Series 90 Lighted Pushbutton Switches - Staco Systems

Series 90 Lighted Pushbutton Switches - Staco Systems

Series 90 Lighted Pushbutton Switches - Staco Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Series</strong> <strong>90</strong> <strong>Lighted</strong> <strong>Pushbutton</strong> <strong>Switches</strong>

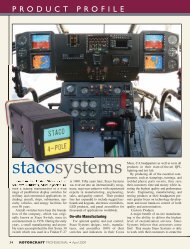

Company History<br />

<strong>Staco</strong> <strong>Systems</strong> has designed and manufactured switches since its commencement<br />

in 1958. During the early years, a small manufacturing and assembly team<br />

accomplished the first series 30 switch used in a Fokker F-27 in 1960. Fifty years<br />

later, <strong>Staco</strong> <strong>Systems</strong> has evolved into an internationally recognized, high-tech<br />

endeavor with numerous experienced experts in manufacturing, engineering,<br />

sales, and quality control. Our product line has expanded to include rugged<br />

keyboards and keypads, electronic controllers, and panel assemblies for<br />

hundreds of applications worldwide.<br />

Switch History<br />

1960 1962 1967 1978 1986<br />

<strong>Series</strong> 30, 1M<br />

Fokker F-27<br />

<strong>Series</strong> 40<br />

Lockheed P3<br />

Rotary <strong>Switches</strong><br />

Douglas DC-7B<br />

<strong>Series</strong> 30, 40, 60,<br />

1M<br />

Boeing E-3A<br />

<strong>Series</strong> 93, 99<br />

British Aerospace<br />

Hawk 200<br />

1988 1989 1991 1996 Today<br />

<strong>Series</strong> 97 Matrix<br />

Northrop B2<br />

<strong>Series</strong> 80, <strong>90</strong><br />

Aeritalia AMX<br />

<strong>Series</strong> <strong>90</strong><br />

Boeing E-8C<br />

Lockheed F-22<br />

<strong>Series</strong> 93<br />

British Aerospace<br />

Nimrod 2000<br />

Full Sub-Assembly<br />

Capabilities

CONTENTS<br />

Product Line Overview ................................................................................................................................................2<br />

Quick Reference Guide .........................................................................................................................................3<br />

Figure & Table Listings ..........................................................................................................................................4<br />

Individual Mount ..........................................................................................................................................................5<br />

Individual Mount, PC or Solder, Switch/Indicators ................................................................................................5<br />

Display <strong>Pushbutton</strong> ...............................................................................................................................................6<br />

Mounting Procedure - Individual Mount, Crimp or Solder ...................................................................................11<br />

Dimensions - Switch/Indicator, <strong>Pushbutton</strong> .........................................................................................................12<br />

Individual Mount, Crimp Pin, Switch/Indicators ...................................................................................................13<br />

Dimensions - Switch/Indicator .............................................................................................................................14<br />

Seals - Watertight & Solvent Resistant ...............................................................................................................18<br />

Matrix Mount ..............................................................................................................................................................21<br />

Matrix Housing Assemblies .................................................................................................................................21<br />

Matrix Assembly Exploded Views .......................................................................................................................23<br />

Dimensions - Rear Flange Mount Matrix Housing ..............................................................................................25<br />

Dimensions - Front Dress Bezel Matrix Housing ................................................................................................28<br />

Product Design and Engineering Data ......................................................................................................................31<br />

Military and Environmental Specifications ...........................................................................................................31<br />

Electrical and Mechanical Data ...........................................................................................................................33<br />

Display System ....................................................................................................................................................35<br />

Incandescent and LED Circuits and Lighting Control .........................................................................................35<br />

LED Schematics ..................................................................................................................................................36<br />

Legends ...............................................................................................................................................................39<br />

Sunlight Readable Displays ................................................................................................................................40<br />

Night Vision Imaging System Displays................................................................................................................41<br />

Materials and Quality Standards .........................................................................................................................43<br />

Military Cross Reference ...........................................................................................................................................44<br />

MIL-22885/101 ....................................................................................................................................................44<br />

MIL-22885/112.....................................................................................................................................................47<br />

Tables ........................................................................................................................................................................50<br />

Accessories and Other <strong>Staco</strong> <strong>Systems</strong> Products .....................................................................................................59<br />

Ordering Information .................................................................................................................................................63<br />

Model 91 and 92 .................................................................................................................................................63<br />

Model 93 ..............................................................................................................................................................64<br />

Model 98 ..............................................................................................................................................................64<br />

Model 99 ..............................................................................................................................................................64<br />

Seals ...................................................................................................................................................................66<br />

Front Dress Bezel Mount ....................................................................................................................................66<br />

Rear Flange Mount .............................................................................................................................................67<br />

Complete <strong>Systems</strong> ..............................................................................................................................................67<br />

All information in this catalog is effective on the publication date and is subject to change without notice.<br />

All printing and clerical errors are subject to correction.<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

1

OVERVIEW<br />

The <strong>Staco</strong> <strong>Systems</strong> <strong>Series</strong> <strong>90</strong> is a broad product line of lighted pushbutton switches and indicators. This catalog<br />

identifies performance features and options, gives specifications and engineering data, and provides ordering<br />

information.<br />

These manually operated, illuminated switch/indicator and pushbutton assemblies are identified as Models 91, 92,<br />

93, 98, and 99.<br />

The <strong>Series</strong> <strong>90</strong> Matrix Housing Assemblies, which utilize these switches and indicators, are identified as Models<br />

94, 95, 96 and 97.<br />

This product line meets the general requirements of MIL-S-22885, MIL-STD-3009, and, in matrix form,<br />

MIL-S-24317. It specifically meets the requirements of MIL-S-22885/101and MIL-S-22885/112.<br />

2<br />

SERIES <strong>90</strong><br />

<strong>Lighted</strong> Display <strong>Pushbutton</strong> <strong>Switches</strong> and Indicators<br />

• Individual Mount or Matrix Mount<br />

• Light Weight, Short Length<br />

• LED or Incandescent Lighting<br />

• Sunlight Readable Displays<br />

• Night Vision Goggle Compatible Displays<br />

• Standard <strong>Lighted</strong> Displays<br />

• Numerous Switching Options<br />

• Popular Termination Styles<br />

• Dripproof, Splashproof, Watertight (Immersion) Seal, and Solvent<br />

Resistant Options<br />

• Qualified to MIL-PRF-22885/101 for Incandescent Lighting<br />

•<br />

Qualified to MIL-PRF-22885/112 for High Bright LED Lighting and Short<br />

Crimp Pin Termination.<br />

• Meets or Exceeds All Applicable MIL-SPEC Requirements<br />

• High Impact Shock in Accordance with MIL-S-<strong>90</strong>1

QUICK REFERENCE<br />

SWITCHES AND INDICATORS<br />

MODEL DESCRIPTION TERMINATION REFERENCE INFORMATION<br />

91 Switch or indicator assembly Solder or PCB pp. 5,11, 63<br />

(without pushbutton) mount fig. 1-4<br />

in short housing<br />

92 Display pushbutton assembly Into Models pp. 6, 7, 8, 9, 10, 63<br />

91 or 98 fig. 5-14<br />

93 Switch or indicator assembly Solder or PCB pp. 12, 64, 65<br />

with pushbutton in mount fig. 15-21<br />

short housing<br />

98 Switch or indicator (without Crimp pin pp. 13, 14, 15, 16 17, 64<br />

pushbutton) in long housing<br />

99 Switch or indicator with Crimp pin pp. 13, 14, 15, 16, 17, 63, 64<br />

pushbutton in long housing fig. 22-37<br />

MATRIX HOUSINGS<br />

MODEL DESCRIPTION TERMINATION REFERENCE INFORMATION<br />

94 Rear flange mount Solder or PCB pp. 21-22, 25-27, 30<br />

short housing mount fig. 43, 46-49, 59-60<br />

95 Rear flange mount Crimp pin pp. 21-27, 29, 67<br />

long housing fig. 42, 45-49, 59-60<br />

96 Front dress bezel mount Solder or PCB pp. 21-23, 28-30, 66<br />

short housing mount fig. 40, 50, 53-54, 59-60<br />

97 Front dress bezel mount Crimp pin pp. 21-22, 28-30, 66<br />

long housing fig. 51-55, 59-60<br />

SPECIAL PART NUMBERS<br />

PART NUMBER DESCRIPTION PART NUMBER DESCRIPTION<br />

92PXXXX Unique pushbutton with special 94/XXXX<br />

artwork or other non-standard<br />

design requirements.<br />

63XXXX Standard switch with a 92P 95/XXXX Matrix assembly. <strong>Staco</strong> <strong>Systems</strong><br />

pushbutton and switches with assigned code for special despecial<br />

marking or construction. tailed requirements. Includes<br />

housing, switch, pushbutton<br />

15XXX Accessories 96/XXXX and any other special features.<br />

<strong>90</strong>/005 Immersion Seal/High Impact<br />

<strong>90</strong>/006 Shock option. Applicable to 97/XXXX<br />

models 91, 92, 93, 98 and 99.<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

