Petersen Aluminum PAC-CLAD catalog Reed First Source

Petersen Aluminum PAC-CLAD catalog Reed First Source

Petersen Aluminum PAC-CLAD catalog Reed First Source

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

07 61 00/PET<br />

BuyLine 3008

<strong>PAC</strong>-<strong>CLAD</strong> Applications Page 3<br />

<strong>PAC</strong>-<strong>CLAD</strong> Color Availabiliy Page 4<br />

<strong>PAC</strong>-<strong>CLAD</strong> Color Chart Page 5<br />

SNAP-<strong>CLAD</strong> Page 6 & 7<br />

Tite-Loc & Tite-Loc Plus Panels Page 8 & 9<br />

Snap-On Panels Page 10<br />

Redi-Roof Panels Page 11<br />

Integral Panels Page 12<br />

Flush Panels Page 13<br />

M & R Panels Page 14 & 15<br />

Soffit Panels Page 16 & 17<br />

Snow Guards Page 18<br />

Composite Panels/ Column Covers Page 19<br />

<strong>PAC</strong>-Continuous / Tite-Loc / Page 20<br />

<strong>PAC</strong>-LOC Coping<br />

<strong>PAC</strong>-1-Ply / Thrift-Loc / Page 21<br />

Built-Up Gravel Stops<br />

General Considerations/TCS Page 22<br />

Specifications Page 23<br />

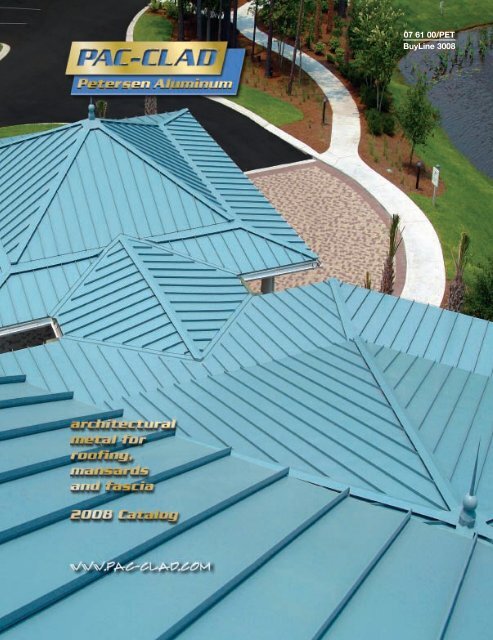

Cover Photo:<br />

Marriott Surfwatch Resort Condominiums, Hilton Head Island, SC<br />

Architect: NCG Architects Inc.<br />

General Contractor: Hardin Construction Company<br />

Roofing Contractor: Southern Roof & Wood Care Corporation<br />

Color: Custom Color - Charlotte Slate<br />

Cabela’s, Buda, TX<br />

Architect: Crabtree, Rohrbauch & Associates<br />

General Contractor: Kraus Anderson<br />

Roofing Contractor: K Post Company<br />

Color: Forest Green<br />

Profile: Snap-Clad & Flush Panel<br />

2<br />

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation was founded in 1965 as a metals service center to the architectural metal<br />

industry. At <strong>Petersen</strong> we strive to provide products of the highest possible quality within reliable, dependable<br />

lead-times. Our strong national sales base allows <strong>PAC</strong> to maintain large inventories and cost economies to our<br />

customers.<br />

In addition to our Chicago-based headquarters, we maintain full production facilities in Annapolis Junction,<br />

Maryland; Tyler, Texas; and Atlanta, Georgia. In addition to the information found in this <strong>catalog</strong>, we maintain<br />

an extensive web site (www.pac-clad.com) and our complete <strong>catalog</strong> is available in standard 3-ring<br />

binder as well as CD-ROM format.<br />

Technical assistance and service are provided by our staff and complimented locally by our nationwide<br />

organization of architectural representatives. We are prepared to offer assistance in material selection, finish<br />

specification, and budgeting. As the scope of our applications is so wide, we encourage your inquiries.<br />

<strong>PAC</strong>-<strong>CLAD</strong> Architectural Sheet and Coil<br />

<strong>PAC</strong>-<strong>CLAD</strong> is a versatile prefinished sheet metal coating (Kynar 500® or Hylar 5000® ) that is applied to<br />

both G-90 galvanized steel and 3105-H14 aluminum. Originally developed for use in abrasive environments,<br />

<strong>PAC</strong>-<strong>CLAD</strong> has proven to be ideally suited for application in roofing, curtainwall, storefront and trim applications.<br />

<strong>PAC</strong>-<strong>CLAD</strong> is now available in thirty-six colors carefully selected to complement a range of building<br />

materials.<br />

<strong>PAC</strong>-<strong>CLAD</strong> Panels<br />

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation maintains extensive roll-forming equipment in each of our regional facilities.<br />

Each of our rollformers provides panels that have been Herr-Voss corrective leveled. Standing seam,<br />

flush, wall and soffit panels are all factory formed in lengths up to 55 feet. Longer lengths are available.<br />

Please consult our factory. Matching flashing and trim may also be factory formed or field formed from <strong>PAC</strong>-<br />

<strong>CLAD</strong> material.<br />

<strong>PAC</strong>-<strong>CLAD</strong> Accessories<br />

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation fabricates a wide range of roofing accessories. Coping, gravel stops, gutters<br />

and downspouts are all formed from our 36 standard <strong>PAC</strong>-<strong>CLAD</strong> colors. <strong>Petersen</strong> <strong>Aluminum</strong> also is a distributor<br />

of Follansbee TCS.<br />

The Descriptions Herein Are Not Warranties<br />

The descriptions in this <strong>catalog</strong> of <strong>Petersen</strong> <strong>Aluminum</strong> Corporation products are given for informational purposes only,<br />

and are not warranties. No express warranties are contained in this <strong>catalog</strong>. <strong>Petersen</strong> <strong>Aluminum</strong> Corporation does not<br />

build or design buildings. It acts solely as a supplier of materials, and assumes no responsibility for the proper use or<br />

installation of those materials, nor for the suitability of those materials for any specific use or for compliance with local<br />

building codes.

Ruffner Hall, Longwood University<br />

Farmsville, VA<br />

Owner: Longwood College<br />

Architect: Kuntz & Associates, Architects<br />

Scoggin-Dickey Hummer Dealership<br />

Lubbock, TX<br />

Owner: Scoggin-Dickey Buick<br />

Architect: Joe D. McKay Architects<br />

General Contractor: Lee Lewis Construction Inc.<br />

Roofing Contractor: Hamilton Roofing<br />

Profile: Curved Tite-Loc Panels<br />

Material: Galvalume Plus<br />

General Contractor: English Construction<br />

Roofing Contractor: Roof Systems of Virginia<br />

Color: Colonial Red<br />

Profile: Tite-Loc Plus<br />

07 61 00/PET<br />

BuyLine 3008<br />

Sea Turtle Village & Cinemas<br />

Bluffton, SC<br />

Distributor: JGA Southern Roof Center/Beacon Sales<br />

Architect: KRA Architecture Inc.<br />

Roofing Contractor: Southern Roof & Wood Care<br />

Profile: Snap-Clad<br />

Color: Forest Green<br />

3

Steel <strong>Aluminum</strong><br />

<strong>PAC</strong>-<strong>CLAD</strong> Cool Colors<br />

Almond<br />

Bone White<br />

Cardinal Red<br />

Charcoal<br />

Colonial Red<br />

Dark Bronze<br />

Evergreen<br />

Granite<br />

Hemlock Green<br />

Hunter Green<br />

Mansard Brown<br />

Medium Bronze<br />

Military Blue<br />

Musket Gray<br />

Patina Green<br />

Sandstone<br />

Sierra Tan<br />

Slate Blue<br />

Slate Gray<br />

Stone White<br />

Teal<br />

Terra Cotta<br />

Matte Black**<br />

<strong>PAC</strong>-<strong>CLAD</strong> Metallic<br />

Aged Copper<br />

Champagne<br />

Copper Penny<br />

Silver<br />

Weathered Zinc<br />

Reflectivity Emissivity<br />

0.56 0.89<br />

0.73 0.89<br />

0.37 0.89<br />

0.28 0.89<br />

0.32 0.89<br />

0.25 0.89<br />

0.26 0.88<br />

0.36 0.89<br />

0.30 0.90<br />

0.26 0.88<br />

0.25 0.88<br />

0.27 0.90<br />

0.34 0.88<br />

0.31 0.89<br />

0.34 0.89<br />

0.53 0.89<br />

0.36 0.89<br />

0.26 0.87<br />

0.36 0.89<br />

0.64 0.88<br />

0.26 0.88<br />

0.36 0.89<br />

0.25 0.85<br />

0.28 0.89<br />

0.41 0.80<br />

0.49 0.87<br />

0.60 0.83<br />

0.30 0.81<br />

3 Yr Exposure<br />

0.57<br />

0.71<br />

0.38<br />

0.35<br />

0.49<br />

0.35<br />

0.59<br />

0.37<br />

0.40<br />

0.47<br />

0.55<br />

SRI*<br />

66<br />

89<br />

41<br />

29<br />

34<br />

25<br />

26<br />

40<br />

32<br />

26<br />

25<br />

28<br />

36<br />

33<br />

37<br />

62<br />

40<br />

26<br />

40<br />

77<br />

26<br />

40<br />

23<br />

29<br />

43<br />

56<br />

70<br />

28<br />

24 ga.<br />

•<br />

•* •<br />

•<br />

22 ga.<br />

•<br />

•<br />

•* •<br />

•<br />

•<br />

•<br />

•<br />

.032<br />

•<br />

•* •<br />

•<br />

.040<br />

•<br />

•<br />

•* •<br />

•<br />

•<br />

•<br />

•<br />

.050<br />

•<br />

•*<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

.063<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

0.31 34<br />

Zinc 0.32 0.89 • • •<br />

<strong>PAC</strong>-<strong>CLAD</strong> Standard Colors (do not meet cool roof requirements)<br />

