Consumeables Catalog - Lincoln Electric

Consumeables Catalog - Lincoln Electric Consumeables Catalog - Lincoln Electric

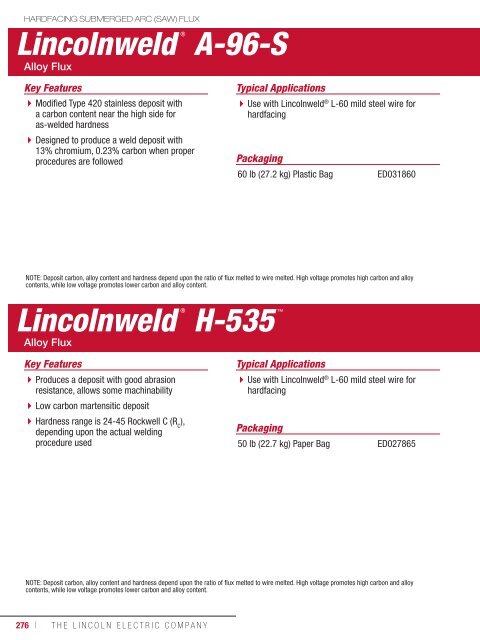

HARDFACING SUBMERGED ARC (SAW) FLUX Lincolnweld ® Alloy Flux Key Features Modified Type 420 stainless deposit with a carbon content near the high side for as-welded hardness Designed to produce a weld deposit with 13% chromium, 0.23% carbon when proper procedures are followed 276 ı THE LINCOLN ELECTRIC COMPANY A-96-S Typical Applications Use with Lincolnweld ® L-60 mild steel wire for hardfacing Packaging 60 lb (27.2 kg) Plastic Bag ED031860 NOTE: Deposit carbon, alloy content and hardness depend upon the ratio of flux melted to wire melted. High voltage promotes high carbon and alloy contents, while low voltage promotes lower carbon and alloy content. Lincolnweld ® Alloy Flux Key Features Produces a deposit with good abrasion resistance, allows some machinability Low carbon martensitic deposit Hardness range is 24-45 Rockwell C (R ), C depending upon the actual welding procedure used H-535 Typical Applications Use with Lincolnweld ® L-60 mild steel wire for hardfacing Packaging 50 lb (22.7 kg) Paper Bag ED027865 NOTE: Deposit carbon, alloy content and hardness depend upon the ratio of flux melted to wire melted. High voltage promotes high carbon and alloy contents, while low voltage promotes lower carbon and alloy content.

Typical Applications Use with Lincolnweld ® L-60 mild steel wire for hardfacing Packaging 100 lb (45.4 kg) Paper Bag ED010345 HARDFACING SUBMERGED ARC (SAW) FLUX Lincolnweld ® Key Features H-560 EN 760 – S A Z 3 • Alloy Flux High alloy flux depositing primary carbides in a martensitic matrix Excellent material for severe abrasion applications Resistance to abrasion is 50 to 60 times that of plain carbon steel NOTE: Deposit carbon, alloy content and hardness depend upon the ratio of flux melted to wire melted. High voltage promotes high carbon and alloy contents, while low voltage promotes lower carbon and alloy content. Packaging 50 lb (22.7 kg) Paper Bag 550 lb (249 kg) Drum 3000 lb (1361 kg) Bulk Bag Lincolnweld ® 801® EN 760 – S A FB 1; EN 760 – S A FB 2 • Neutral Flux ED019588 ED023403 EDS30786 Key Features Provides smooth beads and excellent slag removal Fast-freezing Typical Applications Hardfacing Use with Lincore ® 20, 30-S, 35-S, 40-S, 42-S, 4130, 8620, 410, 410NiMo, 420 and 96S NOTE: Deposit carbon, alloy content and hardness depend upon the ratio of flux melted to wire melted. High voltage promotes high carbon and alloy contents, while low voltage promotes lower carbon and alloy content. WELDING CONSUMABLES CATALOG ı 277

