sewing machine operations mannual prepared by: orient craft - smallB

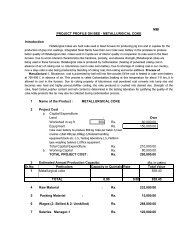

sewing machine operations mannual prepared by: orient craft - smallB

sewing machine operations mannual prepared by: orient craft - smallB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SEWING MACHINE OPERATIONS MANNUAL<br />

PREPARED BY:<br />

ORIENT CRAFT FASHFION INSTITUTE OF TECHNOLOGY<br />

Chenetha bhavan, Nampally, Hyderabad- 500 001<br />

SUBMITTED TO:<br />

GERMAN DEVELOPMENT CO-OPERATION-GTZ<br />

21, Jor Bagh, New Delhi – 110 003<br />

Page | 1

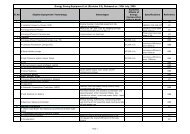

CONTENTS<br />

PARTICULARS Page No.<br />

CHAPTER – I 6<br />

INTRODUCTION<br />

CHAPTER – II 7 To 22<br />

SEWING MACHINE<br />

1. INVENTION OF THE SEWING MACHINE<br />

2. HISTORY OF SEWING MACHINE<br />

3. PARTS OF SEWING MACHINE<br />

4. MACHINE TERMINOLOGY<br />

5. MODERN INDUSTRIAL SEWING MACHINES<br />

A. MULTI - NEEDLE PLEAT GAUGE<br />

B. OVERLOCK MACHINE<br />

C. BARTAK SEWING MACHINE<br />

D. BUTTON SEWING MACHINE<br />

E. BUTTON HOLE MACHINE<br />

F. FEED OF THE ARM<br />

6. MEASURING TOOLS<br />

CHAPTER – III 23 To 27<br />

SELECTION CRITERIA FOR SMO TRAINEES<br />

1. Page board test<br />

2. Color Blindness<br />

3. Visual Dexterity<br />

CHAPTER - IV - TRAINING OF SEWING MACAHINE OPERATORS 28 To 87<br />

1. PAPER EXERCIESES 29 to 61<br />

A. Pedal Control at Maximum Velocity<br />

B. Precise stops at maximum speed<br />

C. Straight stitches at maximum velocity<br />

D. Change of Direction with Needle Down<br />

E. Sewing Curve with One Hand<br />

F. Sewing in Circles<br />

G. Judging changes of direction<br />

H. Sewing curves<br />

I. Over Lock Sewing straight line<br />

J. Over Lock Exact stop<br />

K. Sewing curves<br />

2. THREADING OF MACHINE (Single needle lock stitch <strong>machine</strong>) 62 To 65<br />

Page | 2

A. Thread the Machine and Draw up the Bobbin Thread<br />

B. Threading the bobbin case<br />

C. Bobbin winding<br />

3. FABRIC EXERCISES 66 To 87<br />

A. Sewing 6”x 6” Sewing off the material<br />

B. Sewing 6”x 6” Staying Within Material<br />

C. Sewing 6”x 6” back tack<br />

D. Sew Over 3 Sides 6”x 12”<br />

E. 12 X 6 Top stitch<br />

F. Backtack 6”x 1`2”<br />

G. Baste 6” X 6” in Chain<br />

CHAPTER - V 88 To 90<br />

MEASUREMENTS AND SIZE CHART<br />

1. CIRCUMFERENCE MEASUREMENTS<br />

2. STANDARD MEASUREMENT FOR CHILDREN<br />

3. STANDARD MEASUREMENT FOR TEENAGERS<br />

CHAPTER - VI 91 To 100<br />

MACHINE MAINTAINANCE & SAFETY PRECATIONS<br />

A. Safety- Rules<br />

B. Important safety instructions<br />

C. Machine adjustments and control<br />

CHAPTER - VII 101 To 112<br />

NEEDLE<br />

1. SELECTION OF NEEDLE<br />

2. PART OF THE MACHINE NEEDLS<br />

3. STANDARD NEEDLES<br />

4. TYPE OF NEEDLE AND THEIR USE<br />

5. NEEDLE SIZE AND RELEVANCE OF TYPE OF THE MATERIAL TO BE STICHED<br />

CHAPTER - VIII 113 To 116<br />

SEWING THREAD AND SELECTION CRITERIA<br />

CHAPTER - IX 117 To 127<br />

TYPES OF STITCHES AND SEAM<br />

1. STITCH CLASSIFICATIONS<br />

2. SEAM TYPES AND CLASSIFICATIONS<br />

3. SEAMS & STITCHES OF MEN`S SHIRT<br />