3

4<br />

Figure Listing<br />

Fig. Pg. Description<br />

1 5 Switch schematics, SPDT and DPDT<br />

2 5 Printed circuit board or solder terminals<br />

3 5 Terminal identification<br />

4 5 PCB layout dimensions<br />

5A 7 Incandescent pushbutton types 2, 3, 4, 5, 8, or 9<br />

5B 8 Incandescent pushbutton types 1, 6, 7, or 0<br />

6 8 LED pushbutton display<br />

7 8 Replaceable legend plates, type 8, 9, or 0<br />

8 9 Incandescent lighting schematics<br />

9 9 Typical 5 volt LED circuit diagram<br />

10 9 Typical 28 volt LED circuit diagram<br />

11 10 LED lighting, current sourcing<br />

12 10 LED lighting, current sinking<br />

13 10 CIE chromaticity diagram, incandescent colors<br />

14 10 CIE chromaticity diagram, NVIS compatible colors<br />

15 11 Slot mounting panel cut out<br />

16 12 Dimensions - model 93, flush mount<br />

17 12 Dimensions - model 93, flush mount w/ panel seal<br />

18 12 Dimensions - model 93, extended mount unsealed<br />

19 12 Dimensions - model 93, extended mount w/ panel seal<br />

20 12 Dimensions - model 93, extended mount unsealed<br />

21 12 Dimensions - model 93, matrix mount w/ panel seal<br />

22 14 Model 99 switch/indicator exploded view, long crimp<br />

23 14 Dimensions - Model 99, flush mount<br />

24 14 Dimensions - Model 99, flush mount w/ panel seal<br />

25 15 Dimensions - Model 99, extended mount<br />

26 15 Dimensions - Model 99, extended mount w/ panel seal<br />

27 15 Switch Indicator<br />

28 15 Mounting screw location<br />

29 15 Panel cut out<br />

30 16 Model 99 switch/indicator exploded view, short crimp<br />

31 16 Dimensions - Model 99, flush mount<br />

32 16 Dimensions - Model 99, flush mount w/ panel seal<br />

33 17 Dimensions - Model 99, extended mount<br />

34 17 Dimensions - Model 99, extended mount w/ panel seal<br />

35 17 Switch/indicator assembly<br />

FIGURE & TABLE LISTINGS<br />

Table Listing<br />

Tbl. Pg. Description<br />

1 50 Terminations, circuitry and contact material<br />

2 51 Switch action and pushbutton retainer<br />

3 53 EMI/RFI and sealing<br />

4 53 Incandescent or LED, ground operations and EMI/RFI<br />

5 54 Display style and character definition<br />

6A 55 Incandescent lamp selection and sealing<br />

6B 56 LED configuration and sealing<br />

7 56 Display type<br />

8 57 Cell color<br />

Figure Listing<br />

Fig. Pg. Description<br />

36 17 Receptacle Assembly<br />

37 17 Mounting Screw Location<br />

38 18 Watertight seal dimensions<br />

39 20 <strong>Pushbutton</strong> guard for watertight seal<br />

40 23 Matrix assembly with direct to switch terminations<br />

41 23 Matrix assembly with long crimp pin terminations<br />

42 24 Matrix assembly with short crimp terminations<br />

43 25 Rear flange mount, solder or PCB termination<br />

44 25 Rear flange mount, crimp pin termination<br />

45 26 Rear flange mount, short crimp pin termination<br />

46 27 Rear flange mount, horizontal flanges, unsealed<br />

47 27 Rear flange mount, vertical flanges, unsealed<br />

48 27 Rear flange mount, horizontal flanges, unsealed<br />

49 27 Rear flange mount, four flanges, sealed or unsealed<br />

50 28 Front dress bezel mount, solder or PCB termination<br />

51 29 Front dress bezel mount, long crimp pin termination<br />

52 29 Front dress bezel mount, short crimp pin termination<br />

53 30 Front dress bezel mounting, minimum spacing<br />

54 30 Front dress bezel, mounting cleat assembly<br />

55 30 Front dress bezel, mounting cleat requirements<br />

56 36 LED Voltage Dimming Curve<br />

57 37 5 volt LED circuit schematics<br />

58 38 28 volt Led circuit schematics<br />

59 67 Ordering <strong>Systems</strong><br />

60 67 Ordering <strong>Systems</strong><br />

9 57 Rear flange mount dimensions and panel cutouts<br />

10 58 Front dress bezel mount dimensions and panel cutouts

INDIVIDUAL MOUNT SWITCH/INDICATORS<br />

Switch/Indicator Options<br />

<strong>Switches</strong> are available with SPDT or DPDT circuitry, momentary or<br />

alternate switch action, silver or gold contacts, EMI/RFI shielding,<br />

sealed or unsealed, immersion seal/high shock, and a choice of<br />

solder, printed circuit, or crimp pin terminations. Matching indicators<br />

are also available.<br />

Switch Schematics<br />

Terminals 5 & 7 are Normally Closed (NC).<br />

Terminals 1 & 4 are Normally Open (NO).<br />

Terminals 8 & 10 are Common (C).<br />

For indicator, omit Terminals 1, 4, 5, 7, 8 & 10.<br />

See Figure 8, for lamp circuit schematics.<br />

PC or Solder Terminals<br />

Figure 2<br />

Terminal Identification<br />

Figure 3<br />

PCB Layout Dimensions<br />

Terminal pattern shown above depicts switch terminal<br />

dimensions as viewed from rear of the switch, and shows<br />

all pin diameters and spacing. It is not a circuit board<br />

layout. When laying out the circuit board, hole sizes and<br />

spacing must accommodate the switch terminals and<br />

manufacturing tolerance conditions. Holes not required for<br />

omitted terminals.<br />

REAR VIEW OF<br />

SWITCH HEADER<br />

Figure 4<br />

.040 .001 DIA PIN<br />

(1.02 .03) 12 PLACES<br />

.367<br />

(9.32)<br />

.520<br />

(13.21)<br />

.138<br />

(3.51)<br />

Figure 1<br />

CENTERLINE<br />

OF HEADER<br />

.091<br />

(2.31)<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

2<br />

11<br />

9<br />

.262<br />

(6.65)<br />

.524<br />

(13.31)<br />

.360<br />

(9.14)<br />

.164<br />

(4.17)<br />

5<br />

1<br />

4<br />

8 10<br />

6<br />

.152<br />

(3.86)<br />

7 3<br />

.325<br />

(8.26) .428<br />

(10.87)<br />

12<br />

CENTERLINE<br />

OF HEADER<br />

.513<br />

(13.03)<br />

.260<br />

(6.60)<br />

5

6<br />

SERIES <strong>90</strong> DISPLAY PUSHBUTTON<br />

LED or Incandescent Illumination<br />

Incandescent display pushbuttons accept four T-1 midget flange based<br />

lamps that may be easily serviced from the front mounting panel. The<br />

display pushbutton is also available with a serviceable High Bright LED<br />

light plate, which provide an extended service life. Low power consumption<br />

of the LEDs, as well as the heat sink capabilities of the switch/<br />

indicator assembly, result in a pushbutton that is cool to the touch.<br />

Standard <strong>Lighted</strong> Display<br />

INCANDESCENT LED<br />

Ten Display Types Seven Display Types<br />

Eight Standard Colors Six Standard Colors<br />

Four NVG Colors Seven NVG Colors<br />

Eight Display Styles Eight Display Styles<br />

Five Legend Heights Five Legend Heights<br />

There are ten display types offering a combination of legend characters<br />

or background illumination color. LED configurations are available<br />

in seven types. Designer matched colors enhance display appearance<br />

and contribute to increased operator attention and efficiency.<br />

Graphic designs and custom legend heights in these ten display types<br />

are available. Display styles include full-screen displays, two-way, three-way and four-way split screen displays.<br />

Each of these sections may have its own color and be lighted independently of the others.<br />

Night Vision Goggle Compatibility<br />

Display certification of Night Vision Imaging System (NVIS) compatibility per the requirements of MIL-<br />

STD-3009. Unique lighting capabilities of the <strong>Series</strong> <strong>90</strong> provide display<br />

legends that are fully qualified for both Type I Class A and Type II Class B<br />

night vision goggles. Legends with incandescent lighting are available in<br />

four colors, NVIS Green A, NVIS Green B, NVIS Yellow, and NVIS Red,<br />

all qualified to MIL-STD-3009. LED based units provide NVG compatibility<br />

with NVIS Green B, NVIS Yellow and NVIS Red NVIS Blue and<br />

NVIS White. Trimmed to low level for night operations, the legends are<br />

sharp and clear with no glare or hot spots, and are not detrimental to<br />

darkness adaptation for unaided eye visual monitoring outside the crew<br />

station. For incandescent configurations and white LED-based pushbuttons,<br />

sunlight readable legends and NVG compatibility are combined in<br />

the same pushbutton display.

