Consumeables Catalog - Lincoln Electric

Consumeables Catalog - Lincoln Electric Consumeables Catalog - Lincoln Electric

BATCH | MIG (GMAW) WIRE Blue Max® Stainless Steel • AWS ER316/ER316L Key Features Q2 Lot ® - Certificate showing actual wire composition and calculated ferrite number (FN) available online Available as Batch Managed Inventory “N” Designator - cobalt restriction of 0.05% max Meets the low Si levels typically required in the nuclear industry Meets the low cobalt levels typically required in the nuclear industry. Prior to using this material for ASME Boiler and Pressure Vessel Code Section III applications, please contact the Lincoln Electric Specials Department to receive a Certified Material Test Report (CMTR) which meets all requirements of NCA-3860 Composition controlled to meet nuclear and power generation requirements Each spool is identified with AWS classification and LOT number 336 ı THE LINCOLN ELECTRIC COMPANY MIG 316L N Typical Applications Nuclear power plant components, maintenance and construction Power and process industry related piping Pressure Vessels ASME IX Qualification ASME IX Qualification: QW432 F-No 6, QW442 A-No 8 Conformances AWS A5.9/A5.9M: 2006: ASME SFA-A5.9: Welding Positions All DIAMETERS / PACKAGING Diameter 33 lb (15 kg) in (mm) Steel Spool 0.035 (0.9) 0.045 (1.1) ED033852 ED033853 MECHANICAL PROPERTIES (1) – As Required per AWS A5.9/A5.9M: 2006 Yield Strength (2) MPa (ksi) Tensile Strength MPa (ksi) Elongation % ER316, ER316L ER316, ER316L Ferrite Number Requirements - AWS ER316Si, ER316LSi Not Specified Test Results (3) - As-Welded 405 (59) 560 (81) 40 10

