PIG CASTING MACHINE

PIG CASTING MACHINE

PIG CASTING MACHINE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>PIG</strong> <strong>CASTING</strong> <strong>MACHINE</strong><br />

No. 07-005<br />

NAGATA ENGINEERING CO., LTD.

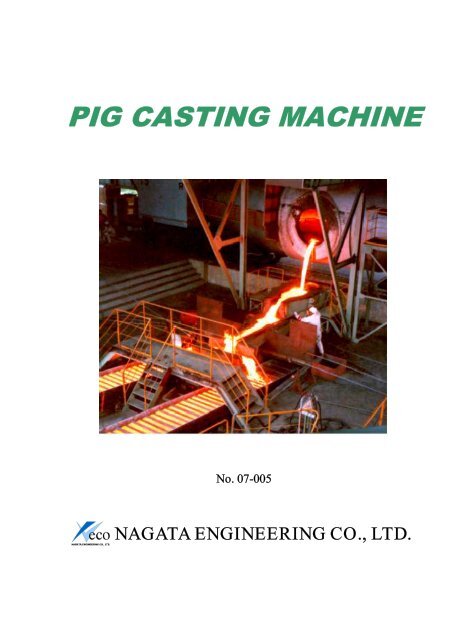

NAGATA’s Pig Casting Machine<br />

We, Nagata Engineering Co., Ltd., had supplied a lot of Pig Casting<br />

Machine to Steel Making Companies, Ferroalloy Companies and etc.<br />

since 1956 including the era of Nagata Seisakusho Co., Ltd. Our Pig<br />

Casting Machine is used widely to produce the pig iron or metal ingot.<br />

We introduce to you the characteristics of this machine hereinafter.<br />

Requirements to Plan<br />

Hot Metal Pouring Rate (T/H)<br />

Unit Weight of Pig Iron (kg/each)<br />

Standard Specification<br />

Rough standard of the specification of the machine is as follows<br />

Maximum (t/h)<br />

Capacity<br />

Machine (m)<br />

Length<br />

Link Pitch (mm)<br />

100 30 ~ 40 300 ~ 400<br />

150 40 ~ 50 400 ~ 450<br />

200 50 ~ 60 450 ~ 600<br />

250 60 ~ 70 600 ~ 720<br />

300 Over 70 600 ~ 720<br />

Mould Pitch<br />

(mm)<br />

Speed (m/min) Inclination °<br />

300 ~ 360 5 ~ 15 5 ~ 15

Constitution of Pig Casting System<br />

Specification of Equipment<br />

Machine Body<br />

1) Machine Head<br />

The driving system is composed with<br />

the set of variable speed controlled<br />

motor, gear reducer and sprocket.<br />

2) Machine Tail<br />

Take-up device is provided on the tail sprocket shaft to give<br />

appropriate tension to the link chain.<br />

Also the Water Cooled Rail is equipped instead of the stationary rollers at<br />

the pouring area to smooth the moulds running.

3) Stationary Roller & Link Chain<br />

We are adopting the Stationary roller type.<br />

This machine can obtain comparatively small power by this type, because<br />

the link chains with the moulds run on the stationary rollers that are<br />

fixed in regular distance.<br />

4) Sticker Device<br />

When the moulds reverse on the machine head, the almost of pig iron is<br />

removed from the mould by lime coating.<br />

In case that the pig iron remained in the mould, the pig iron is removed<br />

by this device.

Scattered Iron Disposing Equipment<br />

When the hot metal is poured in the mould through the casting trough, the<br />

scattered iron occurs by the shock.<br />

The scattered iron is received, and is pulled out from the machine by this<br />

equipment.<br />

Pig Cooling Water System<br />

The pig iron in the mold is cooled by water spray or shower.<br />

Normally, the circulating water from the pond is used as cooling water, and<br />

the cooling zone is given for about 2/3 of machine length.

Mould Coating Equipment<br />

In the case that the mould surface is not coated, the pig iron can not remove<br />

from the mould.<br />

Therefore, the mould surface is coated to remove the pig iron smoothly.<br />

Normally, we are adopting the lime powder as coating material.<br />

AGITATING TANK<br />

POWDER LIME HOPPER<br />

Spray tank<br />

SLURRY PUMP FOR SPRAYING<br />

Return<br />

Slurry pump<br />

P<br />

Agitating tank<br />

Mould Drying Equipment<br />

This equipment is installed to dry the mould surface to prevent the explosion,<br />

because the mould surface is getting wet by the lime slurry spraying.

Swing Pan Conveyor<br />

This machine is used to carry the pig iron from the Pig Casting Machine to<br />

the stock pile, and is very convenient device for the stock piling.

LINES OF BUSINESS<br />

COAL PREPARATION PLANT<br />

● Coal Preparation Engineering<br />

● Variable Wave JIG<br />

● Heavy Medium Separator<br />

INDUSTRIAL <strong>MACHINE</strong>RIES<br />

● Pig Casting Machine<br />

● Mixers [ Pug-mil, Paddle Mixer ]<br />

● Feeders [ Belt Feeder, Table Feeder ]<br />

● Ladle tilting Machine<br />

ENVIRONMENENT INDUSTRIAL <strong>MACHINE</strong>RIES<br />

● Mould Conveyor for melting Slag<br />

● Oil Agglomeration System<br />

● Specific Gravity Separator<br />

NAGATA ENGINEERING CO., LTD.<br />

Head Office:<br />

10-1, Kitaminato-machi, Wakamatsu-ku, Kitakyushu-shi,<br />

Fukuoka, 808-0027 Japan<br />

TEL: 81-93-761-3754<br />

FAX: 81-93-761-5454<br />

URL: http://www.nagata-kit.co.jp<br />

Revise 2007.05<br />

Print 2007.05