Sunlight Readable Display<br />

SERIES <strong>90</strong> DISPLAY PUSHBUTTON<br />

Illuminated sunlight readable legend is clearly legible in 10,000 footcandle ambient light. When not lighted, the<br />

legend is not readable when viewed in the same ambient light.<br />

<strong>Staco</strong> <strong>Systems</strong>'s sunlight readable displays are clearly legible in direct sunlight eliminating the problem of loss of<br />

legend legibility due to reflection of bright ambient light ... the equivalent of direct sunlight at 70,000 feet altitude.<br />

When the display’s dead-front face is unlit, the legend is indiscernible. The display has a viewing angle of an<br />

80°cone perpendicular to the viewing surface. All lighting measurements are made in <strong>Staco</strong> <strong>Systems</strong>'’s in-plant Mil<br />

certified light laboratory. Certification is performed photometrically per the exacting requirements of MIL-S-22885.<br />

Typical <strong>Pushbutton</strong> Display<br />

Choice of seven factory installed Display Types or three customer<br />

assembled and installed Display Types. (See Table 7). All are available<br />

with choice of eight Display Styles (Table 5 ). A color filter, in a choice of<br />

eight designer proven colors (Table 8), goes over each of the four lamps.<br />

Display Type Codes 2, 3, 4, 5, 8 or 9<br />

Configuration shown applies to Type Codes 2, 3, 4, 5, 8 or 9<br />

Figure 5A<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

7

8<br />

SERIES <strong>90</strong> DISPLAY PUSHBUTTON<br />

Display Type Codes 1, 6, 7, or 0<br />

Configuration shown applies to Type Codes 1, 6, 7,or 0<br />

Figure 5B<br />

Typical LED <strong>Pushbutton</strong> Display<br />

Figure 6<br />

Replaceable Legend Plates<br />

For those applications where the customer wishes<br />

to provide or replace legend plates, an alternative<br />

assembly is available in three display styles for use<br />

only with the T-1 flange based lamp pushbutton.<br />

These are similar to factory installed Type 2, Type 5<br />

and Type 6 Displays.<br />

Display Types 8, 9 and 0, consisting of a customer<br />

supplied legend plate stacked between the factory<br />

supplied face screen and diffuser plate, may be substituted<br />

for the standard bonded face plate assembly<br />

in the T-1 lamp pushbuttons. Display Types 9 and<br />

0 replaceable legends are available for LED pushbuttons.<br />

(See Table 7). The usable legend area is<br />

.520” square. Overall size of the face screen is<br />

.575” square with a viewing area of .495” square.<br />

Customer installed legends may not be of equal quality<br />

as compared to the laminated factory installed<br />

assemblies.<br />

SERVICEABLE LED LAMP MODULE<br />

Figure 7

Incandescent Lamp Grounds<br />

Three types of incandescent lamp circuits are available. The schematics<br />

are shown in Figure 8 and the ordering codes in Table 4.<br />

The “Common Lamp Ground” configuration is used when the power<br />

for the display is from a single power bus. “Vertically Split” and<br />

“Horizontally Split” Lamp Grounds allow the use of two power sources<br />

to illuminate the display of a given pushbutton. It should be noted<br />

that the specific lamp circuit option which is utilized is totally independent<br />

of the display style (i.e., full screen, 2-way, 3-way or 4-way<br />

splits) of Table 5.<br />

SERIES <strong>90</strong> DISPLAY PUSHBUTTON<br />

Typical 5 Volt LED Circuit Diagram<br />

Single Common<br />

Circuit Rear View<br />

Figure 9<br />

LED Lighting<br />

Split Common<br />

Circuit Rear View<br />

Single Common<br />

Circuit Rear View<br />

Figure 10<br />

Front View Front View<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

COMMON LAMP GROUND<br />

VERTICAL SPLIT LAMP GROUND<br />

HORIZONTAL SPLIT LAMP GROUND<br />

Split Common<br />

Circuit Rear View<br />

LED displays may be configured as either “current sourcing” or “<br />

current sinking.” Simplified control circuits for each are shown in Figures 11 and 12. Application information is provided<br />

in the Product Design and Engineering Data section. Brightness control and schematics for all 5 and 28 volt<br />

LED display pushbuttons are also provided there. Voltage dimming is an option with 28 volt versions.<br />

Figure 8<br />

Typical 28 Volt LED Circuit Diagram<br />

9

Display <strong>Pushbutton</strong> Colors<br />

SERIES <strong>90</strong> DISPLAY PUSHBUTTON<br />

LED LIGHTING CONTROLS<br />

Typical Current Sourcing Application<br />

Figure 11 Figure 12<br />

Colors are described by the international standard method of coordinates on CIE chromaticity diagrams. Figure<br />

13 represents the colors available for <strong>Series</strong> <strong>90</strong> incandescent configurations plotted in terms of x-y coordinate<br />

areas on the 1931 CIE chart. These colors include the seven colors of MIL-S-22885/101C (red, aviation yellow,<br />

white, lunar white, blue and aviation green) plus lemon yellow.<br />

Night Vision Imaging System colors are plotted in the U’-V’ coordinates of 1976 CIE chart of figure 14. All four of<br />

the colors defined in MIL-STD-3009 are available in incandescent displays. LED applications may use green B,<br />

yellow and red. When ordering, colors are selected from Table 8.<br />

10<br />

Typical Current Sinking Application<br />

Figure 13 – Incandescent colors Figure 14 – NVIS Compatible colors

Mounting Procedure<br />

SERIES <strong>90</strong> DISPLAY PUSHBUTTON<br />

1. Remove pushbutton from switch/indicator assembly by pulling straight out. Use tool # 151<strong>90</strong> for easier removal.<br />

2. Rotate locking screws inside front of switch/indicator assembly counter clockwise with a small screwdriver.<br />

This will release mounting cams.<br />

3. Slide mounting sleeve and panel spacer off of the switch/indicator assembly.<br />

4. Install switch/indicator assembly through panel cut-out from front of panel. Assembly is marked with word “TOP”<br />

to help properly orient position of the assembly in the panel.<br />

5. Replace panel spacer and mounting sleeve.<br />

6. Rotate locking screws clockwise to bring mounting cams to lock position. Recommended mounting torque is 10±2<br />

oz. in. (0.071+ 0.014Nm).<br />

7. Be certain that pushbutton has lamps or dummy lamps installed in all four positions before inserting into mating<br />

switch/indicator assembly.<br />

8. To Insert the pushbutton properly, be sure that the index post is at the top and that the pushbutton is held square<br />

to the switch housing.<br />

9. The two panel spacers, together with the mounting sleeve, provide various options for fitting the switch/ indicator<br />

assembly to mounting panels with thicknesses ranging from essentially zero to a maximum of about .75” (see<br />

dimensional drawings for exact thickness for each configuration).<br />

10. For extended mounting of the assembly, as in conjunction with edge-lit panels, the black panel spacer is left<br />

installed on the assembly before it is inserted in the panel cut-out so as to be in front of the panel when<br />

installation is complete.<br />

11. On sealed switch/indicator assemblies mounted flush, the panel seal is installed under the housing flange and on<br />

the front of the panel. On the extended mount sealed units, the panel seal is place between the panel spacer<br />

and the front the panel. (Refer to dimensional drawings.)<br />

Slot Mounting Panel Cut Out<br />

Mounting Cam<br />

Mounting Sleeve<br />

HORIZONTAL OR VERTICAL SLOT CUT-OUT FOR MODEL 93 OR<br />

MODEL 99 SWITCH/INDICATOR WITH PUSHBUTTON ASSEMBLY<br />

For those applications where horizontal or vertical slot<br />

mounting of two or more individual mount switch/indicators<br />

is required, the formula above provides cut-out dimensions<br />

for the slot.<br />

L = Length of horizontal mounting slot (or height of vertical)<br />

n = Number of units in a row<br />

Panel Spacers<br />

Index Post<br />

<strong>Pushbutton</strong> Assembly with Lamps<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

Figure 15<br />

11

Flush Mount Unsealed<br />

Extended Mount Unsealed<br />

Matrix Mount Unsealed<br />

12<br />

DIMENSIONS – MODEL 93<br />

Flush Mount With Panel Seal<br />

Figure 16 Figure 17<br />

Extended Mount With Panel Seal<br />

Figure 18 Figure 19<br />

Matrix Mount With Panel Seal<br />

Figure 20 Figure 21

Crimp Pin Termination<br />

MODEL 99 SWITCH/INDICATOR<br />

Reduced wiring time with increased reliability - <strong>Staco</strong> <strong>Systems</strong>'s Model<br />

