Review of Cabling Techniques and Environmental Effects Applicable

Review of Cabling Techniques and Environmental Effects Applicable

Review of Cabling Techniques and Environmental Effects Applicable

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

REVIEW OF CABLING TECHNIQUES<br />

AND ENVIRONMENTAL EFFECTS<br />

APPLICABLE TO THE OFFSHORE<br />

WIND FARM INDUSTRY<br />

Technical Report<br />

JANUARY 2008<br />

IN ASSOCIATION WITH

Contents<br />

1 Introduction 11<br />

1.1 Background 11<br />

1.2 Study Description 12<br />

1.3 Report Format 13<br />

2 Legislation 15<br />

2.1 Introduction 15<br />

2.2 Licences <strong>and</strong> Consents 15<br />

3 Cable types <strong>and</strong> installation techniques 18<br />

3.1 Introduction 18<br />

3.2 Cable Types 18<br />

3.3 Offshore Wind Farm Cables 18<br />

3.4 Telecoms Cables 22<br />

3.5 Power Cables 26<br />

3.6 Flowlines, Umbilicals <strong>and</strong> Small Diameter Pipelines 27<br />

3.7 Background to Safe Installation <strong>and</strong> Protection <strong>of</strong> Subsea Cables 27<br />

3.8 Cable Protection Methods 34<br />

3.9 Cable Protection for Offshore Wind Farm Developments 70<br />

3.10 Burial Assessment <strong>and</strong> General Survey <strong>Techniques</strong> 77<br />

3.11 Decommissioning 78<br />

4 Physical change 80<br />

4.1 Introduction 80<br />

4.2 Site Conditions 80<br />

4.3 Level <strong>of</strong> Sediment Disturbance 82<br />

4.4 Seabed Disturbance by Other Activities 89<br />

4.5 Dispersal <strong>and</strong> Re-Deposition <strong>of</strong> Sediment 90<br />

4.6 Mitigation Measures 99<br />

5 Potential impacts <strong>and</strong> mitigation measures 101<br />

5.1 Introduction 101<br />

5.2 Subtidal Ecology 102<br />

5.3 Intertidal Habitats 110<br />

5.4 Natural Fish Resource 113<br />

5.5 Commercial Fisheries 121<br />

5.6 Marine Mammals 125<br />

5.7 Ornithology 128<br />

5.8 Shipping <strong>and</strong> Navigation 131<br />

5.9 Seascape <strong>and</strong> Visual Character 133<br />

5.10 Marine <strong>and</strong> Coastal Archaeology 134<br />

6 Good practice measures 138<br />

7 Gaps in underst<strong>and</strong>ing 140<br />

8 References 142<br />

Appendix A: St<strong>and</strong>ards <strong>and</strong> codes <strong>of</strong> practice relevant to<br />

cable installation & the Offshore wind industry 154<br />

1

<strong>Review</strong> <strong>of</strong> <strong>Cabling</strong> <strong>Techniques</strong> <strong>and</strong> <strong>Environmental</strong> <strong>Effects</strong> <strong>Applicable</strong> to the Offshore Wind<br />

Farm Industry – Technical Report<br />

Acknowledgements<br />

This report was prepared by consultants from Royal Haskoning <strong>and</strong> BOMEL<br />

Ltd. The principal contributors from Royal Haskoning were Dr Samantha Vize,<br />

Christine Adnitt, Robert Stanil<strong>and</strong>, Julia Everard, Alec Sleigh, Rod Cappell, Sean<br />

McNulty <strong>and</strong> Dr Martin Budd. From BOMEL Ltd, the principal contributors were<br />

Ian Bonnon <strong>and</strong> John Carey.<br />

This report has benefited from assistance from Adrian Judd at the Centre <strong>of</strong><br />

Fisheries, Environment <strong>and</strong> Aquaculture Science (CEFAS). The authors also wish<br />

to thank the following consultees:<br />

Natural Engl<strong>and</strong> (Louise Burton, Victoria Copley, Keith Henson, Sarah S<strong>of</strong>fe <strong>and</strong><br />

Michael Young)<br />

English Heritage (Dr Chris Pater)<br />

Countryside Council for Wales (Dr Sarah Wood)<br />

Joint Nature Conservation Committee (Zoe Crutchfield <strong>and</strong> Andrew Prior)<br />

These consultees have assisted in providing comments on the principles <strong>of</strong><br />

the study via correspondence. Their citation here does not indicate current<br />

agreement or support <strong>of</strong> the study outputs.<br />

The research leading to the publication <strong>of</strong> this report was funded by:<br />

●<br />

●<br />

2<br />

Department for Business, Enterprise <strong>and</strong> Regulatory Reform; <strong>and</strong><br />

Department for Environment, Food <strong>and</strong> Rural Affairs.<br />

The project was managed by Dr John Hartley <strong>of</strong> Hartley Anderson Ltd on behalf<br />

<strong>of</strong> the Department Business, Enterprise <strong>and</strong> Regulatory Reform.<br />

The Target Audience<br />

This report is intended to provide technical details on subsea cable installation<br />

techniques <strong>and</strong> associated potential environmental effects, particularly relating<br />

to the <strong>of</strong>fshore wind farm industry. It aims to inform wind farm developers (<strong>and</strong><br />

their consultants), stakeholders <strong>and</strong> regulators during the <strong>Environmental</strong> Impact<br />

Assessment (EIA) stage <strong>and</strong> consents process.

Summary<br />

In the UK today, wind farms are the most developed technology for the<br />

large scale production <strong>of</strong> renewable energy <strong>of</strong>fshore. Given their position<br />

away from l<strong>and</strong>-based urban development, <strong>of</strong>fshore wind farms can be more<br />

substantial in terms <strong>of</strong> their area <strong>and</strong> power generation, compared to their l<strong>and</strong>based<br />

counterparts. Public support for <strong>of</strong>fshore wind farms is generally high,<br />

particularly where evidence is presented through the formal consenting <strong>and</strong><br />

consultation processes that developments are sited in an appropriate location,<br />

where environmental <strong>and</strong> negative economic effects are minimal or can be<br />

effectively managed.<br />

Integral to <strong>of</strong>fshore wind farm development is the installation, operation <strong>and</strong><br />

maintenance <strong>of</strong> the supporting electrical infrastructure <strong>of</strong> intra-array <strong>and</strong> export<br />

cables. This document aims to provide an information resource, intended for<br />

use by wind farm developers, consultants <strong>and</strong> regulators, on the range <strong>of</strong> cable<br />

installation techniques available, their likely environmental effects <strong>and</strong> potential<br />

mitigation, drawing on wind farm <strong>and</strong> other marine industry practice <strong>and</strong><br />

experience. Through the collation <strong>of</strong> existing information <strong>and</strong> experience from a<br />

range <strong>of</strong> sources, the report will assist government, developers, stakeholders <strong>and</strong><br />

regulators during the formal <strong>Environmental</strong> Impact Assessment <strong>and</strong> consenting<br />

process including stages <strong>of</strong> information provision, review <strong>and</strong> approval <strong>of</strong> such<br />

information. Importantly, an underst<strong>and</strong>ing <strong>of</strong> the difficulties <strong>and</strong> constraints <strong>of</strong><br />

cable installation has been provided such that impacts can be avoided, reduced<br />

or minimised. This document also deals with the practical application <strong>of</strong> the<br />

installation <strong>and</strong> mitigation techniques available to developers so that the most<br />

relevant <strong>and</strong> up-to-date technology can be applied in the most appropriate<br />

situation.<br />

This document covers:<br />

●<br />

●<br />

●<br />

The range <strong>of</strong> types <strong>of</strong> cables <strong>and</strong> small diameter pipelines currently installed<br />

in the EU shelf marine environment. Details are given for the types <strong>of</strong> cable<br />

typically used for <strong>of</strong>fshore wind farms <strong>and</strong> also the types <strong>of</strong> cable commonly<br />

used in the telecommunications <strong>and</strong> power cable industries.<br />

The range <strong>of</strong> techniques used to install <strong>and</strong> maintain the aforementioned<br />

cables <strong>and</strong> pipelines. Information is provided on a range <strong>of</strong> commonly<br />

applied cable protection measures, <strong>and</strong> also <strong>of</strong> the burial assessment survey<br />

techniques, commonly used before cable installation.<br />

The physical changes or effects to the seabed <strong>and</strong> sub-surface sediments<br />

expected to occur during cabling activities. The range <strong>of</strong> sediment types likely<br />

to be encountered during cable burial operations is discussed, with the level<br />

<strong>of</strong> sediment disturbance that is likely to occur during cable burial for each<br />

technique.<br />

3

<strong>Review</strong> <strong>of</strong> <strong>Cabling</strong> <strong>Techniques</strong> <strong>and</strong> <strong>Environmental</strong> <strong>Effects</strong> <strong>Applicable</strong> to the Offshore Wind<br />

