You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

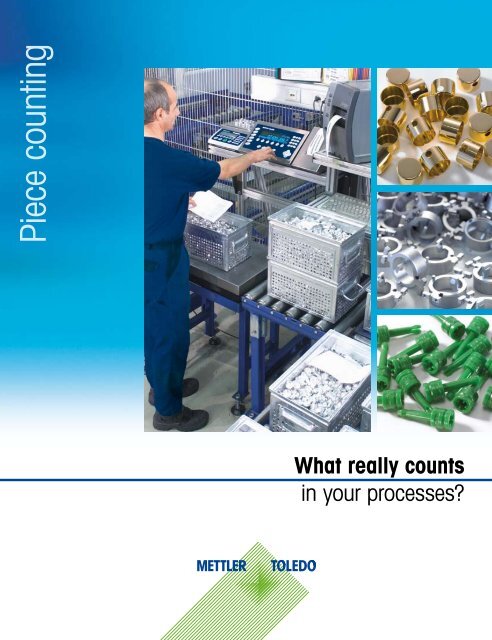

<strong>Piece</strong> <strong>counting</strong><br />

What really counts<br />

in your processes?

<strong>Piece</strong> <strong>counting</strong><br />

2<br />

How can you find the right piece <strong>counting</strong><br />

scales for your needs?<br />

Did you know that even pieces that appear to be identical may have different weights? Different weight is caused<br />

by production tolerances, material stock, tooling machines and operators. The average piece weight must there-<br />

fore be determined with extreme accuracy using a suitable, precise scale. A small error in this value is multiplied<br />

when <strong>counting</strong> bulk volumes. The following procedure will help you make the right selection.<br />

1<br />

2<br />

3<br />

4<br />

5<br />

Determine the average single piece weight:<br />

First you must determine the mean value of the single piece weight. To do this, individually weigh 10 pieces of the<br />

parts to be counted and enter each of the individual piece weights into their own cell in MS Excel ® . Calculate the<br />

average weight by adding all 10 weights and then dividing by 10. Using Excel‘s function for standard deviation,<br />

you can then calculate the absolute standard deviation in grams and the relative standard deviation as a percentage.<br />

Define the maximum weighing range of your piece <strong>counting</strong> scales:<br />

Weigh the heaviest pieces to be counted. Multiply this weight by the maximum number of pieces to be counted in<br />

the same process. This will give you the maximum net weight. The maximum gross weight is the sum of the<br />

maximum net weight and the weight of the heaviest tare container. It may not exceed the weighing range of the scale.<br />

Now find the right piece <strong>counting</strong> scales:<br />

Using the information on the weighing range, the smallest piece weight and its standard deviation, you can now<br />

find the right piece <strong>counting</strong> scale or the right two-scale system in the overview on the following page.<br />

Select the performance level of the display, keyboard and software:<br />

• If you require completely simple yet professional operation using one function for each key, then select an<br />

IND435 terminal or one of the compact scales BBA432 or BBK432.<br />

• If you want to easily and safely count many identical portions, then select an IND445/IND449check+ or<br />

a BBA442/BBA449check+/BBK442. You also can enter the tare value using the numeric keyboard.<br />

• Compact scales BBA462, BBK462 as well as IND465/IND449check+ and IND690count also include a<br />

graphic and plain text display for easy administration of up to 1500 memory locations<br />

(IND690count: 999 memory locations). They support printing of different labels or customized labels.<br />

• The IND690count terminal provides easy operability and first-class functionality. The large and bright<br />

BigWeight ® graphic display guides the user correctly through the <strong>counting</strong> process.<br />

Details on the displays, keyboards and interfaces can be found on pages 4–5.<br />

Select the right-sized model:<br />

• The BBK4x2 and BBA4x2 models are space-saving compact scales.<br />

• If you would like the display to be at the side, in front of or over the piece container, then select one of<br />

the IND terminals.<br />

• Determine the size and model of the floor scale. Decide whether to install the weighing platform in a pit<br />

or if it is to be directly fixed to the floor.<br />

• Select a Series 4 model if you wish to operate the scale with batteries and/or as a mobile unit, e.g. on a cart.<br />

Possible models and their details are given on pages 6–7.

