Consumeables Catalog - Lincoln Electric

Consumeables Catalog - Lincoln Electric Consumeables Catalog - Lincoln Electric

SUBMERGED ARC (SAW) FLUX Lincolnweld ® Industry standard for submerged arc welding applications Excellent operating characteristics in a variety of general welding applications Capable of producing weld deposits with impact toughness exceeding 27 J (20 ft•lbf) at -40°C (-40°F) with Lincolnweld ® L-61 ® Key Features Typical Applications AASHTO Fracture Critical applications with Lincolnweld ® L-61 ® wire Pipe and other double ending applications General purpose structural and multiple pass welds Storage tanks using L-61 ® or LA-85 162 ı THE LINCOLN ELECTRIC COMPANY 860® 800 Series Neutral Flux • EN 760 – S A AB 1 FLUX COMPOSITION (1) AWS TEST RESULTS (1) Flux/Wire Combination L-50 ® L-56 ® L-56 ® L-60 L-61 ® L-61 ® L-S3 LA-71 LA-71 L-70 L-70 LA-75 LA-75 LA-82 LA-85 Weld Condition As-welded As-welded Stress-relieved (3) As-welded As-welded Stress-relieved (3) As-welded As-welded Stress relieved (3) As-welded Stress-relieved (3) As-welded Stress-relieved (3) As-welded As-welded (1) See test results disclaimer on pg. 16. (2) Measured with 0.2% offset. (3) Stress-relieved for 1 hour at 621°C (1150°F). NOTE: For the most up-to-date AWS certificates of conformances please visit www.lincolnelectric.com Recommended Wires For Mild Steel Lincolnweld ® L-50 ® , L-56 ® , L-60, L-61 ® , LA-71, L-S3 For Low Alloy Steel Lincolnweld ® L-70, LA-75, LA-82, LA-85 Product Information Basicity Index: 1.1 Density: 1.4 g/cm3 Packaging 50 lb (22.7 kg) Bag ED019589 %SiO 2 %MnO %MgO %CaF 2 %Na 2 O %Al 2 O 3 %CaO %TiO 2 % Metal Alloys Lincolnweld ® 860 ® 19 11 17 12 2 32 2 2 3 max. Yield Strength (2) Tensile Strength Elongation Charpy V-Notch AWS Classification MPa (ksi) MPa (ksi) (%) J (ft•lbf) @ °C (°F) (A5.17/A5.23) 430 (62) 470 (68) 440 (64) 370 (54) 410 (59) 340 (49) 500 (73) 450 (65) 400 (58) 450 (65) 430 (62) 460 (66) 410 (60) 660 (96) 520 (75) 520 (75) 590 (86) 570 (82) 450 (65) 500 (72) 440 (64) 590 (86) 540 (78) 520 (75) 550 (80) 520 (76) 550 (80) 540 (79) 740 (107) 600 (87) 30 28 29 34 31 37 28 30 32 28 31 32 30 24 26 84 (62) 61 (45) 80 (59) 138 (102) 58 (43) 222 (164) 52 (38) 110 (81) 119 (88) 54 (40) 47 (35) 107 (79) 99 (73) 50 (37) 38 (28) -29 -29 -29 -29 -40 -46 -29 -29 -29 -29 -29 -29 -29 -40 -40 (-20) (-20) (-20) (-20) (-40) (-50) (-20) (-20) (-20) (-20) (-20) (-20) (-20) (-40) (-40) F7A2-EM13K-H8 F7A2-EH11K F7P2-EH11K F6A2-EL12-H8 F7A4-EM12K-H8 F6P5-EM12K-H8 F7A2-EH12K F7A2-EM14K-H8 F7P2-EM14K-H8 F7A2-EA1-A2-H8 F7P2-EA1-A2-H8 F7A2-ENi1K-Ni1-H8 F7P2-ENi1K-Ni1-H8 F9A4-EF2-F2-H8 E8A4-ENi5-Ni5-H8

