Slips and engobes - Alfred's Clay Store

Slips and engobes - Alfred's Clay Store

Slips and engobes - Alfred's Clay Store

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Slips</strong> <strong>and</strong><br />

<strong>engobes</strong><br />

Lecture #11

<strong>Slips</strong> <strong>and</strong> <strong>engobes</strong><br />

• Historically used in Europe to make red clays look like<br />

imported white porcelain<br />

• <strong>Slips</strong> <strong>and</strong> <strong>engobes</strong> are used for many different reasons<br />

– Brighten overlying glazes on darker colored clays<br />

– Create a dense surface over an otherwise porous body<br />

– Allow for a vast pallet of color <strong>and</strong> texture<br />

– Cover up surface imperfections/roughness/even iron spots<br />

– Improve glaze fit without adjusting the glaze or the clay<br />

body (create a buffer layer)<br />

• WYSIWYG<br />

– Don’t run<br />

– Don’t pinhole (during firing)

• Traditionally<br />

– <strong>Slips</strong> are made exclusively of clay<br />

• For wet to leatherhard application<br />

– Engobes always contain fluxes <strong>and</strong> fillers <strong>and</strong><br />

usually contain clay<br />

• Often used for bisque-fired ware<br />

• Usually, though not exclusively, denser than slips<br />

• Today we call both categories “slips”<br />

• <strong>Slips</strong> are distinguished by the state of the<br />

ware to which they are applied <strong>and</strong> by the<br />

extent of vitrification<br />

– I.e. Vitreous or non-vitreous slip<br />

• for wet, leatherhard, green, or bisque application

• C.f . Latin – “sealed earth”<br />

Terra sigillata<br />

– 1 st century B.C. (spread by the Roman empire)<br />

• Historically used to seal a porous clay<br />

– Also used in drain tiles to make them waterproof<br />

• Usually applied to leatherhard-dry clay<br />

• A true slip – Contains just clay<br />

• Made of extremely fine particles (colloidal in size)<br />

– Will not settle or cake over time in the bucket<br />

• Much more opaque than regular slips<br />

– Requires a much thinner coating than regular slips

Terra sigillata<br />

• Dense, silky-smooth, sometimes glossy<br />

– Gloss is temperature dependent based on the clay used<br />

• Generally retained up to C. 04; some can go to C. 2<br />

• Gloss is enhanced by burnishing (re-orients clay particles<br />

parallel to the surface? The jury is deciding on this one)<br />

– Burnishing tools are typically smooth (spoon, river-bed stones);<br />

cloth also works well (t-shirts, cheesecloth, dry-cleaning plastic)<br />

• Historically red clays were used but any plastic (fine) clay<br />

can be used<br />

– White sig. can be prepared from ball clays or kaolins<br />

• Basic Formula<br />

Water 70%<br />

Dry <strong>Clay</strong> 30<br />

Darvan #7 0.1-0.3%<br />

Destroys thixotropy (i.e. helps<br />

non-clays settle)