Weighing<br />

range<br />

6000 lb<br />

3000 kg<br />

2500 lb<br />

1250 kg<br />

1000 lb<br />

500 kg<br />

600 lb<br />

300 kg<br />

300 lb<br />

150 kg<br />

120 lb<br />

60 kg<br />

70 lb<br />

35 kg<br />

30 lb<br />

15 kg<br />

12 lb<br />

6 kg<br />

6 lb<br />

3 kg<br />

1.2 lb<br />

0.6 kg<br />

0.6 lb<br />

0.3 kg<br />

0.2 lb<br />

0.1 kg<br />

IND690 +<br />

AB304-S<br />

IND4x5 +<br />

AB304-S<br />

IND690 +<br />

AB104-S<br />

IND4x5 +<br />

AB104-S<br />

IND690+<br />

X603S<br />

+KA32s<br />

BBK4x2-0.6Px<br />

X603S<br />

IND690 +<br />

X203S<br />

IND4x5 +<br />

X203S<br />

IND690 +<br />

BBK4x2-3Px<br />

+ KCC300S<br />

IND690 +<br />

BBK4x2-3Px<br />

+ KB60s<br />

IND690 +<br />

BBK4x2-3Px<br />

+ KA32s<br />

BBK4x2-3Px<br />

IND690 +<br />

BBK4x2-6Px<br />

+ KCC600s<br />

IND690 +<br />

BBK4x2-6Px<br />

+ KCC300s<br />

BBK4x2-6Px<br />

+<br />

PBA330-60BB<br />

IND690 +<br />

KA32s<br />

BBK4x2-35Sx<br />

BBK4x2-6Px<br />

IND690<br />

PBA330-6A<br />

+ KE1500s<br />

IND690/<br />

PBA330-6A<br />

+ 2256 VLC<br />

BBK4x2-6Px<br />

+<br />

PBA330-<br />

150CC<br />

IND690 +<br />

KA32s<br />

BBK4x2-35sx<br />

BBA4x2-6Px<br />

IND690/<br />

IND4x5+<br />

PBA330-35BB<br />

+<br />

2158 Vertex<br />

IND690/<br />

IND4x5+<br />

PBA330-35BB<br />

+<br />

2158 Vertex<br />

IND690/<br />

IND4x5+<br />

PBA330-35BB<br />

+<br />

2256 VLC<br />

IND4x5 +<br />

PBA330-<br />

300BC<br />

BBA4x2-35Sx<br />

0.0000002 lb 0.000002 lb 0.00002 lb 0.0002 lb 0.002 lb 0.02 lb<br />

Average <strong>Piece</strong> Weight 1)<br />

0.000002 lb 0.00002 lb 0.0002 lb 0.002 lb 0.02 lb 0.2 lb<br />

Average <strong>Piece</strong> Weight 2)<br />

Counting terminals<br />

– IND690count<br />

– IND465<br />

– IND445<br />

– IND435<br />

Reference scales<br />

– X203S<br />

– X603S<br />

– AB104-S<br />

– AB304-S<br />

Series 4 compact scales<br />

– BBK4x2-3Px<br />

– BBK4x2-6Px<br />

– BBK4x2-35Sx<br />

– BBA4x2-6Px<br />

– BBA4x2-35Sx<br />

Weighing platforms<br />

– KA32s<br />

– PBA330-BB35<br />

– PBA330-BB60<br />

– PBA330-6A<br />

– KE3000<br />

– KES3000<br />

– KCS600<br />

– 2158 Vertex Rocker Pin<br />

– 2256 VLC Floor Scale Footed<br />

1) Counts up to 1000 pieces in normal<br />

ambient conditions at a relative standard<br />

deviation of < 0.5% of the average<br />

piece weight.<br />

Standard Deviation is calculated as<br />

described under point 1 on page 2.<br />

2) Counts up to 1000 pieces in normal<br />

ambient conditions at a relative standard<br />

deviation of 0.5–1% of the average<br />

piece weight.<br />

Standard Deviation is calculated as<br />

described under point 1 on page 2.<br />

3

<strong>Piece</strong> <strong>counting</strong><br />

4<br />

The right solution for every job<br />

IND690count: the robust and intelligent <strong>counting</strong> system<br />

• The robust and versatile IND690count stainless steel terminal is IP69k-protected and is therefore also suitable<br />

for use in the harshest industrial environments – with a matching, robust industrial GA46 printer contained<br />

in stainless steel housing for printing barcodes.<br />

• The large, bright, high-contrast ”BigWeight ® “ display allows <strong>counting</strong> results to be easily read without tiring<br />

your eyes – even at large distances and in poorly lit conditions.<br />

• Up to four weighing platforms can be connected, this allows high-resolution, precise weighing ranges of<br />