4. SEAMS & STITCHES OF MENS`S TROUSER<br />

5. SEAMS & STITCHES OF DENIM TROUSER<br />

6. SEAMS & STITCHES OF POLO T - SHIRT<br />

Page | 3

7. SEAMS & STITCHES OF ROUND NECK T – SHIRT<br />

CHAPTER - X 128 To 132<br />

DIFFERENT TYPES OF SEWING DEFECTS & REMIDIES<br />

1. DOUBLE NEEDLE LOCK STICH MACHINE<br />

2. BUTTON HOLING SEWING MACHINE<br />

3. BUTTON STITCH MACHINE<br />

4. OVER LOCK MACHINE<br />

CHAPTER - XI - GARMENT MANUFACTURING 133 To 226<br />

PARTS AND ASSEMBLY PREPARATION OF A SHIRT<br />

1. Straight Long Seams with minimal bursts<br />

2. Attaching one piece to other using folder<br />

3. Placket facing attach using folder<br />

4. Hemming <strong>operations</strong> using folder<br />

5. Square pocket attach<br />

6. Rounded bottom pocket attach<br />

7. Bottom triangle pocket attach<br />

8. Diamond pocket attach<br />

9. Long & Short seams with needle down stoppages at corners<br />

10. Collar run stitch operation<br />

11. Top stitch along edges<br />

12. Hem along the contour<br />

13. Mock neck band hem<br />

14. Sewing with template<br />

15. Mock pick stitching<br />

16. Top stitch handling tree piles<br />

17. Mock centre stitch collar<br />

18. Mock topstitch collar<br />

19. Cuff hem<br />

20. Mock run stitch cuffs<br />

21. Binding operation<br />

22. Binding operation using a folder<br />

23. Mock continuous slv placket attach using a folder<br />

24. Mock split edge placket attach operation using folder<br />

25. Attach two plies using folder<br />

26. Pleats<br />

27. Mock yoke attach with folder<br />

28. Shoulder attach without folder<br />

29. Topstitch shoulder<br />

Page | 4

30. Shoulder attach using folder<br />

31. Sew contour fabric to straight fabric<br />

32. Mock collar attach<br />

33. Binding <strong>operations</strong><br />

34. Mock collar finish<br />

35. Lap seam along contour<br />

36. Mock sleeve attach operation (Lap Seam)<br />

37. Lap seam along contour using folder<br />

38. Mock sleeve attach operation (Lap seam) with folder<br />

39. Topstitch along contour over lap seam<br />

40. Topstitch along contour over lap seam using folder<br />

41. Topstitch sleeve attach<br />

42. Topstitch sleeve attach using folder<br />

43. Hemming long contours (Curved)<br />

44. Long straight hemming<br />

45. Hemming long contours (Curved) using folder<br />

46. Long straight hemming using folder<br />

CHAPTER – XII 227 To 241<br />

DIFFERENT TYPES OF SEWING ATTACHMENTS AND USE ON MACHINE<br />

1. Various Collar Operations<br />

2. Yoking and Shoulder Joining:<br />

3. Pocket Hemming<br />

4. Cuff Hemming - Short Sleeve<br />

5. Tail Hemming<br />

6. Button Stay Hemming<br />

7. Cuff Hemming - Long Sleeve<br />

8. Setting Sleeve Plackets<br />

9. Closing Side Seams<br />

10. Sleeve Setting<br />

11. Attach Center Placket<br />

12. Pleat Gauge<br />

CHAPTER – XII<br />

MONTHLY SCHEDULE FOR SEWING MACHINE OPERATOR TRAINING PROGRAMME 242 To 243<br />

Page | 5

INTRODUCTION<br />

CHAPTER - I<br />

Apparel and Textile industry in India is the largest employer after agriculture. It<br />

provides direct employment to 35 million people and another 56 million are engaged in<br />