Arcadia Green • •<br />

Award Blue • • •<br />

Berkshire Blue • *<br />

Burgundy • • •<br />

Forest Green • • • • •<br />

Hartford Green • • • •<br />

Interstate Blue • • •<br />

<strong>PAC</strong>-<strong>CLAD</strong> ® Metallic finishes are available from stock at a moderate extra cost. <strong>PAC</strong>-<strong>CLAD</strong> ® Copper Penny is a Non-Weathering finish. *Solar Reflectance Index calculated according to ASTM E-1980. **Matte Black (SRI Color) in steel only.<br />

Energystar® Performance Criteria<br />

Emissivity uses ASTM C1371/E408. Reflectivity uses ASTM E903/C1549.<br />

Installation<br />

<strong>PAC</strong>-<strong>CLAD</strong> ® can be cut, formed, nailed, screwed, or riveted using hand or power<br />

tools. Fabricate and install in accordance with drawings and normal sheet metal practices<br />

using hand or power tools. Keep cutting edges sharp, clean, and properly<br />

aligned. Exercise care during fabrication and installation to avoid damage.<br />

Maintenance<br />

Maintenance is not required. This finish is a member of the Teflon ® family, and is<br />

self-cleaning. If cleaning is desired, it can be washed with a mild soap and water followed<br />

by a clean-water rinse.<br />

Samples<br />

These color reproductions are as accurate as modern printing technology will permit.<br />

Free material samples are available on request.<br />

4<br />

Textures<br />

<strong>PAC</strong>-<strong>CLAD</strong> ® is available with a smooth texture or a standard E-5 stucco embossed pattern,<br />

available at extra cost.<br />

* Low Gloss/Low Sheen<br />

This finish is a full Kynar 500 ® /Hylar 5000 ® finish, but is formulated in a low<br />

gloss/low sheen in order to minimize the appearance of oil-canning.<br />

Technical Data for Kynar 500 ® /Hylar 5000 ® Coating<br />

•Life Expectancy—20 years exposure – Chalk: rating of 8 or better. Color: 5∆E<br />

(Hunter Units) change.<br />

•Accelerated Weathering—(ASTM G-23 Type EH) 5,000 hours - Chalk: rating of 8<br />

or better. Color: ≤5∆E (Hunter Units) color change.<br />

•Humidity Resistance—(ASTM 2247) 2,000 hours - No change in pencil hardness.<br />

•Salt Spray Resistance—(ASTM B 117) – 2,000 hours for <strong>Aluminum</strong>, creepage at<br />

scribe ≤1/32”, no blisters. 2,000 hours for hot dipped Galvanized, creepage at<br />

scribe 1/8”, few #8 blisters.<br />

•Chemical/Acid Pollution Resistance—(ASTM D 1808) – Pass.<br />

•Solvent Resistance—(NCCA procedure 11-18, no comparable ASTM test) – Pass.<br />

•Formability—(ASTM D 3281 and ASTM D 1737) – Can be formed without film<br />

fracture using normal metal shop practices to a 1 to 2-T bend radius<br />

•Hardness—(ASTM D 3363) – ≥F pencil hardness.<br />

•Gloss—30 ± 5 at 60º (low gloss/sheen available).<br />

•Abrasion Resistance—(ASTM D 968) - Coefficient of 65 ± 10.<br />

•Adhesion—(ASTM D 3359 and NCCA procedure No. 11-5) – Pass.<br />

•Impact Resistance—(ASTM D 2794 and NCCA Technical Bulletin No. 11-6) – 70<br />

inch/lbs., no tape pick-off.<br />

Recycled Content<br />

•<strong>PAC</strong>-<strong>CLAD</strong> <strong>Aluminum</strong> - 91%<br />

•<strong>PAC</strong>-<strong>CLAD</strong> Steel - 28 to 35%

Standard Colors<br />

▲Stone White ▲Bone White ▲Slate Gray ▲Musket Gray ▲Charcoal<br />

▲ Almond ▲Sandstone ▲Granite ▲Medium Bronze ▲Dark Bronze<br />

▲ Sierra Tan ▲Terra Cotta ▲Colonial Red ▲Cardinal Red Burgundy<br />

▲Patina Green Arcadia Green ▲Hemlock Green ▲Teal Hartford Green<br />

Berkshire Blue Award Blue ▲Hunter Green Forest Green ▲Evergreen<br />

▲Slate Blue ▲Military Blue Interstate Blue ▲Mansard Brown ▲Matte Black<br />

<strong>PAC</strong>-<strong>CLAD</strong> Metallic Colors<br />

▲Zinc ▲Silver ▲Copper Penny ▲Aged Copper<br />

▲Champagne ▲Weathered Zinc<br />

▲ <strong>PAC</strong>-<strong>CLAD</strong> Cool Colors<br />

Due to the limitations of the four color printing process, this color chart is not an accurate representation of our actual colors. Color<br />

charts and sample chips are available on request at no charge.<br />

07 61 00/PET<br />

BuyLine 3008<br />

Materials<br />

<strong>PAC</strong>-<strong>CLAD</strong> is available in prime quality aluminum, 24<br />

gauge and 22 gauge G-90 galvanized steel finished with a<br />

<strong>PAC</strong>-<strong>CLAD</strong> Kynar 500 ®/Hylar 5000 ® finish (top side) and a<br />

polyester washcoat (bottom side). Other metals available<br />

include mill finish aluminum, copper, galvanized steel, ternecoated<br />

stainless steel, stainless, Galvalume Plus and<br />

anodized.<br />

A strippable vinyl film can be applied for protection during<br />

fabrication and installation, if desired. Vinyl masking is recommended<br />

on all applications requiring extra handling. The<br />

vinyl must be removed immediately after installation.<br />

Warranty<br />

Life expectancy is 20 years plus. A 20-year, non-prorated<br />

warranty covering color fade, chalking, and film integrity is<br />

available at no extra charge. Warranty terms vary slightly for<br />

Cardinal Red, Award Blue, Interstate Blue and embossed finishes.<br />

<strong>PAC</strong>-<strong>CLAD</strong> Metallics<br />

Due to new technology, <strong>Petersen</strong> <strong>Aluminum</strong> can now supply<br />

metallic finishes with the economy of a one-pass, two-coat<br />

system. These colors are ideal for curtainwall and roofing<br />

applications. A <strong>PAC</strong>-<strong>CLAD</strong> Metallic 20 year, non-prorated finish<br />

warranty applies. This is a directional finish.<br />

▲ Cool Colors<br />

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation is pleased to introduce<br />

<strong>PAC</strong>-<strong>CLAD</strong> Cool Colors: a new and updated color palette<br />

designed to improve the energy saving performance of our<br />

metal roofing products without requiring compromise in color<br />

selection.<br />

In creating this new product line, we worked with our coating<br />

supplier, The Valspar Corporation, to significantly broaden<br />

the range of <strong>PAC</strong>-Clad colors that would meet ENERGY<br />

STAR ®, LEED and/or cool roof certification requirements<br />

for solar reflectance and emissivity ratings.<br />

This color chart includes solar reflectance and emissivity<br />

ratings for each color. It also includes availability by material<br />

and gauge. In addition, we are able to provide reflectance<br />

and emissivity ratings for custom color projects where<br />

required. If you have any questions regarding the information<br />

herein, please contact us at 1-800-323-1960; or visit our<br />

website at www.pac-clad.com.<br />

Recycled Content:<br />

• <strong>PAC</strong>-<strong>CLAD</strong> <strong>Aluminum</strong> - 91%<br />

Post Consumer - 35%<br />

Post Industrial - 53%<br />

• <strong>PAC</strong>-<strong>CLAD</strong> Steel - 28 to 35%<br />

Post Consumer - 23%<br />

Post Industrial - 7.3%<br />

5

NEW<br />

NEW<br />

NEW<br />

6<br />

Product Features<br />

•Architectural/structural panel<br />

•Herr-Voss corrective leveled<br />

•Factory applied sealant available<br />

•Continuous interlock<br />

•Labor-saving one-piece design<br />

•Stiffener beads available<br />

•Striations available<br />

•Factory eave notching available<br />

Material<br />

•.040 aluminum panel available<br />

•16 oz. cold rolled copper<br />

•36 standard colors (24 gauge steel)<br />

•34 standard colors (aluminum)<br />

•11 standard colors (22 gauge steel)<br />

•Smooth and stucco embossed available<br />

•20 year non-prorated finish warranty<br />

•Galvalume Plus available<br />

UL Classification<br />

•UL-580 Class 90 wind uplift<br />

•UL-1897 wind uplift<br />

•UL-790 Class A fire rated<br />

•UL-263 fire resistance rated<br />

•UL-2218 impact resistance rated<br />

•UL-90 rated aluminum panel up to 16” O.C.<br />

ASTM Tests<br />

•ASTM E1592 tested<br />

•ASTM E283/1680 tested<br />

•ASTM E331/1646 tested<br />

Florida Building Product Approvals<br />

•.032 <strong>Aluminum</strong>: FL Prod. Approv. #5569<br />

•24 ga. Steel: FL Prod. Approv. #5569<br />

Miami-Dade Product Approvals<br />

•.032 <strong>Aluminum</strong>: NOA No.: 05-0830.02<br />

•24 ga. Steel: NOA No.: 07-0301.01<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

SNAP-<strong>CLAD</strong> Panels feature architectural panel aesthetics as well as structural panel performance. SNAP-<br />