0.1 mg to 6000 kg/0.0000002 lb to 12,000 lb using just one IND690count terminal.<br />

• The integrated database provides 999 flexible storage locations for part data.<br />

• The IND690count terminal can be connected to a warehouse management system via Ethernet TCP/IP, Profibus DP,<br />

DeviceNet, USB, Bluetooth, WLAN, RS232, RS422, RS485, digital inputs/outputs and RFID, making it the central<br />

tool for registering incoming/outgoing goods and for inventory management.<br />

Intelligent commissioning and portioning using BBK462, BBA462 and IND465<br />

• The bright graphic display avoids misunderstandings, as it guides the user through the <strong>counting</strong> process using<br />

plain text instructions.<br />

• An integrated database with 1,500 flexible storage locations allows part data to be managed easily.<br />

• Barcode scanners are used to ensure error-free, efficient part selection.<br />

• Monotonous work, such as filling many identical packaging units, can be done efficiently. The filling guide informs<br />

the user when the target has been reached. Underfilling or overfilling is therefore avoided.<br />

• Free design of barcode print-outs on labels, e.g., with name of company, address, alphanumerical part ID, date,<br />

time, variables, lot ID and order number.<br />

• Can be integrated into existing systems using Ethernet TCP/IP and digital inputs/outputs.<br />

• A second scale can be connected for larger volumes or for exact piece weight sampling.<br />

Correct Order filling using BBK442, BBA442, IND445, BBA449check+, IND449check+<br />

• Tedious work, such as filling many identical packaging units, is simplified, as the filling guide informs the user<br />

when the target has been reached. The BBA449check+ has the colorWeight ® function. It supports the operator<br />

with a color change of the display if the target weight is reached. Underfilling or overfilling is therefore avoided.<br />

• Comes with a database of 99 flexible storage locations for target counts with tolerances and tare values.<br />

• Flexible print-outs with name of company, address, and numerical part ID. The part ID can be entered using the scale<br />

keyboard or a barcode reader.<br />

• A second scale can be connected for large volumes or for exact piece weight sampling to BBK442, BBA442 and IND445.<br />

• The tare values can be entered on the keyboard.<br />

Simple, safe and professional: BBK432, BBA432, IND435<br />

• Secure entry due to allocation of one single function to each key minimizes operator error.<br />

• Keys and display have been optimized simply and without compromise for <strong>counting</strong>.<br />

• Password-protected settings.<br />

• A second scale can be connected for large volumes or for exact piece weight sampling.

METTLER TOLEDO<br />

METTLER TOLEDO<br />

METTLER TOLEDO<br />

METTLER TOLEDO<br />

USB<br />

EtherNet<br />

DeviceNet<br />

RS232<br />

MonoBloc provides the highest rate of <strong>counting</strong><br />

precision and repeatability – for reliable results.<br />

The BBK4x2 scales and K-Line weighing platforms<br />

are equipped with unique MonoBloc technology<br />

for maximum repeatability and precision of weighing<br />

and <strong>counting</strong> results.<br />

Their high measuring resolution allows for a high<br />

weighing range at a very high rate of precision,<br />

linearity and repeatability. Generally, this means:<br />

MonoBloc is 10–20 times more accurate than<br />

strain gauge technology.<br />

RefOpt: User-friendly, precise determination<br />

of piece weights<br />

Using the “automatic reference optimization“ function,<br />

you can count easily, efficiently and correctly.<br />

The scale continuously optimizes the piece weight.<br />

Interfaces<br />

Depending on the model, the METTLER TOLEDO<br />

<strong>counting</strong> systems and <strong>counting</strong> scales can be<br />

integrated into a modern materials management<br />

system. With Ethernet TCP/IP, Profibus DP, USB,<br />

Bluetooth, DeviceNet and RFID, all types of connection<br />

are covered and all data can flow freely.<br />

WLAN R F I D<br />

Battery powered<br />

Selected models also available with optional rechargeable<br />

battery for mobile use.<br />

5

<strong>Piece</strong> <strong>counting</strong><br />

6<br />

The right models and sizes for<br />

your application<br />

Combine small, medium and large platforms with modular compact scales and the powerful IND <strong>counting</strong><br />

terminals. Position the terminal in the ideal location for your needs: to the side, the front or on a mount.<br />

