Watertube and Firetube Boilers page 31 - The Practical Knowledge ...

Watertube and Firetube Boilers page 31 - The Practical Knowledge ...

Watertube and Firetube Boilers page 31 - The Practical Knowledge ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Watertube</strong> <strong>and</strong> <strong>Firetube</strong> <strong>Boilers</strong> <strong>page</strong> <strong>31</strong><br />

101 PRACTICAL KNOWLEDGE OF STEAM BOILERS THIRD EDITION<br />

Question<br />

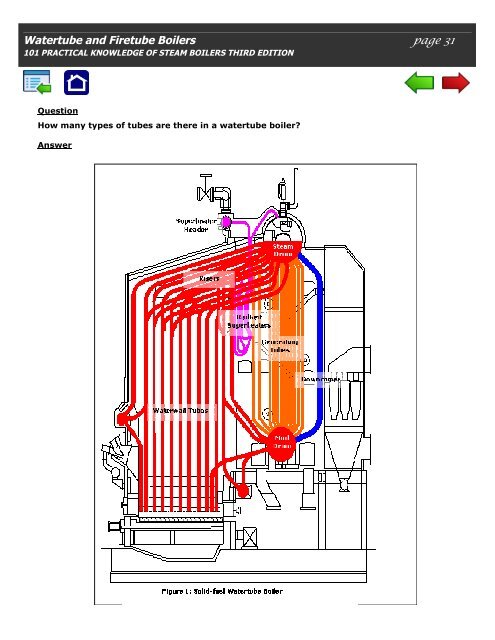

How many types of tubes are there in a watertube boiler?<br />

Answer

<strong>The</strong>re are six basic types:<br />

1. Downcomers: <strong>The</strong>se tubes have large diameters of which main function is to circulate water from<br />

the steam drum to mud drum or any other collecting bottom headers. <strong>The</strong> downcomers are normally<br />

placed outside the boiler casing so that it cannot absorb heat. Fresh boiler feed water flows through<br />

downcomers by gravitation <strong>and</strong> introducing heat to the downcomers will cause reversal of flow <strong>and</strong><br />

upset the boiler natural circulation.<br />

2. Generating tubes: <strong>The</strong>se tubes form a large bank of heater exchangers <strong>and</strong> located at the<br />

convective bank of the boiler. <strong>The</strong> heat transfer occurs through convection. <strong>The</strong> tubes form largest<br />

heating surface thus the highest proportion of steam is generated in the generating tubes.<br />

3. Risers: return steam <strong>and</strong> water from the top waterwall headers to the steam drum.<br />

4. Waterwall tubes: these tubes protect the boiler sidewall refractory from the direct heat of<br />

combustion <strong>and</strong> generate a small amount of steam. <strong>The</strong>re are many types of waterwall tubes<br />

construction.<br />

5. Superheater: consists of small-diameter tubes (OD is in the range of 32~51 mm <strong>and</strong> thickness in<br />

the range of 3~7 mm), <strong>and</strong> receives saturated steam from the boiler proper <strong>and</strong> superheat the steam.<br />

6. Screen tubes: protect the convective superheaters from direct radiant heat from the furnace. <strong>The</strong><br />

screen tubes consist of two to three staggered rows of tubes, which are usually connected from the<br />

steam drum to the water drum.

<strong>Watertube</strong> <strong>and</strong> <strong>Firetube</strong> <strong>Boilers</strong> <strong>page</strong> 32<br />

101 PRACTICAL KNOWLEDGE OF STEAM BOILERS THIRD EDITION<br />

Question<br />

What is a bent-tube boiler?<br />

Answer<br />

Normally, the bent-tube boiler has several drums (multi-drum). It is more flexible because it may enter the<br />

drum radially. <strong>The</strong> bent-tubes allow free expansion <strong>and</strong> contraction. It is also a rapid steamer <strong>and</strong> response<br />

to fluctuating load is small because of the relatively small volume for the generating capacity. <strong>The</strong> gas<br />

baffles are arranged in many different patterns.<br />

Question<br />

What is the weakest area (in regards to construction) of a bent tube water-tube boiler?<br />

Answer<br />

All boiler pressure parts are built to last for a long time. All parts are carefully calculated <strong>and</strong> high factor of<br />

safety was considered in the design.<br />

<strong>The</strong> weakest however, in regards to construction, is the area where the tube is bent at the largest bending<br />

radius. <strong>The</strong> tube thickness decreases at the outer tube surface but thicker at the inner as shown in the<br />

example below.

Question<br />

<strong>The</strong> firetube boilers are normally restricted to 250 psig. Elaborate the reasons.<br />

Answer<br />

Required thickness of a shell or a tube is a function of the radius. <strong>The</strong>refore, as the tube or shell gets larger,<br />

the thickness has to be increased to withst<strong>and</strong> the pressure. In order to contain high pressure, the shell has<br />

to be very big <strong>and</strong> very thick, which may be heavier <strong>and</strong> more expensive. <strong>The</strong> mobility of a very large boiler<br />

shell is also difficult.<br />

<strong>The</strong> formula to calculate the required drum thickness is:<br />

Where t = minimum required thickness<br />

P = MAWP<br />

S = maximum stress<br />

t = ___PD___<br />

2S + 2yP