98 Switch/Indicator and the Model 99 Switch/Indicator and Display<br />

<strong>Pushbutton</strong>, offer individually mounted units with crimp pin termination<br />

receptacles. These units provide the advantage of fast and easy wiring<br />

as well as quick and simple post installation maintenance. The crimp<br />

pin terminals and the termination receptacle, may be removed from<br />

switch/indicator. All soldering is eliminated, greatly reducing installation<br />

time. Termination receptacles may also be prewired for connection after<br />

switch/indicator assemblies have been installed. The crimp pin terminals<br />

and associated installation tools are all military standard parts to assure<br />

wide availability and high reliability.<br />

Connecting wires, with socket contact crimp pins, are shown inserted in the switch/indicator termination recep-<br />

tacle. Wires can be removed and replaced individually, or the termination receptacle, with all wires left in place,<br />

can be removed and replaced as a single unit.<br />

Switch/Indicator Options<br />

Model 98 and 99 assemblies with crimp pin termination receptacles are available with SPDT or DPDT circuitry,<br />

momentary or alternate switch action, silver or gold contacts, EMI/RFI shielding, with or without moisture sealing<br />

and with the optional Immersion Seal/High Impact Seal/Solvent Resistant Seal. Matching Indicators are also<br />

available.<br />

Display <strong>Pushbutton</strong> Options<br />

Model 92 lighted display pushbutton is used with both the Model 93 and Model 99 Switch/Indicator with<br />

<strong>Pushbutton</strong> assembly. The same illumination and display options are available for both the Model 93 and Model<br />

99 Assemblies.<br />

Assembly<br />

Model 99 assembly is comprised of a termination receptacle, a switch/indicator body, and a display pushbutton.<br />

The termination receptacle and/or individual wires and the pushbutton can be removed for servicing and<br />

replaced without disturbing the switch/indicator installed in a control panel.<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

13

14<br />

MODEL 99 SWITCH/INDICATOR - LONG CRIMP PIN<br />

Exploded View<br />

Figure 22<br />

DIMENSIONS – MODEL 99 - LONG CRIMP PIN<br />

Flush Mount Unsealed Flush Mount With Panel Seal<br />

Figure 23<br />

Figure 24

DIMENSIONS – MODEL 99 - LONG CRIMP PIN<br />

Extended Mount Unsealed<br />

Switch/Indicator Assembly<br />

Model 9816 through 9820 assembly<br />

Receptacle<br />

Assembly<br />

(MIL-C-3<strong>90</strong>29/16-168)<br />

Extended Mount With Panel Seal<br />

Figure 25 Figure 26<br />

Figure 27<br />

Figure 29<br />

Panel Cut Out<br />

Mounting Screw Location<br />

VIEW FROM FRONT OF PANEL<br />

Figure 28<br />

Visit www.stacosystems.com or call 714-549-3041 for more information 15

16<br />

MODEL 99 SWITCH/INDICATOR - SHORT CRIMP PIN<br />

Exploded View<br />

Flush Mount Unsealed Flush Mount With Panel Seal<br />

Figure 31<br />

Figure 30<br />

DIMENSIONS – MODEL 99 - SHORT CRIMP PIN<br />

Figure 32

DIMENSIONS - MODEL 99 - SHORT CRIMP PIN<br />

Extended Mount Unsealed<br />

Switch/Indicator Assembly<br />

Model 9821 through 9825 assembly<br />

Figure 37<br />

Extended Mount With Panel Seal<br />

Figure 33 Figure 34<br />

Figure 35<br />

Mounting Screw Location<br />

(18.92)<br />

Receptacle Assembly<br />

(MIL-C-3<strong>90</strong>29/22-192)<br />

Figure 36<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

VIEW FROM FRONT<br />

OF PANEL<br />

17

WATERTIGHT SEAL<br />

The Watertight Seal is part of the <strong>Staco</strong> <strong>Systems</strong> <strong>Series</strong> <strong>90</strong> fam-<br />

ily of illuminated pushbutton switches and indicators. It is covered<br />

by MIL-S-22885/112. Assemblies incorporating this seal can be<br />

ordered as an option to the <strong>Series</strong> <strong>90</strong>.<br />

This Watertight Seal is a flexible elastomeric boot which is an inte-<br />

gral part of the pushbutton and provides a seal at the front panel.<br />

The flexible nature of the seal allows actuation of the switch under<br />

three feet of water while still sealing against leakage through the<br />

switch or panel opening.<br />

This same seal performs as a Splashproof Seal to protect against<br />

washdowns using directed streams of water.<br />

The seal is intended to protect the switch/indicator, as well as the behind-the-panel areas, against elements such<br />

as rain, fog, snow, salt spray, sand and dust.<br />

The watertight seal also insures that the pushbutton remains attached to the switch under high impact shock con-<br />

ditions (approximately 1,500 Gs). The combination of pushbutton with watertight seal will remain attached to the<br />

switch when tested per MIL-S-<strong>90</strong>1 for Class I and Class II equipment.<br />

Panel Spacing of switches or indicators with watertight seals installed is 1.06 inches (26.9 mm) minimum center<br />

to center horizontally or vertically. If the <strong>Pushbutton</strong> Guard (Assembly 15204/005) is to be installed, the minimum<br />

horizontal center to center spacing is 1.40 inches (35.6 mm).<br />

Dimensions<br />

18<br />

Figure 38

Watertight Seal Specifications<br />

WATERTIGHT SEAL<br />

When properly assembled and installed the Watertight Seal<br />

will perform to the following requirements.<br />

Temperature Storage 65°C to +95°C;<br />

Operating 55°C to +85°C<br />

Thermal Shock -55°C to +85°C per MIL-STD-202, Method 107,<br />

Test Condition A<br />

Vibration 15 Gs, 10 to 2 kHz per MIL-STD-202, Method 204,<br />

Test Condition B<br />

Shock, Standard 75 G’s per MIL-STD-202, Method 213 Test Condition B<br />

Shock, High Impact Per MIL-S-<strong>90</strong>1, Class II - no damage or contact transfers.<br />

Per MIL-S-<strong>90</strong>1, Class I - no damage and no parts come<br />

adrift but electrical contacts may transfer until reactuated.<br />

Splashproof, Sealed Per MIL-S-22885, para. 4.8.20.1,and MIL-STD-108,<br />

para. 4.9 when Watertight Seal installed.<br />

Watertight, Sealed Per MIL-S-22885, para. 4.8.20.2, and MIL-STD-108, para. 4.13<br />

(3 feet of water, 1.3 psi) when Watertight Seal installed.<br />

Dripproof, Sealed Per MIL-S-22885, para. 4.8.20.3, and MIL-STD-108,<br />

para. 4.3, when Watertight Seal installed.<br />

Salt Spray Per MIL-STD-202, Method 101, Test Condition B.<br />

No evidence of excessive corrosion.<br />

Sand and Dust Per MIL-STD-202, Method 110,<br />

Test Condition B and MIL-S-22885.<br />

Solvent Resistant Seal<br />

The Solvent Resistant Seal is identical to the watertight seal except that it is made of materials resistant to petroleum<br />

based products and solvents. The seal is intended to protect the switch/indicator, as well as the behind-thepanel<br />

areas, against petroleum based products and solvents in factory, flightline or refinery environments.<br />

The Solvent Resistant Seal material and the pushbutton faceplate protective coating are resistant to the following substances:<br />

Motor Oil (multipurpose) Transmission Fluid<br />

Petroleum Oil (crude) Silicone Greases<br />

Unleaded Gasoline Animal Fats<br />

Diesel Fuel Prestone Antifreeze<br />

JP-4 Denatured Alcohol<br />

JP-5 Mineral Oil<br />

Methanol Linseed Oil<br />

Water Soap Solutions<br />

Ethanol<br />

Hydrochloric Acid 10%<br />

Sodium Hydroxide 10%<br />

Ammonium Hydroxide 10%<br />

Kerosene<br />

Isopropyl Alcohol<br />

Sea water<br />

Detergent Solutions<br />

Solvent Resistant Seals can be ordered by adding /006 to the coded part number (see ordering information; the<br />

/005 would be replaced by the /006).<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