Connect the compact BBK and BBA models to bench and floor scales to form two-scale systems.<br />

Compact Scales Small Sizes<br />

NTEP-approved BBA4x2: Class III, 7,500d<br />

BBK4x2: Class II, 60,000d<br />

Housing Die-cast aluminum<br />

Measuring method BBK4x2 MonoBloc/BBA4x2 Strain Gauge<br />

Power supply 110V AC or built-in rechargeable battery<br />

Dimensions (in/mm) 10.40 × 13.20 × 4/265 × 335 × 100<br />

Platform size (in/mm) 6.50 × 6.50/165 × 165 1<br />

Platform size (in/mm) 7.90 × 9.50/200 × 240 2<br />

Interfaces Ethernet TCP/IP, USB, digital I/O,<br />

up to 3× RS232, RS485, connection for<br />

second scale (depending on application level)<br />

Model Weighing range Resolution Platform<br />

size<br />

BBK432-3PL 6 lb × 0.00002 lb 3 kg × 0.01g 1<br />

BBK442-3PD 6 lb × 0.00002 lb 3 kg × 0.01g 1<br />

BBK462-3PT 6 lb × 0.00002 lb 3 kg × 0.01g 1<br />

BBK432-6PL 12 lb × 0.00005 lb 6 kg × 0.02g 2<br />

BBK442-6PD 12 lb × 0.00005 lb 6 kg × 0.02g 2<br />

BBK462-6PT 12 lb × 0.00005 lb 6 kg × 0.02g 2<br />

BBA432-3PL 6 lb × 0.0005 lb 3 kg × 0.2g 2<br />

BBA442-3PD 6 lb × 0.0005 lb 3 kg × 0.2g 2<br />

BBA462-3PT 6 lb × 0.0005 lb 3 kg × 0.2g 2<br />

BBA432-6PL 12 lb × 0.00005 lb 6 kg × 0.5g 2<br />

BBA442-6PD 12 lb × 0.00005 lb 6 kg × 0.5g 2<br />

BBA462-6PT 12 lb × 0.00005 lb 6 kg × 0.5g 2<br />

AB Balances<br />

Reference balances for small parts<br />

Model Weighing range Resolution<br />

AB104-S 110 g 0.0001 g<br />

AB304-S 320 g 0.0001 g<br />

Platform size (in/mm) Ø 3.15/80<br />

Compact Scales Large Sizes<br />

NTEP-approved BBA4x2: Class III, 7,500d<br />

BBK4x2: Class II, 60,000d<br />

Housing Die-cast aluminum<br />

Measuring method BBK4x2 MonoBloc/BBA4x2 Strain Gauge<br />

Power supply 110V AC or built-in rechargeable battery<br />

Dimensions (in/mm) 14.17 × 14.56 × 4.53/360 × 370 × 115<br />

Platform size (in/mm) 9.45 × 13.78/240 × 350 3<br />

Interfaces thernet TCP/IP, USB, digital I/O,<br />

up to 3 × RS232, RS485, connection for<br />

second scale (depending on application level)<br />

Model Weighing range Resolution Platform<br />

size<br />

BBK432-15SL 30 lb × 0.0001lb 15 kg × 0.05 g 3<br />

BBK442-15SD 30 lb × 0.0001lb 15 kg × 0.05 g 3<br />

BBK462-15ST 30 lb × 0.0001lb 15 kg × 0.05 g 3<br />

BBK432-35SL 70 lb × 0.0001lb 35 kg × 0.1g 3<br />

BBK442-35SD 70 lb × 0.0001lb 35 kg × 0.1g 3<br />

BBK462-35ST 70 lb × 0.0001lb 35 kg × 0.1g 3<br />

BBA432-15SL 30 lb × 0.002 lb 15 kg × 1g 3<br />

BBA442-15SD 30 lb × 0.002 lb 15 kg × 1g 3<br />

BBA462-15ST 30 lb × 0.002 lb 15 kg × 1g 3<br />

BBA432-35SL 70 lb × 0.005 lb 35 kg × 2g 3<br />

BBA442-35SD 70 lb × 0.005 lb 35 kg × 2g 3<br />

BBA462-35ST 70 lb × 0.005 lb 35 kg × 2g 3<br />

BBA432-60SL 120 lb × 0.01lb 60 kg × 5g 3<br />

BBA442-60SD 120 lb × 0.01lb 60 kg × 5g 3<br />

BBA462-60ST 120 lb × 0.01lb 60 kg × 5g 3<br />

