Cargo and ballast simulators - Kongsberg Maritime

Cargo and ballast simulators - Kongsberg Maritime

Cargo and ballast simulators - Kongsberg Maritime

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

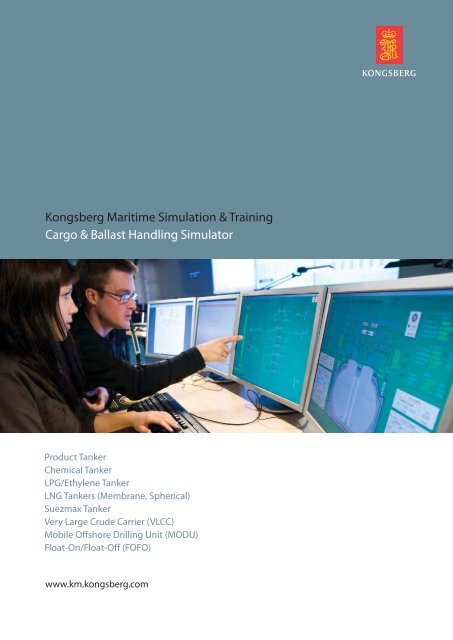

<strong>Kongsberg</strong> <strong>Maritime</strong> Simulation & Training<br />

<strong>Cargo</strong> & Ballast H<strong>and</strong>ling Simulator<br />

Product Tanker<br />

Chemical Tanker<br />

LPG/Ethylene Tanker<br />

LNG Tankers (Membrane, Spherical)<br />

Suezmax Tanker<br />

Very Large Crude Carrier (VLCC)<br />

Mobile Offshore Drilling Unit (MODU)<br />

Float-On/Float-Off (FOFO)<br />

www.km.kongsberg.com

<strong>Cargo</strong> & Ballast H<strong>and</strong>ling Simulator<br />

We maximize<br />

marine performance<br />

by providing The Full Picture<br />

2<br />

Core competencies<br />

Real equipment know-how<br />

Regulatory underst<strong>and</strong>ing<br />

Operational experience<br />

External interfaces<br />

Visualization<br />

E-learning<br />

User interface<br />

Hydrodynamics<br />

Physical modelling<br />

Training & Exercises<br />

Software architecture<br />

Assessment & Evaluation<br />

Technology<br />

Software<br />

Hardware<br />

Our mission<br />

We shall earn the respect <strong>and</strong> recognition for our dedication to provide innovative<br />

<strong>and</strong> reliable marine electronics that ensure optimal operation at sea. By utilising <strong>and</strong><br />

integrating our technology, experience <strong>and</strong> competencies in positioning, hydroacoustics,<br />

communication, control, navigation, simulation, <strong>and</strong> automation, we aim to give our<br />

customers The Full Picture. The Full Picture yields professional solutions <strong>and</strong> global<br />

services that make a diff erence, enabling you to stay ahead of the competition.<br />

Our philosophy<br />

Our success depends on the success of our customers. Actively listening to our customers <strong>and</strong><br />

truly underst<strong>and</strong>ing their needs, <strong>and</strong> then translating these needs into successful products<br />

<strong>and</strong> solutions, is central to achieving our goal. Our people are the key to our success <strong>and</strong> we<br />

empower them to achieve. Working together in a global network of knowledge, guided by<br />

our values, engenders innovation <strong>and</strong> world class performance. Every day we have to think a<br />

little diff erently, because every client is unique. We aspire to translate the imagination <strong>and</strong><br />

dedication of our staff into successful technologies <strong>and</strong> solutions. Our commitment is to add<br />

value to your operations by providing you with The Full Picture.<br />

Products<br />

Applications<br />

St<strong>and</strong>ard<br />

Procedures<br />

Emergency<br />

Procedures<br />

Process<br />

Underst<strong>and</strong>ing<br />

Stability<br />

Flow Control<br />

Fuel Economy<br />

Product Tanker<br />

Chemical Tanker<br />

LPG/Ethylene<br />

Tanker<br />

LNG Tankers<br />

Very Large Crude<br />

Carrier (VLCC)<br />

MODU &<br />

FOFO Vessel

The Dem<strong>and</strong> for <strong>Maritime</strong> Personnel<br />

The labour situation within the maritime sector is a topic that attracts much attention worldwide. Many fear we are entering a period where<br />

