FINGER JOINT TEMPLATES LEIGH - Leigh Jigs

FINGER JOINT TEMPLATES LEIGH - Leigh Jigs

FINGER JOINT TEMPLATES LEIGH - Leigh Jigs

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DEDICATED CUSTOMER SUPPORT<br />

1-800-663-8932<br />

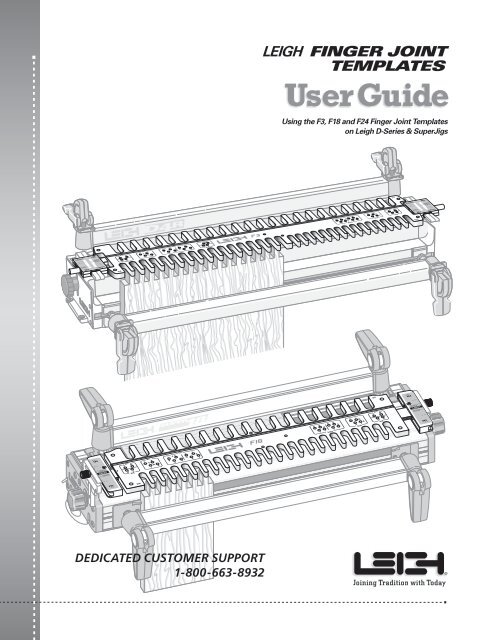

<strong>LEIGH</strong><br />

<strong>FINGER</strong> <strong>JOINT</strong><br />

<strong>TEMPLATES</strong><br />

Using the F3, F18 and F24 Finger Joint Templates<br />

on <strong>Leigh</strong> D-Series & Super<strong>Jigs</strong>

ii Introduction F3, F18 & F24 Fi n ger Jo i n t te m p l at e s UsergUide FOREWORD<br />

Inch<br />

Templates<br />

Metric<br />

Templates<br />

Your new <strong>Leigh</strong> Finger Joint Template<br />

You now own a superb finger jointing system. The<br />

<strong>Leigh</strong> Finger Joint template and adjustable e-Bush<br />

will help you rout finger or box joints with unique<br />

adjustment for precise tightness of fit.<br />

“Finger” and “Box”: Both words are used universally<br />

to title this simple but strong joint. As the first<br />

machine-made joint, it’s old enough to be called<br />

antique, so we have been even-handed in using both<br />

terms throughout this guide.<br />

We recommend that you first mount the template on<br />

your <strong>Leigh</strong> Jig, carefully following the instructions<br />

in the first section of the user guide. Then before<br />

you try to do any actual joinery routing, read the<br />

rest of the guide, following along with the basic<br />

functions. By all means, cut a few practice joints in<br />

scrap boards before you use the template to rout a<br />

precious hardwood workpiece.<br />

If you have any questions that are not answered in this<br />

user guide, please call <strong>Leigh</strong> international customer<br />

support: 1-800-663-8932<br />

or email: help@leighjigs.com.<br />

For support contacts in your country of purchase<br />

see Appendix IV – Customer Support.<br />

Full Size<br />

(Inches)<br />

F3 5/16 3/8 1/2<br />

F18<br />

F24<br />

F3M<br />

F18M<br />

F24M<br />

LEI GH FIN GER (BOX) JOI N T SI ZES<br />

3/8 1/2<br />

3/8 1/2<br />

Full Size<br />

(mm)<br />

8 10 12<br />

10 12<br />

10 12<br />

Half Size<br />

(Inches)<br />

5/32 3/16 1/4<br />

3/16 1/4<br />

3/16 1/4<br />

Half Size<br />

(mm)<br />

4 6<br />

5 6<br />

5 6<br />

Quarter Size<br />

(Inches)<br />

3/32 1/8<br />

3/32 1/8<br />

3/32 1/8<br />

Quarter Size<br />

(mm)<br />

2<br />

3<br />

3<br />

Half-Blind<br />

(Inches)<br />

5/16 3/8 1/2<br />

3/8 1/2<br />

3/8 1/2<br />

Half-Blind<br />

(mm)<br />

8 10 12<br />

10 12<br />

10 12<br />

Double Sizes<br />

(Inches)<br />

5/8 3/4 1<br />

3/4 1<br />

3/4 1<br />

Double Sizes<br />

(mm)<br />

16 20 24<br />

20 24<br />

20 24

CONTENTS F3, F18 & F24 Fi n ger Jo i n t te m p l at e s UsergUide Introduction<br />

INTRODUCTION ..............................................................................................ii<br />

Chapter 1 – Assembly, Mounting, and Template Alignment .......................1<br />

Chapter 2 – Using Your Template Safely .......................................................5<br />

Chapter 3 – Operation Concept and Basic Template Functions ...................7<br />

Chapter 4 – Guidebushes and the Unique <strong>Leigh</strong> e-Bush..............................9<br />

Chapter 5 – Board Width Selection ............................................................. 11<br />

