Spacemaster SX Electric Wire Rope Hoists & Options - Ergonomic ...

Spacemaster SX Electric Wire Rope Hoists & Options - Ergonomic ...

Spacemaster SX Electric Wire Rope Hoists & Options - Ergonomic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® ®<br />

<strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967<br />

www.rmhoist.com<br />

January 2007<br />

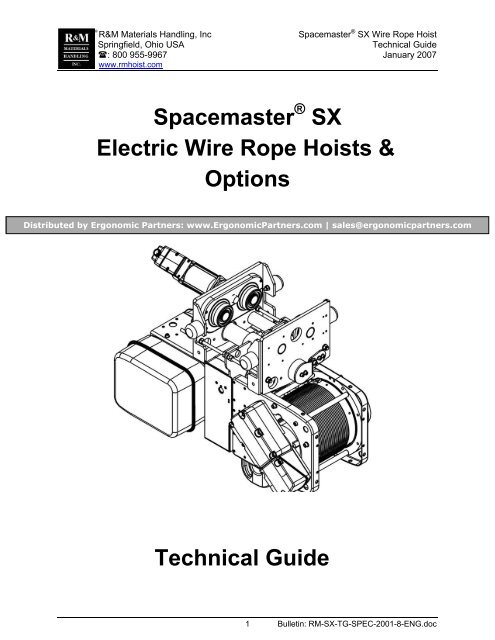

<strong>Spacemaster</strong> ® <strong>SX</strong><br />

<strong>Electric</strong> <strong>Wire</strong> <strong>Rope</strong> <strong>Hoists</strong> &<br />

<strong>Options</strong><br />

Technical Guide<br />

1 Bulletin: RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

Table of Contents<br />

1 PERFORMANCE ................................................................................................................... 6<br />

1.1 General ..............................................................................................................................................................6<br />

2 HOIST DUTY SERVICE CLASSIFICATION.......................................................................... 6<br />

2.1 FEM Hoist Duty Service Classification ...............................................................................................................6<br />

2.2 ASME Hoist Duty Service Classification.............................................................................................................7<br />

2.3 Comparison of Hoist Duty Service Classifications..............................................................................................7<br />

3 HOIST FEATURES ................................................................................................................ 8<br />

3.1 Standard Features .............................................................................................................................................8<br />

4 HOIST CHARACTERISTICS ................................................................................................. 9<br />

4.1 Height of Lift and Drum Code.............................................................................................................................9<br />

4.2 Hoist Speeds......................................................................................................................................................9<br />

4.3 Suspension Type Code......................................................................................................................................9<br />

4.4 Reeving Code ....................................................................................................................................................9<br />

4.5 <strong>Rope</strong> Type Code ................................................................................................................................................9<br />

4.6 Hoist Duty Rating ...............................................................................................................................................9<br />

4.7 Hoist Characteristics Table ..............................................................................................................................10<br />

5 MAIN COMPONENTS - HOIST ........................................................................................... 20<br />

6 HOIST MOTOR ....................................................................................................................20<br />

6.1 Hoist Motor Features........................................................................................................................................20<br />

6.2 Optional Hoist Motor Features .........................................................................................................................20<br />

6.3 Ambient Conditions ..........................................................................................................................................21<br />

6.4 P-Motors...........................................................................................................................................................21<br />

6.5 T-Motors...........................................................................................................................................................21<br />

6.6 Motor Temperature Protection .........................................................................................................................21<br />

6.7 Motor Cooling...................................................................................................................................................21<br />

6.8 Hoist Motor Brake ............................................................................................................................................21<br />

6.9 50 Hertz Hoist Motor Data –Two-speed ...........................................................................................................22<br />

6.10 50 Hertz Hoist Motor Currents –Two-speed .....................................................................................................24<br />

6.11 60 Hertz Hoist Motor Data – Two-speed ..........................................................................................................26<br />

6.12 60 Hertz Hoist Motor Currents –Two-speed .....................................................................................................28<br />

6.13 100 Hertz Hoist Motor Data – Inverter Motors..................................................................................................30<br />

6.14 120 Hertz Hoist Motor Data-Inverter Motor ......................................................................................................31<br />

6.15 Hoist Motor Currents – Inverter Motor (100 & 120 Hertz).................................................................................32<br />

7 HOIST GEARBOX ............................................................................................................... 34<br />

7.1 Hoist Gear Reducer .........................................................................................................................................34<br />

7.2 Hoist Gear Lubricant ........................................................................................................................................34<br />

8 ROPE DRUM .......................................................................................................................35<br />

8.1 Drum Data........................................................................................................................................................35<br />

8.2 Drum Length Code...........................................................................................................................................35<br />

8.3 <strong>Rope</strong> Clamps ...................................................................................................................................................36<br />

8.4 <strong>Rope</strong> Guide ......................................................................................................................................................36<br />

9 REEVING ILLUSTRATION.................................................................................................. 38<br />

9.1 Single Reeved..................................................................................................................................................38<br />

9.2 Double Reeved ................................................................................................................................................38<br />

9.3 <strong>Rope</strong> Anchor ....................................................................................................................................................39<br />

10 WIRE ROPE......................................................................................................................... 40<br />

10.1 <strong>Wire</strong> <strong>Rope</strong> Technical Data ...............................................................................................................................40<br />

10.2 Heavy Duty <strong>Wire</strong> <strong>Rope</strong> – RR09........................................................................................................................41<br />

11 BOTTOM BLOCK ................................................................................................................ 42<br />

11.1 Bottom Block Dimensions ................................................................................................................................42<br />

11.2 Block Construction ...........................................................................................................................................43<br />

11.3 RSN and HBC Hook Dimensions .....................................................................................................................44<br />

2 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

11.4 DIN Hooks – HOK09 ........................................................................................................................................44<br />

11.5 Other Hooks – HOK07 .....................................................................................................................................44<br />

11.6 Ramshorn (twin-points) Hooks – HOK03 .........................................................................................................44<br />

11.7 Sheaves ...........................................................................................................................................................45<br />

12 HOIST LIMIT SWITCH - STANDARD SETTING ................................................................. 46<br />

12.1 <strong>SX</strong>1 Hoist .........................................................................................................................................................46<br />

12.2 <strong>SX</strong>2-<strong>SX</strong>7 <strong>Hoists</strong> ...............................................................................................................................................47<br />

13 OVERLOAD DEVICE, MECHANICAL (MEC) ..................................................................... 48<br />

14 TROLLEY............................................................................................................................. 49<br />

14.1 Special Low Headroom Hoist ...........................................................................................................................49<br />

14.2 Low Headroom Hoist........................................................................................................................................50<br />

14.3 Normal Headroom Hoist...................................................................................................................................51<br />

14.4 Patented Track Wheel Option – TR26 .............................................................................................................51<br />

14.5 Swivel Trolley for Curved Track .......................................................................................................................52<br />

14.6 Double Girder Trolley .......................................................................................................................................53<br />

14.7 Trolley Gauge...................................................................................................................................................53<br />

14.8 Cross Mounting Double Girder Hoist................................................................................................................53<br />

15 INVERTER CONTROL......................................................................................................... 54<br />

15.1 Infinitely Variable (EP) Speed Control..............................................................................................................54<br />

15.2 Multi-step (MS) Speed Control .........................................................................................................................54<br />

15.3 Dynamic Braking ..............................................................................................................................................54<br />

15.4 Factory settings of Inverters.............................................................................................................................54<br />

16 VARIABLE FREQUENCY DRIVE TYPES........................................................................... 55<br />

16.1 CMXC AFD ......................................................................................................................................................55<br />

16.2 ControlMaster Select VFD................................................................................................................................56<br />

16.3 ControlMaster Plus VFD...................................................................................................................................57<br />

16.4 ControlMaster Elite VFD...................................................................................................................................58<br />

17 INVERTER TROLLEY SPEEDS.......................................................................................... 59<br />

17.1 Low Headroom - Inverter Trolley......................................................................................................................59<br />

17.2 Normal Headroom – Inverter Trolley ................................................................................................................59<br />

17.3 Double Girder - Inverter Trolley........................................................................................................................60<br />

18 TWO-SPEED TROLLEY SPEEDS ...................................................................................... 60<br />

18.1 Low Headroom – Two-speed Trolley ...............................................................................................................60<br />

18.2 Normal Headroom – Two-speed Trolley...........................................................................................................61<br />

18.3 Double Girder – Two-speed Trolley .................................................................................................................61<br />

19 GEK DRIVE.......................................................................................................................... 62<br />

19.1 MF06 Inverter-duty Motor.................................................................................................................................62<br />

19.2 Compact Brake ................................................................................................................................................62<br />

19.3 MF06 Two-speed Motor ...................................................................................................................................62<br />

19.4 D.C. Brake........................................................................................................................................................62<br />

20 GEK GEAR LUBRICANTS.................................................................................................. 63<br />

21 BRIDGE AND TROLLEY MOTOR DATA............................................................................ 64<br />

21.1 Inverter Duty Motor Data – MF06.....................................................................................................................64<br />

21.2 Inverter Duty Motor Data – MF07.....................................................................................................................65<br />

21.3 Two-speed Motor Data – MF06........................................................................................................................65<br />

21.4 Two-speed Motor Data – MF07........................................................................................................................66<br />

