Issue 17 - Free-Energy Devices

Issue 17 - Free-Energy Devices

Issue 17 - Free-Energy Devices

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

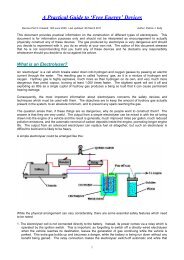

can be transformed into a magnetic perpetual<br />

motion machine. This ME is shown in Fig. 6.<br />

To improve the gravity application in the MGE,<br />

we worked out a “magnetic whirligig” device,<br />

where constant magnets perform back-andforth<br />

motion (Fig. 6).<br />

Fig. 6. A perpetual motion machine with rotating shutter<br />

This MGE is made up of a horizontal disk 8,<br />

sectioned with magnetic screens 7 and a<br />

spring mechanism 9 installed on the vertical<br />

axis 11 and connected with a lever 10 to a<br />

mobile constant magnet 2, with load 6 set in<br />

a vertical non-magnetic tube 1; constant<br />

magnets 2, 4 are installed inside the tube with<br />

like poles 3, 5 set oppositely to repulse the<br />

upper mobile magnet 2 from the fixed lower<br />

magnet 4.<br />

The principle of this MGE operation is in the<br />

following: magnet 2 moves upward under the<br />

action of magnetic repulsion forces of magnet<br />

4 if there is no shutter 7 between them.<br />

And vice versa – during the next ME<br />

semicycle magnet 2 moves down under the<br />

action of gravity, if magnets 2, 4 are shielded<br />

with a shutter – screen 7- when a segment<br />

disk 8 is rotated. The disk moves like a<br />

whirligig, as the spring inside the cylindrical<br />

ring 9 compresses and decompresses cyclically<br />

when the lever 10 connected with a mobile<br />

magnet 2 and a recoil spring inside the rim 9<br />

performs back-and forth motion.<br />

The rotation velocity of the disk depends on<br />

the MGE design factor, on the constant<br />

magnets mass and properties. One can install<br />

an electric generator 12 on axis 11. The<br />

advantage of these MGEs is valid usage of<br />

magnetic forces of repulsion in constant<br />

magnets.<br />

Polar Magnetic Orbital Engines<br />

Let us consider another method to directly<br />

convert magnetic energy alone of constant<br />

magnets (CM) into mechanical energy of<br />

their interrotation with heterogeneity of<br />

their magnetic fields on magnetic poles and<br />

aclinic lines of there CM. The most typical<br />

designs of such polar MEs are depicted in Fig.<br />

7- 9. Experimentally, due to magnetic field<br />

heterogeneity of the central stator magnet<br />

and the rotor magnet, due to the rotor magnet<br />

moment of inertia and perpetual attractionrepulsion<br />

forces interchange on various parts<br />

of the constant rotor magnet trajectory, all<br />

these polar ME devices proved to be quite<br />

efficient.<br />

a) ME With a Mobile Rotor Magnet In the<br />

Axis Plane<br />

When the CM of the rotor 2 and the rim 3 are<br />

initially set between aclinic line and the<br />

constant stator 1 magnet, when its poles are<br />

initially oriented on interattraction to the<br />

opposite magnetic pole of the central fixed<br />

stator magnet and after the initial impulse of<br />

the rotor magnet 2 towards the closest<br />

magnetic pole of the central magnet 1, the<br />

mobile rotor- magnet 2 starts to accelerate<br />

spontaneous axial and orbital rotation around<br />

the central fixed constant magnet 1 in the<br />

upper dead point.<br />

It mechanically passes the area above the<br />

magnetic pole of the central CM and, with its<br />

lines of force, repulses from the like pole of<br />

the stator 1 magnet. Having passes the aclinic<br />

line, CM 1 takes a 180° turn. Experimentally,<br />

the mobile magnet 2 can sometimes perform<br />

mechanically four or more axial turns on the<br />

axis of the base 4 during its full orbital turn.<br />

54 New <strong>Energy</strong> Technologies, <strong>Issue</strong> #3(18) 2004