You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

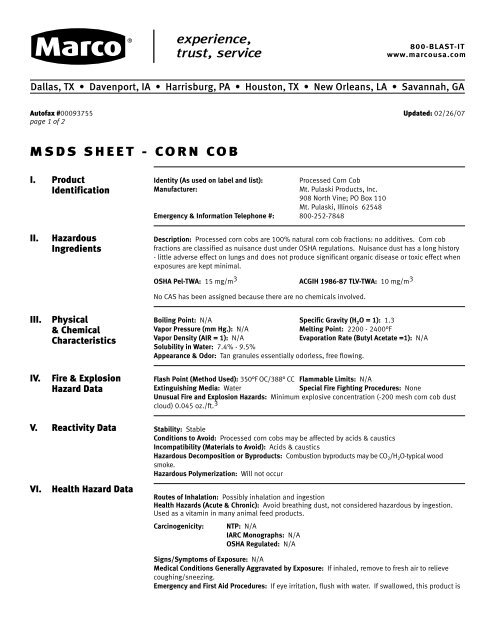

Dallas, TX • Davenport, IA • Harrisburg, PA • Houston, TX • New Orleans, LA • Savannah, GA<br />

Autofax #00093755<br />

page 1 of 2<br />

m s d s s h e e t - Co r n Co b<br />

I. Product<br />

Identification<br />

II. hazardous<br />

Ingredients<br />

III. Physical<br />

& Chemical<br />

Characteristics<br />

IV. Fire & explosion<br />

hazard data<br />

V. reactivity data<br />

VI. health hazard data<br />

Identity (As used on label and list): Processed <strong>Corn</strong> <strong>Cob</strong><br />

Manufacturer: Mt. Pulaski Products, Inc.<br />

908 North Vine; PO Box 110<br />

Mt. Pulaski, Illinois 62548<br />

Emergency & Information Telephone #: 800-252-7848<br />

Updated: 02/26/07<br />

Description: Processed corn cobs are 100% natural corn cob fractions: no additives. <strong>Corn</strong> cob<br />

fractions are classified as nuisance dust under OSHA regulations. Nuisance dust has a long history<br />

- little adverse effect on lungs and does not produce significant organic disease or toxic effect when<br />

exposures are kept minimal.<br />

OSHA Pel-TWA: 15 mg/m3 ACGIH 1986-87 TLV-TWA: 10 mg/m3 No CAS has been assigned because there are no chemicals involved.<br />

Boiling Point: N/A Specific Gravity (H 2O = 1): 1.3<br />

Vapor Pressure (mm Hg.): N/A Melting Point: 2200 - 2400°F<br />

Vapor Density (AIR = 1): N/A Evaporation Rate (Butyl Acetate =1): N/A<br />

Solubility in Water: 7.4% - 9.5%<br />

Appearance & Odor: Tan granules essentially odorless, free flowing.<br />

Flash Point (Method Used): 350°F OC/388° CC Flammable Limits: N/A<br />

Extinguishing Media: Water Special Fire Fighting Procedures: None<br />

Unusual Fire and Explosion Hazards: Minimum explosive concentration (-200 mesh corn cob dust<br />

cloud) 0.045 oz./ft. 3<br />

Stability: Stable<br />

Conditions to Avoid: Processed corn cobs may be affected by acids & caustics<br />

Incompatibility (Materials to Avoid): Acids & caustics<br />

Hazardous Decomposition or Byproducts: Combustion byproducts may be CO 2/H 2O-typical wood<br />

smoke.<br />

Hazardous Polymerization: Will not occur<br />

Routes of Inhalation: Possibly inhalation and ingestion<br />

Health Hazards (Acute & Chronic): Avoid breathing dust, not considered hazardous by ingestion.<br />

Used as a vitamin in many animal feed products.<br />

Carcinogenicity: NTP: N/A<br />

IARC Monographs: N/A<br />

OSHA Regulated: N/A<br />

Signs/Symptoms of Exposure: N/A<br />

Medical Conditions Generally Aggravated by Exposure: If inhaled, remove to fresh air to relieve<br />

coughing/sneezing.<br />

Emergency and First Aid Procedures: If eye irritation, flush with water. If swallowed, this product is

Autofax #00093755<br />

page 2 of 2<br />

m s d s s h e e t - Co r n Co b<br />

VII. Precautions for<br />

safe handling &<br />

Use<br />

VII. Control<br />

measures<br />

VIII. silicosis Warning<br />

Dallas, For more TX information • Davenport, call: IA • Harrisburg, PA • Houston, TX • New Orleans, LA • Savannah, GA<br />

800-bLAst-It<br />

Phone: 800-252-7848<br />

Fax: 563-324-6258<br />

e-mail: sales@marcousa.com<br />

www.marcousa.com<br />

not considered harmful. Product is used as animal feed.<br />

Updated: 02/26/07<br />

Steps to be Taken in Case Material is Released or Spilled: Not classified as hazardous material in<br />

purchased form. Sweep/shovel and dispose of normally.<br />

Waste Disposal Method: Dispose of all waster according to Federal, State and Local regulations.<br />

Precautions to be Taken in Handling and Storing: Store in a dry area, take care to not puncture/tear<br />

paper bags or tote bags is used as shipping containers.<br />

Other Precautions: Processed corn cobs do not render fluids non-flammable, neutral or less hazardous.<br />

Respiratory Protection: If bag is broken or product spilled, a NIOSH or MSHA approved respirator may be<br />

necessary to avoid inhaling dust.<br />

Ventilation: None<br />

Protective Gloves: None required<br />

Eye Protection: Standard goggle if necessary.<br />

Other Protective Clothing or Equipment: None required<br />

Work/Hygienic Practices: Normal and routine hygiene practices recommended.<br />

Breathing dust containing silica will cause silicosis, a fatal lung disease.<br />

Breathing dust during blasting operations will cause asbestosis, lead poisoning<br />

and/or other serious or fatal diseases. A NIOSH-approved, well-maintained, supplied-air abrasive<br />

blasting respirator must be used by anyone blasting, anyone handling or using the abrasive and<br />

anyone in the area of the dust. Harmful dust containing toxic material from abrasives or surfaces<br />

being blasted can remain suspended in the air for long periods of time after blasting has ceased.<br />

Failure to avoid the above danger will result in death or serious injury.<br />

You must comply with all OSHA, local, City, State, Province, Country and<br />

jurisdiction regulations, ordinances and standards, related to your particular<br />

work area and environment. Keep unprotected individuals out of the work area. Failure to avoid the<br />

above danger will result in death or serious injury.<br />

dIsCLAImer: The information in this MSDS was obtained from sources, which we believe are reliable. However,<br />

the information is provided without any representation or warranty, expressed or implied, regarding accuracy.<br />

These conditions or methods of handling, storage use and disposal of the product are beyond our control and<br />

may be beyond our knowledge. For this and other reasons, we do not assume responsibility and expressly<br />

disclaim liability for loss, damage or expense arising out of or in any way connected with the handling, storage,<br />

use or disposal of the product. Customers/users of silica must comply with all applicable health and safety laws,<br />

regulations and orders, including the OSHA Hazardous Communication Standard.<br />

M a r c o • 3 4 2 5 E a s t L o c u s t S t r e e t • D a v e n p o r t , I o w a 5 2 8 0 3 • C e r t i f i e d I S O 9 0 0 1 : 2 0 0 0