- Page 228 and 229: SUBMERGED ARC (SAW) ELECTRODE Linco

- Page 230 and 231: SUBMERGED ARC (SAW) FLUX Lincolnwel

- Page 232 and 233: TIG (GTAW) CUT LENGTHS Lincoln® St

- Page 234 and 235: TIG (GTAW) CUT LENGTHS Lincoln® St

- Page 236 and 237: METAL-CORED (GMAW-C) WIRE Outershie

- Page 238 and 239: HARDFACING STICK (SMAW) ELECTRODE W

- Page 240 and 241: HARDFACING STICK (SMAW) ELECTRODE W

- Page 242 and 243: HARDFACING STICK (SMAW) ELECTRODE W

- Page 244 and 245: HARDFACING STICK (SMAW) ELECTRODE W

- Page 246 and 247: HARDFACING STICK (SMAW) ELECTRODE W

- Page 248 and 249: HARDFACING METAL-CORED GAS-SHIELDED

- Page 250 and 251: HARDFACING METAL-CORED (GMAW-C) WIR

- Page 252 and 253: HARDFACING FLUX-CORED SELF-SHIELDED

- Page 254 and 255: HARDFACING FLUX-CORED SELF-SHIELDED

- Page 256 and 257: HARDFACING FLUX-CORED SELF-SHIELDED

- Page 258 and 259: HARDFACING FLUX-CORED SELF-SHIELDED

- Page 260 and 261: HARDFACING FLUX-CORED SELF-SHIELDED

- Page 262 and 263: HARDFACING METAL-CORED SUBMERGED AR

- Page 264 and 265: HARDFACING METAL-CORED SUBMERGED AR

- Page 266 and 267: HARDFACING METAL-CORED SUBMERGED AR

- Page 268 and 269: HARDFACING METAL-CORED SUBMERGED AR

- Page 270 and 271: HARDFACING METAL-CORED SUBMERGED AR

- Page 272 and 273: HARDFACING METAL-CORED SUBMERGED AR

- Page 274 and 275: HARDFACING METAL-CORED SUBMERGED AR

- Page 276 and 277: HARDFACING METAL-CORED SUBMERGED AR

- Page 280 and 281: HARDFACING SUBMERGED ARC (SAW) FLUX

- Page 282 and 283: MIG (GMAW) WIRE SuperGlaze Aluminum

- Page 284 and 285: MIG (GMAW) WIRE SuperGlaze Aluminum

- Page 286 and 287: MIG (GMAW) WIRE SuperGlaze Aluminum

- Page 288 and 289: SuperGlaze ® MIG (GMAW) WIRE Alumi

- Page 290 and 291: TIG (GTAW) CUT LENGTHS SuperGlaze A

- Page 292 and 293: ALUMINUM & CAST IRON CONSUMABLES No

- Page 294 and 295: PIPELINER ® STICK (SMAW) ELECTRODE

- Page 296 and 297: PIPELINER ® STICK (SMAW) ELECTRODE

- Page 298 and 299: PIPELINER ® STICK (SMAW) ELECTRODE

- Page 300 and 301: PIPELINER ® STICK (SMAW) ELECTRODE

- Page 302 and 303: PIPELINER ® STICK (SMAW) ELECTRODE

- Page 304 and 305: Pipeliner® Welding Positions All P

- Page 306 and 307: PIPELINER ® FLUX-CORED SELF-SHIELD

- Page 308 and 309: PIPELINER ® FLUX-CORED GAS-SHIELDE

- Page 310 and 311: PIPELINER ® FLUX-CORED GAS-SHIELDE

- Page 312 and 313: PIPELINER ® CONSUMABLES Electrode

- Page 314 and 315: PIPELINER ® CONSUMABLES Electrode

- Page 316 and 317: PIPELINER ® CONSUMABLES EN and ISO

- Page 318 and 319: Agency Approvals NOTE: Approvals ar

- Page 320 and 321: PIPELINER ® CONSUMABLES Notes 318

- Page 322 and 323: Power Generation & Nuclear Lincoln

- Page 324 and 325: BATCH | STICK (SMAW) ELECTRODE Exca

- Page 326 and 327: STICK (SMAW) ELECTRODE Excalibur®

HARDFACING SUBMERGED ARC (SAW) FLUX<br />

<strong>Lincoln</strong>weld ®<br />

Alloy Flux<br />

Key Features<br />

Modified Type 420 stainless deposit with<br />

a carbon content near the high side for<br />

as-welded hardness<br />

Designed to produce a weld deposit with<br />

13% chromium, 0.23% carbon when proper<br />

procedures are followed<br />

276 ı THE LINCOLN ELECTRIC COMPANY<br />

A-96-S<br />

Typical Applications<br />

Use with <strong>Lincoln</strong>weld ® L-60 mild steel wire for<br />

hardfacing<br />

Packaging<br />

60 lb (27.2 kg) Plastic Bag ED031860<br />

NOTE: Deposit carbon, alloy content and hardness depend upon the ratio of flux melted to wire melted. High voltage promotes high carbon and alloy<br />

contents, while low voltage promotes lower carbon and alloy content.<br />

<strong>Lincoln</strong>weld ®<br />

Alloy Flux<br />

Key Features<br />

Produces a deposit with good abrasion<br />

resistance, allows some machinability<br />

Low carbon martensitic deposit<br />

Hardness range is 24-45 Rockwell C (R ), C<br />

depending upon the actual welding<br />

procedure used<br />

H-535<br />

Typical Applications<br />

Use with <strong>Lincoln</strong>weld ® L-60 mild steel wire for<br />

hardfacing<br />

Packaging<br />

50 lb (22.7 kg) Paper Bag ED027865<br />

NOTE: Deposit carbon, alloy content and hardness depend upon the ratio of flux melted to wire melted. High voltage promotes high carbon and alloy<br />

contents, while low voltage promotes lower carbon and alloy content.