a massive shortage of qualifi ed personnel can, among other factors, represent a possible threat to both quality <strong>and</strong> safety st<strong>and</strong>ards. At the<br />

same time, customers, authorities <strong>and</strong> other stakeholders constantly increase their dem<strong>and</strong> for higher quality, precision, safety <strong>and</strong> corporate<br />

social responsibility. Based on this complex situation, the maritime industry worldwide is expected to have a strong focus on recruiting new,<br />

qualifi ed personnel in years to come.<br />

High Quality Training: a Necessity<br />

For ship owners <strong>and</strong> operators, competence is the key to safety, reliability <strong>and</strong> economy. Safety reduces the risk of injuries to personnel <strong>and</strong><br />

minimizes the risk of damage to the environment. Reliability minimizes the ever increasing cost of being off -hire. A well-run cargo <strong>and</strong> <strong>ballast</strong><br />

operation managed by competent people improves economy. Onboard training using real equipment presents a number of challenges.<br />

Increased risk to personnel <strong>and</strong> equipment combined with limited access to required marine assets <strong>and</strong> related escalating costs are creating<br />

increased dem<strong>and</strong> for simulation technology. Simulation under highly realistic circumstances presents a safer <strong>and</strong> more cost-effi cient training<br />

alternative. Simulation has already proven its eff ectiveness <strong>and</strong> is, without doubt, the future of maritime training. Due to the almost unlimited<br />

possibilities provided by simulation, better results can be achieved in a safer, more effi cient manner, which in turn produces higher quality<br />

personnel.<br />

Index<br />

The Need for Simulators in the <strong>Maritime</strong> Industry 5<br />

NEPTUNE <strong>Cargo</strong> & Ballast H<strong>and</strong>ling Simulator 6–9<br />

NEPTUNE Instructor System 10<br />

KONGSBERG’s Guarantees 12–13<br />

Certifi cates <strong>and</strong> Approvals 14<br />

3

CCTV - Simulation of a cargo operation<br />

4

The Need for Simulators in the <strong>Maritime</strong> Industry<br />

Diff erent tasks – diff erent needs<br />

Investment in maritime <strong>simulators</strong> is no longer limited to just the<br />

largest academies <strong>and</strong> organizations. Today’s simulator customers<br />

represent a broad mix of diff erent organizations, from public training<br />

academies <strong>and</strong> universities, training centres <strong>and</strong> vocational schools,<br />

to shipping <strong>and</strong> oil & gas companies, as well as military training<br />

organizations including Navies, Coast Guards <strong>and</strong> <strong>Maritime</strong> Police.<br />

Accordingly, cargo & <strong>ballast</strong> h<strong>and</strong>ling <strong>simulators</strong> must be fl exible<br />

to meet the user’s various needs. Simulators today can be delivered<br />

tailor-made, ensuring that both functionality <strong>and</strong> cost meet the exact<br />

requirements of the user.<br />

Competence saves money & environment<br />

The importance of process underst<strong>and</strong>ing is crucial for optimum cargo<br />

<strong>and</strong> <strong>ballast</strong> h<strong>and</strong>ling. Proper simulator training is an eff ective way to<br />

build crew competence. Competent personnel work more effi ciently<br />

through reduced off -hire costs, <strong>and</strong> achieve higher productivity with<br />

lower risk of environmental damage. To avoid negative learning, it is a<br />

necessity that the simulation training is highly realistic <strong>and</strong> adaptable to<br />

real life situations. The latest maritime simulation technology provides<br />

impressive integration between cargo h<strong>and</strong>ling simulator <strong>and</strong> real vessel<br />

control systems, which gives a new level of realism, as crew can train on<br />

exactly the same equipment that they will fi nd onboard a real vessel.<br />

Educating the best personnel<br />

Compared to conventional training, <strong>simulators</strong> off er a more structured<br />

method of building high levels of competence. During simulation<br />

training, one can isolate <strong>and</strong> freeze each sub-system to underst<strong>and</strong><br />