related activities. Around 14% of industrial production of the country is contributed <strong>by</strong> the<br />

sector. Indeed the apparel sector place a major role in Indian economy and also in foreign<br />

exchange earnings. Apparel exports contribute approximately 9% in India’s total exports<br />

earnings and accounts for about 4% of world trade in textiles and apparels. It is pertinent to<br />

mention that the apparel sector predominantly consist of Small and Medium Enterprises<br />

(SMEs). With the abolition of quota regime under WTO and opening of markets, there is<br />

competition from many countries to retain the existing global market share and also look for<br />

new markets. India has set a target under 11 th plan to earn $ 50 billion through exports of<br />

textiles and apparels. To reach the target Indian apparel industry has to work on many<br />

fronts to be successful in a totally competitive international environment particularly<br />

focusing on factors like development of skilled human resource, quality and productivity,<br />

design development and product diversification and improving lead time and pricing,<br />

effective marketing management.<br />

Indian Small and Medium Enterprises (SMEs) alone cannot attain competitiveness<br />

without the support of likeminded international partners like German Technical Co<br />

operation (GTZ) to enhance the competitiveness of SMEs. Indeed GTZ is committed under<br />

SME Financing and Development Project for the development of apparel sector and<br />

identified it as the priority sector for intervention.<br />

Against the back ground the GTZ has undertaken the task of MSMEs competency<br />

building through business development services in Readymade garments cluster at<br />

Hyderabad with the support of Orient Craft Fashion Institute of Technology (OCFIT)<br />

particularly in preparing manual for <strong>sewing</strong> <strong>machine</strong> operators.<br />

In furtherance of the same, OCFIT with a view to assist development of readymade<br />

garment cluster in Hyderabad focusing around 50 RMGs (16 micro units, 14 small units and<br />

20 medium and large units), studied their working pattern, commercial viability and<br />

<strong>prepared</strong> this manual to assist the <strong>sewing</strong> <strong>machine</strong> operators.<br />

Indeed this manual is <strong>prepared</strong> based on best international <strong>sewing</strong> practices world<br />

over with a focus on exports of readymade garments from India through SMEs.<br />

Page | 6

CHAPTER - II<br />

SEWING MACHINE<br />

Page | 7

1. INVENTION OF THE SEWING MACHINE<br />

The democratization of fashion began with the invention of the <strong>sewing</strong> <strong>machine</strong>, which<br />

turned a handi<strong>craft</strong> into an industry. The <strong>sewing</strong> <strong>machine</strong> made the mass production of clothing<br />

possible. In 1829, a French tailor named Thimmonier patented a wooden chain-stitch <strong>sewing</strong><br />

<strong>machine</strong>, but all existing models were destroyed <strong>by</strong> rioting tailors who feared for their jobs. Walter<br />

