Merck Effect pigments

Merck Effect pigments

Merck Effect pigments

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Merck</strong><br />

<strong>Effect</strong> <strong>pigments</strong><br />

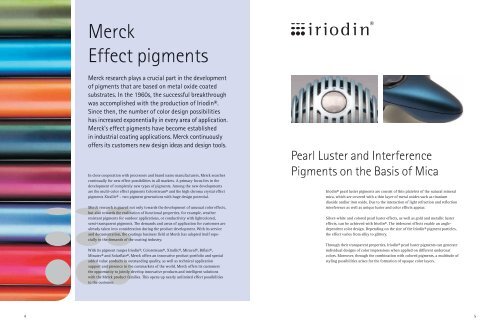

<strong>Merck</strong> research plays a crucial part in the development<br />

of <strong>pigments</strong> that are based on metal oxide coated<br />

substrates. In the 1960s, the successful breakthrough<br />

was accomplished with the production of Iriodin®.<br />

Since then, the number of color design possibilities<br />

has increased exponentially in every area of application.<br />

<strong>Merck</strong>’s effect <strong>pigments</strong> have become established<br />

in industrial coating applications. <strong>Merck</strong> continuously<br />

offers its customers new design ideas and design tools.<br />

In close cooperation with processors and brand name manufacturers, <strong>Merck</strong> searches<br />

continually for new effect possibilities in all markets. A primary focus lies in the<br />

development of completely new types of <strong>pigments</strong>. Among the new developments<br />

are the multi-color effect <strong>pigments</strong> Colorstream® and the high chroma crystal effect<br />

<strong>pigments</strong> Xirallic® – two pigment generations with huge design potential.<br />

<strong>Merck</strong> research is geared not only towards the development of unusual color effects,<br />

but also towards the realization of functional properties, for example, weather<br />

resistant <strong>pigments</strong> for outdoor applications, or conductivity with lightcolored,<br />

semi-transparent <strong>pigments</strong>. The demands and areas of application for customers are<br />

already taken into consideration during the product development. With its service<br />

and documentation, the coatings business field at <strong>Merck</strong> has adapted itself especially<br />

to the demands of the coating industry.<br />

With its pigment ranges Iriodin®, Colorstream®, Xirallic®, Miraval®, Biflair®,<br />

Minatec® and Solarflair®, <strong>Merck</strong> offers an innovative product portfolio and special<br />

added value products in outstanding quality, as well as technical application<br />

support and presence in the coremarkets of the world. <strong>Merck</strong> offers its customers<br />

the opportunity to jointly develop innovative products and intelligent solutions<br />

with the <strong>Merck</strong> product families. This opens up nearly unlimited effect possibilities<br />

to the customer.<br />

Pearl Luster and Interference<br />

Pigments on the Basis of Mica<br />

Iriodin® pearl luster <strong>pigments</strong> are consist of thin platelets of the natural mineral<br />

mica, which are covered with a thin layer of metal oxides such as titanium<br />

dioxide and/or iron oxide. Due to the interaction of light refraction and reflection<br />

interference as well as unique luster and color effects appear.<br />

Silver-white and colored pearl luster effects, as well as gold and metallic luster<br />

effects, can be achieved with Iriodin®. The iridescent effects enable an angledependent<br />

color design. Depending on the size of the Iriodin® pigment particles,<br />

the effect varies from silky to glittery.<br />

Through their transparent properties, Iriodin® pearl luster <strong>pigments</strong> can generate<br />

individual designs of color impressions when applied on different undercoat<br />

colors. Moreover, through the combination with colored <strong>pigments</strong>, a multitude of<br />

styling possibilities arises for the formation of opaque color layers.<br />

4 5

Pigment<br />

Preparations for<br />

Powder Coatings –<br />

Iriodin ® PC<br />

In addition to our Iriodin® products, we offer special preparations<br />

for use in powder coatings. Iriodin® PC pearl luster<br />

<strong>pigments</strong> were developed expressly for the corona process,<br />

which is mainly used for powder coating applications.<br />

PC stands for Powder Coating.<br />

Iriodin® PC <strong>pigments</strong> are offered for interior and exterior<br />

applications. Special solutions are available for the dryblend<br />

as well as the bonding process. The product program<br />

deliberately focuses on the attractive color segment of silverwhite<br />

and gold luster <strong>pigments</strong>.<br />

High Chroma Crystal <strong>Effect</strong><br />

Pigments on the Basis of<br />

Aluminum Oxide<br />

Xirallic® <strong>pigments</strong> are based on a synthetic substrate, namely, aluminum<br />

oxide (corundum) flakes. Through the employment of a new crystallization<br />

process, it is possible to produce aluminum oxide platelets with a<br />

perfectly planar surface and a tight particle size distribution. The substrate<br />

is coated with highly refractive metal oxides.<br />

Xirallic® demonstrates a very strong glitter effect with a distinct<br />

shimmer behavior and distinguishes itself through strong and very pure<br />

colors. The effect is increased by directed light (for example sunlight).<br />

Analogous to the classical interference <strong>pigments</strong>, silver-white effect<br />