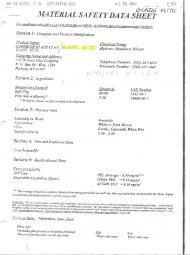

• Ball mill ingredients<br />

<strong>and</strong> place in jar,<br />

undisturbed for three<br />

days<br />

• After three days,<br />

layers should be well<br />

defined<br />

• Top layer is siphoned<br />

off<br />

• Sig. is then carefully<br />

siphoned off (careful<br />

not to include bottom<br />

layer)<br />

Procedure for<br />

making terra<br />

sigillata

Drawbacks to terra sigillata<br />

• Glazes cannot be layered overtop of terra<br />

sigillata<br />

– Glaze tends to dissolve terra sig. layer<br />

• Terra sig. is too thin to withst<strong>and</strong> glaze fusion<br />

• A lot of clay is wasted in preparing terra<br />

sig.<br />

– 50 lbs. of ball clay yields roughly 2 gallons of<br />

sig.<br />

• This can be somewhat improved by ball milling<br />

• Preparation is somewhat tedious<br />

• Limited firing range

Formulating slips<br />

• A slip can be made by using the clay body itself,<br />

minus any large fillers (i.e.. No grog)<br />

• Advantage<br />

– Compositionally very similar to body<br />

• CTE is almost identical to body<br />

• Drawbacks<br />

– Slip must be applied to very wet clay to avoid cracking<br />

– Slip can’t be lighter in color than the body without<br />

radically changing the sources of clay<br />

• To improve on these limitations <strong>and</strong> to tailor the<br />

slip to our needs, we often include other ingredients

So…<br />

• Slip ingredients usually include:<br />

– <strong>Clay</strong>s<br />

– Fluxes<br />

– Fillers<br />

• A slip may also require:<br />

– Hardeners<br />

– Opacifiers<br />

– Colorants<br />

• These additions depend on the composition of the slip

<strong>Clay</strong>s<br />

• Chosen for their relative color <strong>and</strong> shrinkage<br />

• Light colored clays are necessary for a wide pallet of<br />

colors<br />

– Especially true when developing light colors<br />

• Combinations of kaolin <strong>and</strong> ball clay are normally<br />

used to adjust shrinkage<br />

– More ball clay = more shrinkage<br />

– More kaolin = less shrinkage<br />

– Total clay is usually between 40-80%<br />

• Improve slip’s adherence to the body in dry state<br />

• Help keep slip in suspension<br />

• Improve the brushing qualities of non-plastics

• Amplified by<br />

the presence<br />

of clay<br />

• Can be<br />

exaggerated<br />

by adding salt<br />

Thixotropy<br />

• Retains brushstrokes (can<br />

be good or bad, depending<br />

on your needs)

No salts Salts<br />

Grolleg 48%<br />

Frit 2110 52%<br />

Darvan 811 0.14%<br />

+ Epsom Salts

Fluxes<br />

• Help fuse the slip to the body<br />

• Selection is temperature dependent <strong>and</strong><br />

reflects what we already know for clay<br />

bodies<br />

– High temp-Feldspars/+auxiliary fluxes<br />

– Mid temp-Neph Sy/Talc/Frits<br />

– Low temp-Frits/Talc<br />

• Color response to oxides or stains will be<br />

enhanced or impeded by our choice flux<br />

– Similar to a glaze in this respect

Hi Soda<br />

3110<br />

Hi Calcium/Boron<br />

3124<br />

Hi Calcium/Boron/Alumina<br />

3195<br />

Hi Magnesium<br />

Talc

Fillers<br />

• Silica is the most commonly used<br />

– Promotes hardness (depending on the amount of<br />

vitrification)<br />

– Reduces drying shrinkage<br />

– Promotes whiteness<br />

• Pyrax can also be used (though not as white as<br />

flint)<br />

• Talc (color killer)<br />

• Wollastonite<br />

• Calcined clay (i.e. glomax)<br />

• Filler content usually ranges from 15-30%

Hardeners<br />

• Used to improve hardness of slip after drying (anti<br />

smudging)<br />

– <strong>Slips</strong> high in clay usually don’t require additional hardeners<br />

– Required in low clay-content slips (esp. when ball clay is absent)<br />

• Inorganic<br />

– Borax is soluble<br />

• Recrystallizes when it dries, forming a tough finish<br />

• Can be used up to 5% but other fluxes may need to be decreased (borax is<br />

a boron source so it acts like a flux)<br />

– Bentonite/Vee Gum<br />

• Fine size hardens upon drying (up to 2% Bentonite /up to 1% Vee Gum))<br />

• Organic<br />

– Sugar (dissolved in water first!)<br />

– Gums (CMC, Gum Arabic)<br />

– Spoil with time/can migrate to the top of the container

Opacifiers<br />

• Help ensure whiteness <strong>and</strong> allow for thin application<br />

without loss of opacity<br />

• <strong>Clay</strong> is opaque; recipes low in clay depend on opacifiers<br />

– Not as necessary when dark stains/oxides are used<br />

• Tin Oxide<br />

– Traditional opacifier (600+ years); gives warm whites<br />

– very expensive!<br />

• Zircopax (zirconium silicate)<br />

– Cooler whites (can be compensated with small rutile additions);<br />

more affordable than Tin<br />

• Opacifiers tint colors<br />

– Don’t use if black/dark colors are what you want<br />

– May impede development of saturated colors (I.e. bright yellow,<br />

red etc..)