<strong>and</strong> acquire knowledge, perform critical operations over <strong>and</strong> over<br />

again to train skills, <strong>and</strong> test <strong>and</strong> develop attitudes by training in<br />

situations that dem<strong>and</strong> complex decision making. Through the use of<br />

advanced assessment systems, simulator training can help to isolate<br />

areas requiring improvement <strong>and</strong> support the development of “tailormade”<br />

exercises. In this way, the training will focus on bringing out<br />

the best in every student.<br />

LNG membrane tank<br />

Students training on cargo h<strong>and</strong>ling <strong>simulators</strong><br />

at Kalmar <strong>Maritime</strong> Academy, Sweden<br />

Valve inspection<br />

KONGSBERG’s solution<br />

As a major world-wide supplier of ship automation <strong>and</strong> control systems, KONGSBERG has a thorough underst<strong>and</strong>ing of the industry’s<br />

training needs <strong>and</strong> detailed knowledge of the systems used onboard. We have designed our <strong>simulators</strong> around this knowledge to provide the<br />

most realistic <strong>and</strong> eff ective training possible. To meet the present <strong>and</strong> future training needs in the maritime industry, we have developed<br />

the NEPTUNE cargo & <strong>ballast</strong> h<strong>and</strong>ling simulator, which is the result of detailed studies that have defi ned the optimum solution. NEPTUNE<br />

provides high fi delity real-time simulation, supporting unique education <strong>and</strong> training of personnel. Through the use of physical models,<br />

NEPTUNE real-time simulation models are completely integrated to produce a “domino eff ect” on adjacent subsystems. Faults <strong>and</strong><br />

alarms will have cascading eff ects throughout the system if not acknowledged properly. In addition to an extremely high level of realism,<br />

the NEPTUNE cargo & <strong>ballast</strong> h<strong>and</strong>ling simulator off ers user-friendliness <strong>and</strong> fl exibility, key features for providing high levels of instructor<br />

control <strong>and</strong> greater variety of course off erings – capabilities dem<strong>and</strong>ed by shipowners <strong>and</strong> training institutes worldwide.<br />

5

NEPTUNE <strong>Cargo</strong> & Ballast H<strong>and</strong>ling Simulator<br />

The world’s most advanced simulator<br />

Behind the NEPTUNE cargo & <strong>ballast</strong> h<strong>and</strong>ling simulator lies an<br />

investment of more than 140 person-years of development.<br />

This major investment has resulted in the most advanced cargo <strong>and</strong><br />

<strong>ballast</strong> h<strong>and</strong>ling simulator available in the market today. NEPTUNE<br />

builds competence from the ground up by providing the most realistic<br />

depiction of cargo & <strong>ballast</strong> h<strong>and</strong>ling operations. In order to learn the<br />

complex load <strong>and</strong> discharge operations, NEPTUNE <strong>simulators</strong> enable<br />

high quality training in every aspect, from single sub-systems to the<br />

overall running of a loading or discharge operation. Simulating the<br />

entire range of operations from normal conditions through extraordinary<br />

situations, students are given the opportunity to experience day-to-day<br />

operational requirements <strong>and</strong> learn the vital skills for dealing with<br />

abnormal situations <strong>and</strong> emergency conditions.<br />

From desktop to full mission systems<br />

KONGSBERG is dedicated to making NEPTUNE available to as many<br />

users as possible. The NEPTUNE cargo & <strong>ballast</strong> h<strong>and</strong>ling simulator<br />

is extremely fl exible <strong>and</strong> can be confi gured from a PC desktop to<br />

an operational full mission simulator using custom panels <strong>and</strong> ship<br />

equipment. In addition, KONGSBERG provides an e-learning (webenabled)<br />

module <strong>and</strong> the possibility to use fl oating licences, giving<br />

the training centre maximum value for money. With a full range of<br />

simulation systems available, KONGSBERG has a cost-eff ective solution<br />

to fi t every requirement <strong>and</strong> budget.<br />

The NEPTUNE cargo & <strong>ballast</strong> h<strong>and</strong>ling simulator off ers a wide range<br />

of highly realistic models of diff erent vessel types. Our desktop system<br />

is based on the same core software for all confi gurations, <strong>and</strong> is ideal<br />

for operation <strong>and</strong> process studies. The full mission systems off er a<br />

physical familiarity with the real shipboard environment, <strong>and</strong> include<br />

a cargo control room, cargo h<strong>and</strong>ling room <strong>and</strong> instructor room.<br />