19

Hazardous Environment Seal<br />

WATERTIGHT SEAL<br />

For switches or indicators intended for use in a nuclear, biological or chemical warfare (NBC) environment,<br />

please consult the factory. Hazardous Environmental Seals can be ordered by adding /007 to the coded part<br />

number.<br />

<strong>Pushbutton</strong> Guard For Watertight Seal<br />

The pushbutton guard is for application with the Watertight Seal or Solvent Resistant Seal. For application with<br />

unsealed or dripproof sealed configurations, see the Accessories section.<br />

<strong>Pushbutton</strong> Guard is transparent and spring loaded.<br />

Lift to allow switch actuation.<br />

Prevents accidental operation.<br />

Slips over switch housing upon installation.<br />

Minimal panel spacing is 1.40” (35.6 mm).<br />

See the Accessories section for <strong>Pushbutton</strong> Guards for general purpose applications which do not use<br />

watertight seals.<br />

20<br />

PART NUMBER APPLICATION<br />

15204/005 Watertight Seal<br />

15204/006 Solvent Resistant Seal<br />

15204/007<br />

Figure 39<br />

NBC Resistant Seal

MATRIX HOUSING ASSEMBLIES<br />

<strong>Series</strong> <strong>90</strong> Matrix Housing Assemblies<br />

Matrix Housings are available in two different<br />

mounting configurations and any<br />

matrix arrangement to meet the customer’s<br />

required number of stations. Constructed of<br />

square aluminum alloy tubes, the lightweight,<br />

yet rugged assembly actually strengthens<br />

the panel, regardless of cutout size. Matrix<br />

Housings are constructed to meet the<br />

requirements of MIL-S-24317. Installation<br />

time is greatly reduced, requiring only one<br />

panel cutout instead of many. For non-EMI/<br />

RFI applications, a black anodized finish per<br />

MIL-A-8625 is applied to the housing. For<br />

EMI/RFI shielded applications, a chemical<br />

film finish, per MIL-C-5541, is applied. <strong>Series</strong><br />

<strong>90</strong> <strong>Switches</strong> and Indicators are inserted in<br />

the front of the matrix and locked in place by<br />

rotating the screw actuated locking cams.<br />

Termination Options<br />

Solder, PCB, and crimp pin terminations are available. Model 94 and 96 Matrix Housings for solder and printed<br />

circuit terminations provide for direct connection of wires to the switch/indicator terminals. Model 95 and 97<br />

Matrix Housings, for crimp pin connections, are lengthened to accommodate a crimp pin receptacle. The<br />

mounted receptacle mates with a standard crimp pin switch/indicator, enabling the crimp pin socket contact to<br />

make electrical connection to the switch/indicator terminals. The crimp pin matrix assembly allows the switch<br />

to be removed from the front of the housing, leaving the receptacle and wiring in place. The receptacle can<br />

also be removed from the rear of the housing, leaving the switch in place, or the wire may be removed from the<br />

receptacle without disturbing the receptacle or switch/indicator assembly.<br />

Rear Flange Mount Matrix Housings<br />

Model 94 and 95 Matrix Housings for rear mounting of the assembly to the customer’s control panel are available<br />

with flanges having slotted mounting holes. Flanges may be located horizontally on the top and bottom<br />

of the housing, vertically on the two sides, or on all four sides for applications where extreme vibration may<br />

be encountered or for EMI/RFI shielding to assure complete panel contact for grounding. All units conform to<br />

shock requirements of MIL-STD-202, Method 213, condition B.<br />

Flange set-back is custom made to accommodate customer’s desired panel thickness. Flange set-back, dimension “H”<br />

shown on housing drawings, measured from the pushbutton top to front of the mounting flange is variable, depending on<br />

panel thickness and desired pushbutton extension, and must be specified by customer in the part number rationale. See<br />

ordering information. The matrix housing is shipped fully assembled, ready to be installed in the customer’s control panel.<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

21

MATRIX HOUSING ASSEMBLIES<br />

Front Dress Bezel Mount Matrix Housings<br />

Models 96 and 97 Matrix Housings are supplied with attractive extruded aluminum dress bezel. The entire<br />

assembly mounts from the front of the customer’s control panel through a single panel cutout. Mounting<br />

cleats, inserted in a groove on the rear of the dress bezel and self-locking screws, tightened against the rear<br />

panel, securely fasten the matrix housing assembly in place. No mounting hardware is visible from the front<br />

panel. The required number of mounting cleats, with self locking screws, are supplied with the fully assembled<br />

housing. Additional cleat assemblies, packaged 5 per bag, may be ordered separately as Part number 15098.<br />

Model 95 and 97 Matrix Housing and<br />

Crimp Pin Termination Receptacles<br />

Crimp pin receptacles are supplied installed in the Model 95 and<br />

97 Matrix Housings. Locking cams, actuated by screws in the rear<br />

of the receptacle securely lock the receptacle into the housing.<br />

Model 95 Switch Indicator<br />

Easily inserted or removed from front of panel using<br />

only a small screwdriver to tighten or loosen the<br />

screw actuated locking cams on each side.<br />

Model 92 Display <strong>Pushbutton</strong><br />

Up to four lighted message areas. Accepts<br />

four T-1 flange based lamps. Also available<br />

with integral LED lighted areas.<br />

Model 94 Matrix Housing With Rear Mount Flanges<br />

Flange set-back is custom made to fit desired<br />

panel thicknesses. Housing accepts switch/indicator<br />

assemblies with solder, or printed circuit terminations.<br />

Switch/indicators are securely held in place by screw<br />

actuated locking cams. Switch/indicator terminations<br />

protrude from rear of the matrix housing.<br />

Locking Cams<br />

22<br />

MATRIX MOUNTING<br />

Actuated by screws (2) in front of switch/indicator assembly. Locking cams securely<br />

hold receptacle in the matrix housing frame. Recommended mounting torque 10 ± 2<br />

oz. in. (0.071 ± 0.014 Nm).<br />

Locking Cams<br />

Actuated by screws (2) in rear of receptacle.<br />

Locking cams securely hold receptacle in the<br />

matrix housing frame. Recommended mounting<br />

torque 10 ± 2 oz. in. (0.071 ± 0.014 Nm).<br />

Locking Cams<br />

Actuated by screws (2) in front of switch/indicator<br />

assembly. Locking cams securely hold receptacle<br />

in the matrix housing frame. Recommended<br />

mounting torque 10 ± 2 oz. in. (0.071 ± 0.014 Nm).<br />

Model 91 Switch Indicator<br />

Easily inserted or removed from front of<br />

panel using only a small screwdriver to<br />

tighten or loosen the screw actuated locking<br />

cams. Wires are connected directly<br />

to the switch/indicator terminations. Unit<br />

shown has solder terminations.<br />

Model 92 Display <strong>Pushbutton</strong><br />

Up to four lighted message areas. Accepts<br />

four T-1 flange based lamps. Also available<br />

with integral LED lighted areas.

MATRIX ASSEMBLY<br />

Matrix Assembly With Direct To Switch Terminations<br />

Model 96 Front Dress Bezel Mount with Short Housing<br />

(Model 97 is Dress Bezel with Long Housing and Crimp Terminations)<br />

Figure 40<br />

Matrix Assembly With Crimp Pin Terminations<br />

Long Crimp Pin<br />

Model 95 Rear Flange Mount with Long Housing and Crimp Terminations<br />

(Model 94 is Flange Mount with Short Housing)<br />

Figure 41<br />

FEMALE<br />

OR 15280<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

23

Short Crimp Pin<br />

CRIMP CONTACT, 15276<br />

MIL-C-3<strong>90</strong>29/22-192<br />

24<br />

MATRIX ASSEMBLY<br />

MATRIX ASSEMBLY<br />

Matrix Assembly With Crimp Pin Terminations<br />

Figure 42

DIMENSIONS REAR FLANGE - MODEL MOUNT99<br />

Rear Flange Mount – Solder or PCB Termination<br />

Model 94<br />

Rear Flange Mount – Crimp Pin Terminations<br />

Model 95<br />

1<br />

Figure 43<br />

Figure 44<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

NOTES:<br />

1<br />

Flange set-back<br />

(Dimension “H”) is the distance<br />

from the face of the<br />

pushbutton to the surface<br />

of the mounting flange. for<br />

an unsealed unit,, only the<br />

panel thickness and relationship<br />

of pushbutton to<br />

front panel need be considered.<br />

for a sealed unit, the<br />

thickness of the switch and<br />

panel seal also need to be<br />

considered.<br />

NOTES:<br />

1<br />

Flange set-back<br />

(Dimension “H”) is the distance<br />

from the face of the<br />

pushbutton to the surface<br />

of the mounting flange. for<br />

an unsealed unit,, only the<br />

panel thickness and relationship<br />

of pushbutton to<br />

front panel need be considered.<br />

for a sealed unit, the<br />

thickness of the switch and<br />

panel seal also need to be<br />

considered.<br />

25

26<br />

REAR FLANGE MOUNT<br />

Rear Flange Mount – Short Crimp Pin Terminations<br />

Model 95<br />

NOTES:<br />

1<br />

Figure 45<br />

Flange set-back<br />

(Dimension “H”) is the distance from the face of the pushbutton to the surface of the mounting<br />

flange. for an unsealed unit,, only the panel thickness and relationship of pushbutton to front<br />

panel need be considered. for a sealed unit, the thickness of the switch and panel seal also<br />

need to be considered.

