360 Modena gear box manual - All Ferraris

360 Modena gear box manual - All Ferraris

360 Modena gear box manual - All Ferraris

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

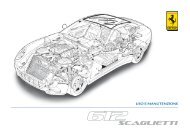

Component maintenance and overhaul<br />

In order to carry out a visual check of the components, it is advisable to thoroughly wash all the<br />

metallic parts using a solvent, biodegradable if possible, and blow them with compressed air.<br />

Pay particular attention to the internal lubrication channels, on the <strong>gear</strong><strong>box</strong> shafts, housing and<br />

covers, which must be spotlessly clean.<br />

Check that the housing and the covers show no indentations and that the bearing seats are intact,<br />

without scoring or ridging. If this is the case, they must be replaced immediately.<br />

Check that the surfaces and the edges of the <strong>gear</strong> toothing show no signs of wear or spalling. The<br />

contact area must extend over the whole surface of the toothing and must look smooth and uniform.<br />

Replace all <strong>gear</strong>s showing signs of said defects.<br />

Before reassembling the double <strong>gear</strong>s (31 and 32), it is necessary to visually check the coupling<br />

surfaces: they must show no signs of scoring or buckling. Check that the <strong>gear</strong>s have maintained the<br />

minimum specified interference with the lay shaft ( D 1.01). If this is not the case, replace the<br />

components immediately.<br />

Check the sides of the sliding sleeve for signs of wear, along with the contact surfaces of the <strong>gear</strong><br />

shift forks. It is extremely important that the contact surfaces of the fork and the sleeve remain<br />

upright in respect of the support rods.<br />

Check that the shimming surfaces of the idle <strong>gear</strong>s, the spacers and the shoulder rings show no<br />

signs of snagging or seizure. Replace if this is the case.<br />

Check that the engaging teeth of the sleeves and of the idle <strong>gear</strong>s show no signs of snagging,<br />

spalling or excessive wear, which would impede engagement.<br />

Check the threading and the grooving on the shafts and the synchronised elements on the reverse<br />

driving <strong>gear</strong> are in good condition.<br />

Plugs for tapping the machined holes are fitted on the <strong>gear</strong><strong>box</strong> housing along with tapered thread<br />

plugs (56, 57 and 58) which close the lubrication ducts. When disassembling, apply LOCTITE 510<br />

on the threading.<br />

The oil bleeding neck (59) is fitted flush on the housing. Check that it is not clogged with foreign