21.5 Two-speed Motor Data – MF10........................................................................................................................66<br />

22 HOIST CONTROLS ............................................................................................................. 67<br />

22.1 Monorail Package Hoist (Solo Hoist)................................................................................................................67<br />

22.2 Crane Package Hoist .......................................................................................................................................67<br />

22.3 Power Supply and Control Voltage ..................................................................................................................67<br />

23 HOIST PROTECTION RATING ........................................................................................... 67<br />

24 PENDANT ............................................................................................................................ 68<br />

3 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

24.1 Technical Data .................................................................................................................................................68<br />

24.2 Direction Symbols or Labels.............................................................................................................................68<br />

25 HOIST MONITOR ................................................................................................................ 69<br />

25.1 Hoist Monitor – HS11 .......................................................................................................................................69<br />

25.2 Optional Features.............................................................................................................................................70<br />

25.3 Hoist Monitor Select – HS12 ............................................................................................................................70<br />

25.4 HoistMonitor Elite – HS13 ................................................................................................................................71<br />

25.5 HoistMonitor Plus – PE10 ................................................................................................................................71<br />

26 OUTDOOR SERVICE PROTECTION.................................................................................. 72<br />

27 SURFACE TREATMENT..................................................................................................... 72<br />

27.1 Hoist & Trolley Color ........................................................................................................................................72<br />

27.2 End Truck Color ...............................................................................................................................................73<br />

27.3 Standard Painting Method................................................................................................................................73<br />

28 MATERIALS ........................................................................................................................ 74<br />

29 HOIST OPTIONS ................................................................................................................. 77<br />

29.1 Second Hoist Brake – BRA01 ..........................................................................................................................77<br />

29.2 Bumper Extensions between Trolleys – DES29...............................................................................................77<br />

29.3 Contactor Control, Trolley – Two-speed...........................................................................................................77<br />

29.4 Control Transformer & Mainline Contactor – DES02........................................................................................77<br />

29.5 Hoist Motor, IP66 Protection – HM04...............................................................................................................77<br />

29.6 Crank Shaft for Hoist Motor – HM11 ................................................................................................................77<br />

29.7 Derailment Catches for Double Girder Trolleys – OTH23 ................................................................................77<br />

29.8 Hoist Drum Brake – HS07................................................................................................................................77<br />

29.9 Hoist Motor External Fan – MOT08..................................................................................................................78<br />

29.10 Hoist without <strong>Electric</strong>al Controls – ELE65 ........................................................................................................78<br />

29.11 Limit Switch, Hoist Operating with Bypass – LIM17 .........................................................................................79<br />

29.12 Limit Switch, Extra - Level Setting – LIM16......................................................................................................80<br />

29.13 Limit Switch, Hook Operated – HS22..............................................................................................................81<br />

29.14 Limit Switch, Trolley Traveling One-step (Slowdown) – LIM13 ........................................................................81<br />

29.15 Limit Switch, Trolley Traveling One-step (Stop) – LIM14 .................................................................................81<br />

29.16 Limit Switch, Trolley Traveling Two-step (Slowdown + Stop) - LIM15..............................................................81<br />

29.17 Lockable Hook in Bottom Block – HOK02........................................................................................................81<br />

29.18 Lug Mount Suspension.....................................................................................................................................81<br />

29.19 Manual Brake Release for Hoist Motor – BRA07 .............................................................................................81<br />

29.20 Manual Brake Release for Trolley Motor – BRA05...........................................................................................81<br />

29.21 Nonstandard Voltage/frequency for Hoist.........................................................................................................81<br />

29.22 Rain Cover for Hoist Motor – HS04..................................................................................................................82<br />

29.23 Rain Cover for Trolley Motor – MOT10 ............................................................................................................82<br />

29.24 Special Paint Thickness – PAI03 .....................................................................................................................82<br />

29.25 Stainless Steel Hoist Enclosure, IP66 – PAN03...............................................................................................82<br />

29.26 Stainless Steel Hoist Enclosure, IP55 – PAN14...............................................................................................82<br />

29.27 Stainless <strong>Wire</strong> <strong>Rope</strong> – RR08............................................................................................................................82<br />

29.28 Standby Heater for Hoist Control Panel – PAN02 ............................................................................................82<br />

29.29 Standby Heater for Motors – MOT03 (hoist) MOT04 (trolley) MOT16 (bridge) ................................................82<br />

29.30 Transformer for Trolley Control – ELE68..........................................................................................................82<br />

29.31 Trolley Motor, IP66 Protection – TM04.............................................................................................................82<br />

29.32 Trolley Motor, Thermal Protection – TM10.......................................................................................................82<br />

29.33 Trolley Rail Gauge, One Step Smaller from Standard – PRI06........................................................................82<br />

29.34 Trolley Rail Gauge, One Step Larger from Standard – PRI07..........................................................................83<br />

29.35 Trolley Speed, Faster than Standard – SPD10 ................................................................................................83<br />

29.36 Trolley Speed, Slower than Standard – SPD11 ...............................................................................................83<br />

29.37 Trolley, Double Girder High Connection – DES01 ...........................................................................................83<br />

29.38 Trolley, Double Girder Low Connection – DES01 ............................................................................................83<br />

29.39 Trolley, Special Flange Width for Low Headroom – DIM19..............................................................................83<br />

29.40 Trolley, Special Flange Width for Normal Headroom – DIM20.........................................................................83<br />

29.41 Multi-hook Leveling – HS18 .............................................................................................................................83<br />

4 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

30 HOIST SPEEDS...................................................................................................................83<br />

31 QX CRANE PACKAGE ....................................................................................................... 84<br />

32 BRIDGE PANEL .................................................................................................................. 84<br />

33 CRANE ELECTRIFICATION PACKAGE ............................................................................ 84<br />

34 BRIDGE PANEL DIMENSIONS........................................................................................... 85<br />

35 LIMIT SWITCH, BRIDGE TRAVEL ONE-STEP (SLOWDOWN) – LIM10 .......................... 85<br />

36 PLUG CONNECTORS......................................................................................................... 86<br />

36.1 Control Plugs....................................................................................................................................................86<br />

36.2 Power Plugs .....................................................................................................................................................86<br />

36.3 Plug Kits and Stainless Steel Enclosures.........................................................................................................87<br />

37 BRIDGE GIRDER................................................................................................................. 87<br />

38 TANDEM HOISTS................................................................................................................ 87<br />

39 CRANE OPTIONS ............................................................................................................... 88<br />

39.1 Anti-collision Device for Crane – OTH08..........................................................................................................88<br />

39.2 Anti-collision Device for Second Crane – BT20................................................................................................88<br />

39.3 Bumper Extensions between End Trucks – DES44 .........................................................................................88<br />

39.4 Contactor Control, Bridge –Two-speed ............................................................................................................88<br />

39.5 Flashing Light for Bridge Traveling – ELE20 ....................................................................................................88<br />

39.6 Horn – ELE05...................................................................................................................................................88<br />

39.7 Limit Switch, Bridge Traveling One-step (Stop) – LIM11..................................................................................89<br />

39.8 Limit Switch, Bridge Traveling Two-step (Slowdown + Stop) – LIM12 .............................................................89<br />

39.9 Limit Switch, Hook Operated, Trips Mainline Contactor – ELE64 ....................................................................89<br />

39.10 Limit Switch, Trolley Travel, Trips all Trolleys on Bridge – ELE63 ...................................................................89<br />

39.11 Load Display – HS09 .......................................................................................................................................89<br />

39.12 Load Display for Two <strong>Hoists</strong> on Crane – HS10 ................................................................................................89<br />

39.13 Longer Chain for Trolley Tow Arm & Festoon ..................................................................................................89<br />

39.14 Manual Brake Release for Bridge Motor – BRA06 ...........................................................................................89<br />

39.15 Nonstandard Voltage/frequency for Crane.......................................................................................................89<br />

39.16 Pliotex Type <strong>Wire</strong> Marking – ELE48.................................................................................................................89<br />

39.17 Provision for Crane Lights (115v, max. 3x400W) – ELE70 ..............................................................................90<br />

39.18 Provision for Lights on Bridge (as main voltage) – ELE62 ...............................................................................90<br />

39.19 Rain Cover for Bridge Motor – MOT18.............................................................................................................90<br />

39.20 Stainless Steel Bridge Control Enclosure, IP66 – PAN04 ................................................................................90<br />

39.21 Standby Heater for Bridge Control Panel – PAN08..........................................................................................90<br />

39.22 Standby Heater for Pendant Enclosure – PEN03.............................................................................................90<br />

39.23 Standby Heater for Bridge Motor – MOT17......................................................................................................90<br />

39.24 Thermal Protection for Bridge Motor – MOT16 ................................................................................................90<br />

39.25 Transformer for Entire Crane – ELE67.............................................................................................................90<br />

39.26 Transformer for Bridge Control – ELE69..........................................................................................................90<br />

39.27 Bridge Motor, IP66 Protection – BM04.............................................................................................................90<br />

40 CONVERSIONS................................................................................................................... 91<br />

5 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

1 Performance<br />

1.1 General<br />

<strong>Hoists</strong> are designed for lifting and transporting of materials only. Under no conditions or circumstances<br />

are hoists to be used for lifting or transporting of personnel.<br />

<strong>Spacemaster</strong> ® <strong>SX</strong> wire rope hoists are designed for indoor use where the ambient temperature between<br />