<strong>CLAD</strong> Panels, produced in continuous lengths, are corrective leveled to provide superior flatness and feature<br />

an optional factory-applied sealant bead for improved weather resistance. (minimum panel length is 4 feet)<br />

SNAP-<strong>CLAD</strong> Panels feature a 1-3/4” leg height and a continuous interlock for improved structural performance<br />

and wind resistance. A concealed fastener clip system has been designed to allow for thermal expansion/contraction<br />

while providing extraordinary hold-down strength. Two clips are available: a standard clip<br />

for most mansard and fascia applications and a high-performance clip for roofing application and UL 90 rated<br />

assemblies.<br />

UL 90 Classified<br />

SNAP-<strong>CLAD</strong> Panels carry a UL 90 classification over a wide variety of substrates and assemblies including<br />

5/8” plywood, purlins, and rigid insulation in conjunction with bearing plates (UL Construction No. 254,<br />

255, 261, 303, 343, 508). For further details, contact <strong>Petersen</strong> <strong>Aluminum</strong> .<br />

Air and Water Infiltration<br />

SNAP-<strong>CLAD</strong> Panels meet the full performance requirements of the ASTM E283/1680 air infiltration test<br />

and the ASTM E331/1646 water penetration test. Please contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation for complete<br />

test results.<br />

Materials<br />

a) 24 ga. G-90 hot-dipped galvanized steel d) .040 3105-H14 aluminum<br />

b) 22 ga. G-90 hot-dipped galvanized steel e) 16 oz. cold rolled copper<br />

c) .032 3105-H14 aluminum<br />

Trim<br />

All flashing and trim will be fabricated by manufacturer or qualified fabricator. Flashing shall be <strong>PAC</strong>-<strong>CLAD</strong><br />

aluminum (.032-.080 gauge as specified) or <strong>PAC</strong>-<strong>CLAD</strong> steel (24 ga. or 22 ga. as specified). A 20 year,<br />

non-prorated finish warranty shall be supplied covering finish performance.<br />

Installation<br />

SNAP-<strong>CLAD</strong> Panels are intended for use in roofing, mansard, and fascia applications. Substrates may<br />

include 5/8” (min.) plywood, nailboard insulation or equal with an underlayment of 30# (min.) roofing felt<br />

applied horizontally from eave to ridge. Other substrates may include metal decking, purlins or rigid insulation<br />

in conjunction with bearing plates. A minimum 2:12 pitch is recommended in most applications.<br />

Contact <strong>Petersen</strong> for detail assistance on projects requiring lower slopes. For Coastal applications, aluminum<br />

panels along with stainless steel clips must be used for warranty. Consult a local architect/engineer for compliance<br />

with local codes and conditions.<br />

Eave Notching<br />

Factory-produced eave notching is now available at nominal additional cost on SNAP-<strong>CLAD</strong> Panels and<br />

Redi-Roof Standing Seam Panels. Factory eave notching saves on labor cost by eliminating the need for cost-<br />

EAVE NOTCHING<br />

USE HEMMING<br />

TOOL TO FIELD<br />

BEND AT NOTCH<br />

EAVE NOTCH (OPTIONAL)<br />

AT FORMED SEAMS<br />

ly field cutting in providing a properly trimmed<br />

eave detail.<br />

Note: SNAP-<strong>CLAD</strong> has UL-90 classification up<br />

to 16” O.C. on .032 and .040 aluminum. See<br />

roof deck construction in Underwriter Laboratories<br />

roofing materials and systems directory.

SNAP-<strong>CLAD</strong><br />

10", 12", 16” or 18" O.C. .032 aluminum*<br />

1-3/4" high .040 aluminum*<br />

24 gauge steel<br />

22 gauge steel<br />

16 oz. copper* NEW<br />

sealant bead (optional)<br />

10", 12," 16" or 18" O.C.<br />

1-3/4"<br />

*UL-90 rated 18 “O.C. is not available in aluminum or<br />

copper.<br />

UL Construction Code Maximum Clip Spacing<br />

S U B S T R A T E S<br />

OPEN FRAME 5/8” PLYWOOD RIGID INSULATION 3<br />

GAUGE WIDTH PURLINS 2 OVER 22 GA. STEEL DECK<br />

WITH BEARING PLATES<br />

22 ga. 10” UL 261 (5’-0”) UL 343 (3’-0”) UL 303 (4’-0”)<br />

22 ga. 12” UL 254 (5’-0”) UL 343 (3’-0”) UL 303 (4’-0”)<br />

24 ga. 10” UL 261 (4’-0”) UL 343 (3’-0”) UL 303 (4’-0”)<br />

24 ga. 12” UL 254 (4’-0”) UL 343 (3’-0”) UL 303 (4’-0”)<br />

24 ga. 16” UL 255 (4’-0”) UL 343 (3’-0”) UL 303 (4’-0”)<br />

24 ga. 18” UL 255 (4’-0”) UL 343 (3’-0”) UL 303 (4’-0”)<br />

.032. 10” UL 261 (3’-0”)<br />

.032. 16” UL 508 (1’-6”) UL 303 (1’-6”)<br />

16 oz. copper 16” UL 614 (2”-0”)<br />

1. Contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation for complete UL construction assemblies.<br />

2. For complete information regarding appropriate purlin spacing, contact <strong>Petersen</strong><br />

<strong>Aluminum</strong> Corporation directly.<br />

3. Insulation thickness varies between 1” and 4 1/2” according to R-value desired. Refer to UL<br />

Roofing Materials Directory.<br />

4. See roof deck construction in Underwriter Laboratories roofing materials and systems directory.<br />

5. Please consult <strong>Petersen</strong> <strong>Aluminum</strong> for projects specifying open purlins.<br />

Amicalola Falls State Park & Lodge<br />

Dawsonville, GA<br />

Owner: Georgia Department of Natural Resources<br />

Roofing Contractor: Roof Craft Systems Inc.<br />

Distributor: CRS<br />

Color: Greystone<br />

Profile: Snap-Clad<br />

Top Photo: Cabela’s, Buda, TX<br />

Architect: Crabtree, Rohrbauch & Associates<br />

General Contractor: Kraus Anderson<br />

Roofing Contractor: K Post Company<br />

Color: Forest Green<br />

Profile: Snap-Clad & Flush Panel<br />

07 61 00/PET<br />

BuyLine 3008<br />

7

NEW<br />

NEW<br />

Product Features<br />

•Herr-Voss corrective leveled<br />

•Stiffener beads available<br />

•Striations available<br />

Material<br />

•36 standard colors (steel)<br />

•34 standard colors (aluminum)<br />

•11 standard colors (22 ga. steel)<br />

•20 year non-prorated finish warranty<br />

•Smooth and stucco embossed available<br />

•Galvalume Plus available<br />

UL Classification<br />

•UL-580 Class 90 rated up to 18”O.C.<br />

•UL-1897 wind uplift<br />

•UL-790 Class A fire rated<br />

•UL-263 fire resistance rated<br />

•UL-2218 impact resistance<br />

ASTM Tests<br />

•ASTM E1592 tested<br />

•ASTM E331 tested<br />

•ASTM E283 tested<br />

Florida Building Product Approvals<br />

•.032 <strong>Aluminum</strong>: FL Prod. Approv. #6191<br />

•24 ga. Steel: FL Prod. Approv. #6191<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

Top Photo:<br />

Gaylord Texan<br />

Grapevine, TX<br />

Owner: Gaylord Properties<br />

Architect: Hnedak/Bobo Architects - Memphis, TN<br />

General Contractor: Centex<br />

Roofing Contractor: Supreme Systems - Dallas TX<br />

Profile: Tite-Loc, Snap-Clad, Snap On Standing Seam,<br />

Corrugated Panels<br />

Material: Galvalume Plus<br />

Woodholme Elementary School<br />

Baltimore, MD<br />

Owner: Baltimore County Public Schools<br />

Architect: Grimm and Parker<br />

General Contractor: Oak Contracting<br />

Roofing Contractor: Cole Roofing<br />

Color: Custom Color - Medium Green Metallic<br />

Profile: Curved and Straight Tite-Loc Panels<br />

8<br />

NEW<br />

TITE-LOC Panels combine structural panel performance with architectural panel aesthetics. TITE-LOC Panels<br />

are corrective leveled to provide superior panel flatness. A factory-applied sealant bead is applied for additional<br />

weather resistance.(minimum panel length is 4 feet)<br />

TITE-LOC Panels feature a 2” leg height that requires mechanical field seaming after installation. Panels<br />

have a concealed-fastener floating clip system designed to allow for thermal expansion/contraction. For further<br />

details, please contact <strong>PAC</strong>.<br />

UL 90 Classified<br />

TITE-LOC Panels carry a UL 90 classification over a wide variety of substrates and assemblies including<br />

5/8” plywood, purlins, and rigid insulation in conjunction with bearing plates (UL Construction No. 90, 176,<br />

180, 238B, 437, 449, 451, 452, 487, 616, 617). For further details, contact <strong>Petersen</strong> <strong>Aluminum</strong> Corp.<br />

Air and Water Infiltration<br />

TITE-LOC Panels meet the full performance requirements of the ASTM E283/1680 air infiltration test and<br />

the ASTM E331/1646 water penetration test. Please contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation for complete<br />

test results.<br />

Materials<br />

a) 24 ga. G-90 hot-dipped galvanized steel c) .032 3105-H14 aluminum<br />

b) 22 ga. G-90 hot-dipped galvanized steel d) .040 3105-H14 aluminum (Tite-Loc Panel only)<br />