Maximum fl exibility<br />

Diff erent simulator confi gurations are available. The cargo control room<br />

may be represented by any combination of interactive mimic panels,<br />

operational panels/consoles or desk-top stations. Our concept allows<br />

individually laid out control rooms to meet exact customer requirements.<br />

The system can be upgraded or exp<strong>and</strong>ed at any time during its life<br />

span, <strong>and</strong> is based on the same core software for all confi gurations.<br />

The illustration shows a typical simulator confi guration of networked d systems including<br />

<strong>Cargo</strong> H<strong>and</strong>ling Room with Local Operating Station (LOS) consoles, <strong>Cargo</strong> Control Room<br />

with full console <strong>and</strong> panel confi guration, Instructor Station <strong>and</strong> Simulator mulator Laboratory with<br />

Debrief Facilities.<br />

6<br />

Creating realistic training situations<br />

We tailor your training facility to your specifi c needs <strong>and</strong> develop<br />

training programs to meet your goals. To enable this, the NEPTUNE<br />

architecture is extremely fl exible, <strong>and</strong> can be used across a range of<br />

diff erent interfaces off ering benefi ts in value, fl exibility <strong>and</strong> realism.<br />

In addition, we are able to integrate our NEPTUNE cargo & <strong>ballast</strong><br />

h<strong>and</strong>ling simulator with KONGSBERG’s K-Chief, a real automation<br />

system. This gives a new level of realism, as crew can train on the<br />

identical equipment that they will later operate onboard ships.

“STAR Center is pleased to report that <strong>Kongsberg</strong>’s<br />

NEPTUNE cargo h<strong>and</strong>ling simulator has met our<br />

high expectations. The years of development work<br />

shows in the accuracy <strong>and</strong> realism of the simulation<br />

models. The graphic user interface on the instructor<br />

<strong>and</strong> student stations is very intuitive <strong>and</strong> easy to use.<br />

The instructor system provides signifi cant fl exibility<br />

in building <strong>and</strong> running challenging simulation<br />

exercises. Unique scenarios can be developed using<br />

pre-programmed embedded faults <strong>and</strong> student<br />

performance can easily be monitored <strong>and</strong> assessed.<br />

The ability to replay the exercises is also a very<br />

valuable tool <strong>and</strong> the e-Coach capabilities are useful<br />

for developing tutorials for introduction to certain<br />

topics.”<br />

Brian Long, Director, STAR Center, USA<br />

Skills transfer<br />

The learning objective is to underst<strong>and</strong> <strong>and</strong> operate the entire cargo &<br />

<strong>ballast</strong> h<strong>and</strong>ling system in a safe, timely <strong>and</strong> cost-eff ective manner.<br />

Whether you choose a NEPTUNE full mission or desktop, your<br />

students or employees will learn a vast array of skills thanks to the<br />

pedagogical values <strong>and</strong> high fi delity realism the NEPTUNE simulator<br />

systems off er.<br />

Typical training applications include the following:<br />

• Routine <strong>and</strong> emergency procedures<br />

• Familiarisation with all parts of the cargo system<br />

• Planning of cargo loading <strong>and</strong> discharge<br />

• Use of loading computer<br />

• Line up for loading <strong>and</strong> <strong>ballast</strong>ing<br />

• Line up for discharge<br />

• Stripping of tanks by means of vacuum <strong>and</strong> ejector systems<br />

• Topping up <strong>and</strong> fi nalising loading<br />

• Aeration, inerting <strong>and</strong> nitrogen supply<br />

• Compressor systems, heaters <strong>and</strong> boosters on LPG/E tankers<br />

• LNG tankers with compressor systems <strong>and</strong> boil off<br />

• Mulitple loading/discharge operations with fl exible connections<br />

on chemical tankers<br />

• Discharge pump operation with dynamic pump <strong>and</strong> system<br />

performance curves<br />

• Flow control in relation to stability <strong>and</strong> mechanical forces<br />