Hunt, an American, developed a <strong>sewing</strong> <strong>machine</strong> in 1832 but failed to patent it. Thus, the man who<br />

is usually credited with its invention is Elias Howe, who patented his in 1846. All of Howe’s <strong>machine</strong>s<br />

were run <strong>by</strong> hand.<br />

In 1859, Isaac Singer, whose name has become a household word because of his mass<br />

production of the <strong>sewing</strong> <strong>machine</strong>. He developed the foot treadle, an improvement that left the<br />

hands free to guide the fabric, and mass-produced these <strong>machine</strong>s. Singer spent $1 million a year on<br />

sales promotion and, <strong>by</strong> 1867, was producing a thousand <strong>machine</strong>s per day (Electrically powered<br />

models were not available until 1921). To save time and to keep control over production,<br />

entrepreneurs brought workers and <strong>machine</strong>ry together in factories. This caused many people in<br />

search of work to move to the cities where the factories were located.<br />

In 1849, when the Gold Rush attracted thousands of men in California in search of gold, a 20year<br />

old Bavarian immigrant <strong>by</strong> the name of Levi Strauss opened a dry goods store in San Francisco.<br />

In 1873 he began to manufacture long-wearing pants with riveted pockets, using a tough cotton<br />

fabric called serge de Nimes. (Loomed in Nimes, France), later shortened to denim. They are an item<br />

of wearing apparel that has remained basically the same for nearly 150 years.<br />

Another early use for <strong>sewing</strong> <strong>machine</strong>s was to make Civil War uniforms. The Union army<br />

recorded the chest an height measurements of more than a million soldiers to come up with the first<br />

standardization of sizes. After the war, <strong>sewing</strong> <strong>machine</strong>s and uniform sizing promoted the mass<br />

production of everyday men’s wear.<br />

Page | 8

2. HISTORY OF SEWING MACHINE<br />

Historians of the early days of the <strong>sewing</strong> <strong>machine</strong> can argue for hours over the simple<br />

matter of who invented what is, in many ways, one of the most important <strong>machine</strong>s ever<br />

devised.<br />

The story really starts in 1755 in London when a German immigrant, Charles Wiesenthal,<br />

took out a patent for a needle to be used for mechanical <strong>sewing</strong>. There was no mention of a<br />

<strong>machine</strong> to go with it, and another 34 years were to pass before Englishman Thomas Saint<br />

invented what is generally considered to be the first real <strong>sewing</strong> <strong>machine</strong>.<br />

In 1790 the cabinet maker patented a <strong>machine</strong> with which an awl made a hole in leather<br />

and then allowed a needle to pass through. Critics of Saint's claim to fame point out that<br />

quite possibly Saint only patented an idea and that most likely the <strong>machine</strong> was never built.<br />

It is known that when an attempt was made in the 1880s to produce a <strong>machine</strong> from Saint's<br />

drawings it would not work without considerable modification.<br />

The story then moves to Germany where, in around 1810, inventor Balthasar Krems<br />

developed a <strong>machine</strong> for <strong>sewing</strong> caps. No exact dates can be given for the Krems models as<br />

no patents were taken out.<br />

An Austrian tailor Josef Madersperger produced a series of <strong>machine</strong>s during the early years<br />

of the 19th century and received a patent in 1814. He was still working on the invention in<br />

1839, aided <strong>by</strong> grants from the Austrian government, but he failed to get all the elements<br />

together successfully in one <strong>machine</strong> and eventually died a pauper. Two more inventions<br />

were patented in 1804, one in France to a Thomas Stone and a James Henderson -- a<br />

<strong>machine</strong> which attempted to emulate hand <strong>sewing</strong> -- and another to a Scott John Duncan<br />

for an embroidery <strong>machine</strong> using a number of needles. Nothing is known of the fate of<br />

either invention.<br />

America's first real claim to fame came in 1818 when a Vermont churchman John Adams<br />

Doge and his partner John Knowles produced a device which, although making a reasonable<br />

stitch, could only sew a very short length of material before laborious re-setting up was<br />

necessary.<br />

One of the more reasonable claimants for inventor of the <strong>sewing</strong> <strong>machine</strong> must be<br />