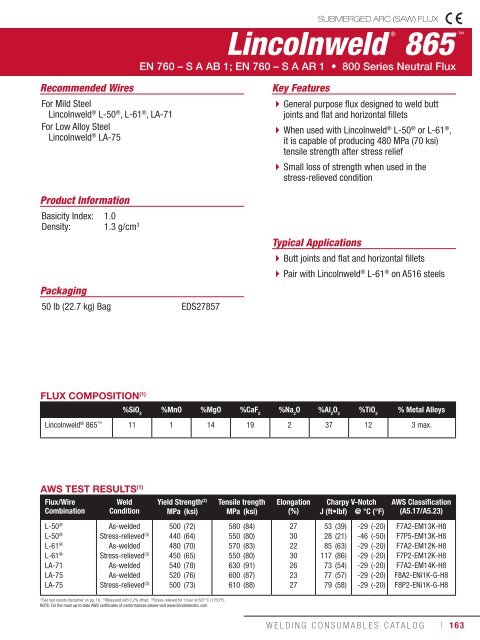

Recommended Wires For Mild Steel Lincolnweld ® L-50 ® , L-61 ® , LA-71 For Low Alloy Steel Lincolnweld ® LA-75 Product Information Basicity Index: 1.0 Density: 1.3 g/cm3 Packaging 50 lb (22.7 kg) Bag EDS27857 FLUX COMPOSITION (1) SUBMERGED ARC (SAW) FLUX Lincolnweld ® 865 EN 760 – S A AB 1; EN 760 – S A AR 1 • 800 Series Neutral Flux General purpose flux designed to weld butt joints and flat and horizontal fillets When used with Lincolnweld ® L-50 ® or L-61 ® Key Features , it is capable of producing 480 MPa (70 ksi) tensile strength after stress relief Small loss of strength when used in the stress-relieved condition Typical Applications Butt joints and flat and horizontal fillets Pair with Lincolnweld ® L-61 ® on A516 steels %SiO 2 %MnO %MgO %CaF 2 %Na 2 O %Al 2 O 3 %TiO 2 % Metal Alloys Lincolnweld ® 865 11 1 14 19 2 37 12 3 max. AWS TEST RESULTS (1) Flux/Wire Combination L-50 ® L-50 ® L-61 ® L-61 ® LA-71 LA-75 LA-75 Weld Condition As-welded Stress-relieved (3) As-welded Stress-relieved (3) As-welded As-welded Stress-relieved (3) Yield Strength (2) Tensile trength Elongation Charpy V-Notch AWS Classification MPa (ksi) MPa (ksi) (%) J (ft•lbf) @ °C (°F) (A5.17/A5.23) 500 (72) 440 (64) 480 (70) 450 (65) 540 (78) 520 (76) 500 (73) (1) See test results disclaimer on pg. 16. (2) Measured with 0.2% offset. (3) Stress-relieved for 1 hour at 621°C (1150°F). NOTE: For the most up-to-date AWS certificates of conformances please visit www.lincolnelectric.com 580 (84) 550 (80) 570 (83) 550 (80) 630 (91) 600 (87) 610 (88) 27 30 22 30 26 23 27 53 (39) 28 (21) 85 (63) 117 (86) 73 (54) 77 (57) 79 (58) -29 (-20) -46 (-50) -29 (-20) -29 (-20) -29 (-20) -29 (-20) -29 (-20) F7A2-EM13K-H8 F7P5-EM13K-H8 F7A2-EM12K-H8 F7P2-EM12K-H8 F7A2-EM14K-H8 F8A2-ENi1K-G-H8 F8P2-ENi1K-G-H8 WELDING CONSUMABLES CATALOG ı 163

- Page 114 and 115: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 116 and 117: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 118 and 119: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 120 and 121: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 122 and 123: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 124 and 125: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 126 and 127: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 128 and 129: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 130 and 131: Structural Welding Code Seismic Sup

- Page 132 and 133: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 134 and 135: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 136 and 137: Structural Welding Code Seismic Sup

- Page 138 and 139: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 140 and 141: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 142 and 143: Structural Welding Code Seismic Sup

- Page 144 and 145: Structural Welding Code Seismic Sup

- Page 146 and 147: Structural Welding Code Seismic Sup

- Page 148 and 149: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 150 and 151: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 152 and 153: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 154 and 155: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 156 and 157: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 158 and 159: FLUX-CORED GAS-SHIELDED (FCAW-G) WI