• Communication to terminal, deck <strong>and</strong> cargo control room<br />

Contol room at the full mission cargo h<strong>and</strong>ling simulator<br />

at Dalian <strong>Maritime</strong> University, China<br />

Students running an exercise at the cargo h<strong>and</strong>ling simulator<br />

at Chalmers University of Technology, Sweden<br />

7

High fi delity models<br />

All NEPTUNE cargo & <strong>ballast</strong> h<strong>and</strong>ling simulator models are re developed<br />

based on actual ship specifi cations <strong>and</strong> performance data. ata. Various<br />

cargo system confi gurations <strong>and</strong> load conditions can be e simulated<br />

through “reality-based” exercises. Through the realism of NEPTUNE<br />

simulation, “Learning by Doing” can be accomplished; <strong>and</strong> nd this results<br />

in raising competence to perform safe, sustainable <strong>and</strong> competitive<br />

cargo operations on board.<br />

Extensive model library<br />

The product line is under continuous development with a library<br />

currently including the following models:<br />

<strong>Cargo</strong> H<strong>and</strong>ling Models:<br />

Product Tanker<br />

Chemical Tanker<br />

LPG/Ethylene Tanker<br />

LNG Tankers (Membrane <strong>and</strong> Spherical)<br />

Suezmax Tanker<br />

Very Large Crude Carrier (VLCC)<br />

Ballast H<strong>and</strong>ling Models:<br />

Mobile Off shore Drilling Unit (MODU)<br />

Semi-submersible Heavy-Lift Ship Float-On/Float-Off (FOFO)<br />

8<br />

NEPTUNE <strong>Cargo</strong> & Ballast H<strong>and</strong>ling Simulator<br />

Although realism <strong>and</strong> pedagogical values are at the forefront efront of<br />

NEPTUNE, we are dedicated to exploring <strong>and</strong> improving g every<br />

single aspect of cargo & <strong>ballast</strong> h<strong>and</strong>ling simulation to ensure our<br />

customers, students <strong>and</strong> crew members get the most out ut of our<br />

solutions. Some of the features that make NEPTUNE the e leading<br />

cargo & <strong>ballast</strong> h<strong>and</strong>ling simulator system are described d below.<br />

CCTV- Simulation of manifold waterspray<br />

CCTV - Surveillance<br />

A Closed Circuit TV surveillance camera function can be integrated<br />

into the Neptune cargo & <strong>ballast</strong> h<strong>and</strong>ling simulator, giving students<br />

a more complete training scenario. As in real cargo operations, the<br />

CCTV mode provides the student/operator a view of the deck <strong>and</strong><br />

manifold areas to monitor loading arm conditions <strong>and</strong> detect oil or<br />

gas leaks.

“Co-located with our <strong>Kongsberg</strong> liquid cargo simulator, the <strong>Kongsberg</strong> 2-DOF full mission <strong>ballast</strong> control room<br />

simulator <strong>and</strong> related fi ve part-task desktop <strong>simulators</strong> have been in operation since 1994. The installed<br />

mathematical model of the semi-submersible mobile off shore drilling unit (MODU) forms part of our<br />

off shore training markets. With instructor control <strong>and</strong> full remote monitoring of the simulator, the system<br />

covers all <strong>ballast</strong> control room training requirements for our customers.<br />

These <strong>Kongsberg</strong> <strong>simulators</strong> have served CMS well over the past fi fteen years <strong>and</strong> our Centre is now<br />

planning to upgrade both the full mission <strong>and</strong> desktop versions to complement our full suite of <strong>Kongsberg</strong><br />

cargo h<strong>and</strong>ling, bridge <strong>and</strong> engine room <strong>simulators</strong>.”<br />

Capt. Christopher Hearn, Director, The Centre for Marine Simulation, Fisheries <strong>and</strong> Marine Institute of Memorial University,<br />