Barthelme Thimmonier who, in 1830, was granted a patent <strong>by</strong> the French government. He<br />

used a barbed needle for his <strong>machine</strong> which was built almost entirely of wood. It is said that<br />

he originally designed the <strong>machine</strong> to do embroidery, but then saw its potential as a <strong>sewing</strong><br />

<strong>machine</strong>.<br />

Page | 9

Unlike any others who went before him, he was able to convince the authorities of the<br />

usefulness of his invention and he was eventually given a contract to build a batch of<br />

<strong>machine</strong>s and use them to sew uniforms for the French army. In less than 10 years after the<br />

granting of his patent Thimmonier had a factory running with 80 <strong>machine</strong>s, but then ran<br />

into trouble from Parisian tailors. They feared that, were his <strong>machine</strong>s successful, they<br />

would soon take over from hand <strong>sewing</strong>, putting the <strong>craft</strong>smen tailors out of work.<br />

Late one night a group of tailors stormed the factory, destroying every <strong>machine</strong>, and causing<br />

Thimmonier to flee for his life. With a new partner he started again, produced a vastly-<br />

improved <strong>machine</strong> and looked set to go into full-scale production; but the tailors attacked<br />

again. With France in the grip of revolution, Thimmonier could expect little help from the<br />

police or army and fled to England with the one <strong>machine</strong> he was able to salvage.<br />

He certainly produced the first practical <strong>sewing</strong> <strong>machine</strong>, was the first man to offer<br />

<strong>machine</strong>s for sale on a commercial basis and ran the first garment factory. For all that, he<br />

died in the poor house in 1857.<br />

In America a quaker Walter Hunt invented, in 1833, the first <strong>machine</strong> which did not try to<br />

emulate hand <strong>sewing</strong>. It made a lock stitch using two spools of thread and incorporated an<br />

eye-pointed needle as used today. But again it was unsuccessful for it could only produce<br />

short, straight, seams.<br />

Nine years later Hunt's countryman, John Greenough, produced a working <strong>machine</strong> in which<br />

the needle passed completely through the cloth. Although a model was made and exhibited<br />

in the hope of raising capital for its manufacture, there were no takers.<br />

Perhaps all the essentials of a modern <strong>machine</strong> came together in early 1844 when<br />

Englishman John Fisher invented a <strong>machine</strong> which although designed for the production of<br />

lace, was essentially a working <strong>sewing</strong> <strong>machine</strong>. Probably because of miss-filing at the<br />

patent office, this invention was overlooked during the long legal arguments between Singer<br />

and Howe as to the origins of the <strong>sewing</strong> <strong>machine</strong>.<br />

Despite a further flurry of minor inventions in the 1840s, most Americans will claim that the<br />

<strong>sewing</strong> <strong>machine</strong> was invented <strong>by</strong> Massachusetts farmer Elias Howe who completed his first<br />

prototype in 1844 just a short time after Fisher.<br />

A year later it was patented and Howe set about trying to interest the tailoring trade in his<br />

invention. He even arranged a competition with his <strong>machine</strong> set against the finest hand<br />

sewers in America. The <strong>machine</strong> won hands down but the world wasn't ready for<br />

mechanized <strong>sewing</strong> and, despite months of demonstrations, he had still not made a single<br />

sale.<br />

Desperately in debt Howe sent his brother Amasa to England with the <strong>machine</strong> in the hope<br />

that it would receive more interest on the other side of the Atlantic. Amasa could find only<br />

one backer, a corset maker William Thomas, who eventually bought the rights to the<br />

invention and arranged for Elias to come to London to further develop the <strong>machine</strong>.<br />

Page | 10

The two did not work well together, each accusing the other of failing to honor agreements<br />

and eventually Elias, now almost penniless, returned to America. When he arrived home he<br />

found that the <strong>sewing</strong> <strong>machine</strong> had finally caught on and that dozens of manufacturers,<br />

including Singer, were busy manufacturing <strong>machine</strong>s -- all of which contravened the Howe<br />

patents.<br />

A long series of law suits followed and were only settled when the big companies, including<br />