X203S/X603S Balances<br />

Reference balances for small parts<br />

Model Weighing range Resolution<br />

X203S 210 g 0.001 g<br />

X603S 610 g 0.001 g<br />

Platform size (in/mm) 5 × 5/127 ×127

K Line High Precision<br />

High-precision bench and floor scales for use in harsh industrial<br />

environments. Can be used as reference scales or bulk scales.<br />

NTEP-approved Class III 10,000d<br />

Class II 32,000d<br />

Weighing ranges 6–6,000 lb/3–3,000 kg<br />

Resolution 0.00002–0.1lb/0.01–50 g<br />

Platform sizes 13.8 × 11 to 59 × 59 in<br />

2158 Vertex Rocker Pin Floor Scale<br />

Carbon steel painted or stainless steel floor scales for use as<br />

bulk scales in harsh industrial environments.<br />

NTEP-approved Class III 5,000d<br />

Weighing ranges 1,000–20,000 lb<br />

Resolution 5,000d, 10,000d (option, non-approved)<br />

Platform sizes 3 × 3 to 5 × 7 ft or custom dimensions<br />

2256 VLC Floor Scales<br />

Floor scales for use in harsh industrial environments.<br />

NTEP-approved Class III 5,000d<br />

Weighing ranges 1,000–10,000 lb/450–4,500 kg<br />

Resolution 0.2–2 lb/0.1–1kg<br />

Platform sizes 3 × 3 to 5 × 7 ft<br />

PBA330 and CBUx Bench Scales<br />

Scales that can be used as bench, stand, and floor-mounted<br />

for use as bulk scales.<br />

NTEP-approved PBA330 class III 5,000d<br />

CBUx class III 10,000d<br />

Weighing ranges 12–1,200 lb/6–600 kg<br />

Resolution 0.002 to 0.2 lb/1–200 g<br />

Platform sizes 9 × 9 to 24 × 32 in<br />

240 × 240 to 600 × 800 mm<br />

IND4x5 Weighing Terminal<br />

NTEP-approved class III 10,000d for strain gauge cells<br />

class II 100,000d with approved balance<br />

Housing Die cast aluminum<br />

Protection IP65<br />

Measuring method Strain gauge<br />

Power supply 110V AC or built-in rechargeable battery<br />

Connection Can connect up to 2 scales<br />

Optional Interfaces Ethernet TCP/IP, USB, digital I/O,<br />

RS232, RS485<br />

IND449check+ Weighing Terminal<br />

NTEP-approved class III 10,000d for strain gauge cells<br />

class II 100,000 with approved balance<br />

Housing Stainless steel<br />

Protection IP69k<br />

Measuring method Strain gauge<br />

Power supply 110V AC or built-in rechargeable battery<br />

Optional Interfaces Ethernet TCP/IP, USB, digital I/O, RS232, RS485<br />

BBA449check+ Compact Scale<br />

NTEP-approved Class III 5,000d<br />

Housing Stainless Steel<br />

Protection IP69k<br />

Measuring method Strain gauge<br />

Power supply 110V AC or built-in rechargeable battery<br />

Platform size A 9,4 × 11.8 in<br />

Platform size QA 9 × 9 in<br />

Platform size B 15.7 × 19.7 in<br />

Platform size QB 12 × 12 in<br />

Platform size BB 11.8 × 15.7 in<br />

Model Weighing range Resolution Pf. size (in)<br />

BBA449 003Z 6 lb × 0.001lb 3 kg × 0.0005 g A<br />

BBA449 006Z 12 lb × 0.002 lb 6 kg × 0.001g A, QA<br />