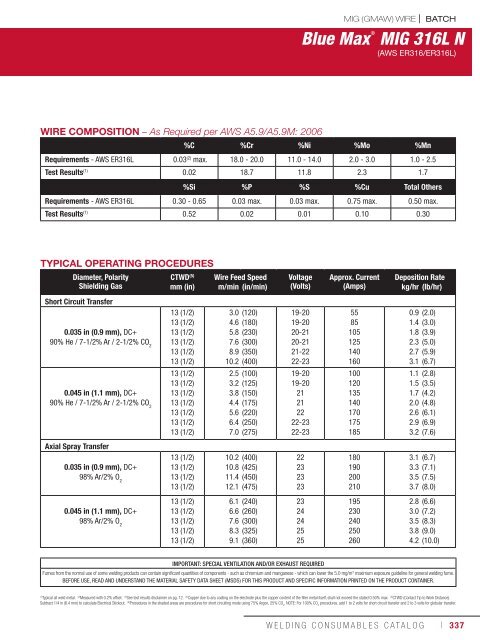

TYPICAL OPERATING PROCEDURES Diameter, Polarity Shielding Gas Short Circuit Transfer 0.035 in (0.9 mm), DC+ 90% He / 7-1/2% Ar / 2-1/2% CO 2 0.045 in (1.1 mm), DC+ 90% He / 7-1/2% Ar / 2-1/2% CO 2 IMPORTANT: SPECIAL VENTILATION AND/OR EXHAUST REQUIRED Blue Max ® MIG (GMAW) WIRE | BATCH MIG 316L N (AWS ER316/ER316L) WIRE COMPOSITION – As Required per AWS A5.9/A5.9M: 2006 %C %Cr %Ni %Mo %Mn Requirements - AWS ER316L 0.03 (2) max. 18.0 - 20.0 11.0 - 14.0 2.0 - 3.0 1.0 - 2.5 Test Results (1) 0.02 18.7 11.8 2.3 1.7 Axial Spray Transfer 0.035 in (0.9 mm), DC+ 98% Ar/2% O 2 0.045 in (1.1 mm), DC+ 98% Ar/2% O 2 CTWD (5) Wire Feed Speed Voltage Approx. Current Deposition Rate mm (in) m/min (in/min) (Volts) (Amps) kg/hr (lb/hr) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) 13 (1/2) %Si %P %S %Cu Total Others Requirements - AWS ER316L 0.30 - 0.65 0.03 max. 0.03 max. 0.75 max. 0.50 max. Test Results (1) 0.52 0.02 0.01 0.10 0.30 3.0 (120) 4.6 (180) 5.8 (230) 7.6 (300) 8.9 (350) 10.2 (400) 2.5 (100) 3.2 (125) 3.8 (150) 4.4 (175) 5.6 (220) 6.4 (250) 7.0 (275) 10.2 (400) 10.8 (425) 11.4 (450) 12.1 (475) 6.1 (240) 6.6 (260) 7.6 (300) 8.3 (325) 9.1 (360) 19-20 19-20 20-21 20-21 21-22 22-23 19-20 19-20 21 21 22 22-23 22-23 Fumes from the normal use of some welding products can contain significant quantities of components - such as chromium and manganese - which can lower the 5.0 mg/m 3 maximum exposure guideline for general welding fume. BEFORE USE, READ AND UNDERSTAND THE MATERIAL SAFETY DATA SHEET (MSDS) FOR THIS PRODUCT AND SPECIFIC INFORMATION PRINTED ON THE PRODUCT CONTAINER. (1) Typical all weld metal. (2) Measured with 0.2% offset. (3) See test results disclaimer on pg. 12. (4) Copper due to any coating on the electrode plus the copper content of the filler metal itself, shall not exceed the stated 0.50% max. (5) CTWD (Contact Tip to Work Distance). Subtract 1/4 in (6.4 mm) to calculate Electrical Stickout. (6) Procedures in the shaded areas are procedures for short circuiting mode using 75% Argon, 25% CO 2 . NOTE: For 100% CO 2 procedures, add 1 to 2 volts for short circuit transfer and 2 to 3 volts for globular transfer. 22 23 23 23 23 24 24 25 25 55 85 105 125 140 160 100 120 135 140 170 175 185 180 190 200 210 195 230 240 250 260 0.9 (2.0) 1.4 (3.0) 1.8 (3.9) 2.3 (5.0) 2.7 (5.9) 3.1 (6.7) 1.1 (2.8) 1.5 (3.5) 1.7 (4.2) 2.0 (4.8) 2.6 (6.1) 2.9 (6.9) 3.2 (7.6) 3.1 (6.7) 3.3 (7.1) 3.5 (7.5) 3.7 (8.0) 2.8 (6.6) 3.0 (7.2) 3.5 (8.3) 3.8 (9.0) 4.2 (10.0) WELDING CONSUMABLES CATALOG ı 337

