Additional Information submitted during the information exchange on ...

Additional Information submitted during the information exchange on ... Additional Information submitted during the information exchange on ...

This document has not been fully peer reviewed and

This document has not been fully peer reviewed and

- Page 1 and 2: EUROPEAN COMMISSION DIRECTORATE-GEN

- Page 3 and 4: 2 PURIFICATION OF NON-FERTILISER GR

- Page 5: List of tables Table 1.1: Typical c

- Page 9 and 10: This document has not been fully pe

- Page 11 and 12: This document has not been fully pe

- Page 13 and 14: This document has not been fully pe

- Page 15 and 16: This document has not been fully pe

- Page 17 and 18: This document has not been fully pe

- Page 19 and 20: This document has not been fully pe

- Page 21 and 22: This document has not been fully pe

- Page 23 and 24: This document has not been fully pe

- Page 25 and 26: This document has not been fully pe

- Page 27 and 28: This document has not been fully pe

- Page 29 and 30: This document has not been fully pe

- Page 31 and 32: This document has not been fully pe

- Page 33 and 34: This document has not been fully pe

- Page 35: This document has not been fully pe

- Page 39 and 40: This document has not been fully pe

- Page 41: This document has not been fully pe

- Page 44 and 45: This document has not been fully pe

- Page 46 and 47: This document has not been fully pe

- Page 48 and 49: References 41 Solvay S.A. (2003). "

- Page 50 and 51: References 95 CEFIC-Brunner Mond (2

- Page 52 and 53: Glossary SS Suspended Solids (conte

- Page 54 and 55: Glossary Ca 2+ Calcium ion CaC2 Cal

- Page 56: Glossary (NH4)2SO4 Ammonium sulphat

This document has not been fully peer reviewed and <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>informati<strong>on</strong></str<strong>on</strong>g> within is not validated nor endorsed by <str<strong>on</strong>g>the</str<strong>on</strong>g> TWG<br />

<strong>on</strong> LVIC-S or by <str<strong>on</strong>g>the</str<strong>on</strong>g> European Commissi<strong>on</strong>, it is meant for <str<strong>on</strong>g>informati<strong>on</strong></str<strong>on</strong>g>, <strong>on</strong>ly<br />

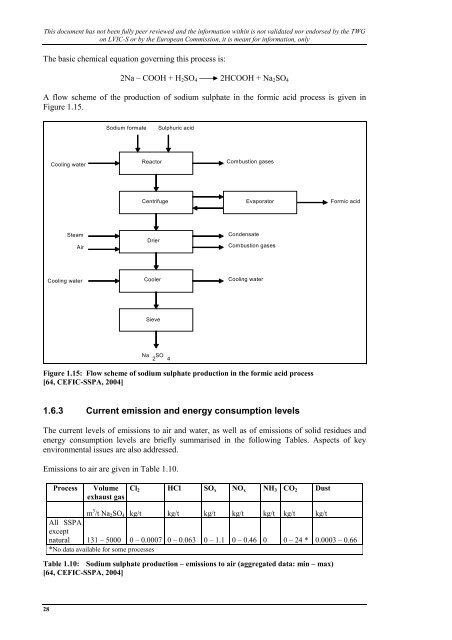

The basic chemical equati<strong>on</strong> governing this process is:<br />

28<br />

2Na – COOH + H2SO4<br />

2HCOOH + Na2SO4<br />

A flow scheme of <str<strong>on</strong>g>the</str<strong>on</strong>g> producti<strong>on</strong> of sodium sulphate in <str<strong>on</strong>g>the</str<strong>on</strong>g> formic acid process is given in<br />

Figure 1.15.<br />

Cooling water<br />

Steam<br />

Air<br />

Cooling water<br />

Sodium formate<br />

Reactor<br />

Centrifuge<br />

Drier<br />

Cooler<br />

Sieve<br />

Na 2 SO 4<br />

Sulphuric acid<br />

Combusti<strong>on</strong> gases<br />

C<strong>on</strong>densate<br />

Evaporator<br />

Combusti<strong>on</strong> gases<br />

Cooling water<br />

Figure 1.15: Flow scheme of sodium sulphate producti<strong>on</strong> in <str<strong>on</strong>g>the</str<strong>on</strong>g> formic acid process<br />

[64, CEFIC-SSPA, 2004]<br />

1.6.3 Current emissi<strong>on</strong> and energy c<strong>on</strong>sumpti<strong>on</strong> levels<br />

Formic acid<br />

The current levels of emissi<strong>on</strong>s to air and water, as well as of emissi<strong>on</strong>s of solid residues and<br />

energy c<strong>on</strong>sumpti<strong>on</strong> levels are briefly summarised in <str<strong>on</strong>g>the</str<strong>on</strong>g> following Tables. Aspects of key<br />

envir<strong>on</strong>mental issues are also addressed.<br />

Emissi<strong>on</strong>s to air are given in Table 1.10.<br />

Process Volume<br />

exhaust gas<br />

Cl2 HCl SOx NOx NH3 CO2 Dust<br />

m 3 /t Na2SO4<br />

All SSPA<br />

except<br />

kg/t kg/t kg/t kg/t kg/t kg/t kg/t<br />

natural 131 – 5000 0 – 0.0007 0 – 0.063 0 – 1.1 0 – 0.46 0 0 – 24 * 0.0003 – 0.66<br />

*No data available for some processes<br />

Table 1.10: Sodium sulphate producti<strong>on</strong> – emissi<strong>on</strong>s to air (aggregated data: min – max)<br />

[64, CEFIC-SSPA, 2004]