Chapter 6 – Box Joint Procedures ................................................................13<br />

Chapter 7 – Half-Blind Box Joint Procedures ..............................................17<br />

Chapter 8 – Half, Quarter, and Double Size Box Joints ..............................19<br />

Chapter 9 – Hints and Tips ...........................................................................25<br />

Appendix I – Attaching the <strong>Leigh</strong> e-Bush to the Router ............................27<br />

Appendix II – Bit Selection and Joint Specification ....................................29<br />

Appendix III – Template Parts List ...............................................................31<br />

Appendix IV – Customer Support................................................................35<br />

Are there operational differences between the F3 and F18/24?<br />

No. While the F18 and F24 are illustrated for most of the proce- illustrated in each step are identical whether performed on the<br />

dures in this guide, the differences between the F3 and the F18/24 F3/F3M, F18/24, or F18M/24M. Icon types for template pin<br />

do not affect the operational instructions. Movements and settings positions are the same on all templates.<br />

F18/F18M<br />

F3/F3M<br />

COMBINED<br />

INCH & METRIC<br />

SCALES<br />

SUPERJIG<br />

STYLE SUPPORT<br />

BRACKETS<br />

Although joint sizes may differ<br />

between the F3, F18 and F24,<br />

everything in these frames is<br />

operationally identical<br />

COMBINED<br />

INCH &<br />

METRIC<br />

SCALES<br />

D4R STYLE<br />

SUPPORT<br />

BRACKETS<br />

iii

iv Introduction F3, F18 & F24 Fi n ger Jo i n t te m p l at e s UsergUide TERMINOLOGY<br />

➂<br />

3<br />

➀<br />

➁<br />

Important: Inches and Millimetres<br />

Because <strong>Leigh</strong> makes F3, F18 and F24 Templates in inch and<br />

metric models, measurements in this user guide are shown in both<br />

inches and millimetres. Dimensions are indicated with "inches"<br />

first, followed by "millimetres" in square parentheses.<br />

Examples: 1 ⁄2"[12mm], or<br />

3 ⁄4"x5 1 ⁄2"x8" or longer [20x140x200mm].<br />

Do not be concerned if the inch/millimetre equivalents are not<br />

always exact. Just use the dimensions which apply to your jig.<br />

Reading the Settings Illustrations<br />

The F Template scales have dual markings for inch and metric.<br />

Note: The scales on some templates may indicate a 1 ⁄4"[6mm] size. This<br />

comb size is only available on F1600 Templates.<br />

The template scales are illustrated in a panel overlaying the main<br />

illustration ➀ when settings are specified in an instruction. The<br />

inactive (upside down) part of the scale is not shown in the illustration.<br />

Scale settings for instructions are shown with a red line ➁.<br />

When calibration marks on the support brackets ➂ are highlighted,<br />

they are illustrated in red for clarity. On the jig, the lines<br />

are black.<br />

Scale Icons<br />

The <strong>Leigh</strong> Finger Joint Template has two modes. Position the<br />

selected comb to the front (toward you, the operator). This<br />

places the<br />

Inactive scale upside down.<br />

and<br />

Active scale right side up.<br />

Template Icons and Numbers (engraved)<br />

Template positioning holes (see page 7)

TERMINOLOGY<br />

Which Way Round Should the Board Go?<br />

We devised these icons to indicate which side of a board faces out<br />

(toward you when it is clamped in the jig), and which faces are in<br />

or out when assembled.<br />

jBoards are clamped in the jig both “face in” and “face out” for<br />

alternate end cuts; e.g. all regular box joint ends are routed this<br />

way<br />

iInside of board. All half-blind box joints are clamped in the<br />

jig with the inside i face away from the jig toward you, the<br />

operator.<br />

Shaded icons are on the other side of the board.<br />

How to Read the Symbols<br />

To help you understand the instructions and illustrations in this<br />

user guide, we have used a number of international symbols, plus<br />

a few special ones of our own. They are all explained below. You<br />

needn’t worry about memorizing these symbols now because they<br />

are repeated frequently throughout the guide, and you will soon<br />

get used to them.<br />

The following symbols indicate:<br />

eThis edge against side stop<br />

fThis edge against side stop<br />

As above, other side of board<br />

Caution: use special care for this operation<br />

<br />

➀➁➂ Numbered References in text<br />

± Plus/Minus<br />

= Equals<br />

F3, F18 & F24 Fi n ger Jo i n t te m p l at e s UsergUide<br />

Introduction<br />

v

vi Introduction F3, F18 & F24 Fi n ger Jo i n t te m p l at e s UsergUide

F3, F18 & F24 FingerJoint templ ates UsergUide<br />

CHAPTER 1<br />

Assembly, Mounting and<br />

Template Alignment<br />

Assembly and Mounting<br />

Before you begin mounting the <strong>Leigh</strong> Finger Joint Template to your <strong>Leigh</strong> Jig, make sure you have received the model ordered<br />