14°F and 104°F (-10°C and 40°C), and the elevation is less than 3300 ft [1000m], and the relative<br />

humidity is less than 90%.<br />

When specially equipped, the hoists may be used for outdoor use or in more extreme ambient<br />

temperature conditions -4°F to 122°F (-20°C and 50°C) or a higher elevation.<br />

The sound intensity level of the hoist in the assumed operating location does not exceed 70dB.<br />

2 Hoist Duty Service Classification<br />

2.1 FEM Hoist Duty Service Classification<br />

Service conditions have important influence on the performance of wearing parts of a hoist such as gears,<br />

bearings, rope, sheaves, electrical equipment, brake linings, load and lift limit devices, wheels, etc.<br />

Careful consideration of the hoist-duty service classifications will enable the user to evaluate the<br />

application, and to obtain a hoist designed for optimum performance and minimum maintenance.<br />

According to FEM9.511 standard, the hoist-duty service classification can be determined from its 1) load<br />

spectrum 2) average daily operating time.<br />

2.1.1 FEM Load Spectrum<br />

The load spectrum can be determined from the table below.<br />

LIGHT<br />

Occasional full loads.<br />

Usually light load.<br />

Small fixed load.<br />

MEDIUM<br />

Occasional full loads.<br />

Usually light load.<br />

Average fixed load.<br />

HEAVY<br />

Repetitive full loads.<br />

Usually average load.<br />

Heavy fixed load.<br />

VERY HEAVY<br />

Usually almost full loads.<br />

Very heavy fixed load.<br />

Load %<br />

Load %<br />

Load %<br />

Load %<br />

Operating time %<br />

Operating time %<br />

Operating time %<br />

Operating time %<br />

6 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

2.1.2 FEM Average Daily Operating Time<br />

The average daily operating time of the hoist can be calculated from the running time of the hoisting<br />

machinery [hours/day].<br />

2∗<br />

H ∗ N ∗T<br />

t =<br />

V ∗60<br />

♦ H = average hoisting height [m]<br />

♦ N = number of work cycles per hour [cycles/h]<br />

♦ T = daily working time [h]<br />

♦ V = hoisting speed [m/min]<br />

2.1.3 Determining the FEM hoist duty service classification<br />

When the load spectrum and the average daily operating time of the hoist are identified, the duty service<br />

classification of the hoist is obtained from the table below.<br />

Load spectrum Average daily operating time<br />

ISO/FEM<br />

(hours per day)<br />

LIGHT<br />

MEDIUM<br />

HEAVY<br />

VERY HEAVY<br />

≤ 0.5 ≤ 1 ≤ 2 ≤ 4 ≤ 8 ≤ 16<br />

M3<br />

1Bm<br />

M4<br />

1Am<br />

M3<br />

1Bm<br />

M4<br />

1Am<br />

M5<br />

2m<br />

2.2 ASME Hoist Duty Service Classification<br />

For information about ASME Hoist Duty Service Classification, reference ASME publication catalog<br />

ASME HST-4 (latest edition) for electric wire rope hoists.<br />

M3<br />

1Bm<br />

M4<br />

1Am<br />

M5<br />

2m<br />

M4<br />

1Am<br />

2.3 Comparison of Hoist Duty Service Classifications<br />

Code 3 4 5 6<br />

ISO M3 M4 M5 M6<br />

FEM 1Bm 1Am 2m 3m<br />

ASME HST-4M H2 H3 H4 H4*<br />

Starts per Hour<br />

FEM 150 180 240 300 360<br />

ASME HST-4M 75 150 300 300 ---<br />

FEM Intermittent Duty-ANSI/ASME Uniformly Distributed Work Periods (min/hr)<br />

FEM<br />

ASME HST-4M 7.5 15 30 30 ---<br />

*None of the <strong>Spacemaster</strong> ® <strong>SX</strong> hoists is or can be rated higher than ASME H4 duty service classification.<br />

M6<br />

3m<br />

M5<br />

2m<br />

M6<br />

3m<br />

M7<br />

4m<br />

M5<br />

2m<br />

M6<br />

3m<br />

M7<br />

4m<br />

M6<br />

3m<br />

M7<br />

4m<br />

7 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

3 Hoist Features<br />

3.1 Standard Features<br />

Two-speed hoist motor (6:1 ratio) with thermal protection, class F insulation<br />

D.C. disc hoist brake<br />

Compact hoist gear box<br />

Overload limit device<br />

Over-travel protection<br />

<strong>Rope</strong> guide<br />

**Hoist and trolley controls<br />

Inverter trolley control (except <strong>SX</strong>1 hoist; contactor control)<br />

65 fpm [20 m/min] trolley speed (except <strong>SX</strong>1 hoist; 80/20 fpm [25/6.3 m/min])<br />

Trolley drive with inverter-duty motor with brake (except <strong>SX</strong>1; two-speed motor)<br />

Crown tread wheels on under-hung trolley – suitable for flat or tapered flange<br />

Flat tread wheels on double girder trolley<br />

Trolley bumper and safety drop lug<br />

HBC or RSN style hook with spring-return safety latch<br />

IP55 protection for motor<br />

Standard hoist nameplate carries a CSA c/us rating and a NEMA 3R rating for electrical<br />

enclosures<br />

Plugs for power (some exceptions) and controller cables (except <strong>SX</strong>1 hoist; hardwired)<br />

Wiring Diagram<br />

Hoist Owner’s manual - Paper + CD (1 set)<br />

Includes: Hoist (load) test certificate<br />

Hook certificate for RSN or HBC hook<br />

<strong>Wire</strong> rope certificate<br />

** For monorail applications, the mainline contactor, control transformer and the pushbutton pendant are<br />

available as equipment adders except these items are standard equipment on the <strong>SX</strong>1 hoist.<br />

** For crane applications, the mainline contactor and control transformer are supplied as standard in the<br />

bridge panel. The pushbutton pendant is selected as part of the crane components.<br />

8 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

4 Hoist Characteristics<br />

The hoist characteristics table is a summary of the hoist characteristics, which include:<br />

Height of lift and corresponding drum (length) code<br />

Hoist speeds including alternate speeds for both two-speed and inverter controls<br />

Availability of standard suspension types for each model<br />

Reeving Code<br />

<strong>Rope</strong> type code for each model<br />

Hoist duty rating<br />

4.1 Height of Lift and Drum Code<br />

The height of lift along with the corresponding drum length code is listed for each basic model. In this<br />

table, height of lift is specified in meters. To convert meters to feet, multiply by 3.281. The drum code is<br />

included in the hoist model code.<br />

4.2 Hoist Speeds<br />

The published hoist speeds are nominal. The actual hoist speed could vary ±15% when comparing hoists<br />

with the same nominal speed but with different reeving, different gearing and/or different motor type.<br />

Always use VFD hoisting controls when better speed accuracy is needed on hoists operating together.<br />

4.3 Suspension Type Code<br />

Suspension types that are available for the hoist model are marked with a code. Special suspensions are<br />

not included here.<br />

Suspension Code in table Description<br />

J Special low headroom hoist<br />

L Low headroom hoist<br />

DH Double girder trolley–high: Height above the rail is higher than the<br />

standard trolley - to get better headroom below the rail.<br />

D0 Double girder trolley–standard<br />

DW Double girder trolley–low: Height above the rail is lower than the standard<br />

trolley – to get better overhead clearance but it increases headroom.<br />

N Normal headroom hoist<br />

F Foot mount<br />

4.4 Reeving Code<br />

Reeving code Description Reeving code Description<br />

021 2 part single 022 2 part double<br />

041 4 part single 042 4 part double<br />

061 6 part single 062 6 part double<br />

081 8 part single 082 8 part double<br />

A2 2 part single Smaller rope diameter; reduced capacity; longer lift; <strong>SX</strong>4 low headroom hoists only<br />

A4 4 part single Smaller rope diameter; reduced capacity; longer lift; <strong>SX</strong>4 low headroom hoists only<br />

4.5 <strong>Rope</strong> Type Code<br />

The rope type code is listed for each height of lift. The characteristics of the wire rope can be found in the<br />

<strong>Wire</strong> <strong>Rope</strong> section. The double-reeved hoists use two separate ropes – a right-hand lay and a left-hand<br />

lay. See <strong>Wire</strong> <strong>Rope</strong> section for definition of <strong>Rope</strong> Type code.<br />

4.6 Hoist Duty Rating<br />

ASME hoist duty ratings (H3, H4, etc.) apply to hoists marked with typical U.S. capacities (for example, 1<br />

ton = 2000 lbs = 907 kg) and do not apply to hoists marked with typical metric capacities (for example, 1<br />

metric ton = 1,000 kg = 2,200 lbs). FEM/ISO ratings apply to hoists with typical metric capacities.<br />