- Page 288 and 289: SuperGlaze ® MIG (GMAW) WIRE Alumi

- Page 290 and 291: TIG (GTAW) CUT LENGTHS SuperGlaze A

- Page 292 and 293: ALUMINUM & CAST IRON CONSUMABLES No

- Page 294 and 295: PIPELINER ® STICK (SMAW) ELECTRODE

- Page 296 and 297: PIPELINER ® STICK (SMAW) ELECTRODE

- Page 298 and 299: PIPELINER ® STICK (SMAW) ELECTRODE

- Page 300 and 301: PIPELINER ® STICK (SMAW) ELECTRODE

- Page 302 and 303: PIPELINER ® STICK (SMAW) ELECTRODE

- Page 304 and 305: Pipeliner® Welding Positions All P

- Page 306 and 307: PIPELINER ® FLUX-CORED SELF-SHIELD

- Page 308 and 309: PIPELINER ® FLUX-CORED GAS-SHIELDE

- Page 310 and 311: PIPELINER ® FLUX-CORED GAS-SHIELDE

- Page 312 and 313: PIPELINER ® CONSUMABLES Electrode

- Page 314 and 315: PIPELINER ® CONSUMABLES Electrode

- Page 316 and 317: PIPELINER ® CONSUMABLES EN and ISO

- Page 318 and 319: Agency Approvals NOTE: Approvals ar

- Page 320 and 321: PIPELINER ® CONSUMABLES Notes 318

- Page 322 and 323: Power Generation & Nuclear Lincoln

- Page 324 and 325: BATCH | STICK (SMAW) ELECTRODE Exca

- Page 326 and 327: STICK (SMAW) ELECTRODE Excalibur®

- Page 328 and 329: STICK (SMAW) ELECTRODE Excalibur®

- Page 330 and 331: BATCH | MIG (GMAW) WIRE SuperArc®

- Page 332 and 333: BATCH | MIG (GMAW) WIRE SuperArc®

- Page 334 and 335: BATCH | MIG (GMAW) WIRE Blue Max®

- Page 336 and 337: BATCH | MIG (GMAW) WIRE Blue Max®

- Page 340 and 341: BATCH | MIG (GMAW) WIRE Blue Max®

- Page 342 and 343: TIG (GTAW) CUT LENGTHS Lincoln® Lo

- Page 344 and 345: BATCH | TIG (GTAW) CUT LENGTHS Linc

- Page 346 and 347: BATCH | ORBITAL TIG (GTAW) WIRE Sup

- Page 348 and 349: BATCH | FLUX-CORED GAS-SHIELDED (FC

- Page 350 and 351: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 352 and 353: SUBMERGED ARC (SAW) FLUX AND WIRE C

- Page 354 and 355: SUBMERGED ARC (SAW) WIRE AND FLUX L

- Page 356 and 357: SUBMERGED ARC (SAW) WIRE AND FLUX L

- Page 358 and 359: PACKAGING Tubes, Cans & Cartons 5 l

- Page 360 and 361: PACKAGING Reels & Stem REELS Wire T

- Page 362 and 363: PACKAGING Spools A SPOOLS Wire Type

- Page 364 and 365: PACKAGING Coils, Boxes & Bags COILS

- Page 366 and 367: PACKAGING Drums & Pails DRUMS Wire

- Page 368 and 369: PACKAGING Storage & Handling Stick

- Page 370 and 371: PACKAGING Storage & Handling Metal-

- Page 372 and 373: PACKAGING Storage & Handling Submer

- Page 374 and 375: APPENDIX AWS Classification System

- Page 376 and 377: APPENDIX AWS Classification System

- Page 378 and 379: APPENDIX AWS Classification System

- Page 380 and 381: APPENDIX AWS Classification System

- Page 382 and 383: APPENDIX Stick Electrode Types of C

- Page 384 and 385: APPENDIX Submerged Arc Fluxes Flux

- Page 386 and 387: APPENDIX Submerged Arc Flux/Wire Se

TYPICAL OPERATING PROCEDURES<br />

Diameter, Polarity<br />

Shielding Gas<br />

Short Circuit Transfer<br />

0.035 in (0.9 mm), DC+<br />

90% He / 7-1/2% Ar / 2-1/2% CO 2<br />

0.045 in (1.1 mm), DC+<br />

90% He / 7-1/2% Ar / 2-1/2% CO 2<br />

IMPORTANT: SPECIAL VENTILATION AND/OR EXHAUST REQUIRED<br />

Blue Max ®<br />

MIG (GMAW) WIRE | BATCH<br />

MIG 316L N<br />

(AWS ER316/ER316L)<br />

WIRE COMPOSITION – As Required per AWS A5.9/A5.9M: 2006<br />

%C %Cr %Ni %Mo %Mn<br />

Requirements - AWS ER316L 0.03 (2) max. 18.0 - 20.0 11.0 - 14.0 2.0 - 3.0 1.0 - 2.5<br />

