Issue 17 - Free-Energy Devices

Issue 17 - Free-Energy Devices

Issue 17 - Free-Energy Devices

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Direct Conversion of Magnetic Field of<br />

Constant Magnets <strong>Energy</strong> and Its Application<br />

In Power Engineering and Mechanics<br />

Global and ever increasing energetic and<br />

ecological crises of the Earth prompt scientists<br />

and engineers to scan for new alternative,<br />

pollution-free sources of energy, among them<br />

based on constant magnets and electrets [1-4].<br />

The well-known magnetic engines (ME) by<br />

Serl, Minato and Floyd are unfortunately not<br />

perfect, but they marked the beginning of ME<br />

history and development [1]. The article lists<br />

original designs of new, totally non-current ME.<br />

In spite of the fact, that magnetic nature has<br />

not been totally solved yet, constant magnets<br />

are really bringing us to revolution in energetic<br />

and mechanics. Huge headway in the sphere of<br />

constant magnets permits us to anticipate in the<br />

not too distant future the creation of magnetic<br />

motor generators and other useful devices based<br />

on their principles, with capacity up to 100- 200<br />

kW.<br />

Non-contact Magnetic Rotational Bearing of<br />

Rotation<br />

Bearings are the most widespread and<br />

important element of many devices, ranging<br />

from a motorcar to a spaceship and rocket.<br />

However, the mechanical bearings have<br />

practically exhausted their potentialities. They<br />

wear out rapidly, need regular maintenance and<br />

are short-lived. Moreover, mechanical bearings<br />

have a limitation on speed of rotation and<br />

reliability that limits the area of their usage.<br />

There are electromagnetic non-contact<br />

rotational bearings. Still they are rather<br />

complicated and expensive devices. Headway<br />

in updating the properties of constant magnets<br />

allows creating a high-capacity, simple in design<br />

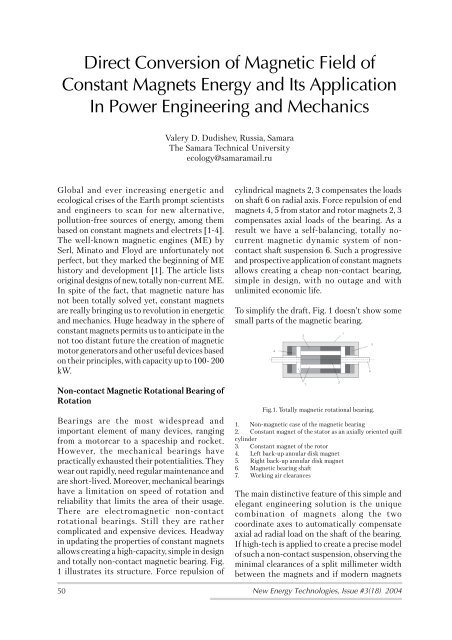

and totally non-contact magnetic bearing. Fig.<br />

1 illustrates its structure. Force repulsion of<br />

Valery D. Dudishev, Russia, Samara<br />

The Samara Technical University<br />

ecology@samaramail.ru<br />

cylindrical magnets 2, 3 compensates the loads<br />

on shaft 6 on radial axis. Force repulsion of end<br />

magnets 4, 5 from stator and rotor magnets 2, 3<br />

compensates axial loads of the bearing. As a<br />

result we have a self-balancing, totally nocurrent<br />

magnetic dynamic system of noncontact<br />

shaft suspension 6. Such a progressive<br />

and prospective application of constant magnets<br />

allows creating a cheap non-contact bearing,<br />

simple in design, with no outage and with<br />

unlimited economic life.<br />

To simplify the draft, Fig. 1 doesn’t show some<br />

small parts of the magnetic bearing.<br />

Fig.1. Totally magnetic rotational bearing.<br />

1. Non-magnetic case of the magnetic bearing<br />

2. Constant magnet of the stator as an axially oriented quill<br />

cylinder<br />

3. Constant magnet of the rotor<br />

4. Left back-up annular disk magnet<br />

5. Right back-up annular disk magnet<br />

6. Magnetic bearing shaft<br />

7. Working air clearances<br />

The main distinctive feature of this simple and<br />

elegant engineering solution is the unique<br />

combination of magnets along the two<br />

coordinate axes to automatically compensate<br />

axial ad radial load on the shaft of the bearing.<br />

If high-tech is applied to create a precise model<br />

of such a non-contact suspension, observing the<br />

minimal clearances of a split millimeter width<br />

between the magnets and if modern magnets<br />

50 New <strong>Energy</strong> Technologies, <strong>Issue</strong> #3(18) 2004