Consumeables Catalog - Lincoln Electric

Consumeables Catalog - Lincoln Electric Consumeables Catalog - Lincoln Electric

FLUX-CORED SELF-SHIELDED (FCAW-S) WIRE Innershield ® Key Features Fast travel speeds and high deposition rates Maximum penetration Flat bead profile on butt welds Join dissimilar plate thicknesses with even heat distribution Typical Applications Single pass welding on up to 2.8 mm (0.110 in) thicknesses Sheet metal Automotive 86 ı THE LINCOLN ELECTRIC COMPANY -131 NR® Mild Steel, Flat & Horizontal • AWS E70T-10 Conformances AWS A5.20/A5.20M: ASME SFA-A5.20: Welding Positions Flat & Horizontal DIAMETERS / PACKAGING Diameter 600 lb (272 kg) Speed-Feed ® in (mm) Reel 3/32 (2.4) ED012163 MECHANICAL PROPERTIES (1) – As Required per AWS A5.20/A5.20M Transverse Tensile Strength MPa (ksi) E70T-10 E70T-10 Warning NR-131 is NOT recommended for welding multiple passes. Longitudinal Bend Test Requirements - AWS E70T-10 480 (70) min. 180° over 3/4 in Radius No openings exceeding 1/8 in Hardness Rockwell B – Typical Results (3) 505-560 (75-80) Passed 99 DEPOSIT COMPOSITION (1) – As Required per AWS A5.20/A5.20M %C %Mn %Si %S %P %Al Requirements - AWS E70T-10 Not Specified Typical Results (3) 0.22-0.26 0.42-0.65 0.20-0.27 0.005-0.007 0.007-0.02 1.18-1.49 TYPICAL OPERATING PROCEDURES Diameter, CTWD Wire Feed Speed Voltage Approx. Current Melt-Off Rate Deposition Rate Efficiency Polarity mm (in) m/min (in/min) (volts) (amps) kg/hr (lb/hr) kg/hr (lb/hr) (%) 3.8 (150) 25-26 390 6.5 (14.3) 5.3 (11.6) 81 3/32 in (2.4 mm), 38 5.1 (200) 25-27 490 8.6 (19.0) 7.1 (15.6) 82 Single Arc, DC- (1-1/2) 6.4 (250) 26-27 570 10.8 (23.7) 8.9 (19.6) 82 8.9 (350) 26-28 720 15.0 (33.1) 33.6 (27.6) 83 10.8 (425) 27-28 810 18.2 (40.1) 15.2 (33.6) 83 3.3 (130) 25-26 550 11.1 (24.5) 8.1 (17.9) 72 3/32 in (2.4 mm), 44 4.4 (175) 26-27 740 15.0 (33.0) 12.0 (26.4) 79 Twinarc, DC- (1-3/4) 5.7 (225) 26-28 910 19.3 (42.5) 15.8 (34.8) 81 7.0 (275) 27-29 1030 23.5 (51.9) 19.1 (42.0) 80 8.3 (325) 28-30 1090 27.9 (61.4) 21.9 (48.2) 78 (1) Typical all weld metal. (2) See test results disclaimer on pg. 16.