Farm Industry – Technical Report<br />

●<br />

●<br />

●<br />

●<br />

4<br />

The potential environmental impacts that could occur during the installation<br />

<strong>and</strong> maintenance <strong>of</strong> subsea cables. Impacts are described <strong>and</strong> discussed<br />

for intertidal habitats, subtidal ecology, natural fish resources, commercial<br />

fisheries, marine mammals, ornithology, shipping <strong>and</strong> navigation, seascape<br />

<strong>and</strong> visual character, <strong>and</strong> marine <strong>and</strong> coastal archaeology. Impacts are<br />

divided into those that could cause potentially significant impacts <strong>and</strong> those<br />

that may arise but are unlikely to cause significant effects.<br />

Mitigation measures that can be used to reduce the level <strong>of</strong> significance <strong>of</strong><br />

environmental effects.<br />

Examples <strong>of</strong> good practice measures that could be adopted during all phases<br />

<strong>of</strong> project planning <strong>and</strong> used in conjunction with mitigation measures to<br />

reduce potential disturbance from cabling activities; <strong>and</strong><br />

Knowledge gaps identified during this review, including gaps in underst<strong>and</strong>ing<br />

<strong>of</strong> the actual environmental impacts resulting from cable burial activities.<br />

The key impacts relating to cable laying in the marine environment occur during<br />

the installation process. Cable burial <strong>and</strong> other protection measures (i.e. outer<br />

protective cable armouring, concrete <strong>and</strong> frond mattresses, rock dumping, <strong>and</strong><br />

grout / s<strong>and</strong> bags) are used in order to reduce the risk <strong>of</strong> damage to the cable<br />

<strong>and</strong> to ensure the safety <strong>of</strong> other users <strong>of</strong> the sea. Where cables are not afforded<br />

adequate protection, damage can occur through abrasion (i.e. on rocky seabed<br />

types) <strong>and</strong> interaction with human activities such as snagging or entanglement<br />

from bottom trawl fishing gear, anchoring or navigational dredging.<br />

Dependant upon prevailing conditions <strong>of</strong> depth, seabed morphology,<br />

hydrodynamics <strong>and</strong> geology, a range <strong>of</strong> cable burial technology is available<br />

to developers, such as cable ploughs, tracked burial machines, free swimming<br />

remotely operated vehicles (ROVs) <strong>and</strong> burial sleds.<br />

Induced changes to the prevailing physical conditions <strong>of</strong> an area, such as the<br />

suspension, dispersal <strong>and</strong> subsequent deposition <strong>of</strong> seabed sediments, changes<br />

to seabed morphology <strong>and</strong> the direct impacts associated with the presence <strong>and</strong><br />

operation <strong>of</strong> cable burial equipment can lead to a range <strong>of</strong> potential environmental<br />

impacts. The nature, extent <strong>and</strong> significance <strong>of</strong> these impacts will be a function<br />

<strong>of</strong> site specific characteristics (i.e. seabed type, tidal <strong>and</strong> wave conditions) <strong>and</strong><br />

the chosen installation method. The key potential environmental impacts, which<br />

can, in specific circumstances, be associated with cable burial, include:<br />

●<br />

●<br />

●<br />

Disturbance to sessile, encrusting, <strong>and</strong> attached fauna <strong>and</strong> flora which can be<br />

dislodged/disturbed;<br />

Smothering <strong>of</strong> sessile species due to increased sediment deposition <strong>and</strong> sidecast;<br />

Damage to the filtering mechanisms <strong>of</strong> certain species, the gills <strong>of</strong> sensitive<br />

fish species <strong>and</strong> eggs <strong>and</strong> larvae from increases in suspended sediment <strong>and</strong><br />

subsequent deposition;

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

The potential release <strong>of</strong> contaminants, previously retained in the sediment;<br />

Disturbance to important fisheries habitats such as spawning grounds,<br />

nursery grounds, feeding grounds, over-wintering areas for crustaceans,<br />

migration routes <strong>and</strong> shellfish beds;<br />

Disturbance to sensitive habitats, such as saltmarshes, biogenic reefs <strong>and</strong> eel<br />

grass beds;<br />

Noise <strong>and</strong> vibration impacts to fish <strong>and</strong> marine mammals;<br />

Electromagnetic field generation impacts to benthic species, fish <strong>and</strong> marine<br />

mammals;<br />

Risk <strong>of</strong> collision <strong>of</strong> marine mammals with cable installation vessels / support<br />

vessels; marine mammals may be disturbed by the presence <strong>of</strong> vessels <strong>and</strong><br />

cable burial equipment; <strong>and</strong>, cable entanglement with marine mammals;<br />

Marine <strong>and</strong> coastal bird species, particularly at sites <strong>of</strong> importance to nature<br />

conservation, may be disturbed by the presence <strong>of</strong> vessels <strong>and</strong> human<br />

activities;<br />

Navigational risks such as collision with cable installation vessels;<br />

Direct loss or disturbance to artefacts <strong>of</strong> importance to marine <strong>and</strong> coastal<br />

archaeology <strong>and</strong> cultural heritage; <strong>and</strong><br />

Seascape <strong>and</strong> visual impacts related to the cable installation activities <strong>and</strong><br />

the presence <strong>of</strong> cable installation vessels; <strong>and</strong> possible sea surface aesthetic<br />

effects arising from sediment plumes, particularly in areas <strong>of</strong> chalk bedrock.<br />

This study concludes that, although cabling can cover large areas <strong>of</strong> seabed, the<br />

associated environmental impacts are highly transitory, localised in extent <strong>and</strong><br />

temporary in duration. Although the corridor for cable installation impacts can<br />

be long, the footprint <strong>of</strong> impact is narrow, generally restricted to 2-3m width. For<br />

the majority <strong>of</strong> installation scenarios, the seabed <strong>and</strong> associated fauna <strong>and</strong> flora<br />

would be expected to return to a state similar to the pre-disturbance conditions.<br />

Exceptions could occur in hard clays <strong>and</strong> rock seabed types, where the cable<br />

trench would not naturally backfill, requiring intervention to backfill as part <strong>of</strong><br />

construction works or else leaving permanent scarring <strong>of</strong> the seabed.<br />

The environmental impacts associated with the installation, operation <strong>and</strong><br />

maintenance <strong>of</strong> cables associated with <strong>of</strong>fshore wind farms must be considered<br />

in the context <strong>of</strong> other influencing factors. Natural perturbations such as storm<br />

activity can have a significant effect on the structure <strong>and</strong> functioning <strong>of</strong> the<br />

seabed, as can other activities such as oil <strong>and</strong> gas exploration <strong>and</strong> infrastructure,<br />

telecommunication cable installations, certain fishing activities, aggregate<br />

extraction, <strong>and</strong> other sources <strong>of</strong> change to the physical environment. In many<br />

cases, such influencing factors may lead to related environmental impacts <strong>of</strong><br />

greater extent, duration <strong>and</strong> significance than those observed or suspected to<br />

arise as a result <strong>of</strong> the installation <strong>of</strong> <strong>of</strong>fshore wind farm cable infrastructure.<br />

5

Abbreviations<br />

AIS Automatic Identification System<br />

AONB Area <strong>of</strong> Outst<strong>and</strong>ing Natural Beauty<br />

AoSP Areas <strong>of</strong> Special Protection<br />

BAS Burial Assessment Survey<br />

BERR Department for Business, Enterprise <strong>and</strong> Regulatory Reform<br />

BETTA British Trading <strong>and</strong> Transmission Arrangements<br />

BWEA British Wind Energy Association<br />

BS British St<strong>and</strong>ards<br />

BSC Balancing <strong>and</strong> Settlement Code<br />

CEFAS Centre for Environment, Fisheries <strong>and</strong> Aquaculture<br />

CIRIA Construction Industry Research <strong>and</strong> Information Association<br />

CIWEM Chartered Institute <strong>of</strong> Water <strong>and</strong> <strong>Environmental</strong> Management<br />

CMACS Centre for Marine <strong>and</strong> Coastal Studies<br />

COWRIE Collaborative Offshore Wind Research into the Environment<br />

CPA Coast Protection Act (1949)<br />

CRoW Countryside <strong>and</strong> Rights <strong>of</strong> Way Act (2000)<br />

CUSC Connection <strong>and</strong> Use <strong>of</strong> Systems Code<br />

DEFRA Department for Environment, Food <strong>and</strong> Rural Affairs<br />

DNO Distribution Network Operator<br />

DNV Det Norske Veritas<br />

DSV Dive Support Vessel<br />

DTI Department <strong>of</strong> Trade <strong>and</strong> Industry<br />

EA Electricity Act (1989)<br />

EHS Environment <strong>and</strong> Heritage Service (Northern Irel<strong>and</strong>)<br />