FLANGE OPTION CODES<br />

Rear Flange Mount Matrix Housing<br />

Horizontal Flanges, Unsealed<br />

Horizontal Flange Unsealed<br />

Dripproof Seals<br />

Figure 46<br />

Flange Option Code 2; Station Configuration 0302<br />

Figure 48<br />

Flange Option Code 2; Station Configuration 0103<br />

Matrix housings may be ordered with a sealed option<br />

for either the dress bezel front mounting or the<br />

four-flange rear mounting configuration.<br />

When either of these matrix housing assemblies are panel<br />

mounted using a customer-furnished panel seal gasket<br />

and all matrix stations are loaded with switches or indicators<br />

utilizing switch and pushbutton seals, the matrix<br />

assembly is classified as dripproof. Behind the panel<br />

equipment will be protected and the switches and indicators<br />

will operate in the presence of a coarse liquid spray<br />

directed at it. Mounted as described, the unit may be<br />

subjected to the dripproof test of MIL-STD-108, 15 degree<br />

method, with a five gallon quantity of water flowing over<br />

the specimen for a period of five minutes duration.<br />

Vertical Flanges, Unsealed<br />

Four Flanges, Sealed or Unsealed<br />

Flange Option Codes<br />

CODE DESCRIPTION<br />

1 No flanges (unsealed)<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

2 Horizontal flanges only (unsealed)<br />

3 Vertical flanges only (unsealed)<br />

6 Four flange (sealed)<br />

Model 94 or 95<br />

Figure 47<br />

Flange Option Code 2; Station Configuration 0103<br />

Figure 49<br />

Flange Option Code 6 or 7; Station Configuration 0304<br />

7 Four flange (unsealed)<br />

27

Solder or PCB Termination<br />

Model 96 or 97<br />

Model 96<br />

28<br />

Figure 50<br />

FRONT DRESS BEZEL MOUNT

Crimp Pin Termination<br />

Long Crimp Pin<br />

Model 97<br />

Figure 51<br />

Short Crimp Pin<br />

Figure 52<br />

FRONT DRESS BEZEL MOUNT<br />

10)<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

29

30<br />

FRONT DRESS BEZEL MOUNTING INFORMATION<br />

Minimum Spacing<br />

Mounting Cleat Assembly and Requirements<br />

Figure 54<br />

Figure 53<br />

Figure 55

PRODUCT DIMENSIONS DESIGN & ENGINEERING - MODEL 99 DATA<br />

General Information<br />

<strong>Staco</strong> <strong>Systems</strong> products are designed and manufactured to meet specifications of Original Equipment<br />

Manufacturers who demand dependability, attractive appearance, and maximum value from their products.<br />

Combining imaginative engineering with manufacturing know-how.<br />

Military Specs And Standards<br />

<strong>Staco</strong> <strong>Systems</strong> <strong>Series</strong> <strong>90</strong> <strong>Switches</strong>, Indicators and Display <strong>Pushbutton</strong>s are manufactured to meet or exceed the<br />

requirements of the following specifications and standards where applicable.<br />

Military Specifications<br />

MIL-PRF-22885 <strong>Switches</strong>, <strong>Pushbutton</strong>, Illuminated, General Specification for.<br />

MIL-PRF-22885/101 Switch, <strong>Pushbutton</strong>, Matrix or Individually Mounted, Illuminated, 4-Lamp, SPDT and DPDT, 5.0<br />

Amperes, Silver contacts, 1 Ampere, Gold Contacts (Dripproof, Sunlight Readable,<br />

EMI/RFI Shielded).<br />

MIL-PRF-22885/112 <strong>Switches</strong>, <strong>Pushbutton</strong>, White Light Emitting Diode (LED) Illuminated, Standard, Night Vision<br />

Imaging System (NVIS) and Sunlight Readable Displays, Dimmable SPDT and DPDT,<br />

Low Level to 7 Amperes, Sealed and Unsealed, Solder and Common Termination<br />

System (CTS) Terminations.<br />

MIL-S-24317 Switch Matrix Frame, Multistation.<br />

MIL-S-<strong>90</strong>1 Shock Tests, H.I. (High-Impact),Shipboard Machinery, Equipment and <strong>Systems</strong>, Requirements for.<br />

Military Standards<br />

MIL-STD-3009 Lighting, Aircraft, Interior, Night Vision Imaging System (NVIS) Compatible.<br />

MIL-STD-108 Definitions of, and Basic requirements for, Enclosures for Electric and Electronic Equipment.<br />

MIL-STD-202 Test Methods For Electronic and Electrical Component Parts.<br />

Other Military Specifications<br />

DSCC DWG Switch, <strong>Pushbutton</strong>, Illuminated, 4 Lamp <strong>90</strong>020 (MIL-S-22885/101 w/Legend).<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

31

32<br />

PRODUCT MODEL DESIGN 99 SWITCH/INDICATOR<br />

& ENGINEERING DATA<br />

Environmental Specifications<br />

Temperature Range Operating -55°C to +85°C<br />

Storage -65°C to +95°C<br />

Thermal Shock MIL-STD-202, Method 107, Test Condition A (-55°C to +85°C)<br />

Vibration MIL-PRF-22885 vibration grade 3 (10-2,000 Hz) MIL-STD-202, Method 204, Test Condition B<br />

(15 G peak)<br />

Shock MIL-STD-202, Method 213, Condition B (75G)<br />

Shock - High Impact MIL-S-<strong>90</strong>1, Grade A, Class II (for deck-mounted equipment; hull-mounting not<br />

recommended). Moisture Resistance MIL-STD-202, Method 106, (wet 10 megohms, dry<br />

1,000 megohms).<br />

Dripproof Seal MIL-PRF-22885 Symbol 2 option, test procedures of MIL-STD-108 (5 gal/min).<br />

Splashproof Seal MIL-PRF-22885 Symbol 4 option, test procedures of MIL-STD-108 (15 gal/min).<br />

Watertight Seal MIL-PRF-22885 Symbol 3 option, test procedures of MIL-STD-108 (3 foot submersion,<br />

1 hour).<br />

Solvent Resistant Option is splashproof and water tight plus seal is resistant to most petroleum-based<br />

fuels, solvents, oils, and greases.<br />

Salt Spray MIL-STD-202, Method 101, Test Condition A, (Corrosion, 96 hours).<br />

Explosion MIL-STD-202, Method 109.<br />

Sand and Dust MIL-STD-202, Method 110, Condition B and MIL-S-22885. (Applies to switches equipped<br />

with seals for Dripproof, Splashproof, Watertight or Solvent Resistant options.)<br />

Dripproof Seal of Matrix <strong>Systems</strong><br />

When matrix housing assemblies are mounted to the panel using a customer furnished panel seal gasket and<br />

all matrix stations are loaded with switch/indicators utilizing switch and pushbutton seals, the matrix assembly<br />

will be dripproof. All behind the panel equipment will be protected and the enclosed switch/indicators will operate<br />

satisfactorily in the presence of a coarse spray of liquid directed at it or its mounting surface. With the<br />

matrix assembly mounted as described, the unit may be subjected to the dripproof test of MIL-STD-108 (five<br />

gallons of water flowing over the specimen for a period of five minutes).<br />

Other Matrix Seals<br />

Splashproof seals, watertight seals and solvent resistant seals are not available for matrix configurations.

PRODUCT DIMENSIONS DESIGN & ENGINEERING - MODEL 99 DATA<br />

Electrical Specifications<br />

Switch Contact Ratings<br />

Power Circuits (silver contacts)<br />

250 VAC<br />

UL listed L7 7 Amps, (21 SK83-H 340).<br />

Low level Circuits (gold contacts) Typical application<br />

would be 30 milliamps at 30 millivolts<br />

Switch Contact Resistance<br />

New: < 25 milliohms<br />

End of life: Per MIL-S-22885 (typical < 40 milliohms)<br />

At reduced barometric pressure:<br />

per MIL-STD-202, Method 105, test potential<br />

400 Vrms; test condition C (maximum pressure<br />

of 1.31”Hg or 33.00 mm Hg to simulate an<br />

altitude of 70,000 feet or 21,336 meters).<br />

Switch Schematics<br />

Single-pole double-throw (SPDT) and double-pole double-throw (DPDT) switch circuits are shown schematically in Figure 1.<br />

Mechanical<br />

Physical Dimensions<br />

In this document, all dimensions are shown in inches with millimeters given as reference information. Unless other-<br />

wise specified, tolerances are:<br />

.xx = ± .02 inch (± .5 mm)<br />

.xxx = ± .010 inch (± .25 mm)<br />

Resistive<br />

Indicators .030 inch (.76 mm)<br />

Latchdown Actuation and Displacement<br />

On alternate action (maintained) contact switches, the pushbutton is retained in a latch-down or actuated switch position until<br />

the pushbutton is depressed a second time, releasing the pushbutton and deactivating the switch. When in the actuated<br />

position, the face of the pushbutton is mechanically held depressed from its normal height by approximately .080 inch (2.03 mm).<br />

