004 0.009 0.011<br />

S 0.007 0.009 0.010<br />

<strong>Cr</strong> 8.04 8.60 9.60<br />

Ni 0.15 0.25 0.45<br />

<strong>Mo</strong> 0.90 0.99 1.11<br />

Nb 0.02 0.04 0.09<br />

Al

Actual Chemical Analysis*<br />

Chemical<br />

Analysis Min Median Max<br />

C 0.080 0.098 0.124<br />

Mn 0.69 0.84 1.11<br />

Si 0.12 0.17 0.25<br />

P 0.004 0.008 0.013<br />

S 0.007 0.009 0.014<br />

<strong>Cr</strong> 8.04 8.55 9.51<br />

Ni 0.19 0.27 0.51<br />

<strong>Mo</strong> 0.85 1.00 1.18<br />

Nb 0.02 0.04 0.10<br />

Al 0.001 0.003 0.010<br />

Co

Actual Chemical Analysis historic Data*<br />

Chemical<br />

Analysis<br />

Min Median Max<br />

C 0.090 0.095 0.110<br />

Mn 0.80 0.96 1.15<br />

Si 0.13 0.18 0.22<br />

P 0.003 0.009 0.012<br />

S 0.006 0.008 0.010<br />

<strong>Cr</strong> 8.13 8.93 9.61<br />

Ni 0.04 0.19 0.25<br />

<strong>Mo</strong> 0.92 0.99 1.11<br />

Nb 0.02 0.03 0.00<br />

Al 0.001 0.002 0.003<br />

Co

Tradename<br />

Atom Arc 9015-B9<br />

Classification<br />

E9015-B9H4R<br />

Class<br />

AWS A5.5: 2006, ASME SFA 5.5, SEC. II, PART C,<br />

2007 EDITION, 2008a ADDENDA<br />

Diameter<br />

1/8"<br />

length/Pkg Type<br />

14"<br />

Heat/PKG Code No.<br />

090072<br />

Lot No.<br />

4F924K01<br />

radiography<br />

Satisfactory<br />

<strong>Mo</strong>isture by RC-412 Method<br />

Out of the Can 0.08<br />

Exposed 0.19<br />

Concentricity 2%<br />

Chemical Analysis<br />

ATOM ARC 9015-B9<br />

CErTifiED MATEriAl TEST rEPorT<br />

Certificate of Analysis<br />

Certified Materials Test Report<br />

Diffusible Hydrogen to AWS A4.3<br />

Average Value<br />

ml/100 gr<br />

GC<br />

2.6<br />

Actual Mechanical Properties<br />

Stress Relieved 2 hr. @ 1400 o F (760 o C)<br />

ksi MPa<br />

Yield Strength 81.5 562<br />

Tensile Strength 103.1 711<br />

Reduction in Area 60%<br />

Elongation % in 2" 25%<br />

Actual Charpy V-notch<br />

impact Properties<br />

Testing<br />

Temperature Condition Ft.-lbs J<br />

70ºF (21ºC)<br />

Stress Relieved<br />

2 hr @ 1400 o F (760 o C)<br />

77 104<br />

C Mn Si P S <strong>Cr</strong> <strong>Mo</strong> V Ni<br />

0.09% 0.74% 0.19% 0.009% 0.008% 8.56% 0.96% 0.20% 0.21%<br />

Cu Al N Nb As Sb Sn X-Factor<br />

0.04%

Tradename<br />

Dual Shield B9<br />

Classification<br />

E91T1-B9M<br />

Class<br />

AWS A5.29:2005<br />

Diameter<br />

0.045"<br />

Length/Pkg. Type<br />

33# Spool<br />

Heat/PKG Code No.<br />

N/A<br />

Lot No.<br />

87006<br />

radiography<br />

Satisfactory<br />

Diffusible Hydrogen to AWS A4.3<br />

Average Value<br />

ml/100 gr<br />

GC<br />

5.3<br />

This material does meet “H8” Requirements.<br />

Chemical Analysis<br />

DuAl ShiElD ® B9<br />

CErTifiED MATEriAl TEST rEPorT<br />

Certificate of Analysis<br />

Certified Materials Test Report<br />

Actual Mechanical Properties<br />

Stress Relieved 2 hr. @ 1400 o F (760 o C)<br />

ksi MPa<br />

Yield Strength 85.5 590<br />

Tensile Strength 105.9 731<br />

Reduction in Area 60%<br />

Elongation % in 2" 22%<br />

Actual Charpy V-notch<br />

impact Properties<br />

Testing<br />

Temperature Condition Ft.-lbs J<br />

70ºF (21ºC)<br />

Stress Relieved<br />

2 hr @ 1400 o F (760 o C)<br />

38 52<br />

C Mn Si P S <strong>Cr</strong> <strong>Mo</strong> V Ni<br />

0.09% 0.83% 0.14% 0.010% 0.008% 9.14% 1.03% 0.22% 0.21%<br />

Cu Al N Nb As Sb Sn X-Factor<br />

0.04%

30<br />

<strong>ESAB</strong> <strong>Cr</strong>-<strong>Mo</strong> P-91<br />