EIA <strong>Environmental</strong> Impact Assessment<br />

EMF Electro Magnetic Field<br />

ENA Electricity Networks Association<br />

ES <strong>Environmental</strong> Statement<br />

EU European Union<br />

FEPA Food <strong>and</strong> Environment Protection Act (1985)<br />

GCR Geological Conservation <strong>Review</strong><br />

7

<strong>Review</strong> <strong>of</strong> <strong>Cabling</strong> <strong>Techniques</strong> <strong>and</strong> <strong>Environmental</strong> <strong>Effects</strong> <strong>Applicable</strong> to the Offshore Wind<br />

Farm Industry – Technical Report<br />

HAP Habitat Action Plan<br />

HSE Health & Safety Executive<br />

HVDC High Voltage Direct Current<br />

IEC International Electro-technical Commission<br />

IEEE Institute <strong>of</strong> Electrical <strong>and</strong> Electronics Engineers<br />

ISO International Organisation for St<strong>and</strong>ardisation<br />

JNAPC Joint Nautical Archaeology Policy Committee<br />

JNCC Joint Nature Conservation Committee<br />

LWM Low Water Mark<br />

MCA Maritime <strong>and</strong> Coastguard Agency<br />

MCEU Marine Consents <strong>and</strong> Environment Unit<br />

MCGA Marine <strong>and</strong> Coastguard Agency<br />

MEHRA Marine <strong>Environmental</strong> High Risk Area<br />

MESH Mapped European Seabed Habitats<br />

MHWS Mean High Water Springs<br />

MLWS Mean Low Water Springs<br />

MNR Marine Nature Reserve<br />

MSPP Marine Spatial Planning Pilot<br />

NNR National Nature Reserve<br />

ORCU Offshore Renewables Consents Unit<br />

OREI Offshore Renewable Energy Installations<br />

PIANC Permanent International Association <strong>of</strong> Navigation Congresses<br />

REZ Renewable Energy Zone<br />

ROV Remotely Operated Vehicle<br />

RSPB Royal Society for the Protection <strong>of</strong> Birds<br />

SAC Special Area <strong>of</strong> Conservation<br />

SAP Species Action Plan<br />

SEA Strategic <strong>Environmental</strong> Assessment<br />

SMA Sensitive Marine Area<br />

SMP Shoreline Management Plan<br />

SPA Special Protection Area<br />

SSSI Site <strong>of</strong> Special Scientific Interest<br />

8

TTS Temporary Threshold Shift<br />

TWA Transport <strong>and</strong> Works Act<br />

UKBAP UK Biodiversity Action Plan<br />

UKOOA United Kingdom Offshore Operators Association<br />

VTS Vessel Traffic Services<br />

WAG Welsh Assembly Government<br />

WSI Written Scheme <strong>of</strong> Investigation<br />

WTG Wind Turbine Generator<br />

Abbreviations<br />

9

1<br />

Introduction<br />

1.1 Background<br />

The UK is committed to working towards a 60% reduction in CO 2 emissions by<br />

2050 <strong>and</strong> the development <strong>of</strong> renewable energy technologies, such as wind, is a<br />

core part <strong>of</strong> achieving this aim. As a carbon free source <strong>of</strong> energy, wind power<br />

contributes positively to the UK’s efforts to reduce our carbon emissions to tackle<br />

the threat <strong>of</strong> climate change (Sustainable Development Commission, 2005). The<br />

UK’s <strong>of</strong>fshore wind energy resource is substantial, estimated at around 100,000<br />

GWh <strong>of</strong> practical resource (Sinden, 2004). Other marine renewables, such as<br />

wave <strong>and</strong> tidal are also rapidly developing sectors <strong>of</strong> the renewable energy<br />

industry.<br />

Whilst many <strong>of</strong> the impacts <strong>of</strong> <strong>of</strong>fshore wind farm developments are becoming<br />

increasingly accepted <strong>and</strong> understood, concerns have been raised about the<br />

potential environmental effects <strong>of</strong> certain cable installation techniques (including<br />

by fishermen <strong>and</strong> country conservation agencies). There is a range <strong>of</strong> potential<br />

cable installation <strong>and</strong> protection technologies but to date, there has been limited<br />

centralised knowledge sharing both within the <strong>of</strong>fshore wind industry <strong>and</strong> from<br />

other more established marine industries, such as subsea telecommunications<br />

<strong>and</strong> oil <strong>and</strong> gas. This lack <strong>of</strong> review <strong>and</strong> synthesis can hinder the consideration <strong>of</strong><br />

<strong>Environmental</strong> Statements <strong>and</strong> adoption <strong>of</strong> best practice by developers involved<br />

in the area <strong>of</strong> marine renewables.<br />

The installation, operation <strong>and</strong> maintenance <strong>of</strong> the supporting electrical<br />

infrastructure <strong>of</strong> inter-array <strong>and</strong> export cables are integral to <strong>of</strong>fshore wind farm<br />

development. A range <strong>of</strong> methods for cable installation are available to wind<br />

farm operators, the most applicable being dependant upon prevailing conditions<br />

<strong>of</strong> depth, seabed morphology, hydrodynamics <strong>and</strong> geology. These site specific<br />

characteristics <strong>and</strong> the chosen installation method subsequently manifest a<br />

range <strong>of</strong> impacts on the surrounding environment, the nature <strong>and</strong> extent <strong>of</strong><br />

which can vary significantly.<br />

11

<strong>Review</strong> <strong>of</strong> <strong>Cabling</strong> <strong>Techniques</strong> <strong>and</strong> <strong>Environmental</strong> <strong>Effects</strong> <strong>Applicable</strong> to the Offshore Wind<br />

Farm Industry – Technical Report<br />

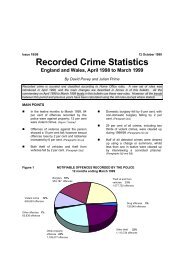

Figure 1.0 Scroby S<strong>and</strong>s <strong>of</strong>fshore wind farm<br />

(Photo courtesy <strong>of</strong> Vestas Wind Systems A/S)<br />

1.2 Study Description<br />

A large number <strong>of</strong> cables associated with energy production, telecommunications<br />

<strong>and</strong> oil <strong>and</strong> gas extraction are already located on or under the seabed <strong>of</strong> the<br />

UK continental shelf. The effects <strong>of</strong> laying these cables have been investigated<br />

to varying degrees <strong>and</strong>, as such, a great deal <strong>of</strong> experience <strong>and</strong> previous<br />

knowledge has already been gathered <strong>and</strong> is held by various industries,<br />

government departments <strong>and</strong> research organisations etc. As with many sectoral<br />

developments, particularly in the marine environment, this information has not<br />

been widely disseminated, reviewed or synthesised for a wider audience or been<br />

made publicly available.<br />

Consequently, the Research Advisory Group on Offshore Renewable Installations<br />

identified a need for Guidance on seabed installation techniques <strong>and</strong> their<br />

potential environmental effects. This guidance is required principally to inform<br />

wind farm developers <strong>and</strong> others during the <strong>Environmental</strong> Impact Assessment<br />

(EIA) <strong>and</strong> determination stages <strong>of</strong> the consents process. The guidance will be<br />

equally <strong>of</strong> use to other burgeoning marine renewable energy technologies, such<br />

as wave <strong>and</strong> tidal.<br />

1.2.1 STUDY AIMS<br />

The study aims to provide an information resource <strong>and</strong> guidance to government<br />

<strong>and</strong> developers on the range <strong>of</strong> cable installation techniques available, their<br />

12

Introduction<br />

likely environmental effects <strong>and</strong> potential mitigation, drawing on wind farm <strong>and</strong><br />

other marine industry practice <strong>and</strong> experience.<br />

Through the collation <strong>of</strong> existing information <strong>and</strong> experience from a range<br />

<strong>of</strong> sources, the guidance will assist government, developers, stakeholders<br />