Trim<br />

All flashing and trim will be fabricated by manufacturer or qualified fabricator. Flashing shall be <strong>PAC</strong>-<strong>CLAD</strong><br />

aluminum (.032-.063 gauge as specified) or <strong>PAC</strong>-<strong>CLAD</strong> steel (24 ga. or 22 ga. as specified). A 20 year,<br />

non-prorated finish warranty shall be supplied covering finish performance.<br />

Installation<br />

TITE-LOC Panels are intended for use in architectural and structural roofing. Substrates may include 5/8”<br />

(min.) plywood, nailboard insulation or equal with an underlayment of 30# (min.) roofing felt applied horizontally<br />

from eave to ridge. Other substrates may include metal decking, purlins or rigid insulation in conjunction<br />

with bearing plates. A minimum 1/2:12 roof pitch is required. Contact <strong>Petersen</strong> for further detail<br />

assistance on projects. For Coastal applications, aluminum panels along with stainless steel clips must be<br />

used for warranty. Consult a local architect/engineer for compliance with local codes and conditions.<br />

Tite-Loc Panels<br />

Tite-Loc Panels are factory-formed to length and field seamed to a 90º lock. Tite-Loc panels have been<br />

designed for application on roof slopes as low as 1/2:12 pitch. As an additional labor-saver, the Tite-Loc<br />

seamer has been designed to travel both up and down slope during installation. Tite-Loc panels are available<br />

in 12”, 16” and 18" widths. Materials available include 22 and 24 gage steel; .032 and .040 aluminum.<br />

Tite-Loc Plus Panels<br />

Tite-Loc Plus Panels are factory-formed to length and designed to be field-seamed to 180º. The panel<br />

combines an attractive thin-rib profile with superior structural performance. Tite-Loc Plus panels are designed<br />

for application over a wide variety of substrates in slopes as low as 1/2:12 pitch. Tite-Loc Plus panels are<br />

available in 12”, 16” and 18" widths. Materials available include 22 and 24 ga. steel; .032 aluminum.<br />

Curved Tite-Loc Panels<br />

Tite-Loc Panels can be curved to a minimum radius of 20’-0”. Tite-Loc curving can be done in the field or<br />

at the factory depending on the radius and length of the panel. For more details about our capabilities,<br />

please contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation.<br />

*24 ga. and 22 ga. panels listed in bold print are UL-90 classified over solid substrate. See roof deck construction in<br />

Underwriter Laboratories roofing materials and systems directory. Tite-Loc and Tite-Loc Plus Panels are shown with<br />

optional striations. Standard product offering is smooth.

*<br />

Tite-Loc Panel<br />

12”, 16” or 18” O.C. .032 aluminum<br />

2” high .040 aluminum<br />

24 gauge steel<br />

22 gauge steel<br />

FACTORY APPLIED SEALANT<br />

12", 16" or 18" O.C.<br />

FACTORY APPLIED SEALANT<br />

12", 16" or 18" O.C.<br />

FACTORY APPLIED SEALANT<br />

12", 16" or 18" O.C.<br />

2"<br />

2"<br />

2"<br />

NEW<br />

FM<br />

APPROVED<br />

* *<br />

Tite-Loc Plus Panel<br />

12”, 16” or 18” O.C. .032 aluminum<br />

2” high 24 gauge steel<br />

22 gauge steel<br />

FACTORY APPLIED SEALANT<br />

12", 16" or 18" O.C.<br />

FACTORY APPLIED SEALANT<br />

12", 16" or 18" O.C.<br />

FACTORY APPLIED SEALANT<br />

12", 16" or 18" O.C.<br />

2"<br />

2"<br />

2"<br />

NEW<br />

Tite-Loc HS Panel<br />

12”, 16” or 17-5/8” O.C. .032 aluminum<br />

2” high 24 gauge steel<br />

22 gauge steel<br />

NEW<br />

12", 16" or 17-5/8" O.C.<br />

12", 16" or 17-5/8" O.C.<br />

12", 16" or 17-5/8" O.C.<br />

07 61 00/PET<br />

BuyLine 3008<br />

2"<br />

2"<br />

2"<br />

9

NEW<br />

NEW<br />

10<br />

Product Features<br />

•Ideal for transition roofs<br />

•Herr-Voss corrective leveled<br />

•Stiffener beads available<br />

Material<br />

•36 standard colors (steel)<br />

•34 standard colors (aluminum)<br />

•11 standard colors (22 ga. steel)<br />

•20 year non-prorated finish warranty<br />

•Smooth and stucco embossed available<br />

•Galvalume Plus available<br />

UL Classification<br />

•UL-580 Class 90 rated over solid substrate<br />

(steel only – up to 18”O.C.)<br />

•UL-1897 wind uplift<br />

•UL-790 Class A fire rated<br />

•UL-263 fire resistance rated<br />

•UL-2218 impact resistance<br />

ASTM Tests<br />

•ASTM E331 tested<br />

•ASTM E283 tested<br />

Florida Building Product Approvals<br />

•.032 <strong>Aluminum</strong>:<br />

FL Prod. Approv. #6191<br />

•24 ga. Steel:<br />

FL Prod. Approv. #6191<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

*<br />

Snap-on Standing Seam<br />

12", 18", 19" or 20" O.C. 24 gauge steel<br />

1" high 22 gauge steel<br />

.032 aluminum<br />

12", 18", 19" or 20" O.C.<br />

1"<br />

Snap-On Panels have been designed for use in roofing, mansard and fascia applications. Snap-On Panels<br />

are designed to be installed over a waterproofed solid substrate and a minimum 3:12 roof pitch. Snap-On<br />

Panels are to be factory roll formed in continuous lengths (minimum panel length is 4 feet).<br />

These panels are ideal for specificationon applications where roof transitions are required. The simplicity of<br />

the pan design combined with corrective leveling provides superior flatness and allows for greater workability<br />

on site.<br />

UL 90 Classified<br />

Steel Snap-On Standing Seam and High Snap-On Standing Seam Panels carry a UL 90 classification for wind<br />

uplift when fastened to an underlayment assembly including 5/8” plywood or OSB (oriented strand board) laminated<br />

to rigid insulation (UL Construction No. 351 & 352). This is one of the few UL 90 Systems that does not<br />

require sealant between plywood boards. For further details contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation.<br />

Air and Water Infiltration<br />

<strong>Petersen</strong> Snap-On Panels meet the full performance requirements of the ASTM E 283 air infiltration test<br />

and the ASTM E 331 water penetration test when applied over a solid substrate. For complete test results,<br />

contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation.<br />

Materials<br />

a) 24 ga. G-90 hot-dipped galvanized steel<br />

b) .032 3105-H14 aluminum<br />

Trim<br />

All flashing and trim will be fabricated by manufacturer or qualified fabricator. Flashing shall be <strong>PAC</strong>-<strong>CLAD</strong><br />

aluminum (.032-.080 gauge as specified) or <strong>PAC</strong>-<strong>CLAD</strong> steel (22 ga. or 24 ga. as specified). A 20 year,<br />

non-prorated warranty shall be supplied covering finish performance.<br />

Curved Panels<br />

The 1" high Snap-On Standing Seam Panel can now be curved to a concave or convex radius, with a minimum<br />

radius of 9 ft. This panel is ideal for barrel vaults and entranceways. Curved panels must be installed<br />

over a waterproofed solid substrate.<br />

Installation<br />

<strong>PAC</strong>-<strong>CLAD</strong> Snap-On Panels shall be installed over solid decking (5/8" plywood, nailboard insulation or<br />

equal) with an underlayment of 30# (min.) roofing felt applied horizontally from eave to ridge. Panels shall<br />

be fastened using <strong>Petersen</strong> Non-Penetrating Clips, fastening on 18" centers (max.). Minimum slope at 3:12<br />

pitch. Consult a local architect or engineer for requirements of local codes and conditions.<br />

Snap-on Batten<br />

11", 12", or 18" O.C. 24 gauge steel<br />

1-1/2" high .032 aluminum<br />

11", 12" or 18" O.C.<br />

1-1/2"<br />

*<br />

High Snap-on Standing Seam<br />

11", 18", or 19" O.C. 24 gauge steel<br />

1-1/2" high .032 aluminum<br />

11", 18" or 19" O.C.<br />

1-1/2"<br />

*24 ga. panels listed in bold print are UL-90 Classified over solid substrate.<br />

See roof deck construction in Underwriter Laboratories roofing<br />

materials and systems directory.