fillEr METAl <strong>Cr</strong>EEP DATA<br />

<strong>ESAB</strong> ASME CErTifiCATE<br />

31

32<br />

<strong>ESAB</strong> ASME CErTifiCATE SAfETy DATA ShEETS<br />

Safety Data Sheets (SDS) are provided for all filler metal products regardless of their respective<br />

manufacturing location. A specfic SDS file can be downloaded from www.esabna.com (website)<br />

or by contacting <strong>ESAB</strong> directly.<br />

SDS files are organized by their respective product family, ie. Atom Arc Low Hydrogen <strong>Welding</strong><br />

<strong>Electrodes</strong> contain all EXX15 and EXX18 grade of product. Note: below are the various file names<br />

and products included.<br />

SDS File No. Product Grouping Product Included<br />

7018-A1 7018-B2L<br />

7970-S<br />

Atom Arc Low Hydrogen<br />

<strong>Welding</strong> <strong>Electrodes</strong><br />

8018-B2<br />

9018-B3<br />

8018-B6<br />

8018-B3L<br />

8018-B6L<br />

8018-B8<br />

9015-B9 9018-B9<br />

7971-2-T<br />

Dual Shield Low Alloy<br />

Flux Cored <strong>Welding</strong> Electrode<br />

8000-B2<br />

9000-B3<br />

B-6<br />

8000-B2L<br />

9000-B3L<br />

B-9<br />

U-515 (EB2) 13.20 SC (EB3)<br />

8000-F<br />

<strong>ESAB</strong> Spoolarc and TIGROD<br />

<strong>Welding</strong> <strong>Electrodes</strong> and Rods<br />

ER80S-B2<br />

ER80S-B6 ER90S-B3<br />

ER80S-B8 ER90S-B9<br />

33

noTES noTES<br />

34 35

World leader in welding and<br />

cutting technology and systems<br />

<strong>ESAB</strong> operates at the forefront of welding and cutting technology. Over one hundred years of continuous<br />

improvement in products and processes enables us to meet the challenges of technological advances in every<br />

sector in which <strong>ESAB</strong> operates.<br />

Quality and environment standards<br />

Quality and the environment are two key areas of focus. <strong>ESAB</strong> is one of few international companies to<br />

have achieved the new ISO 14001 standard in Environmental Management Systems across all our global<br />

manufacturing facilities.<br />

At <strong>ESAB</strong>, quality is an ongoing process that is at the heart of all our production processes and facilities worldwide.<br />

Multinational manufacturing, local representation and an international network of independent distributors bring<br />

the benefits of <strong>ESAB</strong> quality and unrivaled expertise in materials and processes within reach of all our customers,<br />

wherever they are located.<br />

Be Safe When <strong>Welding</strong> or <strong>Cutting</strong><br />

Please read and understand the safety labels, instruction manuals and/or safety data sheet for your welding or cutting<br />

product before you weld or cut. Always follow safe practices and use adequate ventilation when welding or cutting. <strong>Mo</strong>re<br />

information on welding health and safety can be found at www.esabna.com.<br />

<strong>ESAB</strong> <strong>Welding</strong> & <strong>Cutting</strong> <strong>Products</strong> www.esabna.com<br />

U.S.A: 411 South Ebenezer Road | Florence, SC 29501-0504<br />

Canada: 6010 Tomken Road | Mississauga, Ontario L5T 1X9<br />

Mexico: Ave. Diego Diaz de Berlanga No. 130 | Col. Nogalar | San Nicolas de los Garza, N.L. 66480 | <strong>Mo</strong>nterrey, Mexico<br />

Filler Metal Manufacturing: 801 Wilson Avenue | PO Box 517 | Hanover, PA 17331<br />

COR-1078 5m 3/10<br />

Call 1-800-<strong>ESAB</strong>-123 or 1-800-933-7070 (Filler Metal Headquarters)