9 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

4.7 Hoist Characteristics Table<br />

Load Contactor Inverter<br />

Suspension Drum <strong>Rope</strong><br />

Duty Rating<br />

Control Control<br />

Ton Kg L D D D N F J HOL Gear Motor Speed Motor Speed<br />

ASME FEM/ISO<br />

Hoist<br />

Reeving<br />

H 0 W Code<br />

ft m Code<br />

Type Ratio code fpm m/min code fpm m/min<br />

1 1000 <strong>SX</strong>1 021 J A 19'-8" 6 A E 133.8 PX 32/5.3 9.5/1.5<br />

H4 2m/M5 B 39’-4” 12<br />

2 2000 <strong>SX</strong>1 041 J B 19'-8" 6 A E 133.8 PX 16/2.6 4.8/0.7<br />

H4 2m/M5 C 29’-6” 9<br />

3/4 800 <strong>SX</strong>2 021 L H 0 N F A 39’-4” 12 A F 134.2 P1 40/6.6 12/2 T1 40 12<br />

H4+ 3m/M6 C 62’-4” 19<br />

1 1000 <strong>SX</strong>2 021 L H 0 N F A 39’-4” 12 A F 134.2 P1 40/6.6 12/2 T1 40 12<br />

H4 2m/M5 C 62’-4” 19<br />

1 ½ 1600 <strong>SX</strong>2 041 L H 0 N F A 19'-8" 6 A F 134.2 P1 20/3.1 6/1 T1 20 6<br />

H4+ 3m/M6 C 31’-2” 9.5<br />

2 2000 <strong>SX</strong>2 041 L H 0 N F A 19'-8" 6 A F 134.2 P1 20/3.1 6/1 T1 20 6<br />

H4 2m/M5 C 31’-2” 9.5<br />

1 1000 <strong>SX</strong>3 021 L H 0 N F A 39’-4” 12 A F 134.2 P2 40/6.6 12/2 T2 40 12<br />

H4+ 3m/M6 C 62’-4” 19 G 106 P2 50/7.8 15/2.5 T2 50 15<br />

H 87.7 P3 60/9.8 19/3.3 T3 60 19<br />

1 ¼ 1250 <strong>SX</strong>3 021 L H 0 N F A 39’-4” 12 A F 134.2 P2 40/6.6 12/2 T2 40 12<br />

H4+ 3m/M6 C 62’-4” 19 G 106 P2 50/7.8 15/2.5 T2 50 15<br />

H 87.7 P3 60/9.8 19/3.3 T3 60 19<br />

1 ½ 1600 <strong>SX</strong>3 021 L H 0 N F A 39’-4” 12 A F 134.2 P2 40/6.6 12/2 T2 40 12<br />

H4 2m/M5 C 62’-4” 19 G 106 P2 50/7.8 15/2.5 T2 50 15<br />

H 87.7 P3 60/9.8 19/3.3 T3 60 19<br />

2 2000 <strong>SX</strong>3 041 L H 0 N F A 19'-8" 6 A F 134.2 P2 20/3.1 6/1 T2 20 6<br />

H4+ 3m/M6 C 31’-2” 9.5 G 106 P2 25/3.9 7.5/1.3 T2 25 7.5<br />

H 87.7 P3 30/4.9 9.5/1.6 T3 30 9.5<br />

2 ½ 2500 <strong>SX</strong>3 041 L H 0 N F A 19'-8" 6 A F 134.2 P2 20/3.1 6/1 T2 20 6<br />

H4+ 3m/M6 C 31’-2” 9.5 G 106 P2 25/3.9 7.5/1.3 T2 25 7.5<br />

H 87.7 P3 30/4.9 9.5/1.6 T3 30 9.5<br />

3 3200 <strong>SX</strong>3 041 L H 0 N F A 19'-8" 6 A F 134.2 P2 20/3.1 6/1 T2 20 6<br />

H4 2m/M5 C 31’-2” 9.5 G 106 P2 25/3.9 7.5/1.3 T2 25 7.5<br />

H 87.7 P3 30/4.9 9.5/1.6 T3 30 9.5<br />

1 1000 <strong>SX</strong>4 A2 L C 73’-9” 22.5 B F 160.3 P2 40/6.6 12/2 T2 40 12<br />

H4+ 3m/M6 D 98’-5” 30 H 104.7 P4 60/9.8 19/3.3 T4 60 19<br />

1 ¼ 1250 <strong>SX</strong>4 A2 L C 73’-9” 22.5 B F 160.3 P2 40/6.6 12/2 T2 40 12<br />

H4+ 3m/M6 D 98’-5” 30 H 104.7 P4 60/9.8 19/3.3 T4 60 19<br />

1 ½ 1600 <strong>SX</strong>4 A2 L C 73’-9” 22.5 B F 160.3 P2 40/6.6 12/2 T2 40 12<br />

H4 2m/M5 D 98’-5” 30 H 104.7 P4 60/9.8 19/3.3 T4 60 19<br />

2 2000 <strong>SX</strong>4 A4 L C 36’-1” 11 A F 160.3 P2 20/3.1 6/1 T2 20 6<br />

H4+ 3m/M6 D 49’-2” 15 H 104.7 P4 30/4.9 9.6/1.4 T4 30 9.6<br />

2 ½ 2500 <strong>SX</strong>4 A4 L C 36’-1” 11 A F 160.3 P2 20/3.1 6/1 T2 20 6<br />

H4+ 3m/M6 D 49’-2” 15 H 104.7 P4 30/4.9 9.6/1.4 T4 30 9.6<br />

3 3200 <strong>SX</strong>4 A4 L C 36’-1” 11 A F 160.3 P2 20/3.1 6/1 T2 20 6<br />

H4 2m/M5 D 49’-2” 15 H 104.7 P4 30/4.9 9.6/1.4 T4 30 9.6<br />

10 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

Load Contactor Inverter<br />

Suspension Drum <strong>Rope</strong><br />

Duty Rating<br />

Control Control<br />

Ton Kg L D D D N F J HOL Gear Motor Speed Motor Speed<br />

ASME FEM/ISO<br />

Hoist<br />

Reeving<br />

H 0 W Code<br />

ft m Code<br />

Type Ratio code fpm m/min code fpm m/min<br />

1 ½ 1600 <strong>SX</strong>4 021 L H 0 N F B 39’-4” 12 D E 192.6 P3 30/4.9 9.5/1.6 T3 30 9.5<br />

H4+ 3m/M6 C 59’-0” 18 F 160.3 P2 40/6.6 12/2 T2 40 12<br />

H 0 N F E 98’-5” 30<br />

D 78’-9” 24 F H 104.7 P4 60/9.8 19/3.2 T4 60 19<br />

2 2000 <strong>SX</strong>4 021 L H 0 N F B 39’-4”" 12 D E 192.6 P3 30/4.9 9.5/1.6 T3 30 9.5<br />

H4+ 3m/M6 C 59’-0” 18 F 160.3 P3 40/6.6 12/2 T3 40 12<br />

D 78’-9” 24 F H 104.7 P4 60/9.8 19/3.2 T4 60 19<br />

H 0 N F E 98’-5” 30<br />

2 1/2 2500 <strong>SX</strong>4 021 L H 0 N F B 39’-4”" 12 D E 192.6 P3 30/4.9 9.5/1.6 T3 30 9.5<br />

H4 2m/M5 C 59’-0” 18 F 160.3 P3 40/6.6 12/2 T3 40 12<br />

H 0 N F E 98’-5” 30<br />

D 78’-90” 24 F H 104.7 P4 60/9.8 19/3.2 T4 60 19<br />

3 3200 <strong>SX</strong>4 041 L H 0 N F B 19’-8” 6 D E 192.6 P2 16/2.4 4.8/0.8 T2 16 4.8<br />

H4+ 3m/M6 C 29’-6” 9 F 160.3 P2 20/3.1 6/1 T2 20 6<br />

H 0 N F E 49’-2” 15<br />

D 39’-4” 12 H 104.7 P4 30/4.9 9.5/1.6 T4 30 9.5<br />

4 4000 <strong>SX</strong>4 041 L H 0 N F B 19’-8” 6 D E 192.6 P3 16/2.4 4.8/0.8 T3 16 4.8<br />

H4+ 3m/M6 C 29’-6” 9 F 160.3 P3 20/3.1 6/1 T3 20 6<br />

H 0 N F E 49’-2” 15<br />

D 39’-4” 12 H 104.7 P4 30/4.9 9.5/1.6 T4 30 9.5<br />

5 5000 <strong>SX</strong>4 041 L H 0 N F B 19’-8” 6 D E 192.6 P3 16/2.4 4.8/0.8 T3 16 4.8<br />

H4 2m/M5 C 29’-6” 9 F 160.3 P3 20/3.1 6/1 T3 20 6<br />

H 0 N F E 49’-2” 15<br />

D 39’-4” 12 H 104.7 P4 30/4.9 9.5/1.6 T4 30 9.5<br />

6 6000 <strong>SX</strong>4 061 H 0 N F C 19’-8” 6 E F 160.3 P3 13/2 4/0.6 T3 13 4<br />

H4+ 3m/M6 D 26’-3” 8 H 104.7 P4 20/3.1 6/1 T4 20 6<br />

E 32’-9” 10<br />

7 ½ 7500 <strong>SX</strong>4 061 H 0 N F C 19’-8” 6 E F 160.3 P3 13/2 4/0.6 T3 13 4<br />

H4 2m/M5 D 26’-3” 8 H 104.7 P4 20/3.1 6/1 T4 20 6<br />

E 32’-9” 10<br />

7 ½ 8000 <strong>SX</strong>4 081 H 0 N F C 14’-9” 4.5 E F 160.3 P3 10/1.5 3/0.5 T3 10 3<br />