<strong>pigments</strong> and gold, red, lilac, blue, green and turquoise interference<br />

<strong>pigments</strong> can be generated by coating the aluminum oxide flakes with<br />

titanium oxide. Coating the aluminum oxide flakes with iron(III) oxide<br />

produces copper and red effect <strong>pigments</strong>.<br />

6 7

Multi-Color <strong>Effect</strong> Pigments on<br />

the Basis of Silicon Dioxide<br />

The Colorstream® Multi-Color <strong>Effect</strong> Pigments consist, in contrast to the mica<br />

based Iriodin® <strong>pigments</strong>, of synthetically produced silicon dioxide (SiO 2) material.<br />

If these transparent SiO 2 platelets are coated with highly refractive metal oxides,<br />

<strong>pigments</strong> with goniochromatic properties (also known as “Color Travel") arise:<br />

the thickness of the SiO 2 substrate can be controlled in the preparation (a web<br />

coating process), so that at the end a pigment with a true optical three-layersystem<br />

is obtained.<br />

The interference color of those systems is stronger than for the conventional<br />

mica <strong>pigments</strong> for which the effect of the mica is “wiped out” by a broad thickness<br />

distribution.<br />

Weather Resistant Pigments<br />

for Exteriors<br />

The quality requirements on coatings for exterior applications are considerably<br />

higher than for other applications. Therefore <strong>Merck</strong> has developed its own range<br />

of weather resistant <strong>pigments</strong>, which also meets the high demands of the modern<br />

automotive coatings.<br />

There are weather resistant <strong>pigments</strong> for the Iriodin®, Xirallic® and Colorstream®<br />

product families. Through an additional coating, an outstanding weather<br />

resist ance is ensured for all external applications. In order also to be able to use<br />

weatherproof <strong>pigments</strong> in automotive coatings, they must have two additional<br />

properties that differentiate them from standard coatings for external applications.<br />

Firstly they must have a smaller particle size distribution, whereby most<br />

importantly the number of larger particles on the upper end of the particle size<br />

distribution is reduced. This is especially important in order to ensure a problemfree<br />

application of serial color tones for cars. Secondly they must have a tighter<br />

coloristic tolerance. The consistent coloristic quality is especially important<br />

for the use in the Intermix systems, which have a wide field of application, for<br />

example, in repair coatings for the automotive industry.<br />

<strong>Merck</strong> recommends the use of weather resistant <strong>pigments</strong> also for interior<br />

applications when higher demands are placed, for example, to protect against<br />

humidity or UV light. Typical examples for this are furniture or interiors in<br />

sanitary rooms such as bathrooms and toilets, or in kitchens, as well as areas<br />

with moisture and water.<br />

8 9

Silky Silver Luster on the Basis<br />

of Bismuth Oxychloride<br />

Biflair® are unique effect <strong>pigments</strong> made<br />

on the basis of bismuth oxychloride offered<br />

as dispersion.<br />

The Biflair® bismuth oxychloride platelets distinguish themselves by their<br />

silky metallic luster, high degree of whiteness, good hiding power covering<br />

ability and narrow particle size distribution. Biflair® <strong>pigments</strong> are nontoxic<br />

and offered as dispersion.<br />

Biflair bismuth oxychloride dispersions allow many fascinating effects for<br />

a wide spectrum of applications: for example silky silver luster effects for<br />

products in entertainment electronics; for household, sport and high-tech<br />

devices; cosmetic packaging and more.<br />

Glitter <strong>Effect</strong>s based<br />

on Calcium-Aluminum-<br />

Borosilicate<br />

Miraval® effect <strong>pigments</strong> dazzle with their light and uniform purity of<br />

colors, as well as their high transparency and intensive reflective power.<br />

These effect <strong>pigments</strong> with their brilliant shimmer and radiating luster are<br />

based on calcium-aluminum-borosilicate. Varying the concentration level<br />

in the formulation can create fascinating effects ranging from individual<br />

sparkle of luster to a metallic appearance. To retain a delicate glimmer or<br />

luster, Miraval® <strong>pigments</strong> can be added to formulations with a concentration<br />

of less than 1 % without creating a change in the color tone. Combining<br />

Miraval® <strong>pigments</strong> with each other can open up an extraordinary variety of<br />

styling possibilities.<br />

The silver-white pigment Miraval® 5311 Scenic White and Miraval® 5411<br />

Magic White differ from each other by their particle size distribution thus<br />

sparkle. Both <strong>pigments</strong> can be used in different applications, like plastic<br />

coatings and powder coatings. Miraval® interference <strong>pigments</strong>, based on the<br />

same fraction of 20 to 200 µm as Miraval® Magic White, are available in the<br />