Colorants<br />

• Can be added as either oxides/carbonates or stains<br />

• Oxides/carbonates<br />

– Cheaper than stains<br />

– Limited pallet / <strong>and</strong> can also produce bubbling (esp. Carbonates)<br />

• Developing strong colors in slips requires larger amounts of<br />

colorants than for glazes<br />

– Glass in glaze provides depth <strong>and</strong> brilliance<br />

– The drier the slip, the more difficult strong color response is (i.e.<br />

vitreous slips are better c<strong>and</strong>idates for strong color than dry, non-<br />

vitreous slips)<br />

• Addition amounts<br />

– Vary with stain/oxide used; lighter colors require more<br />

• I.e. Yellows require 10-15% stain<br />

• Blues require just 3% cobalt carb. (even .25% is noticeable)

Colorants<br />

• Mottled <strong>Slips</strong><br />

– Additions of granulated materials (I.e. rutile, illmenite,<br />

manganese, homemade aggregates)<br />

– Oxides – More mottled (<strong>and</strong> more concentrated)<br />

– Carbonates – Less mottled/more homogenous<br />

• As in glazes, oxides present in slip will push or pull colors<br />

– Some commercial stains will not give the intended color in the<br />

presence of certain oxides, especially zinc<br />

• Mason color chart identifies these (Esp. greens, purples <strong>and</strong> pinks)<br />

• Cautionary note:<br />

– Many metal oxides are not food safe in slips (because slips lack<br />

the glassy structure found in glazes)<br />

• If its not safe in the raw state, chances are it won’t be safe in a fired slip<br />

either

Slip compositions<br />

• Note changes in flux (for temperature<br />

ranges) <strong>and</strong> clay (for application ranges)

Comparing bodies to slips<br />

V.C. HF 4 All purpose white base slip<br />

Cone 9-12<br />

Grolleg<br />

30<br />

EPK<br />

15<br />

XX Sagger<br />

25<br />

Kaolin<br />

Kaolin<br />

Ball <strong>Clay</strong><br />

Nepheline Syenite 15 Soda Spar<br />

Flint 10<br />

Wet to leather hard application<br />

V.C. Off White Throwing Porcelain<br />

Tile #6<br />

Cone 9-10<br />

30<br />

Kaolin<br />

EPK<br />

C&C<br />

15<br />

15<br />

<br />

<br />

Kaolin<br />

Ball <strong>Clay</strong><br />

Kona F-4 20 Soda spar<br />

Flint<br />

10<br />

Pyrax<br />

10<br />

Macaloid +1<br />

• More<br />

similarities<br />

than<br />

differences<br />

between the<br />

two<br />

• Could we use<br />

a slip as a<br />

clay?

Wet vs. Bisque<br />

• Wet application slips<br />

– High clay = creamy quality perfect for painterly<br />

qualities<br />

– <strong>Clay</strong> <strong>and</strong> slip can be carved as one (sgraffito)<br />

– Ideal for slip trailing/thick, textural layering<br />

• Bisque application slips<br />

– Timing is irrelevant (ware can be slipped at leisure)<br />

– Application can be washed off <strong>and</strong> reapplied<br />

indefinitely<br />

– Can be applied over glazed ware<br />

– Work undergoes distortion from drying <strong>and</strong> firing<br />

before slip is applied (great for precise work)