H4 2m/M5 D 19’-8” 6 H 104.7 P4 16/2.4 4.8/0.8 T4 16 4.8<br />

E 24’-7” 7.5<br />

10 10000 <strong>SX</strong>4 081 H 0 N F C 14’-9” 4.5 E F 160.3 P3 10/1.5 3/0.5 T3 10 3<br />

H3 1Am/M4 D 19’-8” 6 H 104.7 P4 16/2.4 4.8/0.8 T4 16 4.8<br />

E 24’-7” 7.5<br />

11 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

Load Contactor Inverter<br />

Suspension Drum <strong>Rope</strong><br />

Duty Rating<br />

Control Control<br />

Ton Kg L D D D N F J HOL Gear Motor Speed Motor Speed<br />

ASME FEM/ISO<br />

Hoist<br />

Reeving<br />

H 0 W Code<br />

ft m Code<br />

Type Ratio code fpm m/min code fpm m/min<br />

4 4000 <strong>SX</strong>5 021 L H 0 W N F D 59’-0” 18 G E 223.8 P5 30/4.9 9.5/1.6 T5 30 9.5<br />

H4+ 3m/M6 E 78’-9” 24 F 185.3 P5 40/6.6 12/2 T5 40 12<br />

F 104’-11” 32 J H 113.8 P6 60/9.8 19/3.2 T6 60 19<br />

H 0 W N F G 131’-3” 40 J 94.3 P7 80/13 24/4 T7 80 24<br />

5 5000 <strong>SX</strong>5 021 L H 0 N F D 59’-0” 18 G E 223.8 P5 30/4.9 9.5/1.6 T5 30 9.5<br />

H4 2m/M5 E 78’-9” 24 F 185.3 P5 40/6.6 12/2 T5 40 12<br />

F 104’-11” 32 J H 113.8 P6 60/9.8 19/3.2 T6 60 19<br />

H 0 W N F G 131’-3” 40 J 94.3 P7 80/13 24/4 T7 80 24<br />

6 6300 <strong>SX</strong>5 041 L H 0 N F D 29'-6" 9 G E 223.8 P5 16/2.4 4.8/0.8 T5 16 4.8<br />

H4+ 3m/M6 E 39’-4” 12 F 185.3 P5 20/3.1 6/1 T5 20 6<br />

F 52’-6” 16 H 113.8 P6 30/4.9 9.5/1.6 T6 30 9.5<br />

H 0 W N F G 65’-7” 20 J 94.3 P7 40/6.6 12/2 T7 40 12<br />

7 ½ 8000 <strong>SX</strong>5 041 L H 0 N F D 29'-6" 9 G E 223.8 P5 16/2.4 4.8/0.8 T5 16 4.8<br />

H4+ 3m/M6 E 39’-4” 12 F 185.3 P5 20/3.1 6/1 T5 20 6<br />

F 52’-6” 16 H 113.8 P6 30/4.9 9.5/1.6 T6 30 9.5<br />

H 0 W N F G 65’-7” 20 J 94.3 P7 40/6.6 12/2 T7 40 12<br />

10 10000 <strong>SX</strong>5 041 L H 0 W N F D 29'-6" 9 G E 223.8 P5 16/2.4 4.8/0.8 T5 16 4.8<br />

H4 2m/M5 E 39’-4” 12 F 185.3 P5 20/3.1 6/1 T5 20 6<br />

F 52’-6” 16 H 113.8 P6 30/4.9 9.5/1.6 T6 30 9.5<br />

H 0 W N F G 65’-7” 20 J 94.3 P7 40/6.6 12/2 T7 40 12<br />

12 12000 <strong>SX</strong>5 061 H 0 W N F D 19’-8” 6 H F 185.3 P5 13/2 4/0.6 T5 13 4<br />

H4 2m/M5 E 26’-3” 8 H 113.8 P6 20/3.1 6/1 T6 20 6<br />

F 32’-9” 10 J 94.3 P7 25/3.9 7.5/1.3 T7 25 7.5<br />

G 42’-7” 13<br />

15 15000 <strong>SX</strong>5 061 H 0 W N F D 19’-8” 6 H F 185.3 P5 13/2 4/0.6 T5 13 4<br />

H3 1Am/M4 E 26’-3” 8 H 113.8 P6 20/3.1 6/1 T6 20 6<br />

F 32’-9” 10 J 94.3 P7 25/3.9 7.5/1.3 T7 25 7.5<br />

G 42’-7” 13<br />

15 16000 <strong>SX</strong>5 081 H 0 W N F D 14’-9” 4.5 H F 185.3 P5 10/1.5 3/0.5 T5 10 3<br />

H4 2m/M5 E 19’-8” 6 H 113.8 P6 16/2.4 4.8/0.8 T6 16 4.8<br />

F 26’-3” 8 J 94.3 P7 20/3.1 6/1 T7 20 6<br />

G 32’-9” 10<br />

20 20000 <strong>SX</strong>5 081 H 0 W N F D 14’-9” 4.5 H F 185.3 P5 10/1.5 3/0.5 T5 10 3<br />

H3 1Am/M4 E 19’-8” 6 H 113.8 P6 16/2.4 4.8/0.8 T6 16 4.8<br />

F 26’-3” 8 J 94.3 P7 20/3.1 6/1 T7 20 6<br />

G 32’-9” 10<br />

4 4000 <strong>SX</strong>5 022 H 0 W F D 27’-10” 8.5 D F 185.3 P5 40/6.6 12/2 T5 40 12<br />

H4+ 3m/M6 E 42’-7” 13 + H 113.8 P6 60/9.8 19/3.2 T6 60 19<br />

F 59’-0” 18 Dr J 94.3 P7 80/13 24/4 T7 80 24<br />

G 82’-0” 25<br />

H 109’-11” 33.5<br />

J 150’-11” 46<br />

5 5000 <strong>SX</strong>5 022 H 0 W F D 27’-10” 8.5 D F 185.3 P5 40/6.6 12/2 T5 40 12<br />

H4 2m/M5 E 42’-7” 13 + H 113.8 P6 60/9.8 19/3.2 T6 60 19<br />

F 59’-0” 18 Dr J 94.3 P7 80/13 24/4 T7 80 24<br />

G 82’-0” 25<br />

H 109’-11” 33.5<br />

J 150’-11” 46<br />

12 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

Load Contactor Inverter<br />

Suspension Drum <strong>Rope</strong><br />

Duty Rating<br />

Control Control<br />

Ton Kg L D D D N F J HOL Gear Motor Speed Motor Speed<br />

ASME FEM/ISO<br />

Hoist<br />

Reeving<br />

H 0 W Code<br />

ft m Code<br />

Type Ratio code fpm m/min code fpm m/min<br />

6 6300 <strong>SX</strong>5 042 H 0 W F D 13’-1” 4 D F 185.3 P5 20/3.1 6/1 T5 20 6<br />

H4+ 3m/M6 E 21’-3” 6.5 + H 113.8 P6 30/4.9 9.5/1.6 T6 30 9.5<br />

F 29’-6” 9 Dr J 94.3 P7 40/6.6 12/2 T7 40 12<br />

G 41’-0” 12.5<br />

H 54’-1” 16.5<br />

J 75’-5” 23<br />

7 ½ 8000 <strong>SX</strong>5 042 H 0 W F D 13’-1” 4 D F 185.3 P5 20/3.1 6/1 T5 20 6<br />

H4+ 3m/M6 E 21’-3” 6.5 + H 113.8 P6 30/4.9 9.5/1.6 T6 30 9.5<br />

F 29’-6” 9 Dr J 94.3 P7 40/6.6 12/2 T7 40 12<br />

G 41’-0” 12.5<br />

H 54’-1” 16.5<br />

J 75’-5” 23<br />

10 10000 <strong>SX</strong>5 042 H 0 W F D 13’-1” 4 D F 185.3 P5 20/3.1 6/1 T5 20 6<br />

H4 2m/M5 E 21’-3” 6.5 + H 113.8 P6 30/4.9 9.5/1.6 T6 30 9.5<br />

F 29’-6” 9 Dr J 94.3 P7 40/6.6 12/2 T7 40 12<br />

G 41’-0” 12.5<br />

H 54’-1” 16.5<br />

J 75’-5” 23<br />

12 12000 <strong>SX</strong>5 062 H 0 W F E 13’-1” 4 E F 185.3 P5 13/2 4/0.6 T5 13 4<br />

H4+ 3m/M6 F 19’-8” 6 + H 113.8 P6 20/3.1 6/1 T6 20 6<br />

G 26’-2” 8 Er J 94.3 P7 25/4.4 7.5/1.3 T7 25 7.5<br />

H 36’-1” 11<br />

J 49’-2” 15<br />

15 15000 <strong>SX</strong>5 062 H 0 W F E 13’-1” 4 E F 185.3 P5 13/2 4/0.6 T5 13 4<br />

H4 2m/M5 F 19’-8” 6 + H 113.8 P6 20/3.1 6/1 T6 20 6<br />

G 26’-2” 8 Er J 94.3 P7 25/4.4 7.5/1.3 T7 25 7.5<br />

H 36’-1” 11<br />

J 49’-2” 15<br />

15 16000 <strong>SX</strong>5 082 H 0 W F F 14’-9” 4.5 E F 185.3 P5 10/1.6 3/0.5 T5 10 3<br />