NEW<br />

NEW<br />

Product Features<br />

•Available with or without offsets<br />

•Factory eave notching available<br />

•Herr-Voss corrective leveled<br />

•Labor-saving one-piece design<br />

•Stiffener beads available<br />

Material<br />

•36 standard colors (steel)<br />

•34 standard colors (aluminum)<br />

•Smooth and stucco embossed available<br />

•20 year non-prorated finish warranty<br />

•Galvalume Plus available<br />

•16 oz. cold rolled copper<br />

UL Classification<br />

•UL-580 Class 90 wind uplift<br />

(steel & copper only – copper up to 16 O.C.<br />

only)<br />

•UL-790 Class A fire rated<br />

•UL-263 fire resistance rated<br />

•UL-2218 impact resistance rated<br />

•UL-90 rated copper panel up to 12” O.C.<br />

ASTM Tests<br />

•ASTM E283 tested<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

Curved Batten Panel<br />

The Redi-Roof Batten Panel is the industry's only<br />

batten panel which can be radiused concave or convex<br />

with a minimum radius of 9 ft. This panel is ideal for<br />

barrel vaults and cornices. Curved panels must be<br />

installed over a waterproofed solid substrate.<br />

Top Photo, page 10:<br />

Bitterman Residence<br />

Orlando, FL<br />

Owner: Bitterman Family<br />

Roofing Contractor: RAE CO of Ocala<br />

Color: Copper Penny<br />

Profile: Snap-Clad<br />

Top Photo, page 11:<br />

Mandarin Oriental Hotel<br />

Washington DC<br />

Architect: Brennan Beer Gorman & Monk.<br />

General Contractor: Armada Hoffler Construction<br />

Roofing Contractor: Progressive Services, Inc.<br />

Color: Hemlock Green<br />

Profile: Redi-Roof Batten Panel<br />

12" O.C.<br />

07 61 00/PET<br />

BuyLine 3008<br />

Redi-Roof is an architectural metal roofing system available exclusively from <strong>Petersen</strong> <strong>Aluminum</strong><br />

Corporation. It may be specified in either a batten or standing seam profile and is intended for application<br />

over a solid substrate with a minimum 3:12 roof pitch. Typical underlayments include plywood, nailboard insulation<br />

or equal. Panels are to be factory roll-formed in continuous lengths (minimum panel length is 4 feet).<br />

Redi-Roof Panels feature an offset profile which adds strength and allows room for a hex head fastener.<br />

The clip, with it's button punched design, insures an extra-snug fit. The one-piece design of the Redi-Roof<br />

Standing Seam allows for ease of installation.<br />

UL 90 Classified<br />

Steel Redi-Roof Panels carry a UL-90 classification for wind uplift when fastened to an underlayment assembly<br />

including 5/8” plywood or OSB (oriented strand board) laminated to rigid insulation (UL Construction No.<br />

350, 353 & 615). For further details contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation.<br />

Air and Water Infiltration<br />

<strong>Petersen</strong> Redi-Roof Panels meet the full performance requirements of the ASTM E 283 air infiltration test<br />

and the ASTM E 331 water penetration test when applied over a solid substrate. For complete test results,<br />

contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation.<br />

Materials<br />

a) 24 ga. G-90 hot dipped galvanized steel<br />

b) .032 3105-H14 aluminum or equal<br />

c) 16 oz. cold rolled copper (standing seam only)<br />

Trim All flashing and trim will be fabricated by manufacturer or qualified fabricator. Flashing shall be <strong>PAC</strong>-<strong>CLAD</strong><br />

aluminum (.032-.080 gauge as specified) or <strong>PAC</strong>-<strong>CLAD</strong> steel (22 ga. or 24 ga. as specified). A 20 year warranty<br />

shall be supplied covering finish performance.<br />

Installation<br />

<strong>PAC</strong>-<strong>CLAD</strong> Redi-Roof shall be installed over solid decking with an underlayment of 30# (min.) roofing felt<br />

applied horizontally from eave to ridge. Panels shall be fastened using <strong>Petersen</strong> non-penetrating clips, fastening<br />

on 18" centers (max.). Minimum slope at 3:12 pitch. Redi-Roof Batten panels cannot be lapped in the field.<br />

Consult a local architect/engineer for requirements of local codes and conditions.<br />

*<br />

Redi-Roof Standing Seam<br />

12", 16 or 18” O.C. 24 gauge steel<br />

1-9/16" high .032 aluminum<br />

16 oz. copper<br />

12", 16" or 18" O.C.<br />

12", 16" or 18" O.C.<br />

1-9/16"<br />

1-3/8"<br />

*<br />

Redi-Roof Batten<br />

12" O.C. 24 gauge steel<br />

1-1/4" high .032 aluminum<br />

1-1/4"<br />

*24 ga. panels listed in bold print are UL-90 Classified over solid substrate.<br />

See roof deck construction in Underwriter Laboratories roofing<br />

materials and systems directory.<br />

11

NEW<br />

Product Features<br />

•Herr-Voss corrective leveled<br />

•Labor saving one-piece design<br />

•Stiffener beads available<br />

Material<br />

•36 standard colors (steel)<br />

•34 standard colors (aluminum)<br />

•Smooth & stucco available<br />

•20 year non-prorated finish warranty<br />

•Galvalume Plus available<br />

UL Classification<br />

•UL 580 Class 90 rated over solid substrate<br />

(steel only)<br />

•UL-790 Class A fire rated<br />

•UL-263 fire resistance rated<br />

•UL-2218 impact resistance<br />

•Wind load testing results available<br />

ASTM Tests<br />

•ASTM E283 tested<br />

•ASTM E331 tested<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

*24 ga. panels listed in bold print are UL-90 Classified over solid substrate.<br />

See roof deck construction in Underwriter Laboratories roofing<br />

materials and systems directory.<br />

Top Photo:<br />

Boyds Bear Factory<br />

Gettysburg, PA<br />

Architect: LCS Design<br />

General Contractor: Kinsley Construction, Inc.<br />

Roofing Contractor: M. Potteiger, Inc.<br />

Profile: Snap-On Batten & Snap-Clad<br />

Color: Custom Color, Dark Colonial Red & Charcoal<br />

12<br />

<strong>PAC</strong>-<strong>CLAD</strong> Integral Panels are designed for roofing applications, mansards, canopies and fascia. The onepiece<br />

design of the Integral Panels minimizes labor and allows for quick and easy installation. Integral panels<br />

are to be factory roll formed in continuous lengths (minimum panel length is 4 feet).<br />

Standard on-center dimensions are 11”, 18" and 19", but for renovation projects or additions, on-center<br />

dimensions may be custom matched to your requirements. Neoprene panel closures are available for installation<br />

at the eave.<br />

UL 90 Classified<br />

Steel <strong>PAC</strong>-<strong>CLAD</strong> Integral Panels carry a UL 90 Classification for wind uplift when fastened to an underlayment<br />

assembly including 5/8” plywood or OSB laminated to rigid insulation. (UL Construction No. 346 &<br />

347) For further details contact <strong>Petersen</strong> <strong>Aluminum</strong> Corp.<br />

Air and Water Infiltration<br />

<strong>Petersen</strong> Integral Panels meet the full performance requirements of the ASTM E 283 air infiltration test<br />

and the ASTM E 331 water penetration test when applied over a solid substrate. For complete test results,<br />

contact <strong>Petersen</strong> <strong>Aluminum</strong> Corporation.<br />

Materials<br />

a) 24 ga. G-90 hot-dipped galvanized steel<br />

b) .032 3105-H14 aluminum or equal<br />

Fasteners<br />

For roofing applications, use <strong>Petersen</strong> non-penetrating clips. Clips shall be 606l-T6 extruded aluminum,<br />

fastened on 18" centers. Use wood-type screws in fastening clips. For fascia and mansard applications, panels<br />

should be positively fastened to the substrate.<br />

Trim<br />

All flashing and trim will be fabricated by manufacturer or qualified fabricator. Flashing shall be <strong>PAC</strong>-<strong>CLAD</strong><br />

aluminum (.032-.080 gauge as specified) or <strong>PAC</strong>-<strong>CLAD</strong> 24 ga. steel. A 20 year warranty shall be supplied<br />

covering finish performance.<br />

Installation<br />

Roofing Applications: <strong>PAC</strong>-<strong>CLAD</strong> Integral Seam Panels shall be installed over solid decking (5/8" plywood,<br />

nailboard insulation or equal) with an underlayment of 30# (min.) roofing felt applied horizontally<br />

from eave to ridge. Panels shall be fastened using <strong>Petersen</strong> non-penetrating clips, fastened on 18" centers<br />

(max.). Minimum slope at 3:12 pitch. Consult a local architect/engineer for requirements of local codes and<br />

conditions.<br />

*<br />

Integral Standing Seam<br />

11", 18" or 19" O.C. 24 gauge steel<br />

1-1/2" high .032 aluminum<br />

11", 18" or 19" O.C.<br />

1-1/2"<br />

*<br />

Integral Batten<br />

11", 18" or 19" O.C. 24 gauge steel<br />

1-1/2" high .032 aluminum<br />

11", 18" or 19" O.C.<br />

1-1/2"<br />

1-1/2"

NEW<br />

NEW<br />

Product Features<br />

•Corrective leveled for superior flatness<br />

•Available with up to 3 stiffener beads<br />

•Rounded interlock leg provides improved<br />

flush fit<br />

•.040 aluminum panel<br />

Material<br />

•36 standard colors (steel)<br />

•34 standard colors (aluminum)<br />

•11 standard colors (22 gauge steel)<br />

•20 year non-prorated finish warranty<br />

•Galvalume Plus available<br />

Florida Building Product Approvals<br />

•.032 & .040 <strong>Aluminum</strong>,<br />

22 & 24 ga. Steel:<br />

FL Prod. Approv. #7547<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

Top Photo:<br />

The Shoppes at Farmington Valley<br />

Canton, CT<br />

Owner: S.R. Weiner<br />

Architect: ADD Inc.<br />

General Contractor: Tanglewood Inc.<br />

Roofing Contractor: R & S Construction Services<br />

Profile: Snap-Clad<br />

Color: Musket Gray Stucco Embossed<br />

<strong>PAC</strong>-<strong>CLAD</strong> Flush Panels are designed for wall, fascia and soffit applications where a flush or flat appearance is<br />

desired. A rounded interlock leg and concealed fastening system act to improve the flush appearance while providing<br />

additional strength. Panels are factory-formed to length to minimize field cutting (minimum panel length<br />

is 4 feet).<br />

<strong>PAC</strong>-<strong>CLAD</strong> Flush Panels are available in on-center dimensions designed to complement our roofing panel product<br />

line. Flush Panels are available in two configurations:<br />

•Flush Panel<br />

•Reveal Panel<br />

Flush Panels<br />

Uses: <strong>PAC</strong>-Flush Panels are intended for use as vertical wall panels, fascia and soffit applications. Flush<br />