- Page 160 and 161: SUBMERGED ARC (SAW) FLUX Lincolnwel

- Page 162 and 163: SUBMERGED ARC (SAW) FLUX Lincolnwel

- Page 166 and 167: SUBMERGED ARC (SAW) FLUX Lincolnwel

- Page 168 and 169: SUBMERGED ARC (SAW) FLUX Lincolnwel

- Page 170 and 171: SUBMERGED ARC (SAW) FLUX Lincolnwel

- Page 172 and 173: SUBMERGED ARC (SAW) FLUX Lincolnwel

- Page 174 and 175: SUBMERGED ARC (SAW) FLUX Lincolnwel

- Page 176 and 177: Lincolnweld ® Features the chemica

- Page 178 and 179: SUBMERGED ARC (SAW) FLUX Lincolnwel

- Page 180 and 181: SUBMERGED ARC (SAW) FLUX Lincolnwel

- Page 182 and 183: SUBMERGED ARC (SAW) ELECTRODE Linco

- Page 184 and 185: SUBMERGED ARC (SAW) ELECTRODE Linco

- Page 186 and 187: SUBMERGED ARC (SAW) ELECTRODE Linco

- Page 188 and 189: SUBMERGED ARC (SAW) ELECTRODE Linco

- Page 190 and 191: SUBMERGED ARC (SAW) ELECTRODE Linco

- Page 192 and 193: SUBMERGED ARC (SAW) ELECTRODE Linco

- Page 194 and 195: SUBMERGED ARC (SAW) CONSUMABLES Not

- Page 196 and 197: STICK (SMAW) ELECTRODE Excalibur®

- Page 198 and 199: STICK (SMAW) ELECTRODE Excalibur ®

- Page 200 and 201: STICK (SMAW) ELECTRODE Excalibur ®

- Page 202 and 203: STICK (SMAW) ELECTRODE Excalibur ®

- Page 204 and 205: STICK (SMAW) ELECTRODE Excalibur ®

- Page 206 and 207: MIG (GMAW) WIRE Blue Max® Stainles

- Page 208 and 209: MIG (GMAW) WIRE Blue Max® Stainles

- Page 210 and 211: MIG (GMAW) WIRE Blue Max ® Stainle

- Page 212 and 213: MIG (GMAW) WIRE Blue Max® Stainles

Recommended Wires<br />

For Mild Steel<br />

<strong>Lincoln</strong>weld ® L-50 ® , L-61 ® , LA-71<br />

For Low Alloy Steel<br />

<strong>Lincoln</strong>weld ® LA-75<br />

Product Information<br />

Basicity Index: 1.0<br />

Density: 1.3 g/cm3 Packaging<br />

50 lb (22.7 kg) Bag EDS27857<br />

FLUX COMPOSITION (1)<br />

SUBMERGED ARC (SAW) FLUX<br />

<strong>Lincoln</strong>weld ®<br />

865<br />

EN 760 – S A AB 1; EN 760 – S A AR 1 • 800 Series Neutral Flux<br />

General purpose flux designed to weld butt<br />

joints and flat and horizontal fillets<br />

When used with <strong>Lincoln</strong>weld ® L-50 ® or L-61 ® Key Features<br />

,<br />

it is capable of producing 480 MPa (70 ksi)<br />

tensile strength after stress relief<br />

Small loss of strength when used in the<br />

stress-relieved condition<br />

Typical Applications<br />

Butt joints and flat and horizontal fillets<br />

Pair with <strong>Lincoln</strong>weld ® L-61 ® on A516 steels<br />

%SiO 2 %MnO %MgO %CaF 2 %Na 2 O %Al 2 O 3 %TiO 2 % Metal Alloys<br />

<strong>Lincoln</strong>weld ® 865 11 1 14 19 2 37 12 3 max.<br />

AWS TEST RESULTS (1)<br />

Flux/Wire<br />

Combination<br />

L-50 ®<br />

L-50 ®<br />

L-61 ®<br />

L-61 ®<br />

LA-71<br />

LA-75<br />

LA-75<br />

Weld<br />

Condition<br />

As-welded<br />

Stress-relieved (3)<br />

As-welded<br />

Stress-relieved (3)<br />

As-welded<br />

As-welded<br />

Stress-relieved (3)<br />

Yield Strength (2) Tensile trength Elongation Charpy V-Notch AWS Classification<br />

MPa (ksi) MPa (ksi) (%) J (ft•lbf) @ °C (°F) (A5.17/A5.23)<br />

500 (72)<br />

440 (64)<br />

480 (70)<br />

450 (65)<br />

540 (78)<br />

520 (76)<br />

500 (73)<br />

(1) See test results disclaimer on pg. 16. (2) Measured with 0.2% offset. (3) Stress-relieved for 1 hour at 621°C (1150°F).<br />

NOTE: For the most up-to-date AWS certificates of conformances please visit www.lincolnelectric.com<br />

580 (84)<br />

550 (80)<br />

570 (83)<br />

550 (80)<br />

630 (91)<br />

600 (87)<br />

610 (88)<br />

27<br />

30<br />

22<br />

30<br />

26<br />

23<br />

27<br />

53 (39)<br />

28 (21)<br />

85 (63)<br />

117 (86)<br />

73 (54)<br />

77 (57)<br />

79 (58)<br />

-29 (-20)<br />

-46 (-50)<br />

-29 (-20)<br />

-29 (-20)<br />

-29 (-20)<br />

-29 (-20)<br />

-29 (-20)<br />

F7A2-EM13K-H8<br />

F7P5-EM13K-H8<br />

F7A2-EM12K-H8<br />

F7P2-EM12K-H8<br />

F7A2-EM14K-H8<br />

F8A2-ENi1K-G-H8<br />

F8P2-ENi1K-G-H8<br />

WELDING CONSUMABLES CATALOG ı 163