H4 2m/M5 G 19’-8” 6 + H 113.8 P6 16/2.8 4.8/0.8 T6 16 4.8<br />

H 26’-2” 8 Er J 94.3 P7 20/3.1 6/1 T7 20 6<br />

J 37’-8” 11.5<br />

20 20000 <strong>SX</strong>5 082 H 0 W F F 14’-9” 4.5 E F 185.3 P5 10/1.6 3/0.5 T5 10 3<br />

H3 1Am/M4 G 19’-8” 6 + H 113.8 P6 16/2.8 4.8/0.8 T6 16 4.8<br />

H 26’-2” 8 Er J 94.3 P7 20/3.1 6/1 T7 20 6<br />

J 37’-8” 11.5<br />

13 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

Load Contactor Inverter<br />

Suspension Drum <strong>Rope</strong><br />

Duty Rating<br />

Control Control<br />

Ton Kg L D D D N F J HOL Gear Motor Speed Motor Speed<br />

ASME FEM/ISO<br />

Hoist<br />

Reeving<br />

H 0 W Code<br />

ft m Code<br />

Type Ratio code fpm m/min code fpm m/min<br />

6 6300 <strong>SX</strong>6 021 0 N F C 50’-10” 15.5 K E 344.9 P6 30/4.9 9.5/1.6 T6 30 9.5<br />

H4+ 3m/M6 D 68’-10” 21 F 269.1 P6 40/6.6 12/2 T6 40 12<br />

E 91’-10” 28 M G 223.1 P7 50/7.8 15/2.5 T7 50 15<br />

F 118’-1” 36 H 184.1 T8 60 19<br />

G 154’-2” 47 J 143.6 T9 80 24<br />

H 200’-1” 61<br />

J 264’-1” 80.5<br />

K 318’-2” 97<br />

7 ½ 8000 <strong>SX</strong>6 021 0 N F C 50’-10” 15.5 K E 344.9 P6 30/4.9 9.5/1.6 T6 30 9.5<br />

H4 2m/M5 D 68’-10” 21 F 269.1 P6 40/6.6 12/2 T6 40 12<br />

E 91’-10” 28 M G 223.1 P7 50/7.8 15/2.5 T7 50 15<br />

F 118’-1” 36 H 184.1 T8 60 19<br />

G 154’-2” 47 J 143.6 T9 80 24<br />

H 200’-1” 61<br />

J 264’-1” 80.5<br />

K 318’-2” 97<br />

10 10000 <strong>SX</strong>6 021 0 N F C 50’-10” 15.5 K E 344.9 P6 30/4.9 9.5/1.6 T6 30 9.5<br />

H3 1Am/M4 D 68’-10” 21 F 269.1 P7 40/6.6 12/2 T7 40 12<br />

E 91’-10” 28 M G 223.1 P8 50/7.8 15/2.5 T8 50 15<br />

F 118’-1” 36 H 184.1 T9 60 19<br />

G 154’-2” 47 J 143.6 TA 80 24<br />

H 200’-1” 61<br />

J 264’-1” 80.5<br />

K 318’-2” 97<br />

12 ½ 12500 <strong>SX</strong>6 041 0 N F C 24'-6" 7.5 K E 344.9 P6 16/2.4 4.8/0.8 T6 16 4.8<br />

H4+ 3m/M6 D 34’-5” 10.5 F 269.1 P6 20/3.1 6/1 T6 20 6<br />

E 45’-11” 14 G 223.1 P7 25/3.9 7.5/1.3 T7 25 7.5<br />

F 59’-0” 18 H 184.1 T8 30 9.5<br />

G 77’-1” 23.5 J 143.6 T9 40 12<br />

H 100’-0” 30.5<br />

J 131’-2” 40<br />

K 159’-1” 48.5<br />

15 16000 <strong>SX</strong>6 041 0 N F C 24'-6" 7.5 K E 344.9 P6 16/2.4 4.8/0.8 T6 16 4.8<br />

H4 2m/M5 D 34’-5” 10.5 F 269.1 P6 20/3.1 6/1 T6 20 6<br />

E 45’-11” 14 G 223.1 P7 25/3.9 7.5/1.3 T7 25 7.5<br />

F 59’-0” 18 H 184.1 T8 30 9.5<br />

G 77’-1” 23.5 J 143.6 T9 40 12<br />

H 100’-0” 30.5<br />

J 131’-2” 40<br />

K 159’-1” 48.5<br />

20 20000 <strong>SX</strong>6 041 0 N F C 24'-6" 7.5 K E 344.9 P6 16/2.4 4.8/0.8 T6 16 4.8<br />

H3 1Am/M4 D 34’-5” 10.5 F 269.1 P7 20/3.1 6/1 T7 20 6<br />

E 45’-11” 14 G 223.1 P8 25/3.9 7.5/1.3 T8 25 7.5<br />

F 59’-0” 18 H 184.1 T9 30 9.5<br />

G 77’-1” 23.5 J 143.6 TA 40 12<br />

H 100’-0” 30.5<br />

J 131’-2” 40<br />

K 159’-1” 48.5<br />

14 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

Load Contactor Inverter<br />

Suspension Drum <strong>Rope</strong><br />

Duty Rating<br />

Control Control<br />

Ton Kg L D D D N F J HOL Gear Motor Speed Motor Speed<br />

ASME FEM/ISO<br />

Hoist<br />

Reeving<br />

H 0 W Code<br />

ft m Code<br />

Type Ratio code fpm m/min code fpm m/min<br />

20 20000 <strong>SX</strong>6 061 0 N F C 16’-4” 5 L E 344.9 P6 10/1.5 3/0.5 T6 10 3<br />

H4+ 3m/M6 D 22’-11” 7 F 269.1 P6 13/2 4/0.6 T6 13 4<br />

E 29’-6” 9 G 223.1 P7 16/2.4 4.8/0.8 T7 16 4.8<br />

F 39’-4” 12 H 184.1 T8 20 6<br />

G 50’-10” 15.5 J 143.6 T9 25 7.5<br />

H 65’-7” 20<br />

J 86’-11” 26.5<br />

K 105’-0” 32<br />

25 25000 <strong>SX</strong>6 061 0 N F C 16’-4” 5 L E 344.9 P6 10/1.5 3/0.5 T6 10 3<br />

H4 2m/M5 D 22’-11” 7 F 269.1 P6 13/2 4/0.6 T6 13 4<br />

E 29’-6” 9 G 223.1 P7 16/2.4 4.8/0.8 T7 16 4.8<br />

F 39’-4” 12 H 184.1 T8 20 6<br />

G 50’-10” 15.5 J 143.6 T9 25 7.5<br />

H 65’-7” 20<br />

J 86’-11” 26.5<br />

K 105’-0” 32<br />

30 30000 <strong>SX</strong>6 061 0 N F C 16’-4” 5 L E 344.9 P6 10/1.5 3/0.5 T6 10 3<br />

H3 1Am/M4 D 22’-11” 7 F 269.1 P7 13/2 4/0.6 T7 13 4<br />

E 29’-6” 9 G 223.1 P8 16/2.4 4.8/0.8 T8 16 4.8<br />

F 39’-4” 12 H 184.1 T9 20 6<br />

G 50’-10” 15.5 J 143.6 TA 25 7.5<br />

H 65’-7” 20<br />

J 86’-11” 26.5<br />

K 105’-0” 32<br />

30 32000 <strong>SX</strong>6 081 0 N F E 22’-11” 7 L E 344.9 P6 8/1.2 2.4/0.4 T6 8 2.4<br />

H4 2m/M5 F 29’-6” 9 F 269.1 P7 10/1.5 3/0.5 T7 10 3<br />

G 37’-8” 11.5 G 223.1 T8 13 4<br />

H 49’-2” 15 H 184.1 T9 16 4.8<br />

J 65’-7” 20 J 143.6 TA 20 6<br />

K 78’-8” 24<br />

40 40000 <strong>SX</strong>6 081 0 N F E 22’-11” 7 L E 344.9 P6 8/1.2 2.4/0.4 T6 8 2.4<br />

H3 1Am/M4 F 29’-6” 9 F 269.1 P7 10/1.5 3/0.5 T7 10 3<br />

G 37’-8” 11.5 G 223.1 P8 13/2 4/0.6 T8 13 4<br />

H 49’-2” 15 H 184.1 T9 16 4.8<br />

J 65’-7” 20 J 143.6 TA 20 6<br />

K 78’-8” 24<br />

6 6300 <strong>SX</strong>6 022 0 N F E 54’-2” 16.5 G E 344.9 P6 30/4.9 9.5/1.6 T6 30 9.5<br />