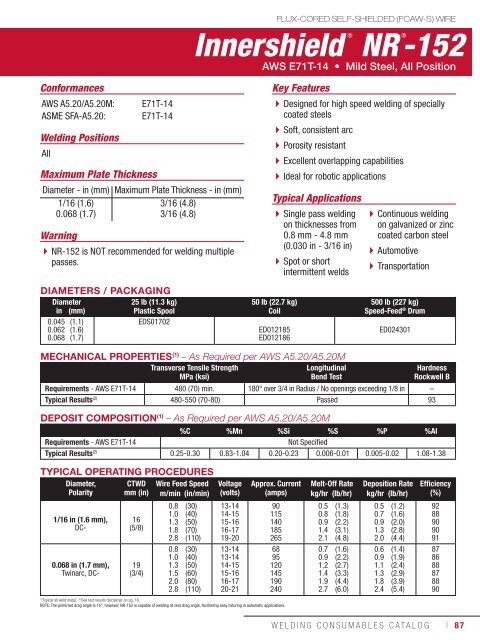

Conformances AWS A5.20/A5.20M: ASME SFA-A5.20: Welding Positions All E71T-14 E71T-14 Maximum Plate Thickness Diameter - in (mm) Maximum Plate Thickness - in (mm) 1/16 (1.6) 3/16 (4.8) 0.068 (1.7) 3/16 (4.8) Warning NR-152 is NOT recommended for welding multiple passes. DIAMETERS / PACKAGING Diameter 25 lb (11.3 kg) in (mm) Plastic Spool 0.045 (1.1) EDS01702 0.062 (1.6) 0.068 (1.7) Innershield ® FLUX-CORED SELF-SHIELDED (FCAW-S) WIRE Typical Applications Single pass welding on thicknesses from 0.8 mm - 4.8 mm (0.030 in - 3/16 in) Spot or short intermittent welds -152 NR® AWS E71T-14 • Mild Steel, All Position Key Features Designed for high speed welding of specially coated steels Soft, consistent arc Porosity resistant Excellent overlapping capabilities Ideal for robotic applications 50 lb (22.7 kg) Coil ED012185 ED012186 MECHANICAL PROPERTIES (1) – As Required per AWS A5.20/A5.20M Transverse Tensile Strength MPa (ksi) Longitudinal Bend Test Continuous welding on galvanized or zinc coated carbon steel Automotive Transportation 500 lb (227 kg) Speed-Feed ® Drum ED024301 Hardness Rockwell B Requirements - AWS E71T-14 480 (70) min. 180° over 3/4 in Radius / No openings exceeding 1/8 in – Typical Results (2) 480-550 (70-80) Passed 93 DEPOSIT COMPOSITION (1) – As Required per AWS A5.20/A5.20M %C %Mn %Si %S %P %Al Requirements - AWS E71T-14 Not Specified Typical Results (2) 0.25-0.30 0.83-1.04 0.20-0.23 0.006-0.01 0.005-0.02 1.08-1.38 TYPICAL OPERATING PROCEDURES Diameter, CTWD Wire Feed Speed Voltage Approx. Current Melt-Off Rate Deposition Rate Efficiency Polarity mm (in) m/min (in/min) (volts) (amps) kg/hr (lb/hr) kg/hr (lb/hr) (%) 0.8 (30) 13-14 90 0.5 (1.3) 0.5 (1.2) 92 1/16 in (1.6 mm), DC- 16 (5/8) 1.0 1.3 1.8 (40) (50) (70) 14-15 15-16 16-17 115 140 185 0.8 0.9 1.4 (1.8) (2.2) (3.1) 0.7 0.9 1.3 (1.6) (2.0) (2.8) 88 90 90 2.8 (110) 19-20 265 2.1 (4.8) 2.0 (4.4) 91 0.8 (30) 13-14 68 0.7 (1.6) 0.6 (1.4) 87 1.0 (40) 13-14 95 0.9 (2.2) 0.9 (1.9) 86 0.068 in (1.7 mm), 19 1.3 (50) 14-15 120 1.2 (2.7) 1.1 (2.4) 88 Twinarc, DC- (3/4) 1.5 (60) 15-16 145 1.4 (3.3) 1.3 (2.9) 87 2.0 (80) 16-17 190 1.9 (4.4) 1.8 (3.9) 88 2.8 (110) 20-21 240 2.7 (6.0) 2.4 (5.4) 90 (1) Typical all weld metal. (2) See test results disclaimer on pg. 16. NOTE: The preferred drag angle is 15°, however, NR-152 is capable of welding at zero drag angle, facilitating easy fixturing in automatic applications. WELDING CONSUMABLES CATALOG ı 87