Panels are not intended for use in roofing or mansard applications.<br />

Materials<br />

a) 24 ga. G-90 hot-dipped galvanized steel b) 22 ga. G-90 hot-dipped galvanized steel<br />

c) .032 3105-H14 aluminum or equal d) .040 3105-H14 aluminum or equal<br />

Stiffening Beads<br />

The Flush Panel and Reveal Panel are available with optional stiffening beads. Stiffening beads are recommended<br />

for longer panel lengths. One, two or three beads are available.<br />

Installation<br />

<strong>PAC</strong>-<strong>CLAD</strong> Flush Panels shall be installed over a solid underlayment or over framing sections as manufactured<br />

by <strong>Petersen</strong> <strong>Aluminum</strong> Corporation. When used in a windscreen application, panels must be fastened (stitched)<br />

through side joints. Consult a local architect/engineer for requirements of local codes and conditions.<br />

Corrective Leveling<br />

<strong>Petersen</strong> Flush Panels are formed on precision roll-forming equipment that includes in-line Herr-Voss corrective<br />

levelers. Corrective leveling works to remove typical metal conditions including coil set, crowning and edge<br />

wave. In-line leveling capabilities allow us to work with source material that is "still-water" flat. The result is a<br />

panel that exhibits superior flatness. Corrective leveling is available at no extra charge. This panel is not available<br />

vented.<br />

Flush Panel**<br />

7", 11", 12” or 18" O.C. .032 aluminum<br />

1" high .040 aluminum<br />

24 gauge steel<br />

22 gauge steel*<br />

7", 11" or 18" O.C.<br />

7", 11" or 18" O.C.<br />

7", 11" or 18" O.C.<br />

1"<br />

1"<br />

1"<br />

7", 11" or 18" O.C.<br />

07 61 00/PET<br />

BuyLine 3008<br />

Reveal Panel<br />

7", 11" or 18" O.C. .032 aluminum<br />

1" high .040 aluminum<br />

24 gauge steel<br />

22 gauge steel<br />

1-1/2"<br />

*Limited color availability<br />

**18” O.C. available in limited applications. Consult<br />

factory for details. 12” O.C. has reduced fastening<br />

flange.<br />

1"<br />

13

14<br />

Product Features<br />

•36 Kynar Colors available in Steel<br />

•34 Kynar Colors available in aluminum<br />

•22ga or 24ga Steel available<br />

•.032 or .040 aluminum<br />

•20-year non-prorated finish warranty<br />

•Galvalume plus available<br />

•Matching Screws and Rivets<br />

•Closure Strips Available<br />

•Precut Short Lengths (2’-0” minimum)<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation has introduced the “M” and “R” exposed fastener<br />

panels in the past and has now expanded it’s panel offerings even more.<br />

We are introducing the 7.2 Rib, 7/8” and 1/2” Corrugated to the line-up. These<br />

corrugated are the most economically and architecturally attractive metal panels.<br />

<strong>Petersen</strong> has these profiles available in a wide range of on-centers and gauges to<br />

give the architect design flexibility on the project. These panels are excellent for<br />

use on walls, equipment screens, linear panels and parapet wall applications.<br />

Note: This panel is not intended for use in the construction of a metal<br />

building or structural roof applications. Please consult with <strong>Petersen</strong><br />

<strong>Aluminum</strong> regarding the application of this panel.<br />

Heifer International<br />

Little Rock, AR<br />

Owner: Heifer International<br />

Architect: Polk Stanley Rowland Curzon Porter Architects, LTD.<br />

Contractors: Ace Glass Co., Harness Roofing<br />

Color: Silver Metallic<br />

Profile: 7/8” Corrugated, M - Panels, Coping

NEW<br />

NEW<br />

M-42 Panel<br />

6"<br />

M-36 Panel<br />

?"<br />

7.2 Panel<br />

?<br />

1"<br />

42"<br />

36"<br />

36"<br />

3/4"<br />

1/2"<br />

?"<br />

NEW<br />

NEW<br />

NEW<br />

R-41 Panel<br />

13-21/32"<br />

R-36 Panel<br />

?"<br />

1/2” Corrugated<br />

2-2/3"<br />

7/8” Corrugated<br />

2-2/3"<br />

41"<br />

36"<br />

40"<br />

34.6"<br />

1"<br />

1-1/4"<br />

1/2"<br />

1/2"<br />

7/8"<br />

07 61 00/PET<br />

BuyLine 3008<br />

15

NEW<br />

NEW<br />

NEW<br />

Product Features<br />

•3 profiles available<br />

•Perforation available for ventilation<br />

(<strong>PAC</strong>-750 & <strong>PAC</strong>-850)<br />

•Roll-formed to exact lengths<br />

•Matching “J” trim available<br />

•Flush panels now available with venting.<br />

Material<br />

•36 standard colors (24 gauge steel)<br />

•34 standard colors (aluminum)<br />

•11 standard colors (22 gauge steel)<br />

•20 year non-prorated finish warranty<br />

•Galvalume Plus available(flush panel only)<br />

UL Classification<br />

•UL 580 Class 90 rated over solid substrate<br />

(steel only)<br />

•UL-790 Class A fire rated<br />

•UL-263 fire resistance rated<br />

•UL-2218 impact resistance<br />

•Wind load testing results available<br />

Florida Building Product Approvals<br />

•<strong>PAC</strong>-850<br />

.032 <strong>Aluminum</strong>:<br />

FL Prod. Approv. #4483<br />

•Flush Panels<br />

.032 & .040 <strong>Aluminum</strong>,<br />

22 & 24 ga. Steel:<br />

FL Prod. Approv. #7547<br />

Open Air Percentages (<strong>PAC</strong> 750/850)<br />

•Half vented - 6%<br />

•Full vented - 12%<br />

These percentages are nominal and may<br />

vary per profile.<br />

A complete specification is available online at<br />

www.pac-clad.com<br />

Florida Welcome Center<br />

Jennings, FL<br />

Owner: FL DOT<br />

General Contractor: Centex Construction<br />

Roofing Contractor: Perry Roofing Contractors<br />

Colors: Silver Metallic<br />

Profiles: Snap-Clad, Flush Panel<br />

16<br />

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation offers a wide variety of pre-formed profiles designed for use in soffit applications.<br />

Steel is not recommended for use in vented soffit applications.<br />

<strong>PAC</strong>-750 Soffit Panels<br />

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation offers a pre-formed soffit panel suitable for both commercial and residential<br />

use. These panels are roll-formed of .032 aluminum. Panels are 12" wide with a “vee” groove every 6" center-to-center<br />

and furnished in continuous lengths of up to 20 feet. Steel is not available in this profile.<br />

<strong>PAC</strong>-850 Soffit Panels<br />

<strong>Petersen</strong> <strong>Aluminum</strong> <strong>PAC</strong>-850 Soffit Panels utilize an innovative hook and grab interlock. These panels are<br />

roll-formed of .032 aluminum. Panels are 12" wide with a “vee” groove every 6" center-to-center and furnished<br />

in continuous lengths of up to 20 feet. Steel is not available in this profile.<br />

Soffit Venting<br />

The <strong>PAC</strong>-750 and <strong>PAC</strong>-850 Soffit Panels can be perforated to allow for air flow and under eave ventilation.<br />

Both <strong>PAC</strong>-750 and <strong>PAC</strong>-850 can come fully vented, half vented, or solid. Contact factory for information<br />

regarding open air percentage. See illustrations as an example.<br />

Soffit "J" Channel<br />

<strong>Petersen</strong> <strong>Aluminum</strong> can provide Soffit “J” Channel as trim to match any of our soffit panels. “J” Channel is<br />

available in lengths up to 12 feet in matching colors.<br />

Flush Panels<br />

The Flush Panel and Reveal Panel may be specified for use as soffit panels. They are roll-formed from .032<br />

aluminum, .040 aluminum, 24 or 22 ga. galvanized and tension-leveled to ensure flatness.<br />

Stiffener beads can be added to the Flush Panel for increased strength and aesthetics. Stiffener beads are<br />

recommended for longer panel lengths. One, two or three beads are available at no additional cost.<br />

Flush Venting<br />

The Flush Panels are available with optional venting strips. Venting is available with one or two strips.

<strong>PAC</strong>-750 Soffit<br />

12" O.C. .032 aluminum<br />

12" O.C.<br />

Flush Panel<br />

7", 11” or 12" O.C. .032 aluminum<br />

1" high .040 aluminum<br />

24 gauge steel<br />

22 gauge steel*<br />

1"<br />

7", 11" or 12" O.C.<br />

*12” O.C. has reduced fastening flange.<br />

1"<br />

7" or 11" O.C.<br />

12" O.C.<br />

1/2"<br />

1/2"<br />

7" or 11" O.C.<br />

<strong>PAC</strong>-750 & <strong>PAC</strong>-850 are also available in vented profiles:<br />

1"<br />

half vent full vent<br />

1"<br />

<strong>PAC</strong>-850 Soffit<br />

12" O.C. .032 aluminum<br />

Soffit Reveal<br />

7" or 11" O.C. .032 aluminum<br />

1" high .040 aluminum<br />

24 gauge steel<br />

22 gauge steel*<br />

1-1/2"<br />

*Limited color availability<br />

12" O.C.<br />

12" O.C.<br />

7" or 11" O.C.<br />

1/2"<br />

07 61 00/PET<br />

BuyLine 3008<br />

Top Photo:<br />

Kenneth Copeland Ministries<br />

Newark, TX<br />

Owner: Kenneth Copeland Ministries<br />

Roofing Contractor: Hipwell Sheet Metal<br />

Profile: Snap-Clad, Reveal Panels<br />

Color: Medium Bronze<br />

17

<strong>Petersen</strong> <strong>Aluminum</strong> Corporation is stocking the patented<br />