H4+ 3m/M6 F 72’-2” 22 + F 269.1 P6 40/6.6 12/2 T6 40 12<br />

G 96’-9” 29.5 Gr G 223.1 P7 50/7.8 15/2.5 T7 50 15<br />

H 127’-11” 39 H 184.1 T8 60 19<br />

J 170’-7” 52 J 143.6 T9 80 24<br />

K 208’-4” 63.5<br />

L 252’-7” 77<br />

M 283’-10” 86.5<br />

N 321’-6” 98<br />

15 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

Load Contactor Inverter<br />

Suspension Drum <strong>Rope</strong><br />

Duty Rating<br />

Control Control<br />

Ton Kg L D D D N F J HOL Gear Motor Speed Motor Speed<br />

ASME FEM/ISO<br />

Hoist<br />

Reeving<br />

H 0 W Code<br />

ft m Code<br />

Type Ratio code fpm m/min code fpm m/min<br />

7 ½ 8000 <strong>SX</strong>6 022 0 N F E 54’-2” 16.5 G E 344.9 P6 30/4.9 9.5/1.6 T6 30 9.5<br />

H4 2m/M5 F 72’-2” 22 + F 269.1 P6 40/6.6 12/2 T6 40 12<br />

G 96’-9” 29.5 Gr G 223.1 P7 50/7.8 15/2.5 T7 50 15<br />

H 127’-11” 39 H 184.1 T8 60 19<br />

J 170’-7” 52 J 143.6 T9 80 24<br />

K 208’-4” 63.5<br />

L 252’-7” 77<br />

M 283’-10” 86.5<br />

N 321’-6” 98<br />

10 10000 <strong>SX</strong>6 022 0 N F E 54’-2” 16.5 G E 344.9 P6 30/4.9 9.5/1.6 T6 30 9.5<br />

H3 1Am/M4 F 72’-2” 22 + F 269.1 P7 40/6.6 12/2 T7 40 12<br />

G 96’-9” 29.5 Gr G 223.1 P8 50/7.8 15/2.5 T8 50 15<br />

H 127’-11” 39 H 184.1 T9 60 19<br />

J 170’-7” 52 J 143.6 TA 80 24<br />

K 208’-4” 63.5<br />

L 252’-7” 77<br />

M 283’-10” 86.5<br />

N 321’-6” 98<br />

12 ½ 12500 <strong>SX</strong>6 042 0 N F E 26'-3" 8 G E 344.9 P6 16/2.4 4.8/0.8 T6 16 4.8<br />

H4+ 3m/M6 F 36’-1” 11 + F 269.1 P6 20/3.1 6/1 T6 20 6<br />

G 47’-7” 14.5 Gr G 223.1 P7 25/3.9 7.5/1.3 T7 25 7.5<br />

H 64’-0” 19.5 H 184.1 T8 30 9.5<br />

J 85’-4” 26 J 143.6 T9 40 12<br />

K 103’-4” 31.5<br />

L 126’-4” 38.5<br />

M 141’-1” 43<br />

N 160’-9” 49<br />

15 16000 <strong>SX</strong>6 042 0 N F E 26'-3" 8 G E 344.9 P6 16/2.4 4.8/0.8 T6 16 4.8<br />

H4 2m/M5 F 36’-1” 11 + F 269.1 P6 20/3.1 6/1 T6 20 6<br />

G 47’-7” 14.5 Gr G 223.1 P7 25/3.9 7.5/1.3 T7 25 7.5<br />

H 64’-0” 19.5 H 184.1 T8 30 9.5<br />

J 85’-4” 26 J 143.6 T9 40 12<br />

K 103’-4” 31.5<br />

L 126’-4” 38.5<br />

M 141’-1” 43<br />

N 160’-9” 49<br />

20 20000 <strong>SX</strong>6 042 0 N F E 26'-3" 8 G E 344.9 P6 16/2.4 4.8/0.8 T6 16 4.8<br />

H3 1Am/M4 F 36’-1” 11 + F 269.1 P7 20/3.1 6/1 T7 20 6<br />

G 47’-7” 14.5 Gr G 223.1 P8 25/3.9 7.5/1.3 T8 25 7.5<br />

H 64’-0” 19.5 H 184.1 T9 30 9.5<br />

J 85’-4” 26 J 143.6 TA 40 12<br />

K 103’-4” 31.5<br />

L 126’-4” 38.5<br />

M 141’-1” 43<br />

N 160’-9” 49<br />

16 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

Load Contactor Inverter<br />

Suspension Drum <strong>Rope</strong><br />

Duty Rating<br />

Control Control<br />

Ton Kg L D D D N F J HOL Gear Motor Speed Motor Speed<br />

ASME FEM/ISO<br />

Hoist<br />

Reeving<br />

H 0 W Code<br />

ft m Code<br />

Type Ratio code fpm m/min code fpm m/min<br />

20 20000 <strong>SX</strong>6 062 0 N F E 18'-1" 5.5 H E 344.9 P6 10/1.5 3/0.5 T6 10 3<br />

H4+ 3m/M6 F 23’-0” 7 + F 269.1 P6 13/2 4/0.6 T6 13 4<br />

G 31’-2” 9.5 Hr G 223.1 P7 16/2.4 4.8/0.8 T7 16 4.8<br />

H 42’-8” 13 H 184.1 T8 20 6<br />

J 55’-9” 17 J 143.6 T9 25 7.5<br />

K 68’-11” 21<br />

L 83’-8” 25.5<br />

M 93’-6” 28.5<br />

N 106’-8” 32.5<br />

25 25000 <strong>SX</strong>6 062 0 N F E 18'-1" 5.5 H E 344.9 P6 10/1.5 3/0.5 T6 10 3<br />

H4 2m/M5 F 23’-0” 7 + F 269.1 P6 13/2 4/0.6 T6 13 4<br />

G 31’-2” 9.5 Hr G 223.1 P7 16/2.4 4.8/0.8 T7 16 4.8<br />

H 42’-8” 13 H 184.1 T8 20 6<br />

J 55’-9” 17 J 143.6 T9 25 7.5<br />

K 68’-11” 21<br />

L 83’-8” 25.5<br />

M 93’-6” 28.5<br />

N 106’-8” 32.5<br />

30 30000 <strong>SX</strong>6 062 0 N F E 18'-1" 5.5 H E 344.9 P6 10/1.5 3/0.5 T6 10 3<br />

H3 1Am/M4 F 23’-0” 7 + F 269.1 P7 13/2 4/0.6 T7 13 4<br />

G 31’-2” 9.5 Hr G 223.1 P8 16/2.4 4.8/0.8 T8 16 4.8<br />

H 42’-8” 13 H 184.1 T9 20 6<br />

J 55’-9” 17 J 143.6 TA 25 7.5<br />

K 68’-11” 21<br />

L 83’-8” 25.5<br />

M 93’-6” 28.5<br />

N 106’-8” 32.5<br />

30 32000 <strong>SX</strong>6 082 0 N F F 18'-1" 5.5 H E 344.9 P6 8/1.2 2.4/0.4 T6 8 2.4<br />

H4 2m/M5 G 23’-0” 7 + F 269.1 P7 10/1.5 3/0.5 T7 10 3<br />

H 31’-2” 9.5 Hr G 223.1 T8 13 4<br />

J 42’-8” 13 H 184.1 T9 16 4.8<br />

K 50’-10” 15.5 J 143.6 TA 20 6<br />

L 62’-4” 19<br />

M 70’-6” 21.5<br />

N 80’-5” 24.5<br />

40 40000 <strong>SX</strong>6 082 0 N F F 18'-1" 5.5 H E 344.9 P6 8/1.2 2.4/0.4 T6 8 2.4<br />

H3 1Am/M4 G 23’-0” 7 + F 269.1 P7 10/1.5 3/0.5 T7 10 3<br />

H 31’-2” 9.5 Hr G 223.1 P8 13/2 4/0.6 T8 13 4<br />

J 42’-8” 13 H 184.1 T9 16 4.8<br />

K 50’-10” 15.5 J 143.6 TA 20 6<br />

L 62’-4” 19<br />

M 70’-6” 21.5<br />

N 80’-5” 24.5<br />

17 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

Load Contactor Inverter<br />

Suspension Drum <strong>Rope</strong><br />

Duty Rating<br />

Control Control<br />

Ton Kg L D D D N F J HOL Gear Motor Speed Motor Speed<br />

ASME FEM/ISO<br />

Hoist<br />

Reeving<br />

H 0 W Code<br />

ft m Code<br />

Type Ratio code fpm m/min code fpm m/min<br />

12 ½ 12500 <strong>SX</strong>7 022 0 F F 50'-10" 15.5 K E 344.9 2 P6 32/4.6 9.6/1.4 2 T6 32 9.6<br />

H4+ 3m/M6 G 67’-3” 20.5 + F 269.1 2 P6 39/6.2 12/2 2 T6 39 12<br />

H 90’-2” 27.5 Kr G 223.1 2 P7 49/7.2 15/2.5 2 T7 49 15<br />

J 123’-0” 37.5 H 184.1 2 T8 63 19<br />

K 150’-11” 46 J 143.6 2 T9 78.7 24<br />

L 182’-5” 55.6<br />

M 205’-0” 62.5<br />

N 232’-11” 71<br />

15 16000 <strong>SX</strong>7 022 0 F F 50'-10" 15.5 K E 344.9 2 P6 32/4.6 9.6/1.4 2 T6 32 9.6<br />

H4 2m/M5 G 67’-3” 20.5 + F 269.1 2 P6 39/6.2 12/2 2 T6 39 12<br />

H 90’-2” 27.5 Kr G 223.1 2 P7 49/7.2 15/2.5 2 T7 49 15<br />

J 123’-0” 37.5 H 184.1 2 T8 63 19<br />

K 150’-11” 46 J 143.6 2 T9 78.7 24<br />

L 182’-5” 55.6<br />

M 205’-0” 62.5<br />

N 232’-11” 71<br />

20 20000 <strong>SX</strong>7 022 0 F F 50'-10" 15.5 K E 344.9 2 P6 32/4.6 9.6/1.4 2 T6 32 9.6<br />