Test Results (1) 0.02 18.7 11.8 2.3 1.7<br />

Axial Spray Transfer<br />

0.035 in (0.9 mm), DC+<br />

98% Ar/2% O 2<br />

0.045 in (1.1 mm), DC+<br />

98% Ar/2% O 2<br />

CTWD (5) Wire Feed Speed Voltage Approx. Current Deposition Rate<br />

mm (in) m/min (in/min) (Volts) (Amps) kg/hr (lb/hr)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

13 (1/2)<br />

%Si %P %S %Cu Total Others<br />

Requirements - AWS ER316L 0.30 - 0.65 0.03 max. 0.03 max. 0.75 max. 0.50 max.<br />

Test Results (1) 0.52 0.02 0.01 0.10 0.30<br />

3.0 (120)<br />

4.6 (180)<br />

5.8 (230)<br />

7.6 (300)<br />

8.9 (350)<br />

10.2 (400)<br />

2.5 (100)<br />

3.2 (125)<br />

3.8 (150)<br />

4.4 (175)<br />

5.6 (220)<br />

6.4 (250)<br />

7.0 (275)<br />

10.2 (400)<br />

10.8 (425)<br />

11.4 (450)<br />

12.1 (475)<br />

6.1 (240)<br />

6.6 (260)<br />

7.6 (300)<br />

8.3 (325)<br />

9.1 (360)<br />

19-20<br />

19-20<br />

20-21<br />

20-21<br />

21-22<br />

22-23<br />

19-20<br />

19-20<br />

21<br />

21<br />

22<br />

22-23<br />

22-23<br />

Fumes from the normal use of some welding products can contain significant quantities of components - such as chromium and manganese - which can lower the 5.0 mg/m 3 maximum exposure guideline for general welding fume.<br />

BEFORE USE, READ AND UNDERSTAND THE MATERIAL SAFETY DATA SHEET (MSDS) FOR THIS PRODUCT AND SPECIFIC INFORMATION PRINTED ON THE PRODUCT CONTAINER.<br />

(1) Typical all weld metal. (2) Measured with 0.2% offset. (3) See test results disclaimer on pg. 12. (4) Copper due to any coating on the electrode plus the copper content of the filler metal itself, shall not exceed the stated 0.50% max. (5) CTWD (Contact Tip to Work Distance).<br />

Subtract 1/4 in (6.4 mm) to calculate <strong>Electric</strong>al Stickout. (6) Procedures in the shaded areas are procedures for short circuiting mode using 75% Argon, 25% CO 2 . NOTE: For 100% CO 2 procedures, add 1 to 2 volts for short circuit transfer and 2 to 3 volts for globular transfer.<br />

22<br />

23<br />

23<br />

23<br />

23<br />

24<br />

24<br />

25<br />

25<br />

55<br />

85<br />

105<br />

125<br />

140<br />

160<br />

100<br />

120<br />

135<br />

140<br />

170<br />

175<br />

185<br />

180<br />

190<br />

200<br />

210<br />

195<br />

230<br />

240<br />

250<br />

260<br />

0.9 (2.0)<br />

1.4 (3.0)<br />

1.8 (3.9)<br />

2.3 (5.0)<br />

2.7 (5.9)<br />

3.1 (6.7)<br />

1.1 (2.8)<br />

1.5 (3.5)<br />

1.7 (4.2)<br />

2.0 (4.8)<br />

2.6 (6.1)<br />

2.9 (6.9)<br />

3.2 (7.6)<br />

3.1 (6.7)<br />

3.3 (7.1)<br />

3.5 (7.5)<br />

3.7 (8.0)<br />

2.8 (6.6)<br />

3.0 (7.2)<br />

3.5 (8.3)<br />

3.8 (9.0)<br />

4.2 (10.0)<br />

WELDING CONSUMABLES CATALOG ı 337