V.C. AT 1 White Vitreous Slip<br />

Cone 6-10<br />

Velvacast<br />

Calcined Kaolin<br />

XX Sagger<br />

Custer Feldspar<br />

Nepheline Syenite<br />

Bisque application slips<br />

10<br />

10<br />

5<br />

25<br />

10<br />

Flint 30<br />

Borax 5<br />

Zircopax 5<br />

C19-1 Dense Bisque Slip<br />

EPK<br />

Cone 04<br />

4<br />

Kaopaque<br />

5<br />

Glowmax<br />

15<br />

Wollastonite<br />

9<br />

Frit 3124<br />

41<br />

Flint 6<br />

Molochite 200 Mesh 20<br />

CMC<br />

+1<br />

• Val’s slip uses calcined clay<br />

• Not creamy compared to<br />

wet application slips<br />

• For thick applications<br />

– Best applied through spraying<br />

– Uses very little raw clay<br />

– Glowmax is calcined<br />

– Molochite is added as a filler

The shrinkage myth<br />

• Many bisque-application slips call for large amounts of<br />

calcined clay<br />

– Myth… During drying, raw clay shrinks / calcined clay<br />

doesn’t so loading up on calcined clay is the answer<br />

– Truth… Water separates particles in both cases…even if you<br />

use just calcined clay, you will get shrinkage (not as much as<br />

with raw clay, but still enough to cause problems)<br />

• Including plastic clay in the recipe increases the strength<br />

of the slip during drying <strong>and</strong> can help it overcome<br />

cracks as the slip is placed in tension during drying<br />

(calcined clay has no strength to overcome this tension)<br />

– Adding too much plastic clay, however, will ultimately<br />

increase shrinkage, tension, <strong>and</strong> cracking…A balance is<br />

required!

Spackle<br />

• For very thick applications on bisqued ware<br />

• Inert<br />

• Lots of calcined materials<br />

– Esp. clays<br />

• Raw clay is used sparingly (10-15%) to suspend<br />

mixture<br />

• Relies heavily on a wide particle size distribution<br />

– Screened material<br />

• Empirical testing (trial <strong>and</strong> error)

• Sudden thickness change from top (thick)<br />

surface to the sides (thin) causes separation

Adding salt to the slip ensures a move even<br />

thickness on both the top <strong>and</strong> sides of a tile<br />

• Without<br />

Epsom<br />

salt<br />

• With<br />

Epsom<br />

salt, the<br />

slip “gels”

¼” thick per<br />

firing without<br />

cracks

Multiple firings,<br />

then cut on a<br />

brick saw<br />

S<strong>and</strong>ed prior<br />

to firing

Spackle<br />

Example<br />

Raw Claw<br />

Cone 04<br />

10<br />

Calcined Kaolin 10<br />

Calcined Ball <strong>Clay</strong> 10<br />

Calcined Fireclay 5<br />

Frit 3110 25<br />

Grog (screened) 30<br />

Wollastonite<br />

10<br />

CMC<br />

+1<br />

Suspension<br />

Low Shrink<br />

Low Shrink<br />

Low Shrink<br />

No shrink<br />

No shrink<br />

• Epsom salt is added to prevent settling<br />

– Added as a saturated solution to the water before adding all<br />

other dry ingredients<br />

– Creates Thixotropy (gelling effect when left undisturbed/coarse<br />

material won’t settle);<br />

– Epsom salt can be added to any slip, provided it contains clay<br />

• Salt affects the raw clay, not the non-plastics<br />

• NOTE: Salt dissolves plaster molds over time!