Actuation Force<br />

The force required to actuate momentary and maintained switches ranges from 1.1 lbs. for unsealed, SPDT, to 2.2<br />

lbs. sealed, DPDT (4.9 tp 9.8N). Add an additional 0.6 lbs. (2.7N) for immersion seal configuration.<br />

<strong>Pushbutton</strong> Extraction Force<br />

Per MIL-S-22885/101, the extraction force is between 2 to 5 lbs. (9 to 22N).<br />

<strong>Pushbutton</strong> Retainer<br />

As an option, a pushbutton retainer tie is available to keep a given pushbutton physically linked to a given switch<br />

during relamping operations.<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

Altitude 28 VDC 115 VAC<br />

(Feet) (Amps) 60 HZ (Amps)<br />

Sea Level 7 7<br />

50,000’ 4 –<br />

Inductive Sea Level 4 7<br />

50,000’ 2.5 –<br />

Lamp Sea Level 2.5 2<br />

50,000’ 2.5 –<br />

Switch Operational Life<br />

Typical application would be 30 Milliamps at 30<br />

Millivolts<br />

Dielectric Strength<br />

At atmospheric pressure:<br />

<strong>Pushbutton</strong> Actuation Travel<br />

Per MIL-STD-202, Method 1,000 Vrms.<br />

<strong>Switches</strong> .12 inch (3.0 mm)<br />

33

Weights<br />

34<br />

PRODUCT MODEL DESIGN 99 SWITCH/INDICATOR<br />

& ENGINEERING DATA<br />

Solder Terminals<br />

Solder terminals are double turret to ensure that wires can be mechanically secured prior to soldering and are<br />

tin-lead plated per MIL-P-81728. Solderability testing is in accordance with MIL-STD-202, Method 208. Terminal<br />

strength tests are conducted as prescribed by MIL-STD-202, Method 211, test condition A.<br />

Printed Circuit Terminals<br />

Printed circuit terminals are plated to facilitate hand, wave or flow soldering methods.<br />

Crimp Pin Terminals<br />

Crimp pin terminals are gold plated per MIL-G-45204. NOTE: crimp pin terminals mate with crimp-on wire terminations<br />

per MIL-C-3<strong>90</strong>29/16-168 and MIL-C-3<strong>90</strong>29/22-192.<br />

EMI/RFI Shielding<br />

When tested per MIL-S-22885 shielding efficiency method, the minimum shielding attenuation is at least 60 dB<br />

over the frequency range from 100 to 1,000 MHz.<br />

The typical weights of the switch or indicator, including mounting hardware of .07 oz., (2 gms) and the pushbutton are:<br />

SWITCH/INDICATOR WITH PUSHBUTTON WEIGHT<br />

Assembly Ounces Grams<br />

Mdl 93 Switch (DPDT w/PB & 4 lamps/LEDs) .061 17<br />

Mdl 93 Switch (SPDT w/PB & 4 lamps/LEDs) .058 16<br />

Mdl 93 Indicator (w/PB & 4 lamps/LEDs) 0.5 14<br />

Mdl 99 Switch (DPDT w/PB & 4 lamps/LEDs) 1.09 31<br />

Mdl 99 Switch (DPDT w/PB & 4 lamps/LEDs) 1.06 30<br />

Mdl 99 Indicator (w/PB & 4 lamps/LEDs) .98 28<br />

<strong>Pushbutton</strong> (w/4 lamps/LEDs 0.13 4<br />

Additional weight for watertight seals 0.08 2<br />

Matrix Weight Per Station<br />

Front Mount<br />

Rear Flange Mount Dress Bezel<br />

Components Termination Termination<br />

Solder/PC Crimp Pin Solder/PC Crimp Pin<br />

1. Matrix Housing .140 oz. .205 oz. .140 oz. .205 oz.<br />

2. Receptacle<br />

Assy.<br />

3. Flange<br />

(per inch) w/rivets<br />

4. Dress Bezel<br />

(per lin. inch)<br />

– .315 oz. – .315 oz.<br />

.075 oz. .075 oz. – –<br />

– – .162 oz. .162 oz.<br />

5. Contact Socket<br />

(12 max per – .006 oz. ea. – .006 oz. ea.<br />

station)<br />

6. Cleat Assy.<br />

(2 to 10 req.)<br />

– – .146 oz. .146 oz.<br />

Matrix Housing Weight Examples<br />

Rear flange mount matrix, 4x3, with 4 flanges,<br />

crimp pin, and 12 pins utilized<br />

Housings 12 @ 0.205 oz. 2.460 oz.<br />

Receptacle Assy 3.780 oz.<br />

Flange 13.61 inches @ .075 oz./in. 1.021 oz.<br />

Socket contacts 12 x 12 @ .006 oz. 0.864 oz.<br />

Matrix housing total 8.125 oz.<br />

Front dress bezel mount matrix, 2x2, w/solder<br />

termination<br />

Housings 4 @ 0.140 oz. 0.560 oz.<br />

Dress bezel 7.97 inches @ .1621 .291 oz.<br />

Cleat assy 2 @ 0.146 0.292 oz.<br />

Matrix housing total 2.143 oz.<br />

Matrix System Total Weight<br />

To obtain matrix system total weight, include<br />

matrix housing, plus switch or indicator weights<br />

with pushbuttons, less individual mounting hard-<br />

ware weights of .07 oz., (2 gms) per station.

PRODUCT DIMENSIONS DESIGN & ENGINEERING - MODEL 99 DATA<br />

Display System<br />

Field of View<br />

The visibility of any legend, symbology or alphanumerics can be viewed from a distance of three feet, without any restrictions<br />

by the periphery of the enclosure for the display, at all angles within an 80 o cone perpendicular to the viewing surface.<br />

Light Sources<br />

Two means for legend lighting are available in the <strong>Series</strong> <strong>90</strong><br />

product line, either incandescent or LED.<br />

Incandescent Lamps<br />

Lamps are flange based, incandescent, T-1 sub-midget type,<br />

which are field replaceable from the front panel. Selection options<br />

are specified in Table 6A. When lamps are not furnished with<br />

the pushbuttons, a removable fiberboard plate will be installed<br />

at the factory. This plate is removed and discarded when lamps<br />

are installed in the field. For proper operation, either this “discard”<br />

plate, four T-1 lamps, or a combination of lamps and “dummy<br />

plugs” (devices which simulate the specified lamps) must be used to prevent damage to the unit.<br />

Factory-supplied lamps have nominal brightness as specified by the manufacturer in Table 6A. These have a mean spherical<br />

candle power (MSCP) tolerance of ± 25%. Unless otherwise specified, all brightness tests performed at the factory, and those<br />

published in this document utilize calibrated lamps with a luminous intensity of .15 ± .01 MSCP.<br />

Light Emitting Diodes (LEDs)<br />

The voltage options are 5 or 28 volts. LED polarity and other options are as specified in Table 6B. These LEDs<br />

are a serviceable part of the pushbutton.<br />

Incandescent Lighting Circuits<br />

Electrical connections for pushbuttons lighted with incandescent lamps are shown in Figure 8. The lamp circuit is<br />

optionally available with:<br />

a) Common lamp ground for all four lamps (full ground plate); b) Vertically split ground plate (the two lamps on<br />

the left half and the two lamps on the right half may be on separate power circuits with separate grounding);<br />

c) Horizontally split ground plate (lighting for the top half and the bottom half may be on separate power circuits).<br />

The choice of lamp circuit grounding scheme is completely independent of the selection of legend display style (full screen<br />

display, two-way horizontal split, etc., as shown in Table 5). The split grounds allow the lamps of a display to be powered from<br />

two separate power sources.<br />

Each incandescent lamp is lighted independently from the other three by applying power to the pin designated in the schematic.<br />

The power may be dc or low-voltage ac, within the rating of the lamp. Standard lamp selections are listed in Table 6A.<br />

Incandescent-based displays are available in the colors indicated in the chromaticity diagram of Figure 13.<br />

LED Lighting Circuits<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

Legend Viewing Dimensions<br />

The display area available for legends:<br />

Viewing Area Nominal Dimensions<br />

Inch (mm)<br />

Full Screen .495” (12.57) square<br />

Half Screen, horizontal .495 x .217” (12.57 x 5.51)<br />

Half Screen, vertical .217 x .495” (5.51 x 12.57)<br />

Quarter Screen .217” (5.51) square<br />

Light emitting diode (LED) arrays within the <strong>Series</strong> <strong>90</strong> pushbuttons are available as an alternative to incandescent lamps.<br />

Each of the four quadrants of a display is lighted using an assembly of three LED chips, giving a total of 12 LED junctions per<br />

pushbutton. Schematics for typical LED configurations are shown in Figures 9 and 10. The required current regulating resistors<br />

are included in the pushbutton. There is also a voltage dimming option.<br />

Unlike the incandescent pushbutton versions without common bussed switch bases, some LED configurations power need<br />

only to be applied to one pin to control the lighting of a half-screen LED display if the display style is full-screen or half-screen<br />

displays.<br />

35

36<br />

PRODUCT MODEL DESIGN 99 SWITCH/INDICATOR<br />

& ENGINEERING DATA<br />

For common lamp circuit configurations common terminals (pins 6 and 9) may be used as the common return circuit for redundancy.<br />