<strong>and</strong> regulators during the EIA <strong>and</strong> consenting process including stages <strong>of</strong><br />

information provision, review <strong>and</strong> approval <strong>of</strong> such information. Importantly,<br />

an underst<strong>and</strong>ing <strong>of</strong> the difficulties <strong>and</strong> constraints <strong>of</strong> cable installation has<br />

been provided such that impacts can be avoided, reduced or minimised. This<br />

document also deals with the practical application <strong>of</strong> the installation <strong>and</strong><br />

mitigation techniques available to developers so that the most relevant <strong>and</strong><br />

up-to-date technology can be applied in the most appropriate situation.<br />

In summary, the specific objectives for this project are as follows:<br />

●<br />

●<br />

●<br />

●<br />

To summarise the range <strong>of</strong> types <strong>of</strong> cables <strong>and</strong> small diameter pipelines<br />

currently installed in the EU shelf marine environment;<br />

To discuss the range <strong>of</strong> techniques used to install <strong>and</strong> maintain the<br />

aforementioned cables <strong>and</strong> pipelines;<br />

To summarise the environmental impacts that could arise as a result <strong>of</strong><br />

these installation <strong>and</strong> maintenance techniques (both reported <strong>and</strong> potential<br />

impacts); <strong>and</strong><br />

To produce a technical report document which reviews cabling techniques<br />

<strong>and</strong> their environmental effects for use in the development <strong>of</strong> wind farm<br />

projects (<strong>and</strong> other marine renewable technologies).<br />

1.3 Report Format<br />

Section 1 describes the project’s background, aims <strong>and</strong> objectives.<br />

Section 2 outlines the relevant legislation applicable to the development <strong>of</strong><br />

<strong>of</strong>fshore wind farms <strong>and</strong> the installation/maintenance <strong>of</strong> cables/pipelines.<br />

Section 3 summarises the types <strong>of</strong> cables <strong>and</strong> pipelines that are currently<br />

installed in the marine environment <strong>and</strong> the range <strong>of</strong> installation techniques<br />

that are available. The relevant characteristics <strong>of</strong> each type are provided, such<br />

as dimensions, construction material, armouring, depth <strong>of</strong> burial, additional<br />

protection measures, normal service life <strong>and</strong> decommissioning. The range <strong>of</strong><br />

installation techniques that are available are also described as well as the type<br />

<strong>of</strong> engineering st<strong>and</strong>ards <strong>and</strong> constraints that might be <strong>of</strong> relevance (i.e. depth<br />

<strong>of</strong> burial in areas <strong>of</strong> sediment movement or where beam trawling occurs).<br />

Section 4 outlines the physical changes or effects to the seabed <strong>and</strong> surface<br />

sediments that could be expected to occur during cabling activity <strong>and</strong> the key<br />

characteristics that influence the extent <strong>of</strong> change.<br />

13

<strong>Review</strong> <strong>of</strong> <strong>Cabling</strong> <strong>Techniques</strong> <strong>and</strong> <strong>Environmental</strong> <strong>Effects</strong> <strong>Applicable</strong> to the Offshore Wind<br />

Farm Industry – Technical Report<br />

Section 5 describes the potential environmental impacts expected during<br />

cabling activities together with possible mitigation measures that could be used<br />

to reduce their scale <strong>of</strong> effect. Impacts are described <strong>and</strong> discussed for:<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

14<br />

Intertidal habitats;<br />

Subtidal ecology;<br />

Natural fish resource;<br />

Commercial fisheries;<br />

Marine mammals;<br />

Ornithology;<br />

Shipping <strong>and</strong> navigation;<br />

Seascape <strong>and</strong> visual character; <strong>and</strong><br />

Marine <strong>and</strong> coastal archaeology.<br />

Section 6 provides examples <strong>of</strong> good practice measures during cabling activities<br />

which could be adopted in conjunction with mitigation measures to minimise<br />

the magnitude <strong>and</strong> significance <strong>of</strong> effects on the local environment.<br />

Section 7 outlines the gaps in underst<strong>and</strong>ing <strong>and</strong> data identified as part <strong>of</strong> this<br />

project.<br />

Section 8 provides a full reference list.

2 Legislation<br />

2.1 Introduction<br />

This section provides an overview <strong>of</strong> the key UK legislation regulating<br />

developmental activities during the construction, operation <strong>and</strong> decommissioning<br />

phases <strong>of</strong> cabling activities associated with <strong>of</strong>fshore wind farm developments.<br />

2.2 Licences <strong>and</strong> Consents<br />

A statutory consenting process exists through which <strong>of</strong>fshore renewable<br />

development applications are considered in relation to UK policy aims <strong>and</strong><br />

international obligations. The consenting process is designed to ensure that<br />

each development decision is made on the basis <strong>of</strong> a comprehensive balanced<br />

consideration <strong>of</strong> impacts, both positive <strong>and</strong> negative.<br />

The consents process in Engl<strong>and</strong> <strong>and</strong> Wales is managed by the Department<br />

for Business, Enterprise <strong>and</strong> Regulatory Reform’s (BERR) Offshore Renewables<br />

Consents Unit (ORCU) <strong>and</strong> other statutory consenting authorities (the Department<br />

for the Environment, Food <strong>and</strong> Rural Affairs (Defra), the Department for Transport<br />

(DfT) <strong>and</strong> the National Assembly for Wales (NAW)). The Scottish Executive is<br />

responsible for administering the consents process for <strong>of</strong>fshore wind farms in<br />

Scottish waters, <strong>and</strong> in Northern Irel<strong>and</strong>, the Department for Enterprise, Trade<br />

<strong>and</strong> Industry (DETI). The above organisations deal with consents received<br />

under the Electricity Act (EA), the Transport <strong>and</strong> Works Act (TWA), Food <strong>and</strong><br />

Environment Protection Act (FEPA) <strong>and</strong> Coast Protection Act (CPA).<br />

The consents process for <strong>of</strong>fshore wind farms, in Engl<strong>and</strong>, Scotl<strong>and</strong> <strong>and</strong> Wales,<br />

is explained in the DTI’s (now BERR) Strategic Planning Framework consultation<br />

paper (2002) <strong>and</strong> full guidance for the consents process is provided within DTI<br />

(now BERR) guidance notes (2004). National Planning Policy Guidelines (NPPG)<br />

6 sets out national planning guidance for renewable energy developments in<br />

Scotl<strong>and</strong> (Scottish Natural Heritage, 2004). In Northern Irel<strong>and</strong>, the DETI has<br />

produced a Strategic Energy Framework for Northern Irel<strong>and</strong> (DETI, 2004) <strong>and</strong><br />

the Department <strong>of</strong> the Environment within the Northern Irel<strong>and</strong> Assembly has<br />

published details on planning process in Planning Policy Statement 1 – ‘General<br />

Principles’ (Department <strong>of</strong> the Environment, 1998).<br />

Under the auspices <strong>of</strong> the Electricity Works (<strong>Environmental</strong> Impact Assessment)<br />

Regulations 2000 (SI 2000/1927), applications for consent for <strong>of</strong>fshore wind<br />

farms (greater than 1MW) must be accompanied by an <strong>Environmental</strong> Statement<br />

(ES), the formal presentation <strong>of</strong> the <strong>Environmental</strong> Impact Assessment process.<br />

In Scotl<strong>and</strong>, this falls under the Electricity Works (<strong>Environmental</strong> Assessment<br />

(Scotl<strong>and</strong>) 2000 Regulations (SI 2000/320) <strong>and</strong> in Northern Irel<strong>and</strong>, the Electricity<br />

(Northern Irel<strong>and</strong>) Order 1992 (SI 1992/231). The ES details the nature <strong>and</strong><br />

extent <strong>of</strong> the potential impacts <strong>of</strong> each aspect <strong>of</strong> the construction, operation<br />

<strong>and</strong> eventual decommissioning <strong>of</strong> the wind farm <strong>and</strong> associated infrastructure.<br />

15

<strong>Review</strong> <strong>of</strong> <strong>Cabling</strong> <strong>Techniques</strong> <strong>and</strong> <strong>Environmental</strong> <strong>Effects</strong> <strong>Applicable</strong> to the Offshore Wind<br />

Farm Industry – Technical Report<br />

It is from the evidence presented in the ES, <strong>and</strong> subsequent critical analysis<br />

by a range <strong>of</strong> appropriate authorities, that the necessary consents are granted<br />

<strong>and</strong> any conditions with regard to mitigation, monitoring <strong>and</strong> best practice are<br />

applied.<br />

Offshore cabling applications <strong>and</strong> <strong>of</strong>fshore wind farm applications require<br />

developers to obtain a number <strong>of</strong> consents. A summary <strong>of</strong> these consents are<br />

set out in Table 2.1. The st<strong>and</strong>ards <strong>and</strong> codes <strong>of</strong> practice necessary for subsea<br />

cabling activities for the development <strong>of</strong> an <strong>of</strong>fshore wind farm are provided in<br />

