W-0005(EU) Silky Touch Emulsion for Deodorant Wipe ... - Lubrizol

W-0005(EU) Silky Touch Emulsion for Deodorant Wipe ... - Lubrizol

W-0005(EU) Silky Touch Emulsion for Deodorant Wipe ... - Lubrizol

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Silky</strong> <strong>Touch</strong> <strong>Emulsion</strong> <strong>for</strong> <strong>Deodorant</strong> <strong>Wipe</strong><br />

(Starting Point Formula)<br />

This emulsion is a starting point <strong>for</strong>mula <strong>for</strong> convenient, easy-to-use deodorant wipes that helps you feel fresh all day. Vegetable-derived Glucate* DO<br />

Emulsifier works as a co-emulsifier in combination with Coco-Glucoside in this PEG-free, lightweight emulsion. Pemulen* TR-2 Polymer stabilizes the oil-inwater<br />

emulsion and allows <strong>for</strong> the suspension of the Modified Corn Starch, while Schercemol* CO Ester provides a soft and silky afterfeel.<br />

:<br />

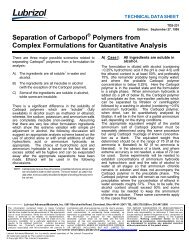

INCI Name, Trade Name Weight % Function<br />

A. 1. Deionized Water 40.47 Diluent<br />

B. 2. Cetyl Ethylhexanoate,<br />

Schercemol* CO Ester<br />

3. Tocopheryl Acetate,<br />

Vitamin E Acetate<br />

4. Methyl Glucose Dioleate,<br />

Glucate* DO Emulsifier<br />

5. Acrylates/C10-30 Alkyl Acrylate Crosspolymer,<br />

Pemulen* TR-2 Polymer<br />

2.00 Emollient<br />

0.50 Antioxidant<br />

0.10 Co-Emulsifier<br />

0.13 Rheology Modifier /<br />

<strong>Emulsion</strong> Stabilizer<br />

C. 6. Sodium Hydroxide (5%) 0.20 Neutralizer<br />

D. 7. Deionized Water 10.00 Diluent<br />

8. Allantoin 0.10 Skin Conditioner<br />

9. Glycerin 5.00 Humectant<br />

10. Coco-Glucoside (50%),<br />

Plantacare ® 818 UP<br />

11. Corn Starch Modified,<br />

Dry-Flo ® AF<br />

0.50 Mild Surfactant<br />

2.00 Absorbent<br />

E. 12. Alcohol Denat. 5.00 Solvent<br />

13. Fragrance,<br />

Euphorie Cedrat #444255<br />

14. Phenoxyethanol (and) Ethylhexylglycerin,<br />

Euxyl ® PE 9010<br />

1.00 Fragrance<br />

1.00 Preservative<br />

F. 15. Deionized Water 30.00 Diluent<br />

North America<br />

9911 Brecksville Road<br />

Cleveland, OH 44141-3247<br />

TEL: 216.447.5000<br />

TEL: 800.379.5389<br />

FAX: 216.447.5250<br />

16. Rosmarinus Officinalis (Rosemary) Leaf Extract,<br />

Propylene Glycol (and) Water,<br />

Vegetol ® Rosemary MCF 772 Hydro<br />

- Continued Next Page -<br />

Mexico<br />

Avenida Interceptor Pte. #69<br />

Parque Industrial ‘La Joya’<br />

Cuautitlán, Izcalli - Mexico City<br />

Edo. de México 54730, México<br />

TEL: 52.55.3067.0860<br />

FAX: 52.55.5870.8956<br />

Brazil<br />

Av. Fagundes Filho<br />

134 - Cj. 101, 10th floor<br />

Edificio Victoria Office Center<br />

São Judas, 04304-010 São Paulo<br />

TEL: 55.11.4082.1330<br />

FAX: 55.11.4082.1345<br />

2.00 Botanical Extract<br />

Europe, Middle East<br />

and Africa<br />

Chaussée de Wavre, 1945<br />

B-1160 Brussels, Belgium<br />

TEL: 32.2.678.19.11<br />

FAX: 32.2.678.20.02<br />

Product Properties:<br />

Appearance Thin light yellow lotion<br />

pH 5.5 – 6.0<br />

Viscosity (mPa·s)** 150 – 450<br />

W-<strong>0005</strong>(<strong>EU</strong>)<br />

Stability: Passed 4 weeks @ 45 °C and RT, Did not pass F/T<br />

** Brookfield RVT @ 20 rpm, 25°C, #2 spindle, measured after 24 hours<br />

Comments:<br />

1. This <strong>for</strong>mula has not been tested on any non-woven<br />

substrate, but is a suggested starting point <strong>for</strong>mulation to help<br />

meet difficult viscosity and emulsion stability criteria.<br />

Preservation and stability may be dependant on the non-woven<br />

substrate that is used <strong>for</strong> application.<br />

2. Due to the alcohol in this <strong>for</strong>mulation, it is recommended that<br />

customers review the environmental and regulatory<br />

requirements of the states and countries where they wish to<br />

market this type of product to be sure that they are in<br />

compliance with local VOC regulations.<br />

3. Due to the alcohol in this <strong>for</strong>mulation, follow safety<br />

precautions appropriate <strong>for</strong> the handling of flammable liquids.<br />