BBA449 015Z 15 lb × 0.002 lb 6 kg × 0.001g A, QB<br />

BBA449 030Z 30 lb × 0.005 lb 15 kg × 0.002 g BB, QB, B<br />

BBA449 060Z 60 lb × 0.01 lb 30 kg × 0.005 g BB, QB, B<br />

BBA449 150Z 150 lb × 0.02 lb 60 kg × 0.01g B<br />

Optional Interfaces Ethernet TCP/IP, USB,<br />

WLAN, digital I/O, RS232, RS485<br />

IND690count Weighing Terminal<br />

NTEP-approved class III 10,000d for strain gauge cells<br />

class II 100,000d for K-Line, BBK, AB, X<br />

Housing Stainless steel<br />

Protection IP69k<br />

Measuring method MonoBloc and strain gauge<br />

Connection Can connect up to 4 scales<br />

Optional Interfaces Ethernet TCP/IP, Profibus DP, DeviceNet,<br />

WLAN, Bluetooth, USB, RFID, digital I/O, RS232,<br />

Current Loop, RS485/422, analog output<br />

7

<strong>Piece</strong> <strong>counting</strong><br />

8<br />

Reliable numbers for incoming goods<br />

facilitate seamless production<br />

Precise weighing and <strong>counting</strong><br />

from 1 mg to 6000 kg<br />

METTLER TOLEDO has a range of<br />

scales that cover all <strong>counting</strong> and<br />

weighing requirements for incoming<br />

goods. The incoming goods area<br />

of a company is often very hectic.<br />

Depending on the situation, many<br />

deliveries are often accepted and<br />

checked at the same time. Packages<br />

have different sizes, ranging from<br />

containers, through pallets, right<br />

down to smaller packages and even<br />

letters with small consignments.<br />

The weighing technology used for<br />

incoming goods must therefore cover<br />

a wide range from 0.000002 to<br />

12,000 lb. In certain circumstances,<br />

as many as 10,000 pieces must be<br />

counted within one package. Precise<br />

weighing down to the last and even<br />

lightest piece requires a precision<br />

bench scale. Counting pieces that are<br />

delivered on pallets or in bulk containers<br />

require high capacity scales.<br />

BigWeight ® display –<br />

never get fatigued<br />

The bright, high-contrast graphic<br />

display of the IND690count,<br />

provides the user with legible in-<br />

structions and information. The patented<br />

BigWeight ® function is unique.<br />

It allows you to avoid reading errors<br />

and premature fatigue. The keys,<br />

which are uniquely labeled for piece<br />

<strong>counting</strong>, enable efficient work<br />

and help prevent operator errors.<br />

Robust industrial equipment<br />

In the shipping and receiving area,<br />

awkward and heavy packages<br />

are transported manually, with a<br />

fork-lift truck, a hand-truck<br />

or even a crane. METTLER TOLEDO<br />

scales withstand these condi-<br />

tions due to their high overload<br />

protection. Their terminals are<br />

protected up to IP69k and continue<br />

to work reliably even in dusty<br />

or damp environments.