- Page 38 and 39: STICK (SMAW) ELECTRODE Shield-Arc®

- Page 40 and 41: STICK (SMAW) ELECTRODE Excalibur ®

- Page 42 and 43: STICK (SMAW) ELECTRODE Excalibur ®

- Page 44 and 45: STICK (SMAW) ELECTRODE Excalibur ®

- Page 46 and 47: STICK (SMAW) ELECTRODE Excalibur ®

- Page 48 and 49: STICK (SMAW) ELECTRODE Notes 46 ı

- Page 50 and 51: MIG (GMAW) WIRE SuperGlide® Typica

- Page 52 and 53: MIG (GMAW) WIRE SuperGlide® Typica

- Page 54 and 55: MIG (GMAW) WIRE SuperArc® Typical

- Page 56 and 57: MIG (GMAW) WIRE SuperArc® Typical

- Page 58 and 59: MIG (GMAW) WIRE SuperArc® Typical

- Page 60 and 61: MIG (GMAW) WIRE SuperArc® Typical

- Page 62 and 63: MIG (GMAW) WIRE SuperArc® Typical

- Page 64 and 65: MIG (GMAW) WIRE SuperArc® Capable

- Page 66 and 67: TIG (GTAW) CUT LENGTHS Lincoln® Ty

- Page 68 and 69: MIG (GMAW) & TIG (GTAW) CONSUMABLES

- Page 70 and 71: METAL-CORED WIRE Metalshield ® Mil

- Page 72 and 73: Structural Welding Code Seismic Sup

- Page 74 and 75: METAL-CORED WIRE Metalshield ® Mil

- Page 76 and 77: METAL-CORED WIRE Metalshield ® Low

- Page 78 and 79: METAL-CORED WIRE Metalshield ® Low

- Page 80 and 81: METAL-CORED WIRE Metalshield ® Low

- Page 82 and 83: METAL-CORED CONSUMABLES Notes 80 ı

- Page 84 and 85: FLUX-CORED SELF-SHIELDED (FCAW-S) W

- Page 86 and 87: Structural Welding Code Seismic Sup

- Page 90 and 91: FLUX-CORED SELF-SHIELDED (FCAW-S) W

- Page 92 and 93: FLUX-CORED SELF-SHIELDED (FCAW-S) W

- Page 94 and 95: Structural Welding Code Seismic Sup

- Page 96 and 97: Structural Welding Code Seismic Sup

- Page 98 and 99: Structural Welding Code Seismic Sup

- Page 100 and 101: Structural Welding Code Seismic Sup

- Page 102 and 103: FLUX-CORED SELF-SHIELDED (FCAW-S) W

- Page 104 and 105: FLUX-CORED SELF-SHIELDED (FCAW-S) W

- Page 106 and 107: FLUX-CORED SELF-SHIELDED (FCAW-S) W

- Page 108 and 109: Structural Welding Code Seismic Sup

- Page 110 and 111: Structural Welding Code Seismic Sup

- Page 112 and 113: Structural Welding Code Seismic Sup

- Page 114 and 115: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 116 and 117: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 118 and 119: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 120 and 121: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 122 and 123: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 124 and 125: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 126 and 127: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 128 and 129: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 130 and 131: Structural Welding Code Seismic Sup

- Page 132 and 133: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 134 and 135: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 136 and 137: Structural Welding Code Seismic Sup