Appendix A.<br />

Specifically, for cabling activities associated with the <strong>of</strong>fshore wind farm industry,<br />

a FEPA <strong>and</strong> CPA licence is required for:<br />

●<br />

●<br />

16<br />

Installation <strong>of</strong> cables; <strong>and</strong><br />

Deposition <strong>of</strong> material for cable/scour protection purposes such as rock<br />

armouring <strong>and</strong> grout bags.<br />

Under FEPA, the decision as to whether a licence will be granted will depend<br />

on the assessment by the Licensing Authority <strong>of</strong> potential hydrological effects,<br />

risk to fish, mammals <strong>and</strong> other marine life from contaminants, noise <strong>and</strong><br />

vibration, effects from potential increases in turbidity, smothering <strong>and</strong> burial <strong>of</strong><br />

marine life, any adverse implications to designated marine conservation areas<br />

or interference to other marine <strong>and</strong> coastal users.<br />

Under CPA, the Secretary <strong>of</strong> State must determine whether marine works will<br />

be detrimental to the safety <strong>of</strong> navigation in relation to the cabling installation/<br />

removal activities.<br />

Guidance for EIA in respect <strong>of</strong> FEPA <strong>and</strong> CPA requirements is provided by CEFAS<br />

(CEFAS, 2004).<br />

If an <strong>of</strong>fshore wind farm development is planning a high voltage electrical<br />

connection to the onshore grid, then use <strong>of</strong> the transmission assets involved –<br />

the <strong>of</strong>fshore substations, related electrical plant, <strong>and</strong> export cables – will require<br />

a transmission licence under the Electricity Act 1989. A distribution licence would<br />

be required if the electrical connection is at low voltage. These licensing regimes<br />

are currently under development <strong>and</strong> are likely to be introduced in 2008 <strong>and</strong> 2007<br />

respectively. Further information on obtaining licences for <strong>of</strong>fshore transmission<br />

<strong>and</strong>/or distribution can be obtained from the Offshore Transmission Team at<br />

BERR <strong>and</strong> on the BERR website.

Legislation<br />

Table 2.1: Statutory licences <strong>and</strong> consents for <strong>of</strong>fshore wind farms<br />

Act <strong>of</strong> Parliament Consent type Competent Authority<br />

Section 36 – Electricity Act (EA) 1989<br />

(as amended by the Energy Act 2004)<br />

Electricity (Northern Irel<strong>and</strong>) Order<br />

1992<br />

Section 37 – Electricity Act (EA) 1989<br />

Section 5 <strong>and</strong> 6 – Electricity Act (EA)<br />

1989<br />

Section 5 – Food & Environment<br />

Protection Act (FEPA) (Part II) 1985<br />

Section 34 – Coast Protection Act<br />

(CPA) 1949<br />

Section 90 or Section 57 –<br />

Town <strong>and</strong> Country Planning Act 1990<br />

Section 57 or Section 28 – Town <strong>and</strong><br />

Country Planning (Scotl<strong>and</strong>) Act 1997<br />

Section 109 – Water Resource Act<br />

1991<br />

Section 20 – Water Environment <strong>and</strong><br />

Water Services (Scotl<strong>and</strong>) Act 2003<br />

For <strong>of</strong>fshore wind power generating<br />

stations within territorial waters adjacent<br />

to Engl<strong>and</strong> <strong>and</strong> Wales.<br />

For overhead electric power lines<br />

associated with <strong>of</strong>fshore wind farm<br />

projects.<br />

For the transmission or distribution <strong>of</strong><br />

electricity.<br />

For depositing articles or material in<br />

the sea/tidal waters below mean high<br />

water springs (MHWS), including the<br />

placement <strong>of</strong> construction material or<br />

disposal <strong>of</strong> waste dredging.<br />

Construction under or over the seashore<br />

lying below MHWS. To make provision<br />

for the safety <strong>of</strong> navigation in relation to<br />

the export cable route <strong>and</strong> inter-turbine<br />

cabling network<br />

Deemed planning permission sought<br />

as part <strong>of</strong> the Section 36 applications<br />

for the onshore elements <strong>of</strong> the cable<br />

route. Section 57 – planning permission<br />

is sought separately, from the relevant<br />

local planning authority.<br />

To erect a structure e.g. cabling in, over<br />

or under a water course that is part <strong>of</strong> a<br />

main river<br />

Transport <strong>and</strong> Works Act 1992 Relating to <strong>of</strong>fshore generating stations<br />

<strong>and</strong> works which may interfere with<br />

rights <strong>of</strong> navigation.<br />

Source: Adapted from DTI guidance (2004)<br />

BERR (Engl<strong>and</strong> & Wales)<br />

Scottish Executive (Scotl<strong>and</strong>)<br />

DETI (Northern Irel<strong>and</strong>)<br />

Ofgem<br />

Marine Consents Environment<br />

Unit (MCEU) <strong>of</strong> DEFRA<br />

Environment <strong>and</strong><br />

Heritage Service (EHS)<br />

<strong>of</strong> the Department <strong>of</strong> the<br />

Environment (DOENI)<br />

Scottish Office <strong>of</strong> Agriculture,<br />

Environment <strong>and</strong> Fisheries<br />

Department (SOAEFD)<br />

MCEU<br />

EHS (DOENI)<br />

SOAEFD<br />

BERR (Engl<strong>and</strong> & Wales)<br />

Scottish Executive (Scotl<strong>and</strong>)<br />

DETINI (Northern Irel<strong>and</strong>)<br />

Environment Agency<br />

(Engl<strong>and</strong> <strong>and</strong> Wales)<br />

Scottish Environment<br />

Protection Agency (SEPA)<br />

(Scotl<strong>and</strong>)<br />

Rivers Agency (Northern<br />

Irel<strong>and</strong>)<br />

BERR (Engl<strong>and</strong> & Wales)<br />

Scottish Executive (Scotl<strong>and</strong>)<br />

DETINI (Northern Irel<strong>and</strong>)<br />

17

3 Cable types <strong>and</strong><br />

18<br />

installation techniques<br />

3.1 Introduction<br />

This section <strong>of</strong> the report lists all <strong>of</strong> the cable types which are anticipated to be<br />

used in the near future for <strong>of</strong>fshore wind farm development work <strong>and</strong> sets the<br />

background to the methodologies which have been developed in other industries<br />

for the safe installation <strong>and</strong> protection <strong>of</strong> subsea cables. It then outlines the<br />

various cable protection methods, including all <strong>of</strong> the various cable burial<br />

methodologies together with details <strong>of</strong> alternative external cable protection<br />

systems. This includes details <strong>of</strong> the cable protection methods which are most<br />

applicable <strong>and</strong> relevant for the <strong>of</strong>fshore wind farm industry. Information on<br />

burial assessment survey techniques which are commonly used as a pre-survey<br />

activity before the main cable installation is included. Finally, this section reviews<br />

how legislation on decommissioning <strong>of</strong> the installed cable systems could also<br />

give rise to procedures which could have an impact on the environment.<br />

3.2 Cable Types<br />

3.2.1 GENERAL<br />

This section <strong>of</strong> the report contains details <strong>of</strong> <strong>of</strong>fshore subsea cables which would<br />

typically be used for <strong>of</strong>fshore wind farms. It also contains details <strong>of</strong> the cables<br />

which are commonly used in the subsea telecommunications <strong>and</strong> power cable<br />

industries.<br />

The design <strong>and</strong> construction <strong>of</strong> a particular subsea cable will be directly governed<br />

by the functionality <strong>of</strong> the cable <strong>and</strong> any requirement to protect the cable from<br />

any potential hostile seabed intervention. Figure 3.1 illustrates a typical range<br />

<strong>and</strong> size <strong>of</strong> cables which can be used for a variety <strong>of</strong> different applications. Some<br />

<strong>of</strong> the cables included in this figure are not all subsea cables.<br />

3.3 Offshore Wind Farm Cables<br />

3.3.1 GENERAL<br />

The design <strong>of</strong> subsea cable systems for <strong>of</strong>fshore wind farms will be influenced<br />

by a number <strong>of</strong> factors. Some <strong>of</strong> the factors are generic, while others are projectspecific:

●<br />

●<br />

●<br />

●<br />

Cable types <strong>and</strong> installation techniques<br />

Connection voltage – Offshore wind farm projects need to be connected to<br />

regional distribution networks, rather than to the national transmission system.<br />

In Engl<strong>and</strong> <strong>and</strong> Wales, these distribution networks currently include 132kV<br />

<strong>and</strong> 33kV systems. Some <strong>of</strong> the early Round 1 <strong>of</strong>fshore wind farm projects<br />

have made connections at 33kV while several others have connections at<br />

132kV. It is probable that all Round 2 sites will secure connections at 132kV.<br />

Cable design – Three-core subsea cables using solid insulation (ERP or XLPE)<br />

are typically used for operation at voltages up to 132kV. Higher voltage cables<br />

that use oil as an insulating medium are not deemed to be environmentally<br />

acceptable owing to the potential risks associated with oil leakage in the<br />

near shore environment. The cables are typically designed to give a power<br />

transmission capacity <strong>of</strong> up to 40MW for a single 33kV cable <strong>and</strong> 160MW for<br />

a single 132kV cable.<br />

Turbine size – Offshore wind farm developers are continually looking to the<br />

turbine manufacturers to develop larger <strong>and</strong> more energy efficient turbines.<br />