(Inch or Metric), and all the necessary parts.<br />

1. 1 e7-Bush incl nut (F3 only)<br />

1 e8-Bush incl nut<br />

1 e10-Bush incl nut<br />

1 Pin Wrench<br />

1 User Guide<br />

2. 1 Template “inch” assembly,<br />

or:<br />

1 Template “metric” assembly<br />

If any of these items are missing, please<br />

notify your supplier or <strong>Leigh</strong> Industries<br />

immediately.<br />

Except for the scale thumbscrews (packed<br />

in a bag attached to the template), your<br />

<strong>Leigh</strong> F-Template comes fully assembled<br />

and requires only mounting and indexing<br />

to your <strong>Leigh</strong> jig. This procedure is<br />

critical to the accuracy of the finished<br />

joinery, so please follow the mounting<br />

instructions carefully.<br />

F18<br />

F18M<br />

F24<br />

F24M<br />

F3<br />

F3M<br />

2<br />

1<br />

e8<br />

e10<br />

Check that you received one of these templates:<br />

e7<br />

(F3/F3M)<br />

1

2 Chapter 1 F3, F18 & F24 Finger Joint templ ates UsergUide<br />

ASSEMBLY, MOUNTING & TEMPLATE ALIGNMENT<br />

1<br />

1-1 Super18 & Super24 Jig Owners D-Series jig owners go<br />

straight to 1-6.<br />

Raise both end support brackets and tighten the support bracket<br />

knobs ➀.<br />

2<br />

1-3 Slide the template onto the support brackets, with the<br />

3 ⁄8"[10mm] comb toward you ➀ and set on the 3 ⁄8"[10mm] setting.<br />

Tighten both thumbscrews ➁.<br />

Do not lower the assembly onto the finger support board.<br />

3<br />

1-5 …pull up on the template bar ➀ while pushing down on the scale ➁<br />

to ensure the bar is touching the two registration pads ➂ inside the scale.<br />

Maintain pressure and tighten the scale lock-screw ➃. Repeat at the other<br />

end. Remove the block and your template is ready to use. To maintain<br />

correct template alignment, follow this procedure whenever you remove<br />

the scales from the finger assembly.<br />

4<br />

2<br />

1<br />

1<br />

1<br />

1 1<br />

2<br />

1-2 Install the two thumbscrews a few turns into the scales ➀.<br />

Loosen the scale lock screw ➁ at both ends (by one turn only).<br />

1<br />

1-4 Align the template so that its centre hole aligns with the hole<br />

in the bar and firmly insert the template pin ➀. Angle trim the end<br />

of a straight block and clamp it tight against the left stop; the top<br />

protruding into the last 3 ⁄8"[10mm] opening ➁. Move the combined<br />

assembly to the right until the left side of the opening touches the<br />

block ➂. Taking care to not move the template assembly…<br />

1-6 Mounting F3/F3M to D-Series <strong>Jigs</strong><br />

Procedure is the same for Inch and Metric 24" templates.<br />

Make sure your jig is mounted as per its User Guide, and the spacer<br />

board is clamped into position.<br />

3<br />

2<br />

2

ASSEMBLY, MOUNTING & TEMPLATE ALIGNMENT F3, F18 & F24 Finger Joint templ ates UsergUide Chapter 1<br />

1<br />

2<br />

1-7 D1258, D1258R and D3 jig owners: If you already own<br />

the <strong>Leigh</strong> Mortise and Tenon Attachment, fit its extended support<br />