H3 1Am/M4 G 67’-3” 20.5 + F 269.1 2 P7 39/6.2 12/2 2 T7 39 12<br />

H 90’-2” 27.5 Kr G 223.1 2 T8 49 15<br />

J 123’-0” 37.5 H 184.1 2 T9 63 19<br />

K 150’-11” 46<br />

L 182’-5” 55.6<br />

M 205’-0” 62.5<br />

N 232’-11” 71<br />

25 25000 <strong>SX</strong>7 042 0 F F 24’-7” 7.5 K E 344.9 2 P6 16/2.4 4.8/0.8 2 T6 16 4.8<br />

H4+ 3m/M6 G 32’-9” 10 + F 269.1 2 P6 20/3.1 6/1 2 T6 20 6<br />

H 44’-3” 13.5 Kr G 223.1 2 P7 25/4 7.5/1.3 2 T7 25 7.5<br />

J 60’-8” 18.5 H 184.1 2 T8 32 9.8<br />

K 75’-5” 23 J 143.6 2 T9 40 12<br />

L 90’-2” 27.5<br />

M 101’-8” 31<br />

N 116’-5” 35.5<br />

30 32000 <strong>SX</strong>7 042 0 F F 24’-7” 7.5 K E 344.9 2 P6 16/2.4 4.8/0.8 2 T6 16 4.8<br />

H4 2m/M5 G 32’-9” 10 + F 269.1 2 P6 20/3.1 6/1 2 T6 20 6<br />

H 44’-3” 13.5 Kr G 223.1 2 P7 25/4 7.5/1.3 2 T7 25 7.5<br />

J 60’-8” 18.5 H 184.1 2 T8 32 9.8<br />

K 75’-5” 23 J 143.6 2 T9 40 12<br />

L 90’-2” 27.5<br />

M 101’-8” 31<br />

N 116’-5” 35.5<br />

40 40000 <strong>SX</strong>7 042 0 F F 24’-7” 7.5 K E 344.9 2 P6 16/2.4 4.8/0.8 2 T6 16 4.8<br />

H3 1Am/M4 G 32’-9” 10 + F 269.1 2 P7 20/3.1 6/1 2 T7 20 6<br />

H 44’-3” 13.5 Kr G 223.1 2 T8 25 7.5<br />

J 60’-8” 18.5 H 184.1 2 T9 32 9.8<br />

K 75’-5” 23<br />

L 90’-2” 27.5<br />

M 101’-8” 31<br />

N 116’-5” 35.5<br />

18 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

Load Contactor Inverter<br />

Suspension Drum <strong>Rope</strong><br />

Duty Rating<br />

Control Control<br />

Ton Kg L D D D N F J HOL Gear Motor Speed Motor Speed<br />

ASME FEM/ISO<br />

Hoist<br />

Reeving<br />

H 0 W Code<br />

ft m Code<br />

Type Ratio code fpm m/min code fpm m/min<br />

40 40000 <strong>SX</strong>7 062 0 F F 16’-4” 5 L E 344.9 2 P6 10/1.6 3/0.5 2 T6 10 3<br />

H4+ 3m/M6 G 21’-3” 6.5 + F 269.1 2 P6 13/2 4/0.6 2 T6 13 4<br />

H 29’-6” 9 Lr G 223.1 2 P7 16/2.3 4.8/0.8 2 T7 16 4.8<br />

J 41’-0” 12.5 H 184.1 2 T8 20 6<br />

K 49’-2” 15 J 143.6 2 T9 25 7.5<br />

L 60’-8” 18.5<br />

M 67’-3” 20.5<br />

N 77’-1” 23.5<br />

50 50000 <strong>SX</strong>7 062 0 F F 16’-4” 5 L E 344.9 2 P6 10/1.6 3/0.5 2 T6 10 3<br />

H4 2m/M5 G 21’-3” 6.5 + F 269.1 2 P6 13/2 4/0.6 2 T6 13 4<br />

H 29’-6” 9 Lr G 223.1 2 P7 16/2.3 4.8/0.8 2 T7 16 4.8<br />

J 41’-0” 12.5 H 184.1 2 T8 20 6<br />

K 49’-2” 15 J 143.6 2 T9 25 7.5<br />

L 60’-8” 18.5<br />

M 67’-3” 20.5<br />

N 77’-1” 23.5<br />

60 60000 <strong>SX</strong>7 062 0 F F 16’-4” 5 L E 344.9 2 P6 10/1.6 3/0.5 2 T6 10 3<br />

H3 1Am/M4 G 21’-3” 6.5 + F 269.1 2 P7 13/2 4/0.6 2 T7 13 4<br />

H 29’-6” 9 Lr G 223.1 2 T8 16 4.8<br />

J 41’-0” 12.5 H 184.1 2 T9 20 6<br />

K 49’-2” 15<br />

L 60’-8” 18.5<br />

M 67’-3” 20.5<br />

N 77’-1” 23.5<br />

60 60000 <strong>SX</strong>7 082 0 F H 21’-3” 6.5 L E 344.9 2 P6 8/1.2 2.4/0.4 2 T6 8 2.4<br />

H4 2m/M5 J 29’-6” 9 + F 269.1 2 P6 10/1.6 3/0.51 2 T6 10 3<br />

K 36’-1” 11 Lr G 223.1 2 P7 13/2 4/0.6 2 T7 13 4<br />

L 44’-3” 13.5 H 184.1 2 T8 16 4.8<br />

M 50’-10” 15.5 J 143.6 2 T9 20 6<br />

N 57’-5” 17.5<br />

80 80000 <strong>SX</strong>7 082 0 F H 21’-3” 6.5 L E 344.9 2 P6 8/1.2 2.4/0.4 2 T6 8 2.4<br />

H3 1Am/M4 J 29’-6” 9 + F 269.1 2 P7 10/1.6 3/0.51 2 T7 10 3<br />

K 36’-1” 11 Lr G 223.1 2 T8 13 4<br />

L 44’-3” 13.5 H 184.1 2 T9 16 4.8<br />

M 50’-10” 15.5<br />

N 57’-5” 17.5<br />

19 RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® ®<br />

<strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967<br />

www.rmhoist.com<br />

January 2007<br />

5 Main Components - Hoist<br />

The hoist motor and gearbox, rope drum and the bottom block are the main hoist components.<br />

6 Hoist Motor<br />

c_homo1a<br />

c_r1hm1a<br />

6.1 Hoist Motor Features<br />

Squirrel cage motor<br />

Double windings for two-speed motor, 6:1 speed ratio<br />

Synchronous speed – See Motor Data<br />

IP55 protection<br />

Class F insulation<br />

Klixon type bimetal switch for thermal protection<br />

P1…P8 code designate standard two-speed hoist motors<br />

T1…TA code designate standard inverter hoist motors<br />

Power ratings – See Motor Data<br />

6.2 Optional Hoist Motor Features<br />

Standby heater (tropicalized protection is standard)<br />

IP66 protection<br />

Class H insulation<br />

1. Hoist motor<br />

2. Hoist gearbox<br />

3. Cover<br />

4. Rotary limit switch<br />

5. Gear guard<br />

6. Drum gear<br />

7. End plate<br />

A, B, C, D mounting bolts<br />

1. Fan cover<br />

2. Fan<br />

3. Inspection port<br />

4. Brake<br />

5. Brake Disc<br />

6. Mounting bolts<br />

7. Friction plate<br />

20 Bulletin: RM-<strong>SX</strong>-TG-SPEC-2001-8-ENG.doc

®<br />

R&M Materials Handling, Inc <strong>Spacemaster</strong> ® <strong>SX</strong> <strong>Wire</strong> <strong>Rope</strong> Hoist<br />

Springfield, Ohio USA Technical Guide<br />

: 800 955-9967 January 2007<br />

www.rmhoist.com<br />

6.3 Ambient Conditions<br />

The standard motor is designed for operation at a minimum ambient temperature –10°C to a maximum<br />

ambient temperature 40°C and maximum altitude of 1000 meters (3280 feet).<br />

6.4 P-Motors<br />

The alpha character P designates a standard two-speed hoist motor and the numeric character indicates<br />

power size.<br />

6.5 T-Motors<br />

The alpha character T designates a standard inverter-duty hoist motor and the numeric character that<br />

follows indicates power size. The inverter-duty motors are specially designed for use with a variable<br />

frequency drive.<br />

6.6 Motor Temperature Protection<br />

As standard, P or T type motor is equipped with normally closed, automatic reset thermal protector<br />

embedded in the stator winding(s).<br />

6.7 Motor Cooling<br />

The hoist motors have ribbed outer frames to maximize convection cooling. The motors are normally<br />

equipped with an integral cooling fan that is driven directly by the motor shaft. The shaft driven fan is only<br />

effective when the motor is energized. In severe environmental conditions, such as high ambient<br />

temperature, a blower fan replaces the shaft driven fan to improve the cooling.<br />

6.8 Hoist Motor Brake<br />