Newfoundl<strong>and</strong> <strong>and</strong> Labrador, Canada<br />

Ballast control<br />

H<strong>and</strong>ling of a Semi-Submersible Platform is a dem<strong>and</strong>ing <strong>and</strong> complex<br />

task. Technical, commercial, environmental <strong>and</strong> safety requirements<br />

will always represent important - <strong>and</strong> often confl icting factors that<br />

have to be dealt with during the platform operations.<br />

This can put immense pressure on the personnel involved <strong>and</strong> it<br />

raises an unquestionable dem<strong>and</strong> for underst<strong>and</strong>ing the systems <strong>and</strong><br />

training for such.<br />

The purpose of the KONGSBERG’s <strong>ballast</strong> h<strong>and</strong>ling simulator is to<br />

provide a training tool that gives a realistic replication of the dynamic<br />

behavior of a Mobile drilling platform for <strong>ballast</strong> <strong>and</strong> position keeping<br />

systems. In this manner, knowledge in <strong>ballast</strong> control can be<br />

acquired without hazardous <strong>and</strong> devastating consequences.<br />

9

NEPTUNE Instructor System<br />

The monitoring, assessment <strong>and</strong> confi guration tool for our NEPTUNE<br />

<strong>simulators</strong> has been designed to enhance the quality of simulation<br />

training by providing complete, intuitive <strong>and</strong> user-friendly control of<br />

student exercises. It enables the instructor to develop customized<br />

exercise modules for individuals, teams or a combination of both from<br />

any PC running the application, with fully controllable areas such as:<br />

• Initial Condition – describes all the variables at the start of the<br />

exercise.<br />

• Triggers – a combination of events that initiate an Action, e-Coach<br />

message or Assessment.<br />

• Actions – derived from Input Variables <strong>and</strong> Malfunctions, which<br />

can be initiated instantaneously, or preprogrammed as part of the<br />

exercise.<br />

• e-Coach Messages – an electronic guidance <strong>and</strong> performance<br />

feedback system.<br />

• Student Station Confi guration – defi ne what information is<br />

accessible <strong>and</strong> visible to students.<br />

• Assessment – monitor <strong>and</strong> assess alarms, <strong>and</strong> any of 6,000<br />

variables in the simulation models.<br />

10<br />

Recording of all activity during the simulation exercise takes place<br />

automatically <strong>and</strong> review/debriefi ng can include the replay of parts of<br />

or the entire exercise in order to focus on specifi c learning objectives.<br />

A unique ‘resume’ functionality also enables an exercise to be<br />

stopped <strong>and</strong> started at will. If a student begins to have problems or<br />

fails in a particular operation, the instructor can pause the simulation<br />

to give guidance or advice, <strong>and</strong> then resume the exercise. The instructor<br />

can also go back to any earlier point in time <strong>and</strong> restart from there.<br />

With the NEPTUNE instructor system, monitoring, assessment <strong>and</strong><br />

debriefi ng have never been easier!<br />

“The NEPTUNE cargo h<strong>and</strong>ling simulator includes a very user-friendly instuctor system. The intuitive drag<br />

<strong>and</strong> drop functionality makes it easy to connect <strong>and</strong> distribute exercises to the student stations. Furthermore,<br />

the student station confi guration tool is extremely fl exible as set-up can be adjusted depending on<br />

student skills <strong>and</strong> purpose of the exercise. The instructor system is indeed powerful <strong>and</strong> contains all the<br />

requirements needed to reach the cargo h<strong>and</strong>ling learning objectives.”<br />

Roy Franche, Assistant Professor, University of Tromsø, Norway<br />

NEPTUNE Instructor System at Dalian <strong>Maritime</strong> University, China

Library of approved exercises<br />

We off er a range of DNV SeaSkill approved LNG exercises, covering<br />

the basic training requirements for LNG operators.<br />

Exercise 1: <strong>Cargo</strong> Tank Drying<br />

Exercise 2: Nitrogen Purging of Inter barrier spaces<br />

Exercise 3: Inerting of <strong>Cargo</strong> Systems<br />

Exercise 4: Gassing Up of <strong>Cargo</strong> Systems<br />

Exercise 5: Cooling Down of <strong>Cargo</strong> Systems<br />

Exercise 6: Commence Loading & De<strong>ballast</strong>ing<br />

Exercise 7: Complete Loading<br />

Exercise 8: Loaded <strong>and</strong> <strong>ballast</strong> Voyage BOG & Forced Vaporization<br />