Supplier References:<br />

<strong>Lubrizol</strong> Advanced Materials, Inc.<br />

(Noveon ®* Consumer Specialties) (2, 4, 5)<br />

Protameen (3)<br />

ISP (8)<br />

Cognis (10)<br />

National Starch (11)<br />

Symrise (13)<br />

Schülke & Mayr (14)<br />

Gattefossé (16)<br />

Asia Pacific<br />

1107-1110 Shui On Centre<br />

6-8 Harbour Road<br />

Wanchai, Hong Kong<br />

TEL: 852.2508.1021<br />

FAX: 852.2512.2241<br />

W-<strong>0005</strong>(<strong>EU</strong>)<br />

Edition: July 7, 2009<br />

Reference # 081030-01FP, LLN-014-06 (FPC)<br />

Original Edition: June 15, 2009<br />

For more in<strong>for</strong>mation visit www.personalcare.noveon.com or contact<br />

your nearest <strong>Lubrizol</strong> Advanced Materials location.<br />

South Asia<br />

501 & 501A, Omega<br />

Hiranandani Business Park<br />

Powai<br />

Mumbai 400 076 India<br />

TEL: 91.22.6698.0590 / 91<br />

FAX: 91.22.6602.7888<br />

China<br />

27/F Majesty Building<br />

No. 138 Pudong Avenue<br />

Shanghai 200120, PRC<br />

TEL: 86.21.3866.0366<br />

FAX: 86.21.5887.6981<br />

The in<strong>for</strong>mation contained herein is believed to be reliable, but no representations, guarantees or warranties of any kind are made as to its accuracy, suitability <strong>for</strong> particular applications or the results to be obtained. The in<strong>for</strong>mation often is based on<br />

laboratory work with small-scale equipment and does not necessarily indicate end product per<strong>for</strong>mance or reproducibility. Formulations presented may not have been tested <strong>for</strong> stability and should be used only as a suggested starting point. Because of the<br />

variations in methods, conditions and equipment used commercially in processing these materials, no warranties or guarantees are made as to the suitability of the products <strong>for</strong> the applications disclosed. Full-scale testing and end product per<strong>for</strong>mance are<br />

the responsibility of the user. <strong>Lubrizol</strong> Advanced Materials, Inc. shall not be liable <strong>for</strong> and the customer assumes all risk and liability <strong>for</strong> any use or handling of any material beyond <strong>Lubrizol</strong> Advanced Materials, Inc.’s direct control. The SELLER MAKES NO<br />

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Nothing contained herein is to be considered as permission,<br />

recommendation, nor as an inducement to practice any patented invention without permission of the patent owner.<br />

<strong>Lubrizol</strong> Advanced Materials, Inc. is a wholly owned subsidiary of The <strong>Lubrizol</strong> Corporation<br />

Noveon is a registered trademark of The <strong>Lubrizol</strong> Corporation<br />

*Trademark owned by The <strong>Lubrizol</strong> Corporation<br />

© Copyright 2009 <strong>Lubrizol</strong> Advanced Materials, Inc.

<strong>Silky</strong> <strong>Touch</strong> <strong>Emulsion</strong> <strong>for</strong> <strong>Deodorant</strong> <strong>Wipe</strong><br />

(Starting Point Formula)<br />

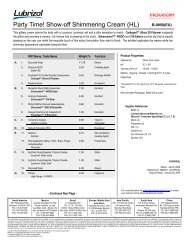

Procedure:<br />

1. PART A: In a vessel large enough to contain entire batch, add Deionized<br />

Water.<br />

2. PART B: add ingredients 2-4 in a separate vessel. Disperse Pemulen*<br />

TR-2 Polymer into oil phase.<br />

3. Add PART B to PART A. Mix <strong>for</strong> 20-30 minutes to allow the polymer to<br />

swell.<br />

4. Neutralize batch with Sodium Hydroxide (5%). Mix vigorously until uni<strong>for</strong>m.<br />

5. PART D: in a separate vessel, mix ingredients 7 to 10. When uni<strong>for</strong>m,<br />

disperse Dry-Flo ® AF. Mix until uni<strong>for</strong>m.<br />

6. Add PART D to batch. Mix until uni<strong>for</strong>m.<br />

7. PART E: Premix ingredients then add to batch. Mix until uni<strong>for</strong>m.<br />

8. PART F: Premix ingredients then add to batch. Mix until uni<strong>for</strong>m.<br />

W-<strong>0005</strong>(<strong>EU</strong>)