brackets ➀ and use for all finger joint and dovetail procedures. If<br />

not, mark the arrow pointers on the standard support brackets ➁<br />

with a dark felt pen. Some D4 and D4R Jig owners already have<br />

extended brackets. Late model D4R brackets are shorter.<br />

Centring Template on Jig All 24" D series jigs<br />

1-9 Loosen the scale bar set screw ➀, at each end of the template.<br />

4<br />

3<br />

1<br />

1-11 Centring the F3 Align the template so that its centre hole ➀<br />

aligns with the hole in the bar. Insert the template pin ➁ with a gentle<br />

twist to seat it. Angle trim the end of a straight block; clamp tight<br />

against the left stop and into the first opening ➂. Move the combined<br />

assembly so the left side of the opening touches the block ➃. Taking<br />

care to not move the template assembly…<br />

2<br />

1<br />

1<br />

2 1<br />

1-8 Before installing the F3/F3M on any 24" D series jig with<br />

adjustable side stops, set and index the stops according to the<br />

jig's user guide. Are the stops 1 1 /2"[38mm] in from each end of<br />

the jig body extrusion ➀ and 24 1 /8"[613mm] apart ➁? If not,<br />

do it now.<br />

D4R jigs have fixed side stops.<br />

3<br />

1-10 Slide the template assembly onto the jig support brackets<br />

with the 3 ⁄8" & 5 ⁄16"[10 & 8 mm] combs toward you and lower it<br />

gently onto the jig's spacer board ➃. Make sure the scale reading<br />

is the same on both scales, then tighten the thumb screws ➂.<br />

1<br />

1-12 …tighten both scale set screws ➀ and ➁. Remove the<br />

block and your <strong>Leigh</strong> F3 is ready to use. ■<br />

4<br />

2<br />

3

4 Chapter 1 F3, F18 & F24 Finger Joint templ ates UsergUide<br />

ASSEMBLY, MOUNTING & TEMPLATE ALIGNMENT

Safety is not optional.<br />

F3, F18 & F24 Fi n gerJo i n t te m p l at e s UsergUide<br />

Read and follow the recommendations in this chapter.<br />

2-1 Read the owner’s manual that came with your router. It is<br />

essential to understand the router manufacturer’s instructions<br />

completely.<br />

2-3 Never drink alcohol or take medications that may cause<br />

drowsiness when you will be operating a router.<br />

CHAPTER 2<br />

Using Your Template Safely<br />

2-2 Always wear approved safety glasses.<br />

Protect yourself from harmful dust with a face mask.<br />

Always wear hearing protection.<br />

For complete comfort and convenience, get yourself a <strong>Leigh</strong> VRS<br />

(Vacuum Router Support) to match your jig model.<br />

2-4 Always disconnect the power source from the router when<br />

fitting bits or guidebushes, or making adjustments.<br />

Before connecting the router to the power source, make sure the<br />

bit and collet revolve freely in all the areas you plan to rout, and<br />

the bit does not touch the guidebush or jig.<br />

5

6 Chapter 2 F3, F18 & F24 Fi n ger Jo i n t te m p l at e s UsergUide<br />

2-5 Do not tilt the router on the jig.<br />

Keep the router flat on the jig assembly.<br />

Note: The optional <strong>Leigh</strong> VRS attachment prevents router tilting.<br />

1<br />

USING YOUR TEMPLATE SAFELY<br />

2-6 If you insist on removing the router from the jig while it<br />

is still revolving, always pull it straight off the jig horizontally,<br />

and do not raise or lower the router until it is completely clear<br />

of the jig.<br />

2-7 Do not rout at face level. 2-8 If you have never used your router before, be sure to follow<br />

the router manufacturer’s instructions for its use. Make plenty<br />

of simple open-face practice cuts without a guidebush before<br />

you try to use the router on the <strong>Leigh</strong> jig. You must, of course,<br />

always use a guidebush when routing on the <strong>Leigh</strong> Jig. ■

Template Modes<br />

Template pin hole icons denote<br />

the type of joint and edge finish<br />

from each position.<br />

Scale Modes<br />

F3, F18 & F24 Finger Joint templ ates UsergUide<br />

CHAPTER 3<br />

Operation Concept and<br />

Basic Template Functions<br />

Square Sockets - tail-board socket at board edge<br />

Square Pins - pin-board pin at board edge<br />

F3 F18 and F24<br />

The inactive scale is always on the<br />

left side of each scale assembly<br />

and is upside down.<br />

5 /16" Comb<br />

1/2" Comb<br />

F3 inch<br />

F3M millimetres<br />

8mm Comb 10mm Comb<br />

12mm Comb<br />

3 /8" Comb<br />

The active scale is always<br />

on the right side of each<br />

scale assembly.<br />

Throughout the manual, the proper pin location<br />

for each step is highlighted with red in<br />

an inset. Only the front (active) pinholes<br />

will be shown.<br />

Reading scales from directly overhead<br />

improves setting accuracy.<br />

The inactive scale is always upside down.<br />

F18 inch<br />

3 /8" Comb<br />

1 /2" Comb<br />

F18M millimetres<br />

10mm Comb<br />

12mm Comb<br />

The active scale is always right<br />

side up and toward you.<br />

7

8 Chapter 3 F3, F18 & F24 Finger Joint templ ates UsergUide<br />

OPERATION CONCEPTS AND BASIC TEMPLATE FUNCTIONS<br />

F18<br />

F3<br />

3-1 The active comb (the one you wish to use) is positioned<br />

toward you at the front of the jig. Depending on the Template<br />

model and comb size selected, the active comb may start at either<br />

the right, or left-hand side of the jig. Combs that are the full<br />

width of the template always start at the left side.<br />

3-3 ...the mating rear side stop, depending on which procedure<br />

is to be used.<br />

1<br />

2<br />

3-5 Mating joints routed under the same comb have to be offset<br />

to achieve correct joint alignment. On <strong>Leigh</strong> templates the offset<br />