color tones blue, red, green, gold, copper, turquoise and lilac.<br />

10 11

Functional Pigments<br />

With the Minatec® product family, <strong>Merck</strong><br />

provides the coating branch with functional<br />

<strong>pigments</strong> for manufacturing light-colored<br />

coatings with conductive or infrared absorbing<br />

properties.<br />

The conductive Pigments Minatec® 31 CM, Minatec® 40 CM and Minatec®<br />

60 CM offer various possibilities to formulate coatings in light colors.<br />

They are suitable for industrial applications that require a surface resistance<br />

of 10 4 to 10 9 ohms. Minatec® <strong>pigments</strong> consist of substrates which<br />

are coated with doped tin oxide.<br />

The major industrial applications in which Minatec® <strong>pigments</strong> are used<br />

include light-colored antistatic flooring and conductive primers. Primers<br />

that contain Minatec® are used to give insulation materials an electrostatic<br />

application (ESTA). An example of this industrial use is the manufacture<br />

of light-colored undercoats for automotive parts made of plastic. Lightcolored<br />

antistatic floor coverings that are formulated with Minatec® are<br />

used for example in the production of electronic components that must<br />

be protected from uncontrolled discharge. Further application areas for<br />

antistatic floor coatings are production facilities, warehouses, clean rooms<br />

or hospitals.<br />

The infrared-absorbing pigment Minatec® 230 A-IR supports the trend of<br />

utilizing infrared radiation in the drying process of coatings. Minatec® 230<br />

A-IR is a light gray-colored pigment, developed particularly to improve the<br />

absorption capabilities of light-colored coatings. Its features allow shorter<br />

drying times for coatings and correspondingly lead to increased production<br />

capacities with smaller energy costs.<br />

Functional Pigments for<br />

Translucent Systems<br />

Under the brand name Solarflair® <strong>Merck</strong> offers<br />

functional <strong>pigments</strong> which allow the visible part<br />

of sunlight to pass, but reflect the sun’s heat rays.<br />

Solarflair® 870 and Solarflair® 875 unfold their unique features in transparent<br />

systems in architecture and horticulture. Whether in skylights,<br />

greenhouse canopy tops or glass winter garden elements, Solarflair® <strong>pigments</strong><br />

absorb only a small portion of visible light, while heat radiation is<br />

considerably reduced. Depending on the individual application conditions,<br />

the room temperature in spaces “protected” by Solarflair® is decreased by<br />

up to 15 degrees Celsius. With Solarflair® rooms stay light and pleasantly<br />

cool at the same time – even under direct solar radiation.<br />

Solarflair® 870 and Solarflair® 875 are also available in weather<br />

resistant grades.<br />

12 13

Our Services for<br />

Your Success<br />

<strong>Merck</strong> places the highest standards of quality on<br />

its products and services. The customer’s desire is<br />

always at the forefront. This is one of the reasons<br />

why <strong>Merck</strong> is present in the core markets around<br />

the world. The global presence enables <strong>Merck</strong> to<br />

support its international customers with competent<br />

consulting, outstanding service and the<br />

necessary technical applications on location.<br />

Technical Application Consulting and Customer Care<br />

The technical application consultants offer support on location, and<br />

with their consultation, make sure that the customer’s effect coating<br />

is a complete success. They take into consideration the interests of the<br />

market during the development of new products and provide customers<br />

with innovative know-how to help them attain decisive competitive<br />

advantages.<br />

<strong>Merck</strong> has technical application laboratories at its disposal, which are<br />

specially geared towards the production, application and testing of coatings.<br />

The laboratories make it possible to work out technical solutions<br />

and to provide customers with demonstration materials and formulation<br />

suggestions.<br />

The color suggestions are also developed on the basis of trend research<br />

and information. The effects are visualized in brochures, color cards,<br />

design and styling tools.<br />

Quality<br />

With its control processes, <strong>Merck</strong> delivers the highest quality, and with a<br />

Certificate of Analysis, it documents that the parameters laid down in the<br />

specification are checked and maintained. In addition, datasheets give<br />

information about further product details. Our plants in Darmstadt and<br />

Gernsheim, Germany are certified according to DIN EN ISO 9001 and also<br />

ISO 14001.<br />

Field service<br />

In numerous market regions of the world, <strong>Merck</strong> has at its disposal a sales<br />

representative specialized in the coating industry in order to be able to<br />

adapt optimally and quickly to the interests of the customers. Only a clear<br />

understanding of the customer’s situation on site guarantees the best<br />

results.<br />

Regulatory Affairs<br />

<strong>Merck</strong>’s Regulatory Affairs department is responsible for the observance<br />

of the legal and safety-relevant interests regarding the development of<br />

effect <strong>pigments</strong> for coating applications.<br />

Distribution<br />

<strong>Merck</strong> offers worldwide customer service, product development that is<br />

oriented toward regional demands, and guarantees worldwide supply with<br />

its products. <strong>Merck</strong> has research and production locations in Gernsheim,<br />

Germany, Onahama, Japan as well as Savannah, Georgia in the USA. In<br />

addition, the company has at its disposal subsidiaries and/or commercial<br />

agencies in most countries of the world.<br />

14 15