Exercise 9: Ballast voyage tank cooling & BOG Management<br />

Exercise 10: Discharging<br />

Exercise 11: Boil Off <strong>and</strong> Tank Warm up<br />

Exercise 12: Gas Freeing<br />

Exercise 13: Air Purge<br />

Exercise 14: Gas Freeing single tank<br />

Exercise 15: Preparation & manifold Connection<br />

Exercise 16: Use of Emergency cargo pump<br />

Exercise 17: Emergency Discharge<br />

Exercise 18: Partly loading<br />

Exercise 19: Part Discharge<br />

Exercise 20: Leaking <strong>Cargo</strong> Tank<br />

“Not everything is pure mathematics, technology,<br />

law or business. When it comes to cargo operations<br />

it is a combination of all.”<br />

Tomas Olsson Neptun, Lecturer at the Department of Shipping<br />

<strong>and</strong> Marine Technology, <strong>and</strong> Head of the <strong>Cargo</strong> Operations Studio<br />

at Chalmers University of Technology (pictured below)<br />

11

KONGSBERG’s Guarantees<br />

Unique experience<br />

KONGSBERG is the world’s leading manufacturer of maritime electronics.<br />

We delivered our fi rst simulator in 1972. Since then we have supplied<br />

systems ranging from desktop computer based training systems to<br />

sophisticated full mission engine room <strong>simulators</strong>, all of which are<br />

based on our experience with real ship systems.<br />

We have delivered high quality engine room <strong>simulators</strong> to the market<br />

for decades, <strong>and</strong> today a large percentage of the world’s ship’s offi cers<br />

<strong>and</strong> engineers are trained on our simulation systems. We take pride<br />

in knowing that KONGSBERG will give your training an additional<br />

competitive edge.<br />

Dedication to quality training<br />

KONGSBERG has been an important contributor to the maritime<br />

sector for many decades. The maritime industry predicts a massive<br />

shortage of professional labour in the years to come, but our commitment<br />

to the future of the sector is very strong <strong>and</strong> we are dedicated to<br />

developing the necessary technology to fulfi l the simulation needs<br />

of the industry. As a manufacturer of real ship systems, we always<br />

stay close to reality when developing <strong>simulators</strong> - our guarantee that<br />

the training represents real world scenarios. In short, KONGSBERG<br />

provides simulation as it should be.<br />

World-class customer support<br />

KONGSBERG’s customer support program provides world-class fl exible<br />

system support to our global simulation system customers. The Long<br />

Term System Support Program (LTSSP) is designed around three levels<br />

of support defi ned as Basic, Priority <strong>and</strong> Premium Customized Care.<br />

Each support level off ering is designed to address the customer’s<br />

needs. Investing in a LTSSP ensures that your simulation system<br />

is always current <strong>and</strong> operating at peak capacity <strong>and</strong> provides the<br />

assistance you need in order to deliver the best simulation training<br />

available.<br />

Premium<br />

Customized Care<br />

Priority Care<br />

Basic Care<br />

Innovation that doesn’t sleep<br />

KONGSBERG has played an important role in the maritime industry for<br />

the last four decades, both as a provider of maritime electronics <strong>and</strong><br />

as an innovator in the maritime industry. We look beyond conventional<br />

approaches <strong>and</strong> established methods to fi nd new reliable solutions to<br />

increase value for our customers. With more than 5,400 employees<br />

networked around the globe, our eff orts are ongoing, 24-7.<br />

Innovation <strong>and</strong> development of new <strong>and</strong> useful technological features<br />

are areas of top priority in our work. A minimum of 10 percent of our<br />

business turnover is re-invested directly into innovation <strong>and</strong> research<br />

& development each year.<br />

13

Certifi cates <strong>and</strong> Approvals<br />

14<br />

The <strong>Kongsberg</strong> <strong>Maritime</strong> AS division of KONGSBERG fulfi ls the quality system of NEMKO <strong>and</strong> IQNet<br />

(International Certifi cation Network) <strong>and</strong> is certifi ed according to the NS-EN ISO 9001:2000 <strong>and</strong> the<br />