The early UK Round 1 developments such as North Hoyle, used 2.5MW wind<br />

turbine generators (WTGs). Current <strong>of</strong>fshore wind farm developments are<br />

planning to use 3.0MW <strong>and</strong> 3.6MW machines <strong>and</strong> plans for a 5.0MW machine<br />

are already well advanced.<br />

Distance from shore – The use <strong>of</strong> a single 132kV cable to shore provides a<br />

cost-effective alternative to the use <strong>of</strong> three or four 33kV cables. The installed<br />

cost (per kilometre) <strong>of</strong> a single 132kV cable is considerably lower than the<br />

installed cost <strong>of</strong> three 33kV cables, but this solution requires an <strong>of</strong>fshore<br />

substation in order to step up to 132kV from the wind farm collection voltage<br />

(usually 33kV). Some <strong>of</strong> the current projects under consideration have more<br />

than one 132kV export cable to link the <strong>of</strong>fshore wind farm to shore.<br />

19

<strong>Review</strong> <strong>of</strong> <strong>Cabling</strong> <strong>Techniques</strong> <strong>and</strong> <strong>Environmental</strong> <strong>Effects</strong> <strong>Applicable</strong> to the Offshore Wind<br />

Farm Industry – Technical Report<br />

Figure 3.1: Diverse Range <strong>of</strong> Different Cable Types<br />

3.3.2 EXPORT CABLES<br />

The function <strong>of</strong> the export cables is to transmit the electrical power from the<br />

<strong>of</strong>fshore wind farm to the appropriate cable connection facility at the shoreline<br />

or l<strong>and</strong>fall. The electrical parameters <strong>of</strong> these cables will depend on the choice<br />

made between two options:<br />

Option 1 – No voltage step-up <strong>of</strong>fshore. The power produced from the <strong>of</strong>fshore<br />

wind farm is transmitted to shore at the collection system voltage. With this<br />

option there is no need for an <strong>of</strong>fshore substation. A number <strong>of</strong> the <strong>of</strong>fshore<br />

turbine structures act as a localised hub from which the export cables then<br />

transmit the generated power back to shore.<br />

Option 2 – Voltage step-up <strong>of</strong>fshore. The power produced by the wind farm<br />

is transmitted to shore at a different voltage level, greater than the collection<br />

voltage. An <strong>of</strong>fshore substation, containing one or more step-up transformers,<br />

is required. The <strong>of</strong>fshore substation acts as the collection point within the wind<br />

farm. The export cables then run from the <strong>of</strong>fshore substation to shore.<br />

20

Cable types <strong>and</strong> installation techniques<br />

High voltage direct current (HVDC) is not economically viable at present due to<br />

the high cost <strong>of</strong> HVDC converters, however it may, in the future, be used for sites<br />

situated further <strong>of</strong>fshore.<br />

The current <strong>and</strong> future generation <strong>of</strong> export cables are likely to be rated with<br />

a voltage <strong>of</strong> 132kV. The cable is likely to be constructed with 3 core copper<br />

conductors, insulation <strong>and</strong> conductor screening, steel wire armour <strong>and</strong> either<br />

ERP or XLPE insulation with a lead sheath. The copper conductor size is typically<br />

estimated at between 300mm 2 <strong>and</strong> 1200mm 2 . The cables will contain optical<br />

fibres embedded between the cores for data transmission <strong>and</strong> communications.<br />

The range <strong>of</strong> indicative cable conductor sizes <strong>and</strong> overall dimensions which<br />

could be used for a 132kV export cable for an <strong>of</strong>fshore wind farm are shown in<br />

Table 3.1.<br />

Table 3.1: Typical Cable Characteristics For 132kv Cable<br />

Details 132kV Cable Type<br />

300 mm² 500 mm² 800 mm² 1000 mm² 1200 mm²<br />

Overall Diameter (mm) 185 193 214 227 232<br />

Weight (kg/m) 58 68 88 100 108<br />

MVA (approx) 127 157 187 200 233<br />

3.3.3 INTER-TURBINE ARRAY CABLES<br />

The inter-turbine array cables are the cables which connect the <strong>of</strong>fshore turbines<br />

into arrays <strong>and</strong> also connect the various arrays together. It is normal practice<br />

to cable several turbines together in an array, with each cable providing a link<br />

between two adjacent turbines. Each end <strong>of</strong> the cable is terminated onto the<br />

high voltage (HV) switchgear located within the turbine tower. Because they<br />

connect to the HV switchgear at the turbines, the operating voltage for the<br />

inter-turbine cables is limited to 36kV. These cables would also connect any<br />

<strong>of</strong>fshore substation to the <strong>of</strong>fshore WTG arrays. The cables between WTGs are<br />

relatively short in length (typically in the range 500m to 950m). However, the<br />

cables between the <strong>of</strong>fshore substation <strong>and</strong> the WTG arrays could be longer <strong>and</strong><br />

possibly up to 3.0km.<br />

The inter-turbine array cables will typically be 33kV, 3-core copper conductors<br />

with insulation/conductor screening <strong>and</strong> steel wire armoured. The insulation<br />

will be either dry type XLPE, wet type XLPE or a combination <strong>of</strong> both. All cables<br />

will contain optical fibres embedded between the cores. A number <strong>of</strong> conductor<br />

sizes would be used depending on the load current that the cable is required to<br />

carry. The ranges <strong>of</strong> indicative cable conductor sizes <strong>and</strong> overall diameters that<br />

may be used are shown in Table 3.2.<br />

21

<strong>Review</strong> <strong>of</strong> <strong>Cabling</strong> <strong>Techniques</strong> <strong>and</strong> <strong>Environmental</strong> <strong>Effects</strong> <strong>Applicable</strong> to the Offshore Wind<br />

Farm Industry – Technical Report<br />

Table 3.2: Typical Cable Characteristics for 33kV cables<br />

Details 33kV Cable Type<br />

22<br />

95 mm² 240 mm² 400 mm² 630 mm² 800 mm²<br />

Overall Diameter (mm) 89 104 127 143 153<br />

Weight (kg/m) 12.2 18.6 38 49 59<br />

MVA (approx) 18 29 36 44 48<br />

3.4 Telecoms Cables<br />

This section outlines the types <strong>of</strong> cables which are commonly used by the subsea<br />

telecommunications industry to install their networks on a worldwide basis. It is<br />

normal practice for the subsea telecommunications industry to conduct a Burial<br />

Assessment Survey in advance <strong>of</strong> the design <strong>of</strong> the cable type along the full route<br />

<strong>of</strong> the cable (see Section 3.10). The Burial Assessment Survey will be used to<br />

assess the level <strong>of</strong> armouring required for a section <strong>of</strong> the cable length together<br />

with the proposed depth <strong>of</strong> burial. Many <strong>of</strong> these cable systems can be in excess<br />

<strong>of</strong> thous<strong>and</strong>s <strong>of</strong> kilometres in length, therefore, the design <strong>of</strong> armouring for the<br />

cable can have a significant influence on the overall cost <strong>of</strong> the cable. There is also<br />

a relationship between the design <strong>of</strong> outer protective armouring <strong>and</strong> the proposed<br />

depth <strong>of</strong> burial to protect the cable in its in-service condition. Hence, the results<br />

<strong>of</strong> the Burial Assessment Survey are used to identify what level <strong>of</strong> burial can be<br />

achieved along the cable route. This assessment will take into account the burial<br />

system to be employed on the project together with the design armouring for the<br />

cable.<br />

Section 3.10 <strong>of</strong> this report reviews Burial Assessment Surveys in more detail.<br />

Table 3.3 gives typical armoured cable characteristics for a number <strong>of</strong> subsea<br />

telecommunication cables. The characteristics <strong>of</strong> these cables are set out in<br />

detail in the following sub-sections.<br />

Table 3.3: Typical Characteristic for Subsea Telecommunication Cables<br />

Characteristic Unit Lightweight<br />

Armour<br />

(AL)<br />

Single<br />

Armour<br />

(A)<br />

Double<br />

Armour<br />

(AA)<br />

Lightweight cable diameter mm 21.5 21.5 21.5<br />

First lay steel wire diameter mm 4.0 4.9 4.9<br />

Number <strong>of</strong> steel armour wires in the lay 19 16 16<br />

Pitch <strong>of</strong> armour wire mm 530 539 539<br />

Second lay mild steel wire diameter mm - - 7.0<br />

Number <strong>of</strong> steel wires in the lay (left h<strong>and</strong>) - - 18<br />