is achieved by moving the template left or right by half the pitch<br />

of the comb. This movement is controlled by the template pin,<br />

at the other end of the template ➀. Note that the template is close<br />

to the scale ➁.<br />

3-2 Clamp your work pieces against the front side stop or...<br />

3-4 The template control pin engages the template to the template<br />

bar using precisely positioned holes ➀. The active template<br />

pin holes are always at the opposite end of the template , out of<br />

the way of the router. Most illustrations will have an inset showing<br />

the correct template pin hole position for the procedure.<br />

1<br />

2<br />

3-6 In this illustration, the template is moved to the right by<br />

half the comb pitch and positioned by the template pin ➀ to rout<br />

the mating half of the joint in 3-5. Note the increased gap between<br />

the scale and template ➁. ■<br />

1

F3, F18 & F24 Finger Joint templ ates UsergUide<br />

4-1 Unlike plain circular template guidebushes ➀, the e-Bush is<br />

elliptical ➁. This innovation effectively changes the guidebush “active<br />

diameter” when it's rotated, and provides benefits not possible with a<br />

plain round guidebush. The F18 & F24 Templates include two <strong>Leigh</strong><br />

e-Bushes*: e-8 for 3 ⁄8"[10mm] combs, and e-10 for 1 ⁄2”[12mm] comb;<br />

the F3 includes those plus the e-7 for 5 ⁄16"[8mm] comb.<br />

1<br />

.500" .480"<br />

2 1<br />

4-3 The e-Bush (e-8 illustrated) fits to the router base or to a<br />

guidebush adaptor in the base. See Appendix I. The ellipse or oval shape<br />

major axis ➀ is ~.500", and minor axis ➁ ~.480" [12,7 x 12,2mm].<br />

Turning the e-Bush 90 degrees in the router base changes the active<br />

guide size by .020"[,50mm] providing infinite adjustment and recordable<br />

settings for perfectly fitting box joints.<br />

*US & CDN Patent Pending. UK Patent No. GB2443974<br />

2<br />

1<br />

2<br />

CHAPTER 4<br />

Guidebushes and the Unique<br />

<strong>Leigh</strong> e-Bush<br />

1<br />

? ? ? ? ?<br />

4-2 Joint Fit and Joint Pitch Box joints routed with standard<br />

sized straight bits ➀ and standard sized guidebushes ➁ against<br />

straight guide surfaces ➂ on pitch centres exactly two times the bit<br />

diameter ➃ will guarantee a loose fitting joint. Bits, guidebushes and<br />

templates are manufactured with necessary plus/minus tolerances<br />

and the router will have some degree of run-out, or “wobble”.<br />

1 2<br />

4-4 Here’s how it works. In normal use, the operator does not<br />

rotate the router more than a few degrees either way ➀. In fact,<br />

because of potential bit-to-bush eccentricity problems it is advisable<br />

to minimize router rotation on jigs ➁.<br />

4<br />

2<br />

3<br />

9

10 Chapter 4 F3, F18 & F24 Finger Joint templ ates UsergUide<br />

GUIDEBUSHES AND THE UNIQUE <strong>LEIGH</strong> e-BUSH<br />

2<br />

4-5 Establish the orientation in which you normally hold and<br />

operate the router on the jig. Now, up-end the router in the same<br />

orientation. Make a small scratch line or permanent ink mark on<br />

the router base or e-Bush adaptor at the 12 o’clock position ➀.<br />

2<br />

+ - + - +<br />

4-7 Turning the e-Bush to zero allows more side-to-side router/<br />

bit movement, and more wood removal, producing larger sockets<br />

and smaller pins, and thus a loose fit.<br />

4-9 When you have the best joint fit, mark the setting in pencil<br />

here. Different wood hardness may require slightly different<br />

settings, so also note the wood species. Use the same bit next<br />

time. ■<br />

1<br />

1<br />

1<br />

- + - + -<br />

4-6 With the e-Bush ➀ turned to “10” in the base ➁ the active<br />

“diameter” is increased, allowing less side-to-side movement, and<br />

resulting in smaller sockets and larger pins. A tight fit! Scale and<br />

movement are exaggerated in this sequence of illustrations.<br />

2<br />

= = = = =<br />

4-8 A few trial-and-error test cuts and e-Bush adjustments will<br />

allow you to establish the correct pin and socket sizes for a perfect<br />

fit. Note: One division of the e-Bush changes the joint glue–<br />

line interface by two thousandths of an inch, that is, 0.002" or<br />

0,050mm.<br />

2<br />

2

F3, F18 & F24 Finger Joint templ ates UsergUide<br />

CHAPTER 5<br />

Board Width Selection<br />

Board widths are determined by the number of fingers you want in your design and whether the joint is symmetrical or<br />

asymmetrical. This chapter makes it easy to determine appropriate widths for the <strong>Leigh</strong> Finger Joint Templates.<br />