ColorGard Snow Retention System. ColorGard is the only<br />

product available which will perfectly match the color of<br />

the roof. ColorGard achieves this by utilizing a strip of the<br />

actual roof material, which is then mounted directly into<br />

ColorGard for a perfect match. This strip can be cut in the<br />

field or at our factory. An architectural alternative to<br />

ColorGard is SnoFence, which uses posts and continuous<br />

rods.<br />

ColorGard utilizes the patented S-5 Clamp for its<br />

strength. The S-5 technology involves gripping the seam<br />

in such a way that there is no penetration to the panel<br />

material. S-5 utilizes round-point set screws for attachment<br />

which are speciallymade for the S-5 ColorGard or<br />

SnoFenceTM Snow Retention System. These systems<br />

eliminate minimum temperature installation requirements<br />

and messy adhesives to apply. ColorGard and SnoFence<br />

can be installed at any temperature. For more information<br />

regarding ColorGard or SnoFence please contact your local<br />

<strong>Petersen</strong> representative.<br />

CLEET- Council Law Enforcement Education & Training<br />

Ada, OK<br />

Architect: Dewberry Design Group Inc.<br />

General Contractor: Atlas General Contractors<br />

Roofing Contractor: Oklahoma Roofing and Sheet Metal, Inc.<br />

Color: Custom Color - Zinc Gray<br />

Profile: Snap-Clad & Flush Panel<br />

18

The <strong>PAC</strong> Composite Wall Panel is a caulked joint panel<br />

system utilizing a composite material comprised of a thermoplastic<br />

core bonded to aluminum skins. This panel system<br />

offers simplicity of fabrication and installation using a<br />

caulked joint. Staggered clip angles allow for non-progressive<br />

installation and adjustable reach to substructure.<br />

The “rout-and-return” fabrication provides sharp edged<br />

panels in a wide variety of shapes. Curved column cover<br />

are avilable. High gloss, andized and stone finishes are<br />

available.<br />

<strong>PAC</strong>-1000 & 2000 Series<br />

The design of the <strong>PAC</strong>-1000 and 2000 “F” Series Column<br />

Covers allows them to be installed leaving only a clean, hairline<br />

joint. The column sections are assembled using a rivnut/<br />

keyhole system to provide a tight inconspicuous vertical seam.<br />

The design of <strong>PAC</strong>-1000 and 2000 “C” and “R” Series<br />

Columns are installed leaving a small open vertical reveal<br />

where the sections meet. Backer rod and caulk are applied to<br />

the vertical reveal joint to complete the installation of our “C”<br />

Series Column Cover. For the “F” Series Column, a metal<br />

channel filler is fabricated to fit into the vertical joint, and is<br />

set in sealant.<br />

Your project may require column or section designs that are<br />

not shown here. <strong>Petersen</strong> <strong>Aluminum</strong> Corporation’s fabrication<br />

capabilities offer a great deal of flexibility and go far beyond<br />

what we can display on this page. Please contact us with<br />

your fabrication needs.<br />

Loeber Motors Mercedes Benz<br />

Lincolnwood, IL<br />

Architect: Valerio, Dewalt, Train Assoc. Inc.<br />

General Contractor: Pepper Construction<br />

Roofing Contractor: Sullivan Roofing, Inc.<br />

Color: Anodic Clear<br />

Profile: Composite Wall Panel<br />

INSIDE CORNER DETAIL<br />

BACKER ROD<br />

& SEALANT<br />

1000 Series<br />

VAPOR BARRIER<br />

ATTACHMENT CLIPS<br />

<strong>PAC</strong>-WALL<br />

INSIDE<br />

CORNER<br />

PANEL<br />

5/8" OR<br />

AS REQ'D<br />

Available in the following variations:<br />

•<strong>PAC</strong>-1000F (Flush Joint)<br />

•<strong>PAC</strong>-1000C (Caulk Joint)<br />

•<strong>PAC</strong>-1000R (Reveal Joint)<br />

2000 Series<br />

Available in the following variations:<br />

•<strong>PAC</strong>-2000F (Flush Joint)<br />

•<strong>PAC</strong>-2000C (Caulk Joint)<br />

•<strong>PAC</strong>-2000R (Reveal Joint)<br />

OUTSIDE CORNER DETAIL<br />

<strong>PAC</strong>-WALL<br />

ROUT &<br />

RETURN<br />

OUTSIDE<br />

CORNER<br />

PANEL<br />

5/8" OR<br />

AS REQ'D<br />

BACKER ROD<br />

& SEALANT<br />

VAPOR BARRIER<br />

ATTACHMENT CLIPS<br />

1" TYP.<br />

Flush Joint<br />

Caulk Joint<br />

Reveal Joint<br />

<strong>PAC</strong>-WALL<br />

PANEL<br />

1"TYP.<br />

BACKER ROD<br />

& SEALANT<br />

07 61 00/PET<br />

BuyLine 3008<br />

SOFFIT DETAIL<br />

VAPOR BARRIER<br />

ATTACHMENT CLIPS<br />

SHIM AS REQ'D<br />

19

FM<br />

APPROVED<br />

FM<br />

APPROVED<br />

<strong>PAC</strong>-Continuous Cleat Coping<br />

The innovative design of the continuous cleat permits<br />

the installation of a sloped coping cap over extra wide<br />

walls. The support of the cleat substantially reduces sagging,<br />

which can induce ponding and the possibility of leaks.<br />

For further weather tightness, neoprene strips are factory<br />

applied to each hold down cleat (see illustration).<br />

Factory-supplied fasteners accompany each coping order<br />

to assure proper attachment of the cleats to the wood nailer.<br />

Field-crimping on the inside leg of the coping to the<br />

inside hold down cleat completes the installation.<br />

•FM Rated for .063 and .050 aluminum, 22 ga. and 24<br />

ga. steel<br />

•Available in Kynar 500 painted and anodized finishes<br />

•Available in up to 12’-0” lengths<br />

•For longer lengths, consult factory<br />

•Available with enhanced FACTORY MUTUAL Ratings up to<br />

FM-I80<br />

•Galvalume Plus available<br />

•ANSI/SPRI ES-1 Approved<br />

Gutter Splice System: TITE-LOC Coping<br />

(patent no. 5,289,662)<br />

The system features a built-in sealing mechanism<br />

incorporated into the splice plate (see illustration). This<br />

proprietary feature not only adds rigidity, but insures a<br />

weathertight joint. Proper installation requires that the<br />

hold-down cleat be attached with four top fasteners and<br />

two face fasteners, spaced as shown. TITE-LOC coping<br />

may be specified with either a neoprene compression pad<br />

or a metal compression strip.<br />

•Available for wall sizes 6" - 16".<br />

•Made 3/4" larger than the wall to compensate for<br />

membranes and inconsistencies.<br />

•FACTORY MUTUAL TESTED (see cleat diagram & wind<br />

uplift chart).<br />

Virginia Beach Central Library<br />

Virginia Beach, VA<br />

Architect: City of Virginia Beach<br />

Roofing Contractor: Roof Systems of Virginia<br />

Color: Stone White<br />

Products: <strong>PAC</strong> Continuous Cleat Coping<br />

20<br />

<strong>PAC</strong>-CONTINUOUS<br />

CLEAT COPING<br />

PATENT # 6216408<br />

Wind Uplift<br />

COPING CAP<br />

NEOPRENE STRIPS<br />

SPLICE PLATE<br />

INSIDE<br />

CONTINUOUS<br />

CLEAT<br />

OUTSIDE<br />

CONTINUOUS<br />

CLEAT<br />

<strong>PAC</strong>-CONTINUOUS<br />

CLEAT COPING<br />

WALL FM FM FM FM FM<br />

MATERIAL WIDTH I-90 I-105 I-120 I-165 I-180<br />

24 ga. Steel 16" Max •<br />

22 ga. Steel 16" Max • •<br />

22 ga. Steel 15" Max • • •<br />

.050, .063 Alum. 24" Max • •<br />

.050, .063 Alum. 16" Max • • • •<br />

.050, .063 Alum. 15" Max • • • • •<br />

TITE-LOC COPING<br />

RENE<br />

NEOP<br />

SEALA<br />

NT STRIP<br />

(factory applied)<br />

STRENGTHENING<br />

BEAD<br />

ROOFI NG<br />

ILS NA<br />

NEOPRENE<br />

COMPRESSION<br />

PAD<br />

HOLD DOWN<br />

CLE AT<br />

SNAP-ON<br />

NGCOPI<br />

SPLI<br />

CE<br />

PLATE<br />

A<br />

TITE-LOC<br />

COPING<br />

A<br />

SPLICE PLATE TO<br />

MATCH COPING<br />

3º PITCH<br />

NEOPRENE<br />

SEALANT STRIP<br />

(factory applied)<br />

OUTSIDE INSIDE<br />

CONTINUOUS CONTINUOUS<br />

HOLD DOWN HOLD DOWN<br />

CLEAT CLEAT REAR HEM LEFT OPEN<br />

FOR FIELD-CRIMPING<br />

NOMINAL WALL SIZE<br />

C<br />

1/2"<br />

SPLICE PLATE TO<br />

MATCH COPING<br />

HOLD<br />

DOWN<br />

CLEAT<br />

3º PITCH<br />

STRENGTHENING<br />

BEAD<br />

NOMINAL WALL SIZE<br />

I 60 = 418 lbs. of upward pressure<br />

I 90 = 628 lbs. of upward pressure<br />

WALL GAUGE FACTORY FACTORY<br />

WIDTH MUTUAL - I 60 MUTUAL - I 90<br />

6" - 12" 24 ga., 22 ga.,<br />

.050,.063, .080, .125 • •<br />

12" - 16" .050, .063, .080, .125 • •<br />

Wind Uplift<br />

*Call for test results and hold down cleat spacing.<br />

C<br />

NEOPRENE SEALANT<br />

STRIP (factory applied)<br />

NEOPRENE<br />

COMPRESSION PAD<br />

COPING<br />

B<br />

B

FM<br />

APPROVED<br />

Fuji Film, Hanover Park, IL<br />

Owner: Industrial Developments International<br />

Architect: Formations Architects & Planners<br />

and Sparks Architects Inc.<br />

General Contractor: Kajima Construction<br />

Services, Inc.<br />

Roofing Contractor: Sullivan Roofing Inc.<br />

Color: Clear Anodized<br />

Products: Flush Panel Soffit &<br />

Custom <strong>Aluminum</strong><br />

Fascia System<br />

Single-Ply Roofing:<br />

<strong>PAC</strong>-1-PLY Gravel Stop<br />

The <strong>PAC</strong>-1-PLY Gravel Stop is designed for use with all<br />

single-ply roofing systems. The <strong>PAC</strong> System is non-penetrating<br />