NEMKO 14001:2004.<br />

All of our products, from desktop to full mission NEPTUNE cargo & <strong>ballast</strong> h<strong>and</strong>ling <strong>simulators</strong>, exceeds<br />

the requirements of STCW 95 Sections A-1/12 <strong>and</strong> B-1/12 that defi ne the performance st<strong>and</strong>ards for<br />

simulator equipment to train maritime <strong>and</strong> off shore crews. NEPTUNE cargo h<strong>and</strong>ling <strong>simulators</strong> are certifi ed <strong>and</strong><br />

approved by Det Norske Veritas (DNV) St<strong>and</strong>ard for Certifi cation of <strong>Maritime</strong> Simulators No. 2.14 October<br />

2007.

We are always there, wherever you need us<br />

KONGSBERG’s customer service organization is designed to provide high-quality, global support, whenever<br />

<strong>and</strong> wherever it is needed. We are committed to providing easy access to support <strong>and</strong> service, <strong>and</strong> to<br />

responding promptly to your needs. Support <strong>and</strong> service activities are supervised from our headquarters in<br />

Norway, with service <strong>and</strong> support centres at strategic locations around the globe – where you are <strong>and</strong> the<br />

action is. As part of our commitment to total customer satisfaction, we off er a wide variety of services to<br />

meet individual customer’s operational needs. <strong>Kongsberg</strong> Support 24 is a solution designed to give<br />

around-the-clock support. For mission-critical operations, <strong>Kongsberg</strong> Support 24 can be extended to<br />

include remote monitoring. We can adapt to the required level of support by off ering service agreements,<br />

on-site spare part stocks <strong>and</strong> quick on-site response arrangements.<br />

Global <strong>and</strong> local support<br />

We provide global support from local<br />

service <strong>and</strong> support facilities at strategic<br />

locations world wide. Service <strong>and</strong><br />

support work is carried out under the<br />

supervision of your personal account<br />

manager, who will ensure that you<br />

receive high-quality service <strong>and</strong> support<br />

where <strong>and</strong> when you need it. Your<br />

account manager will ensure continuity<br />

<strong>and</strong> work closely with your personnel to<br />

improve <strong>and</strong> optimise system availability<br />

<strong>and</strong> performance. Under the direction<br />

of your account manager, <strong>and</strong> with a<br />

local inventory of spare parts, our wellqualifi<br />

ed fi eld service engineers will be<br />

able to help you quickly <strong>and</strong> eff ectively.<br />

Support 24<br />

British Columbia<br />

Washington<br />

Louisiana<br />

New York<br />

North Carolina<br />

Florida<br />

Solid competence reduces cost<br />

We have always recognised the importance<br />

of supporting our products <strong>and</strong> systems<br />

with professional training.<br />

A wide range of courses are therefore<br />

off ered to ensure that you achieve the<br />

goal of full system utilisation with safe<br />

<strong>and</strong> effi cient operation.<br />

Call +47 41418000<br />

E-mail: km.simulation.support@kongsberg.com<br />

Texas<br />

Newfoundl<strong>and</strong><br />

Nova Scotia<br />

Connecticut<br />

Norway<br />

Scotl<strong>and</strong><br />

Engl<strong>and</strong><br />

France<br />

Spain<br />

Nigeria<br />

Brazil<br />

Italy<br />

Sweden<br />

Denmark<br />

Pol<strong>and</strong><br />

Germany<br />

The Netherl<strong>and</strong>s<br />

South Africa<br />

India<br />

Singapore<br />

South Korea<br />

Japan<br />

China<br />

Philippines<br />

Upgrading that pays<br />

Product <strong>and</strong> system upgrades can improve<br />

your simulator's operations <strong>and</strong> reduce<br />

your overall maintenance costs. We will<br />

ensure that existing products <strong>and</strong> systems<br />

can be extended or upgraded based on<br />

st<strong>and</strong>ard upgrade kits.

www.km.kongsberg.com<br />

E-mail: km.simulation.sales@kongsberg.com<br />

Telephone: +47 815 73 700<br />

Design: Allegro Tønsberg © <strong>Kongsberg</strong> <strong>Maritime</strong> AS – May 2010