5-1 Board Widths and Joint Symmetry<br />

Unlike the infinitely variable <strong>Leigh</strong> Dovetail Jig, a fixed template<br />

cannot accommodate any width of board and still produce a neat<br />

and even finish on both side edges of a joint. The boards must be<br />

cut to specific widths, depending on the pitch of the comb.<br />

1<br />

5-3 Symmetrical joints are essential for half-blind corners ➀.<br />

However, ordinary box joints may be asymmetrical and look<br />

okay ➁.<br />

2<br />

1<br />

2<br />

4<br />

3<br />

5-2 Symmetrical joints have pins ➀ on both side edges of one<br />

board and sockets ➁ on both side edges of the mating board.<br />

Asymmetrical joints have a pin ➂ on one side edge and a<br />

socket ➃ on the other side edge of each board.<br />

5-4 The comb pitches on the <strong>Leigh</strong> Finger Joint Templates<br />

are all 2 times the bit diameter plus 1 ⁄32"[0,75mm], so you<br />

cannot simply use bit diameter to calculate board widths. See the board<br />

width charts on Page 12. For symmetrical square joints use board widths in<br />

red column. For asymmetrical square joints use widths in grey column.<br />

1<br />

2<br />

3<br />

11<br />

4

12 Chapter 5 F3, F18 & F24 Finger Joint templ ates UsergUide<br />

Board Width Selection<br />

Board Width - INCHES Board Width - MILLIMETRES<br />

24<br />

12<br />

20<br />

10<br />

16<br />

8<br />

1”<br />

1/2”<br />

3/4”<br />

3/8”<br />

5/8”<br />

5/16”<br />

Symmetrical Asymmetrical<br />

Symmetrical Asymmetrical<br />

Symmetrical Asymmetrical<br />

Symmetrical Asymmetrical<br />

Symmetrical Asymmetrical<br />

Symmetrical Asymmetrical<br />

Symmetrical Asymmetrical<br />

Symmetrical Asymmetrical<br />

Symmetrical Asymmetrical<br />

Symmetrical Asymmetrical<br />

Symmetrical Asymmetrical<br />

Symmetrical Asymmetrical<br />

1<br />

2<br />

36<br />

48<br />

73<br />

3<br />

60<br />

73<br />

98<br />

4<br />

85<br />

98<br />

122<br />

5<br />

110<br />

122<br />

147<br />

6<br />

135<br />

147<br />

172<br />

7<br />

160<br />

172<br />

197<br />

8<br />

184<br />

197<br />

222<br />

9<br />

209<br />

222<br />

246<br />

10<br />

234<br />

246<br />

271<br />

11<br />

259<br />

271<br />

296<br />

12<br />

284<br />

296<br />

321<br />

13<br />

308<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

33<br />

34<br />

35<br />

36<br />

37<br />

38<br />

39<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

47<br />

48<br />

49<br />

50<br />

1<br />

1<br />

2<br />

30<br />

24<br />

40<br />

2<br />

32<br />

61<br />

3<br />

50<br />

40<br />

61<br />

49<br />

3<br />

49<br />

82<br />

4<br />

71<br />

57<br />

82<br />

66<br />

4<br />

66<br />

102<br />

5<br />

92<br />

5<br />

74<br />

102<br />

82<br />

82<br />

123<br />

6<br />

113<br />

6<br />

91<br />

123<br />

99<br />

99<br />

144<br />

7<br />

134<br />

116<br />

7<br />

108<br />

144<br />

116<br />

165<br />

8<br />

154<br />

133<br />

8<br />

124<br />

165<br />

133<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

186<br />

9<br />

175<br />

150<br />

9<br />

141<br />

186<br />

150<br />

206<br />

10<br />

196<br />

166<br />

10<br />

158<br />

206<br />

166<br />

227<br />

11<br />

217<br />

183<br />

11<br />

175<br />

227<br />

183<br />

248<br />

12<br />

238<br />

200<br />

12<br />

191<br />

248<br />