Pitch mm - - 610<br />

Outside diameter mm 36.7 38.5 57.7<br />

Weight in air kg/m 3.0 3.5 9.7<br />

Weight in water kg/m 1.9 2.9 7.0

3.4.1 LIGHTWEIGHT CABLE<br />

Cable types <strong>and</strong> installation techniques<br />

Lightweight cable, as its name suggests, is cable which does not have any<br />

form <strong>of</strong> outer protective armouring. This type <strong>of</strong> cable is typically used in very<br />

deep water (usually in excess <strong>of</strong> 1000m) where the cable risk assessment has<br />

identified that the cable is highly unlikely to be subject to any form <strong>of</strong> hostile<br />

seabed intervention (e.g. anchoring or trawling).<br />

3.4.2 ‘SHARK BITE’ CABLE<br />

Shark Bite cable was initially developed by AT&T in the USA when they<br />

discovered that the electromagnetic field emanating from the power feed<br />

system in their subsea telecommunication cables was agitating the local shark<br />

population. The sharks would then attempt to bite any surface laid sections <strong>of</strong><br />

cable. To protect the cable, a new design, which provided a light single armour<br />

around the cable adequate to repel any potential shark attack, was derived. The<br />

cable also had additional screening installed in the cross sectional make-up in an<br />

attempt to reduce the amount <strong>of</strong> electro magnetic field propagation.<br />

3.4.3 LIGHTWEIGHT ARMOURED CABLE<br />

Lightweight armoured cable is a lighter version <strong>of</strong> single armoured cable where<br />

the steel armour wires would typically be 4mm in diameter, as opposed to the<br />

4.9mm diameter steel wires which are used in the conventional armoured cable<br />

(Figure 3.2). A typical application <strong>of</strong> lightweight armour would be for a deep sea<br />

section <strong>of</strong> cable which was going to be laid over a rocky seabed area <strong>and</strong> where<br />

the risk <strong>of</strong> abrasion damage to a lightweight type cable was considered to be<br />

high.<br />

3.4.4 SINGLE ARMOURED CABLE<br />

Single armoured cable is a cable type which is typically used in conjunction with<br />

cable burial as a means <strong>of</strong> providing overall protection for the installed cable<br />

(Figure 3.3). This type <strong>of</strong> cable would be employed in areas where the risk from<br />

hostile seabed intervention such as fishing had been identified. This may occur<br />

in water depths anywhere between 50m to 1000m.<br />

3.4.5 DOUBLE ARMOURED CABLE<br />

Double armoured cable would typically consist <strong>of</strong> an inner armoured layer<br />

(similar to the single armoured cable type) with steel wires <strong>of</strong> 4.9mm in diameter,<br />

which would then be overlaid with a second layer <strong>of</strong> armouring with steel wires<br />

<strong>of</strong> 7mm in diameter (Figure 3.4). Double armoured cable is significantly heavier<br />

<strong>and</strong> more inflexible than the single armoured cable which makes it more<br />

difficult <strong>and</strong> expensive to produce <strong>and</strong> install. Double armoured cable would<br />

typically be employed where there is a perceived high risk that the cable may<br />

23

<strong>Review</strong> <strong>of</strong> <strong>Cabling</strong> <strong>Techniques</strong> <strong>and</strong> <strong>Environmental</strong> <strong>Effects</strong> <strong>Applicable</strong> to the Offshore Wind<br />

Farm Industry – Technical Report<br />

not achieve the target depth <strong>of</strong> burial, where there is risk <strong>of</strong> crush damage in<br />

areas which are known to be heavily trawled, or across busy shipping lanes or<br />

navigational channels (i.e. at any location where the perceived risk <strong>of</strong> hostile<br />

seabed intervention is high).<br />

Figure 3.2: Typical Cross Section <strong>of</strong> a Lightweight Armoured<br />

Cable (used in deepwater (>1000m) with low risk <strong>of</strong> hostile seabed<br />

intervention)<br />

24

Cable types <strong>and</strong> installation techniques<br />

Figure 3.3: Typical Cross Section <strong>of</strong> a Single Armoured Cable (used<br />

in water depths <strong>of</strong> 50-1000m, where hostile seabed intervention is an<br />

identified risk)<br />

25

<strong>Review</strong> <strong>of</strong> <strong>Cabling</strong> <strong>Techniques</strong> <strong>and</strong> <strong>Environmental</strong> <strong>Effects</strong> <strong>Applicable</strong> to the Offshore Wind<br />

Farm Industry – Technical Report<br />

Figure 3.4: Typical Cross Section <strong>of</strong> a Double Armoured Cable (used<br />

in areas subject to a high risk <strong>of</strong> hostile seabed intervention)<br />

3.4.6 ROCK ARMOURED CABLE<br />

Rock armoured cable is a double armoured cable where the outer layer <strong>of</strong> contrahelically<br />

laid armour has a tight pitch angle which results in a tight packing <strong>of</strong><br />

the armour wire around the cable. This armour type provides a very stiff outer<br />

protection to the cable core <strong>and</strong> this type <strong>of</strong> cable would typically be employed<br />

where the cable would be laid over rocky outcrops in shallow water, where the<br />

cable was perceived to be at high risk from abrasion damage, or other localised<br />

risks resulting from a surface laid cable in a shallow water environment.<br />

3.5 Power Cables<br />

Power cables are defined as subsea cables which are used to either import or<br />

export power capacity. For example, there are a number <strong>of</strong> installed subsea<br />

power cables between the UK <strong>and</strong> France which allow for such power exports<br />

<strong>and</strong> imports. Similar systems are used to connect isl<strong>and</strong> settlements around<br />

the UK such as the Scottish Isles <strong>and</strong> the Isle <strong>of</strong> Wight. These cables are large<br />

diameter cables with similar characteristics <strong>and</strong> behaviour to the export cables<br />

associated with <strong>of</strong>fshore wind farm developments.<br />

26

Cable types <strong>and</strong> installation techniques<br />

Power cable diameters can range from 75mm in diameter up to 240mm in<br />

diameter. The larger size being associated with 132kV export cables from<br />

<strong>of</strong>fshore wind farm developments currently under consideration for Round 2<br />

developments.<br />

3.6 Flowlines, Umbilicals <strong>and</strong> Small Diameter Pipelines<br />

Flowlines, umbilicals <strong>and</strong> small diameter pipelines have been included in this<br />

review on the basis that some <strong>of</strong> the burial systems <strong>and</strong> other cable protection<br />

methods are commonly applied to this group <strong>of</strong> subsea products.<br />

These products fall into the larger diameter category (usually at least 200mm<br />

diameter) <strong>and</strong> are typically used to connect remote wellheads to <strong>of</strong>fshore<br />

platforms <strong>and</strong> to provide interconnect facilities between <strong>of</strong>fshore installations.<br />

As well as containing fibre optics <strong>and</strong> power cores, these products have tubing<br />

within the make-up <strong>of</strong> the product which can be used for chemical injection <strong>and</strong><br />

hydraulic power.<br />

The flowlines <strong>and</strong> umbilicals, by the nature <strong>of</strong> their make-up, are constructed<br />

using a specialist manufacturing process, are heavy, have stiff properties <strong>and</strong><br />

also have a large minimum bend radius.<br />

3.7 Background to Safe Installation <strong>and</strong> Protection <strong>of</strong> Subsea<br />

Cables<br />

This section sets out the history <strong>and</strong> background to the need for protection<br />

methods for subsea cables.<br />

3.7.1 THE NEED FOR CABLE PROTECTION<br />

Cable burial <strong>and</strong> other protection measures are used to ensure cables are<br />

adequately protected from all forms <strong>of</strong> hostile seabed intervention. If a cable is<br />

not adequately protected, damage can <strong>and</strong> will occur. Figure 3.5 illustrates the<br />

results <strong>of</strong> seabed deployed fishing gear becoming entangled with an unprotected<br />

cable system. Figure 3.6 shows a typical deployment <strong>of</strong> bottom trawl fishing<br />

gear <strong>and</strong> Figure 3.7 shows how a trawl or otter board can potentially engage <strong>and</strong><br />

snag a subsea cable giving rise to the damage as illustrated in Figure 3.5.<br />

27

<strong>Review</strong> <strong>of</strong> <strong>Cabling</strong> <strong>Techniques</strong> <strong>and</strong> <strong>Environmental</strong> <strong>Effects</strong> <strong>Applicable</strong> to the Offshore Wind<br />

Farm Industry – Technical Report<br />

Figure 3.5: Fishing Gear Entangled with an Unprotected Cable System<br />

28

Figure 3.6: Typical Deployment <strong>of</strong> Bottom Trawl Gear<br />

Cable types <strong>and</strong> installation techniques<br />

Figure 3.7: Schematic to Illustrate Potential Damage to Cable as a<br />

Trawl / Otter Board Engages a Subsea Cable<br />

29

<strong>Review</strong> <strong>of</strong> <strong>Cabling</strong> <strong>Techniques</strong> <strong>and</strong> <strong>Environmental</strong> <strong>Effects</strong> <strong>Applicable</strong> to the Offshore Wind<br />