Using spackle<br />

on bisqued<br />

work

Spackle <strong>and</strong><br />

bisque slip

Vitreous slips<br />

• Halfway between a glaze <strong>and</strong> a slip<br />

– Less clay/shrinkage than regular slip<br />

• 10-20% clay for suspension <strong>and</strong> green strength<br />

• Higher non-plastics<br />

• Higher fluxes<br />

• Can be applied to dry or bisque ware<br />

– More difficult for wet applications because of low clay/low green<br />

shrinkage (can’t keep up with a drying, shrinking clay body as<br />

easily)<br />

• Can be used alone as a functional surface<br />

– Very vitreous / almost glaze-like<br />

• Think of these as slightly underfired opaque glazes<br />

• Can also be used under glazes to influence texture <strong>and</strong><br />

color of glaze

Vitreous vs. Non-Vitreous<br />

V.C. 5 vitreous slip<br />

EPK<br />

Cone 04<br />

20<br />

Frit 3110<br />

20<br />

Nepheline Syenite 20<br />

Whiting<br />

5<br />

High amount of fluxes<br />

Flint 15<br />

Zinc Oxide 20 Opacity/whiteness<br />

Steve’s non-vitreous slip<br />

EPK<br />

Cone 04<br />

9<br />

Om4<br />

37<br />

High plasticity<br />

Frit 3124<br />

11<br />

Lower fluxes, especially<br />

Nepheline Syenite 9<br />

frit<br />

Talc<br />

28<br />

Flint 9<br />

Zircopax +5 Opacity/whiteness<br />

• Both are for dry<br />

to bisque<br />

application<br />

• V.C. 5 vitrifies at<br />

C. 04<br />

– Not much clay<br />

– High amount of<br />

flux<br />

• Steve’s is quite<br />

porous at C. 04<br />

– More clay <strong>and</strong><br />

less active flux<br />

to melt it

Cracking<br />

• Does not occur r<strong>and</strong>omly<br />

• Every slip has a limit as to how thick it<br />

can be applied before cracking occurs<br />

• Cracks begin where there is a sudden<br />

change in thickness<br />

• This can be used effectively to create<br />

designs<br />

– Brushstrokes are never even<br />

• Bristles create ridges <strong>and</strong> valleys (cracks start<br />

in valleys)<br />

• Direction of strokes can be used to one’s<br />

advantage<br />

– I.e. Grids vs. spirals vs. r<strong>and</strong>om patterns<br />

– Scribing into still wet slip will influence<br />

where cracks occur<br />

Slip surface<br />

Crack

Robert Sperry Steve Heinemann

Cracking in wet to leatherhard applications<br />

• Slip cracks, forming little isl<strong>and</strong>s sometimes with<br />

curled-up edges<br />

– Slip is shrinking too much<br />

• Apply slip when clay is wetter<br />

OR…<br />

• Remove some bentonite or substitute ball clay with kaolin<br />

• Slip doesn’t shrink enough - Slip separates in large<br />

sheets from body<br />

– Slip is not shrinking enough<br />

• Apply when clay is drier OR…<br />

• Add finer clays

Solutions to cracking in drying<br />

stage<br />

• Cracking can be minimized by changing<br />

how the slip is applied<br />

– Dipping vs. pouring vs. brushing vs. sponging<br />

vs. spraying<br />

• High water content can lead to cracks<br />

– More water = more shrinkage<br />

• Deflocculating the slip reduces water, <strong>and</strong><br />

by extension, shrinkage<br />

– Adding salt can help control viscosity of a<br />

deflocculated slip (I.e. Stick-up slip)

Crow’s Foot cracking

Cracking due to trapped air<br />

• <strong>Slips</strong> that are thick can trap air during mixing<br />

• Air bubbles don’t allow slip to shrink (tension is formed)<br />

– Bubbles become nuclei for crow’s foot cracking<br />

– Three cracks propagate from a point<br />

• Sometimes the offending bubble is seen at the surface,<br />

sometimes it is below the surface<br />

• Solution… remove bubbles!<br />

– Tapping the container<br />

• Bubbles will rise <strong>and</strong> pop<br />

– Tilt <strong>and</strong> rotate the container to expose bubbles<br />

• Bubbles at the surface will stretch <strong>and</strong> pop<br />

– Increase water content<br />

• Bubbles will rise <strong>and</strong> pop

Cracking after firing<br />

• Slip goes into kiln defect free but comes out<br />

cracked (very annoying)<br />

• Can be due to minute drying cracks (invisible to the<br />

eye); you have exceeded the maximum thickness<br />

for your slip<br />

– Cracks open up during firing<br />

– Common in high zinc slips (zinc shrinks!)<br />

– Solution - Apply a thinner <strong>and</strong> more even coat of slip<br />

• Can be due to large difference in firing shrinkage<br />

between body <strong>and</strong> slip<br />

• Solution - Compare fired shrinkage of body with that of slip (do<br />

shrinkage test bars for both the slip <strong>and</strong> the body)<br />

– If slip shrinks too much - decrease flux<br />

– If slip doesn’t shrink enough - increase flux

Cracking after firing<br />

• Can also be due to a mismatch in CTE between<br />

body <strong>and</strong> slip<br />

• Sharp transitions <strong>and</strong> corners are usually the<br />

first place this happens (the first place to look)<br />

• Usually a case of shivering, where the crack<br />

runs through the body <strong>and</strong> separates the slip<br />

from the surface<br />

• Remedied by increasing the slip’s CTE

Shivering slip

Witness the awesome<br />

destructive force that is…<br />

Shivering

Measuring<br />

slip<br />

thickness<br />

• Easy to do<br />

<strong>and</strong> more<br />

reliable<br />

than<br />

measuring<br />

water<br />

content

Tape<br />

Using a pin<br />

tool as a<br />

thickness<br />

gauge<br />

• Useful for slips<br />

<strong>and</strong> glazes applied<br />

on dry or bisque<br />

ware<br />

• Stab the slip/glaze<br />

before it hardens<br />

• Tape serves as a<br />

visual reference

END