200<br />

258<br />

208<br />

321<br />

269<br />

13<br />

269<br />

217<br />

13<br />

217<br />

346<br />

14<br />

333<br />

279<br />

225<br />

346<br />

290<br />

14<br />

290<br />

233<br />

14<br />

233<br />

370<br />

15<br />

358<br />

300<br />

242<br />

370<br />

310<br />

15<br />

310<br />

250<br />

15<br />

250<br />

395<br />

16<br />

383<br />

F3M Template<br />

395<br />

420<br />

17<br />

408<br />

420<br />

445<br />

18<br />

F18M Template<br />

432<br />

445<br />

F18M Template<br />

321<br />

267<br />

16<br />

F3M Template<br />

259<br />

267<br />

342<br />

362<br />

469<br />

19<br />

457<br />

383<br />

469<br />

494<br />

20<br />

482<br />

404<br />

494<br />

519<br />

21<br />

507<br />

425<br />

519<br />

544<br />

22<br />

531<br />

544<br />

569<br />

23<br />

556<br />

569<br />

593<br />

24<br />

581<br />

593<br />

618<br />

25<br />

606<br />

618<br />

F24M F3M Template<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

33<br />

34<br />

35<br />

36<br />

37<br />

38<br />

39<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

47<br />

48<br />

49<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

57<br />

58<br />

59<br />

60<br />

1<br />

1<br />

1<br />

29 ⁄32 29 ⁄32<br />

2<br />

1 15 ⁄32<br />

1 3 ⁄32<br />

2<br />

2<br />

1 1 ⁄2<br />

2<br />

1 1 1 ⁄4 1 ⁄4<br />

1 29 1 ⁄32 29 ⁄32<br />

1 9 1 ⁄16 9 ⁄16<br />

3 1 ⁄32<br />

3<br />

2 1 ⁄2<br />

1 7 ⁄8<br />

3 1 ⁄32<br />

2 9 ⁄32<br />

3<br />

2 9 ⁄32<br />

3<br />

1 29 1 ⁄32 29 ⁄32<br />

2 9 2 ⁄16 9 ⁄16<br />

2 7 2 ⁄32 7 ⁄32<br />

4 1 ⁄16<br />

4<br />

3 17 ⁄32<br />

2 21 ⁄32<br />

4 1 ⁄16<br />

3 1 ⁄16<br />

4<br />

3 1 ⁄16<br />

4<br />

2 9 2 ⁄16 9 ⁄16<br />

3 7 3 ⁄32 7 ⁄32<br />

2 7 2 ⁄8 7 ⁄8<br />

5 3 ⁄32<br />

5<br />

4 9 ⁄16<br />

3 7 ⁄16<br />

5 3 ⁄32<br />

3 27 ⁄32<br />

5<br />

3 27 ⁄32<br />

5<br />

3 7 3 ⁄32 7 ⁄32<br />

3 7 3 ⁄8 7 ⁄8<br />

3 17 3 ⁄32 17 ⁄32<br />

6 1 ⁄8<br />

6<br />

5 19 ⁄32<br />

4 7 ⁄32<br />

6 1 ⁄8<br />

4 5 ⁄8<br />

6<br />

4 5 ⁄8<br />

6<br />

3 7 3 ⁄8 7 ⁄8<br />

4 17 4 ⁄32 17 ⁄32<br />

4 3 4 ⁄16 3 ⁄16<br />

7 5 ⁄32<br />

7<br />

6 5 ⁄8<br />

5<br />

7 5 ⁄32<br />

5 13 ⁄32<br />

7<br />

5 13 ⁄32<br />

7<br />

4 17 4 ⁄32 17 ⁄32<br />

5 3 5 ⁄16 3 ⁄16<br />

4 27 4 ⁄32 27 ⁄32<br />

8 3 ⁄16<br />

8<br />

7 21 ⁄32<br />

5 25 ⁄32<br />

8 3 ⁄16<br />

6 3 ⁄16<br />

8<br />

6 3 ⁄16<br />

8<br />

5 3 5 ⁄16 3 ⁄16<br />

5 27 5 ⁄32 27 ⁄32<br />

5 1 5 ⁄2 1 ⁄2<br />

9<br />

6 1 6 ⁄2 1 ⁄2<br />

6 5 6 ⁄32 5 ⁄32<br />

10<br />

7 5 7 ⁄32 5 ⁄32<br />

6 13 6 ⁄16 13 ⁄16<br />

11<br />

7 13 7 ⁄16 13 ⁄16<br />

7 15 7 ⁄32 15 ⁄32<br />

12<br />

8 15 8 ⁄32 15 ⁄32<br />

8 1 8 ⁄8 1 ⁄8<br />

13<br />

331<br />

16<br />

331<br />

352<br />

17<br />

352<br />

373<br />

18<br />

373<br />

393<br />

19<br />

393<br />

414<br />

20<br />

414<br />

435<br />

21<br />

435<br />

456<br />

22<br />

F18M Template<br />

445<br />

F24M Template F18M Template<br />

F3M Template<br />

9 1 9 ⁄8 1 ⁄8<br />

8 25 8 ⁄32 25 ⁄32<br />

14<br />

9 25 9 ⁄32 25 ⁄32<br />

15<br />

10 7 10 ⁄16 7 ⁄16<br />

16<br />

F3 Template<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

9 7 ⁄32<br />

9<br />

8 11 ⁄16<br />

6 9 ⁄16<br />

9 7 ⁄32<br />

6 31 ⁄32<br />

9<br />

6 31 ⁄32<br />

5 27 5 ⁄32 27 ⁄32<br />

10 1⁄4<br />

10<br />

9 23 ⁄32<br />

7 11 ⁄32<br />