Farm Industry – Technical Report<br />

3.7.2 HISTORY<br />

The history <strong>of</strong> safe installation <strong>and</strong> protection <strong>of</strong> subsea cables dates back to<br />

the 19th Century when early telegraph cables across both the North Sea <strong>and</strong><br />

the Atlantic were subject to frequent damage from the local fishing activity <strong>and</strong><br />

other vessels dragging their anchors across the seabed. In this respect, little has<br />

changed in over 250 years <strong>and</strong> all seabed cables <strong>and</strong> pipelines must be assessed<br />

in terms <strong>of</strong> the risks <strong>of</strong> potential damage.<br />

It was only in the early 1980s that effective cable burial became a primary<br />

method for protecting subsea cables. The pioneers in this field were the owners<br />

<strong>of</strong> the various <strong>of</strong>fshore submarine telecommunication networks who realised<br />

that the new fibre optic systems would require a robust protection system to<br />

prevent costly interruptions to service. The new cables were being designed<br />

to carry many thous<strong>and</strong> more circuits than their old analogue predecessors.<br />

British Telecom conducted extensive research programmes through their<br />

Martlesham Research Facility, where a number <strong>of</strong> onshore <strong>and</strong> <strong>of</strong>fshore trials<br />

were undertaken to establish the effectiveness <strong>of</strong> cable burial with varying<br />

depths <strong>of</strong> burial <strong>and</strong> cover. The tests involved the use <strong>of</strong> different types <strong>of</strong> fishing<br />

gear, commonly used both in shallow <strong>and</strong> deep water applications, to simulate<br />

the real conditions <strong>of</strong> fishing gear passing over cables from different angles <strong>of</strong><br />

approach. At the same time, Shell UK Exploration <strong>and</strong> Production (Shell) were<br />

conducting parallel tests to establish the potential effects <strong>of</strong> bottom trawl gear<br />

on medium to small diameter pipelines in the northern North Sea. The Shell<br />

study programme was subsequently supported by seven other North Sea oil <strong>and</strong><br />

gas operators as a joint venture.<br />

3.7.3 SHELL STUDY PROGRAMME ON PIPELINES<br />

The results <strong>of</strong> the pipeline research showed that the concrete coated pipelines<br />

with diameters <strong>of</strong> 16 inches <strong>and</strong> above could be designed to tolerate trawl gear<br />

loads without the need to lower or cover the pipelines. However for smaller<br />

pipelines, or in the case where there was pipeline spanning, it was recognised<br />

that pipeline protection requirements for individual pipelines needed to be<br />

determined on a case by case basis. Subsequent to this research, a number <strong>of</strong><br />

specialist pipeline ploughs <strong>and</strong> large track burial vehicles were developed, built<br />

<strong>and</strong> commissioned <strong>and</strong> put to effective use in the North Sea burying pipelines<br />

<strong>and</strong> flowlines for the <strong>of</strong>fshore oil <strong>and</strong> gas industry.<br />

3.7.4 BRITISH TELECOM RESEARCH<br />

The British Telecom research, having focused on the much smaller targets <strong>of</strong><br />

subsea cables, came to very positive conclusions that cables lowered into open<br />

trenches stood a much improved likelihood <strong>of</strong> being protected from seabed<br />

trawler gear. However, the best form <strong>of</strong> protection was afforded when a degree<br />

<strong>of</strong> cover was placed back over the trenched cable. In this latter condition the otter<br />

boards <strong>and</strong> trawl gear can easily pass over the cable without running the risk <strong>of</strong><br />

30

Cable types <strong>and</strong> installation techniques<br />

snagging the cable <strong>and</strong> hence causing a fault. The early research showed that<br />

depths <strong>of</strong> trenching up to 300mm, with cover over the cable, would give a high<br />

level <strong>of</strong> protection to the subsea cable. However, the confidence in protection<br />

increased significantly with depth <strong>of</strong> burial <strong>and</strong> hence British Telecom initially<br />

specified a 600mm depth <strong>of</strong> burial for the early Trans-Atlantic, Cross Channel<br />

<strong>and</strong> North Sea cables. Figure 3.8 shows some <strong>of</strong> the research undertaken by<br />

British Telecom with a beam trawl passing over a telecom cable lowered in an<br />

open trench which is approximately 750mm wide <strong>and</strong> the cable is in the trench<br />

to a depth <strong>of</strong> approximately 250mm.<br />

Figure 3.8: Early Depth <strong>of</strong> Burial Research<br />

3.7.5 DEVELOPMENT OF SUBSEA CABLE PLOUGHS<br />

To achieve the target depth <strong>of</strong> burial <strong>of</strong> 600mm, as identified by the early British<br />

Telecom research, a number <strong>of</strong> narrow blade subsea ploughs were developed.<br />

These ploughs were designed to lift a wedge <strong>of</strong> soil, place the cable in the<br />

bottom <strong>of</strong> the cut trench <strong>and</strong> allow the displaced wedge <strong>of</strong> soil to naturally<br />

backfill over the cable. This concept is similar to the method used by British Rail<br />

to bury cables adjacent to railway tracks using a narrow blade plough deployed<br />

from a rail bogey.<br />

The new generation <strong>of</strong> subsea telecom cable ploughs were extensively l<strong>and</strong><br />

tested <strong>and</strong> then also trialled <strong>of</strong>fshore before being put into active service. They<br />

became an instant success. The ploughs are towed by the cable laying vessel<br />

which simultaneously pays out cable as the ship makes forward progress<br />

31

<strong>Review</strong> <strong>of</strong> <strong>Cabling</strong> <strong>Techniques</strong> <strong>and</strong> <strong>Environmental</strong> <strong>Effects</strong> <strong>Applicable</strong> to the Offshore Wind<br />

Farm Industry – Technical Report<br />

thus ensuring the cable is simultaneously buried as the cable ship <strong>and</strong> cable<br />

plough make forward progress. The cable plough is fully instrumented <strong>and</strong> has<br />

hydraulically activated functions to allow for varying depth <strong>of</strong> burial. In addition,<br />

the instrumentation package ensures that all critical aspects <strong>of</strong> the operation can<br />

be controlled <strong>and</strong> monitored back on the host vessel as a real time operation.<br />

Between the late 1980s <strong>and</strong> the early 2000s, technologies improved the types<br />

<strong>and</strong> range <strong>of</strong> plough systems <strong>and</strong> these various types are described in detail<br />

in subsequent sections. During this same period <strong>of</strong> time, a number <strong>of</strong> tracked,<br />

remotely operated vehicles (ROVs) <strong>and</strong> free swimming ROVs were also<br />

introduced into the market. These vehicles were primarily used on projects<br />

where shorter lengths <strong>of</strong> cable burial were specified or where work in shallow<br />

water was required. They were also used where the ground conditions were<br />

beyond the capabilities <strong>of</strong> a conventional subsea plough <strong>and</strong> specialist cutting<br />

tools were required to cut into rock strata.<br />

3.7.6 CABLE FAULT ANALYSIS<br />

A number <strong>of</strong> studies have reviewed cable fault rates based on the depth <strong>of</strong><br />

burial <strong>of</strong> the installed system. This research has shown that, on average, most<br />

‘hits’ on cables result from fishing activity <strong>and</strong> that surface laid cables would be<br />

regularly hit with fault occurrence directly related to the level <strong>of</strong> fishing activity.<br />

Cables buried to 0.6m depth are likely to only experience one or two hits in a<br />

10 to 15 year lifetime (probably in areas <strong>of</strong> shallow burial or where s<strong>and</strong>-waves<br />

are mobile) <strong>and</strong> cables buried to 1.0m are likely to have a high probability <strong>of</strong><br />

remaining fault free. These statistics (which have been extracted from various<br />

papers submitted at SubOptic 1997 <strong>and</strong> SubOptic 2001) only provide guideline<br />

information <strong>and</strong> some systems are likely to remain fault free for their operational<br />

life.<br />

Various research has now resulted in some guidelines for the depth <strong>of</strong> burial<br />

when using ploughs, depending on the threat which the installed cable system<br />

may encounter during its operational life. Table 3.4 presents the target burial<br />

depth for subsea ploughs to place cables below the ‘threat line’ for the different<br />

hazards which are expected to pass over the installed cable <strong>and</strong> for varying<br />

seabed conditions. The figures quoted in the table include a 33% safety factor<br />

which recognises that the target depth <strong>of</strong> burial is not always achieved in the<br />