The schematics of Figures 9 and 10 are typical. Figures 56 and 57 provide a complete set of schematics for all standard colored<br />

LED configurations.<br />

Current Requirements for LED Lighting: For 5 volt dc systems, all configurations use 45 mA per quadrant when illuminated.<br />

Thus, a full-screen unit would use 180 mA, a two-way split with one half lighted would use <strong>90</strong> mA, etc.<br />

For 28 volt systems, the current requirements dependent upon the configuration. When operated at 28 volts dc, either for a<br />

full-screen or two-way configuration, the forward current is 20 mA for each half screen which is illuminated (40 mA with both illuminated).<br />

For three-way split, the one-half screen is 20 mA and each quarter screen is 20 mA (for a total of 60 mA with all three<br />

areas illuminated). On four-way split configurations, each quadrant uses 20 mA ( mA with all four areas illuminated).<br />

Maximum current usage for each configuration is tabulated in Table 6B. The current requirements listed are worst-case with all<br />

legend areas lighted at maximum brightness.<br />

LED Lighting Control<br />

The accompanying schematics identify the pins to control the lighting of the specific portions of the displays on<br />

LED-based pushbuttons.<br />

Current Sourcing/Sinking for LEDs<br />

Figures 11 and 12 show simplified schematics of typical control circuits for driving the LED circuits. LED lighted pushbuttons<br />

may be configured through Table 4 for either current sourcing (codes 7 and 9) or current sinking (codes 8 and 10).<br />

One characteristic of current sourcing is that it can be used to isolate the lamp load from direct power connection<br />

if desired. For this, the cathode side of the LEDs is always grounded through a current-regulating resistor. The<br />

driving circuits supply voltage to the anode side of the LEDs to illuminate them.<br />

Current sinking, on the other hand, enables the controlling circuits to switch the cathodes to ground to light the<br />

LEDs. The is a simpler control circuit to implement if MOSFET logic is being used. Also multi-channel output driver<br />

ICs with common grounded emitters are readily available.<br />

Dimming<br />

While incandescent lighting may be controlled by varying the amplitude of the applied ac or dc voltage, this is<br />

not the ideal way to control LED lighting. LEDs are current-driven devices and operate best at the rated current.<br />

Dimming is best accommodated<br />

by turning the LEDs on and off at<br />

a rate of several thousand times<br />

per second. During the period of<br />

time that they are on, they are<br />

driven at their rated current. The<br />

ratio of on-time to off-time then<br />

controls the brightness. The <strong>Staco</strong><br />

<strong>Systems</strong> DDM111 and DDM111A<br />

Digital Dimming Module are an<br />

ideal way to precisely control<br />

LED brightness. The DDM111<br />

and DDM111A may also be voltage<br />

dimmed provided the option<br />

is selected from the catalog<br />

(only available in 28 volts) The<br />

DDM111 and DDM111A are briefly<br />

<br />

described on page 56.<br />

Figure 56

PRODUCT DIMENSIONS DESIGN & ENGINEERING - MODEL 99 DATA<br />

5 Volt LED Circuit Schematics<br />

Common Circuit Split Circuit<br />

Display Styles Code Sealed Code Sealed<br />

Common Lamp Split Lamp<br />

Code Front View Circuit Sourcing Sinking Circuit Sourcing Sinking<br />

Rear View A B Rear View C D<br />

No Yes No Yes No Yes No Yes<br />

1 2 Full<br />

1<br />

Screen<br />

3 4<br />

1 2 Horiz.<br />

2 3 4 Split<br />

Screen<br />

31 41 51 61 31 41 51 61<br />

Vert.<br />

3 Split 31 41 51 61 31 41 51 61<br />

Screen<br />

3 Way<br />

4 Horiz.<br />

Split<br />

Screen<br />

33 43 53 63 33 43 53 63<br />

4 Way<br />

5 Split 35 45 55 65 35 45 55 65<br />

Screen<br />

3 Way<br />

6 Vert.<br />

Split<br />

Screen<br />

3 Way<br />

7 Horiz.<br />

Split<br />

Screen<br />

3 Way<br />

8 Vert.<br />

Split<br />

Screen<br />

12<br />

33 43 53 63 33 43 53 63<br />

33 43 53 63 33 43 53 63<br />

33 43 53 63 33 43 53 63<br />

Figure 57<br />

Visit www.stacosystems.com or call 714-549-3041 for more information<br />

NOTES: See Table 4 for current sourcing and sinking codes 7, 8, 9 and 0.<br />

See Table 5 for display style codes 1 through 8.<br />

See Table 6B for circuit and seal codes 31 through 66.<br />

37

38<br />

PRODUCT MODEL DESIGN 99 SWITCH/INDICATOR<br />

& ENGINEERING DATA<br />

28 Volt LED Circuit Schematics<br />

Common Circuit Split Circuit<br />

Display Styles Code Sealed Code Sealed<br />

Common Lamp Split Lamp<br />

Code Front View Circuit Sourcing Sinking Circuit Sourcing Sinking<br />

Rear View A B Rear View C D<br />

No Yes No Yes No Yes No Yes<br />

1 2 Full<br />

1<br />

Screen<br />

2<br />

3 4<br />

1<br />

3<br />

2<br />

4<br />

Horiz.<br />

Split<br />

Screen<br />

32 42 52 62 32 42 52 62<br />

Vert.<br />

3 Split 32 42 52 62 32 42 52 62<br />

Screen<br />

3 Way<br />

4 Horiz.<br />

Split<br />

Screen<br />

34 44 54 64 34 44 54 64<br />

4 Way<br />

5 Split 36 46 56 66 36 46 56 66<br />

Screen<br />

3 Way<br />

6 Vert.<br />

Split<br />

Screen<br />

3 Way<br />

7 Horiz.<br />

Split<br />

Screen<br />

3 Way<br />

8 Vert.<br />

Split<br />

Screen<br />

2<br />

1<br />

NOTES: See Table 4 for current sourcing and sinking codes 7, 8, 9 and 0.<br />

See Table 5 for display style codes 1 through 8.<br />

See Table 6B for circuit and seal codes 31 through 66.<br />

34 44 54 64 34 44 54 64<br />

34 44 54 64 34 44 54 64<br />

34 44 54 64 34 44 54 64<br />

Figure 58

Legends<br />

PRODUCT DIMENSIONS DESIGN & ENGINEERING - MODEL 99 DATA<br />

Type Style and Fonts<br />

The standard type face used for legend text is Alternate Gothic Number 2 (AG2), a condensed gothic, sans serif style.<br />

The nominal letter height-to-width ratio is approximately 6:1. Always Visible White (AVW) legends are an exception;<br />

they use the Helvetica Light font.<br />

Character Heights<br />

The character height, as defined in this document, is the distance (in decimal inches) from the top to bottom of a<br />

capital letter (no descenders) in the standard font AG2. Unless otherwise specified, the size of punctuation and<br />

symbols in that font will be artistically proportional to the size specified for the capital letters.<br />

As listed in Table 5, the standard character heights for the <strong>Series</strong> <strong>90</strong> Product Line are .072, .087, .100, .125 and<br />

.145. Other AG2 character heights, available by special order (or if needed, for special artwork) are: .060, .066, .075, .077,<br />

.080, .082, .0<strong>90</strong>, .094, .097, .105, .110, .114, .120, .132, .139, .155, .164, .175, .188, .203, .219, .239, .263, .293 and .329.<br />

Standard Character/Symbol Set<br />

The standard AG2 typeface provides capital letters and numerics in all the sizes listed above. Lower case characters<br />

are not available in this font. Many typical European characters such as Ä, Å, É, Ö, Ñ, Ü, and others, are<br />

available as standard within this font. Other symbols available in AG2 include arrows, @, #, $, %, &, (, ), ', !, ., +, /,<br />

:, ;, =, ?, \, _, , *, ±, °, 1 / 2 , 1 / 4 , and others.<br />

The “character height” of an arrow is the length from the tip of the point to the end of the shaft, independently of its<br />

orientation, i.e., a .145” arrow will have the same appearance if vertical or horizontal.<br />

The symbols * and # are available either as proportional to the size of the AG2 font or as full-size characters with<br />

the same height of the capital letters. Unless otherwise specified, the symbol used will be the proportional one.<br />

Optional Fonts<br />

By special order Helvetica Light and Helvetica Medium are available in a range of sizes similar to that of AG2. Either<br />

of these Helvetica typefaces may also be ordered in their normal, condensed, bold, or expanded variations. Both of<br />

these typefaces provide capital letters, numbers, lower case characters, and many of the symbols and European<br />