10 1⁄4<br />

7 3 ⁄4<br />

10<br />

7 3 ⁄4<br />

6 1 6 ⁄2 1 ⁄2<br />

11 9 ⁄32<br />

11<br />

10 3 ⁄4<br />

8 1 ⁄8<br />

11 9 ⁄32<br />

8 17 ⁄32<br />

11<br />

8 17 ⁄32<br />

7 5 7 ⁄32 5 ⁄32<br />

12 5 ⁄16<br />

12<br />

11 25 ⁄32<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

33<br />

34<br />

35<br />

36<br />

37<br />

38<br />

39<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

8 29 ⁄32<br />

12 5 ⁄16<br />

9 5 ⁄16<br />

12<br />

9 5 ⁄16<br />

7 13 7 ⁄16 13 ⁄16<br />

13 11 ⁄32<br />

13<br />

12 13 ⁄16<br />

9 11 ⁄16<br />

13 11 ⁄32<br />

10 3 ⁄32<br />

13<br />

10 3 ⁄32<br />

8 15 8 ⁄32 15 ⁄32<br />

F3M Template<br />

14 3 ⁄8<br />

14<br />

13 27 ⁄32<br />

10 15 ⁄32<br />

14 3 ⁄8<br />

10 7 ⁄8<br />

14<br />

10 7 ⁄8<br />

9 1 9 ⁄8 1 ⁄8<br />

11 1 ⁄4<br />

9 7 9 ⁄16 7 ⁄16<br />

15 13 ⁄32<br />

15<br />

14 7 ⁄8<br />

15 13 ⁄32<br />

11 21 ⁄32<br />

15<br />

11 21 ⁄32<br />

9 25 9 ⁄32 25 ⁄32<br />

12 1 ⁄32<br />

10 3 10 ⁄32 3 ⁄32<br />

16 7 ⁄16<br />

16<br />

15 29 ⁄32<br />

16 7 ⁄16<br />

16<br />

12 7 ⁄16<br />

10 7 10 ⁄16 7 ⁄16<br />

F3 Template<br />

F18 Template<br />

12 7 ⁄16<br />

12 13 ⁄16<br />

13 19 ⁄32<br />

14 3 ⁄8<br />

15 5 ⁄32<br />

15 15 ⁄16<br />

16 23 ⁄32<br />

456<br />

477<br />

23<br />

466<br />

17 1 ⁄2<br />

477<br />

F18 Template<br />

497<br />

24<br />

487<br />

18 9 ⁄32<br />

497<br />

518<br />

25<br />

508<br />

19 1 ⁄16<br />

518<br />

539<br />

26<br />

529<br />

19 27 ⁄32<br />

539<br />

560<br />

27<br />

549<br />

20 5 ⁄8<br />

560<br />

581<br />

28<br />

570<br />

581<br />

601<br />

29<br />

591<br />

601<br />

622<br />

30<br />

F24M Template<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

33<br />

34<br />

35<br />

36<br />

37<br />

38<br />

39<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

47<br />

48<br />

49<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

57<br />

58<br />

59<br />

60<br />

61<br />

62<br />

17 15 ⁄32<br />

17<br />

16 15 ⁄16<br />

17 15 ⁄32<br />

13 7 ⁄32<br />

17<br />

13 7 ⁄32<br />

18<br />

F18 Template<br />

F3 Template<br />

F3 Template<br />

18 1 ⁄2<br />

17 31 ⁄32<br />

18 1 ⁄2<br />

14<br />

18<br />

14<br />

19 17 ⁄32<br />

19<br />

19<br />

19 17 ⁄32<br />

14 25 ⁄32<br />

19<br />

14 25 ⁄32<br />

20 9 ⁄16<br />

20<br />

20 1 ⁄32<br />

20 9 ⁄16<br />

F3 & F24 Template<br />

15 9 ⁄16<br />

20<br />

15 9 ⁄16<br />

F3M Template<br />

21 19 ⁄32<br />

21<br />

21 1 ⁄16<br />

21 19 ⁄32<br />

16 11 ⁄32<br />

21<br />

F18 Template<br />

16 11 ⁄32<br />

22 5 ⁄8<br />

22<br />

22 3 ⁄32<br />

22 5 ⁄8<br />

17 1 ⁄8<br />

22<br />

17 1 ⁄8<br />

23 21 ⁄32<br />

23<br />

F3 & F24 Template<br />

23 1 ⁄8<br />

23 21 ⁄32<br />

17 29 ⁄32<br />

23<br />

17 29 ⁄32<br />

18 11 ⁄16<br />

24<br />

18 11 ⁄16<br />

F24M<br />

19 15 ⁄32<br />

25<br />

19 15 ⁄32<br />

20 1 ⁄4<br />

26<br />

20 1 ⁄4<br />

21 1 ⁄32<br />

27<br />

21 1 ⁄32<br />

21 13 ⁄16<br />

28<br />

21 13 ⁄32<br />

21 13 ⁄16<br />

22 19 ⁄32<br />

29<br />

22 3 ⁄16<br />

22 19 ⁄32<br />

612<br />

Note:<br />

Symmetrical joints: use red column.<br />

Asymmetrical joints: use grey column<br />

22 31 ⁄32<br />

622<br />

23 3 ⁄8<br />

30<br />

F24 Template<br />

23 3 ⁄8<br />

Numbers in white column are number of board sockets and pins<br />

24 1 ⁄8<br />

31<br />

23 3 ⁄4<br />

F24 Template<br />

24 1 ⁄8