and designed for quick and sure installation. <strong>PAC</strong>-<br />

1-PLY Gravel Stops achieve an FM I-90 rating with a maximum<br />

face dimension of 8”. Minimum gauges required<br />

for the I-90 rating are .063 aluminum and 24 ga. steel.<br />

<strong>PAC</strong>-1-PLY Gravel Stops are available in 25 standard<br />

<strong>PAC</strong>-<strong>CLAD</strong> Kynar 500 ® colors or may be anodized (clear<br />

or bronze shades) or custom finished.<br />

Gravel stops are pre-fabricated from heavy gauge .040<br />

- .125 aluminum as well as 22 ga. and 24 ga. <strong>PAC</strong>-<strong>CLAD</strong><br />

galvanized steel.<br />

Maximum section lengths are 12’. Each section is furnished<br />

with a 6” wide splice plate with matching finish.<br />

A continuous galvanized cant dam is provided with each<br />

section.<br />

THRIFT-LOC Gravel Stop<br />

(patent no. 4549377)<br />

The THRIFT-LOC Gravel Stop features a heavier,<br />

stronger compression than traditional Type-F Gravel Stops.<br />

Its design features a more efficient use of metal and it is<br />

our most economical gravel stop. THRIFT-LOC Gravel<br />

Stops achieve an FM I-90 rating with a maximum face<br />

dimension of 5”. Minimum gauges required for the I-90<br />

rating are .040 aluminum and 24 ga. steel.<br />

This system is available in .040 - .063 aluminum as<br />

well as 24 ga. and 22 ga. steel in lengths up to 12'.<br />

Built-Up/Modified Roofing:<br />

Type-F Gravel Stop<br />

The Type-F Gravel Stops have design characteristics<br />

similar to extruded gravel stops, but with much greater<br />

design flexibility. Face and head dimensions are variable<br />

and can be angled at varying degrees. This system is<br />

available in .032 - .125 aluminum as well as 24 ga. and<br />

22 ga. steel in lengths up to 12'.<br />

Gravel Stop Accessories<br />

Accessories are available for all of our gravel stops:<br />

•Mitred/quick-locked corners<br />

•Extenders<br />

•End caps<br />

•Ledge caps<br />

•Other<br />

<strong>PAC</strong>-1-PLY GRAVEL STOP<br />

GRAVEL STOP<br />

SPLICE PLATE<br />

NEOPRENE<br />

COMPRESSION<br />

STRIP<br />

CONTINUOUS<br />

CANT DAM<br />

THRIFT-LOC GRAVEL STOP<br />

TYPE-F GRAVEL STOP<br />

MITRED CORNER<br />

GRAVEL STOP<br />

SPLICE PLATE<br />

MEMBRANE<br />

CONTINUOUS<br />

CANT DAM<br />

CONTINUOUS<br />

HOLD DOWN CLEAT<br />

6" COVER PLATE<br />

GRAVEL STOP<br />

<strong>PAC</strong>-1-PLY GRAVEL STOP<br />

STANDARD<br />

FACE<br />

DIMENSIONS<br />

5"<br />

7"<br />

9"<br />

*OTHER SIZES MADE<br />

TO YOUR SPECIFICATIONS<br />

THRIFT-LOC GRAVEL STOP<br />

STANDARD<br />

FACE<br />

DIMENSIONS<br />

5"<br />

7"<br />

9"<br />

A<br />

*OTHER SIZES MADE<br />

TO YOUR SPECIFICATIONS<br />

TYPE-F GRAVEL STOP<br />

A<br />

07 61 00/PET<br />

BuyLine 3008<br />

4"<br />

GRAVEL STOP<br />

SPLICE PLATE<br />

CONTINUOUS<br />

CANT DAM<br />

21

22<br />

General Considerations<br />

The following is a summary of conditions and considerations<br />

that we consider important to the design<br />

and specification of <strong>PAC</strong>-<strong>CLAD</strong> PANEL projects. For more<br />

specific information concerning your projects, please<br />

contact us directly on our technical service line: 1-800-<br />

<strong>PAC</strong>-<strong>CLAD</strong>. We will gladly provide you with any additional<br />

information you may need.<br />

Finishes<br />

<strong>PAC</strong>-<strong>CLAD</strong> PANELS are available as standard with a<br />

full strength Kynar 500® or Hylar 5000® finish.<br />

Please refer to the color charts on pages 7 & 9 for<br />

color selection. Samples and photo-accurate color charts<br />

are available for your assistance. Other finishes available<br />

include <strong>PAC</strong> 300 Clear and <strong>PAC</strong> 500 Bronze<br />

anodized coatings; Siliconized polyester and acrylics.<br />

Special Colors<br />

Special colors are available for most applications of<br />

greater than 10,000 square feet and may be applied<br />

to either aluminum or G-90 galvanized steel. Contact<br />

<strong>Petersen</strong> for information concerning relative costs and<br />

availability.<br />

Installation<br />

Special care must be taken to insure that panels are<br />

installed over a flat substrate. For roofing applications,<br />

panels typically must be installed over 5/8” or 3/4”<br />

plywood decking with 30# roofing felt (minimum) horizontally<br />

overlayed from the eave to ridge. It is recommended<br />

that clips be installed on 18” centers for all<br />

applications except Snap-Clad (consult specific UL<br />

Construction assemblies for clip spacing). Consult a<br />

local architect/engineer for requirements of local codes<br />

and conditions.<br />

Many well known buildings, designed by some of<br />

the world’s leading architects, are roofed with TCS.<br />

The corporate headquarters of PPG Industries, Coca-<br />

Cola, Square D, Pitney-Bowes, Procter and Gamble,<br />

Bristol-Myers, IBM and General Re-Insurance Company<br />

are among a few of the commercial, institutional and<br />

industrial buildings protected by TCS Roofs.<br />

What is TCS?<br />

TCS is a product that weathers upon exposure to<br />

atmospheric conditions. In most areas it attains a<br />

Accessories<br />

Most applications require additional metalwork<br />

including fascia, storefront trim, copings, gravel stops,<br />

downspouts, etc. Such metalwork may be specified for<br />

fabrication by manufacturer or for fabrication from flat<br />

sheet as provided by manufacturer. Flashings fabricated<br />

from <strong>PAC</strong>-<strong>CLAD</strong> flat sheet are fully covered under<br />

<strong>Petersen</strong>’s 20 year finish warranty. <strong>PAC</strong>-<strong>CLAD</strong> flat sheet<br />

provides an exact color match to <strong>PAC</strong>-<strong>CLAD</strong> PANELS.<br />

Lengths<br />

All panels are custom cut-to-length before roll-forming<br />

and are available in lengths up to 40’. Minimum<br />

length is 4’-0”. Lengths are accurate to 1/4”. Custom<br />

cut-to-length is available at no up-charge and helps to<br />

improve project economy. Consult factory for lengths<br />

over 55 feet.<br />

Panel Widths<br />

Most of our <strong>PAC</strong>-<strong>CLAD</strong> Panels are available in nonstandard<br />

on-center dimensions. Contact <strong>Petersen</strong><br />

<strong>Aluminum</strong> for product availability and cost. <strong>PAC</strong>-<strong>CLAD</strong><br />

panel standard widths are nominal and could vary.<br />

Pitch<br />

TITE-LOC Panels are designed for a roof pitch of<br />

1/2:12 or greater. SNAP-<strong>CLAD</strong> Panels have been<br />

designed to be installed on applications as low as 2:12<br />

pitch. Integral Panels and Snap-On Panels have been<br />

designed for a minimum 3:12 pitch. Greater pitch may<br />

be required in snow country and in areas of extreme<br />

climate conditions.<br />

Fire Ratings<br />

<strong>PAC</strong>-<strong>CLAD</strong> Panels have been evaluated by<br />

Underwriter’s Laboratories for inclusion in a variety of<br />

fire-rated “P-Assemblies” and are classified in section<br />

CETW of the UL Fire Resistance Directory - Vol. 1.<br />

Several panel assemblies have been evaluated as Class<br />

pleasing slate gray color. The core metal, however,<br />

remains unaffected due to the sacrificial characteristics<br />

of the terne coat.<br />

Terne-coated stainless steel, or TCS II, is type 304<br />

stainless steel coated both sides with terne alloy (50%<br />

tin, 50% zinc). It is highly corrosion resistant which<br />

makes it an ideal roofing or coping material.<br />

<strong>Petersen</strong> <strong>Aluminum</strong> is a distributor of the following<br />

Follansbee TCS materials:<br />

A fire rated. Contact <strong>PAC</strong> for complete information on<br />

components and assemblies.<br />

Oil Canning<br />

All <strong>Petersen</strong> material is prime quality aluminum and<br />

G-90 galvanized steel. All materials used are specified<br />