Conformances<br />

AWS A5.20/A5.20M:<br />

ASME SFA-A5.20:<br />

Welding Positions<br />

All<br />

E71T-14<br />

E71T-14<br />

Maximum Plate Thickness<br />

Diameter - in (mm) Maximum Plate Thickness - in (mm)<br />

1/16 (1.6)<br />

3/16 (4.8)<br />

0.068 (1.7)<br />

3/16 (4.8)<br />

Warning<br />

NR-152 is NOT recommended for welding multiple<br />

passes.<br />

DIAMETERS / PACKAGING<br />

Diameter 25 lb (11.3 kg)<br />

in (mm)<br />

Plastic Spool<br />

0.045 (1.1)<br />

EDS01702<br />

0.062 (1.6)<br />

0.068 (1.7)<br />

Innershield ®<br />

FLUX-CORED SELF-SHIELDED (FCAW-S) WIRE<br />

Typical Applications<br />

Single pass welding<br />

on thicknesses from<br />

0.8 mm - 4.8 mm<br />

(0.030 in - 3/16 in)<br />

Spot or short<br />

intermittent welds<br />

-152 NR®<br />

AWS E71T-14 • Mild Steel, All Position<br />

Key Features<br />

Designed for high speed welding of specially<br />

coated steels<br />

Soft, consistent arc<br />

Porosity resistant<br />

Excellent overlapping capabilities<br />

Ideal for robotic applications<br />

50 lb (22.7 kg)<br />

Coil<br />

ED012185<br />

ED012186<br />

MECHANICAL PROPERTIES (1) – As Required per AWS A5.20/A5.20M<br />

Transverse Tensile Strength<br />

MPa (ksi)<br />

Longitudinal<br />

Bend Test<br />

Continuous welding<br />

on galvanized or zinc<br />

coated carbon steel<br />

Automotive<br />

Transportation<br />

500 lb (227 kg)<br />

Speed-Feed ® Drum<br />

ED024301<br />

Hardness<br />

Rockwell B<br />

Requirements - AWS E71T-14 480 (70) min. 180° over 3/4 in Radius / No openings exceeding 1/8 in –<br />

Typical Results (2) 480-550 (70-80) Passed 93<br />

DEPOSIT COMPOSITION (1) – As Required per AWS A5.20/A5.20M<br />

%C %Mn %Si %S %P %Al<br />

Requirements - AWS E71T-14 Not Specified<br />

Typical Results (2) 0.25-0.30 0.83-1.04 0.20-0.23 0.006-0.01 0.005-0.02 1.08-1.38<br />

TYPICAL OPERATING PROCEDURES<br />

Diameter, CTWD Wire Feed Speed Voltage Approx. Current Melt-Off Rate Deposition Rate Efficiency<br />

Polarity mm (in) m/min (in/min) (volts) (amps) kg/hr (lb/hr) kg/hr (lb/hr) (%)<br />

0.8 (30) 13-14 90<br />

0.5 (1.3) 0.5 (1.2) 92<br />

1/16 in (1.6 mm),<br />

DC-<br />

16<br />

(5/8)<br />

1.0<br />

1.3<br />

1.8<br />

(40)<br />

(50)<br />

(70)<br />

14-15<br />

15-16<br />

16-17<br />

115<br />

140<br />

185<br />

0.8<br />

0.9<br />

1.4<br />

(1.8)<br />

(2.2)<br />

(3.1)<br />

0.7<br />

0.9<br />

1.3<br />

(1.6)<br />

(2.0)<br />

(2.8)<br />

88<br />

90<br />

90<br />

2.8 (110) 19-20 265 2.1 (4.8) 2.0 (4.4) 91<br />

0.8 (30) 13-14 68<br />

0.7 (1.6) 0.6 (1.4) 87<br />

1.0 (40) 13-14 95<br />

0.9 (2.2) 0.9 (1.9) 86<br />

0.068 in (1.7 mm), 19 1.3 (50) 14-15 120 1.2 (2.7) 1.1 (2.4) 88<br />

Twinarc, DC- (3/4) 1.5 (60) 15-16 145 1.4 (3.3) 1.3 (2.9) 87<br />

2.0 (80) 16-17 190 1.9 (4.4) 1.8 (3.9) 88<br />

2.8 (110) 20-21 240 2.7 (6.0) 2.4 (5.4) 90<br />

(1) Typical all weld metal. (2) See test results disclaimer on pg. 16.<br />

NOTE: The preferred drag angle is 15°, however, NR-152 is capable of welding at zero drag angle, facilitating easy fixturing in automatic applications.<br />

WELDING CONSUMABLES CATALOG ı 87