Several printers connectable<br />

Several label printers can be connected<br />

to the IND690. This increases<br />

efficiency if you need several label<br />

sizes. The layout and configuration of<br />

the label size can be stored directly<br />

on the printer. You don’t need an<br />

additional IT system just for printing.<br />

Always the correct scale, with<br />

multiple connection capabilities<br />

Always count and weigh on the right<br />

scale and at the right place.<br />

Up to four scales can be connected to<br />

an IND690count terminal.<br />

Network capable<br />

The data recorded via the barcode<br />

readers, keyboards or RFID<br />

readers can be transferred to an<br />

IND690count terminal via RS232,<br />

USB or Bluetooth. The data is then<br />

transferred via Ethernet TCP/IP or<br />

Profibus to the ERP system or the<br />

PLC. The IND690count terminal then<br />

assumes the function of a local<br />

network node with user guidance.<br />

Greater efficiency with a database<br />

The IND690count has a database with 999 storage<br />

locations for the part ID, piece weight, tare weight<br />

and target weight with tolerances. The stored values<br />

can be called up by barcode reader or keyboard.<br />

The database can be easily edited and stored<br />

on the computer using the “COUNT Tool“ software<br />

and loaded onto the IND690count.<br />

9

<strong>Piece</strong> <strong>counting</strong><br />

10<br />

Every piece is important –<br />

in the warehouse, when taking inventory,<br />

order filling and shipping goods<br />

User-friendly order filling<br />

with colorWeight ®<br />

Even if there is a large number of<br />

bags, order filling remains easy<br />

and efficient. The BBA449check+<br />

supports the operator with the<br />

colorWeight ® function in target<br />

weighing. The back-lit display of<br />

this <strong>counting</strong> scale can change its<br />

color from light blue to green,<br />

yellow or red. The limits for the color<br />

change can be set with the key<br />

board. It can change to one of the<br />

three colors after the preset number<br />

of parts is reached. The customer<br />

can determine which color he wants<br />

to allocate to which status.<br />

The scale can also signal the filling<br />

status to a machine with digital I/O.<br />

Target count not reached.<br />

Still far away from target.<br />

Target count not reached.<br />

Close to target.<br />

Target count reached, OK.<br />

Overfill.<br />

Target count exceeded.

Network capable<br />

Data recorded using barcode readers<br />

or keyboards can be transferred to<br />

the scale. The data is transferred via<br />

Ethernet TCP/IP to a computer or<br />

the ERP system. The compact scales<br />

BBA4x2, BBK4x2 or the IND4x5<br />

terminal assume the role of local network<br />

nodes.<br />

Greater efficiency with a database<br />

The IND465, BBA462 and BBK462<br />

models have a database with<br />

1500 storage locations. The storage<br />

locations offer enough space for<br />

the part ID, piece weight, tare weight<br />

and target weight with tolerances.<br />

The stored values can be called up<br />

by barcode reader or keyboard.<br />

The database can be easily edited,<br />

managed and stored on the computer<br />

using the “Smart Manager”<br />

program. It can also be used to<br />

download data to the scale.<br />

The “Smart Manager” even allows<br />

import/export of data files for<br />

use with MS Excel ® .<br />

Printers<br />

Select your ideal solution from<br />

a multitude of various label,<br />

strip and ticket printers. The print<br />

possibilities vary depending<br />

on the built-in application.<br />

Mobile <strong>counting</strong> in the order picking warehouse<br />

As it can be powered by battery, the scale can<br />

be operated on a cart. Compact scales BBK462<br />

and BBA462 have 1500 storage locations for<br />

target weight, tolerance, identification, piece weight<br />

and tare weight. Barcode readers, a keyboard or<br />

printer can be also connected. This keeps the scale<br />

mobile throughout the day and allows it to be<br />

used independently in the order picking warehouse.<br />

11

High-resolution<br />

two-scale system<br />

<strong>Piece</strong> weights vary from piece to piece. It depends on the machine, the day or the<br />

operator who has produced the parts. A small error when determining the average<br />

piece weight is multiplied when <strong>counting</strong> larger quantities. Therefore, when there<br />

is a large variation, the average piece weight must be determined using a greater<br />

number of reference pieces. You also require a high-resolution and high-precision<br />

reference scale.<br />

For very small parts, the AB104-S and AB304-S platforms are used. The AB104-S and<br />

AB304-S can be connected as reference scales or stand-alone scales to the IN690count,<br />

IND465, IND445, IND435 and IND449check+ <strong>counting</strong> terminals. They act as pure<br />

reference scales together with compact scale models BBK432, BBK442 and BBK465.<br />

This allows you to use all the features that make the METTLER TOLEDO scales so userfriendly<br />

and efficient with the highest resolution and precision.<br />

USA<br />

<strong>Mettler</strong>-<strong>Toledo</strong>, Inc.<br />

1900 Polaris Parkway<br />

Columbus, OH, 43240<br />

Tel. (1) 800 523 5123<br />

Subject to technical changes<br />

© 0x/2008 <strong>Mettler</strong>-<strong>Toledo</strong> AG<br />

Printed in Switzerland<br />

MTSI XXXXXXX<br />

Canada<br />

<strong>Mettler</strong>-<strong>Toledo</strong>, Inc.<br />

2915 Argentia Road, Unit 6<br />

Mississauga, Ontario, L5N 8G6<br />

Tel. (1) 800 523 5123<br />

www.mt.com/<strong>counting</strong><br />

<strong>Mettler</strong>-<strong>Toledo</strong> AG<br />

Sales International<br />

CH-8606 Greifensee<br />

Switzerland<br />

Tel. + 41 44 944 22 11<br />

For more information