You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ICHCA International <strong>Safe</strong>ty Panel Briefing Pamphlet No 30<br />

2.2 <strong>Tank</strong> Swap Bodies<br />

2.2.1 Length Under European (CEN) standards the majority <strong>of</strong> tank swap<br />

bodies (<strong>of</strong>ten referred to as swap tanks) have a length <strong>of</strong> 7.15m,<br />

7.45m, 7.85m or 13.6m. The CEN standard EN 1432 for swap<br />

tanks also includes four other lengths: 6.05m (20ft), 7.15m,<br />

9.125m (30ft) and 12.192m (40ft). However these standards do<br />

not appear to be used too <strong>of</strong>ten as many manufacturers produce<br />

different lengths <strong>of</strong> swap tanks to suit particular cargoes<br />

depending on road regulations (length and mass).<br />

The most common length is 7.15m which has approximately<br />

80% <strong>of</strong> the market.<br />

2.2.2 Width 2.5m and 2.55m wide.<br />

2.2.3 Height 2.670m (EN 1432) and 2.591m.<br />

2.2.4 Volume 30,000 to 36,000 litres.<br />

2.2.5 Stacking Some designs can be stacked but this is an optional feature in<br />

EN 1432. Where they can be stacked they are tested for a<br />

superimposed mass <strong>of</strong> two identical, laden tanks. Note: see<br />

section 12.2 for more information about stacking <strong>of</strong> loaded<br />

containers.<br />

2.2.6 Transport Originally designed for road, rail and RO-RO / short sea and<br />

<strong>of</strong>ten not stacked. Swap tanks with top lift capability can be<br />

stacked on deck on deep sea vessels.<br />

2.3 Domestic Loading Units<br />

<strong>Tank</strong> swap bodies have reduced stacking capability when<br />

compared with ISO designs. This precludes stacking <strong>of</strong> these<br />

units in the lower tiers <strong>of</strong> an on-deck stow. The extra width <strong>of</strong><br />

the design, prevents stacking within most deep sea cells or<br />

adjacent to other containers on deck<br />

2.3.1 Domestic loading units can be built to suit the requirements <strong>of</strong> the local<br />

customer and can therefore have any dimensions which comply with local<br />

road and rail regulations.<br />

2.3.2 These units are not shipped internationally and would be transported<br />

by road or rail only.<br />

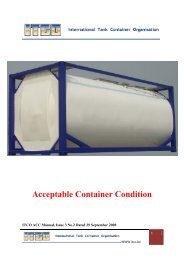

3 <strong>Tank</strong> Designs<br />

3.1 ISO <strong>Tank</strong> <strong>Containers</strong><br />

3.1.1 There are three main structural types <strong>of</strong> tank container used in the<br />

international transport <strong>of</strong> bulk liquids and liquefied gases - beam, frame and<br />

collar. All designs have been manufactured since the 1970s.<br />

3.1.2 All designs can be top lifted, must be stackable and the pressure vessel /<br />

barrel as well as all valves and other service equipment must remain within<br />

the ISO envelope, i.e. no part can protrude past the outer faces <strong>of</strong> the corner<br />

fittings.<br />

3.1.3 Frame <strong>Tank</strong>s<br />

3.1.3.1 This design consists <strong>of</strong> two end frames separated by two main beams at low<br />

level forming a support frame. Since there is more material in the support<br />

frame than with other designs the tare is relatively high. Often the lower<br />

beams are “castellated” a method <strong>of</strong> lightening the main beams by cutting<br />

Page 2 ©ICHCA International Limited