Wheeler & Wilson and Grover & Baker, joined together, pooled their patents, and fought as<br />

a unit to protect their monopoly.<br />

Singer did not invent any notable <strong>sewing</strong>-<strong>machine</strong> advances, but he did pioneer the hirepurchase<br />

system and aggressive sales tactics.<br />

Both Singer and Howe ended their days as multi-millionaires.<br />

So the argument can go on about just who invented the <strong>sewing</strong> <strong>machine</strong> and it is unlikely<br />

that there will ever be agreement. What is clear, however, is that without the work of those<br />

long-dead pioneers, the dream of mechanized <strong>sewing</strong> would never have been realized.<br />

Page | 11

3. PARTS OF SEWING MACHINE:<br />

Page | 12

4. MACHINE TERMINOLOGY<br />

The parts of the lockstitch <strong>machine</strong>, which are identified below.<br />

Arm The horizontal part of the head that houses the drive shafts.<br />

Bed The working surface of the <strong>machine</strong> under winch is located the<br />

mechanism at handles the lower thread. On a flat bed <strong>machine</strong>, the bed<br />

rests In the cut-out of the table.<br />

Belt (motor belt or <strong>machine</strong><br />

belt)<br />

The circular strap that transmits motion from the pulley to the hand<br />

wheel, allowing the <strong>machine</strong> to operate.<br />

Bobbin Mechanism The parts - bobbin, bobbin case, and bobbin tension spring - that control<br />

the lower thread and Its tension.<br />

Bobbin winder The part that fills another bobbin while the <strong>machine</strong> is stitching.<br />

check spring (tension spring or<br />

take-up spring)<br />

A small wire spring behind or at the top of the tension discs. It provides<br />

a. small amount of tension on the needle thread and acts as a shock<br />

absorber. On some <strong>machine</strong>s, the check spring is mounted separately.<br />

Faceplate The cover on the left side of the bead that covers the needle bar and the<br />

presser bar.<br />

feed dogs (feed dog, feeder or<br />

feed) fly wheel)<br />

The toothed mechanism beneath the presser foot that moves fabric<br />

forward and backward.<br />

Fittings The parts - presser foot, feed dogs, and throat plate - that control the<br />

cloth during stitching.<br />

Hand wheel (balance or<br />

flywheel)<br />

The part that controls the motion of the <strong>machine</strong> manually and/or<br />

electrically.<br />

Head The part of the <strong>machine</strong> above the table, containing the stitching<br />

mechanism.<br />

Heel The back of the presser foot.<br />

Hook(rotary hook or <strong>machine</strong><br />

hook)<br />

Knee Lift (Knee Lifter or knee<br />

press)<br />

A rotating device that hooks the needle thread to carry it around the<br />

bobbin and form the “lock” on the lockstitch.<br />

A lever mounted at the right under the <strong>sewing</strong> table to lift and lower the<br />

presser foot with the right knee.<br />

Motor The electrical unit that drives the <strong>machine</strong>.<br />

Page | 13

Needle The part that penetrates the fabric. It carries the thread to the hook or<br />

shuttle and up again to make the stitch.<br />

Needle bar A vertical bar that holds one or more needles and moves the needle up<br />

and down.<br />

Needle screw (needle bar clamp) The screw that holds the needle in the needle bar.<br />

Oil gauge The part that Indicates the amount of oil in self-oiling <strong>machine</strong>s.<br />

Pan (<strong>machine</strong> pan) The metal pan. under the head that catches oil, lint and metal shards.<br />

On self-lubricating <strong>machine</strong>s, it holds the oil.<br />

Presser bar The bar to which the presser foot is attached.<br />

Presser bar lifter A lever at the back of presser bar to raise and lower the presser foot <strong>by</strong><br />

hand. It is used to raise the presser foot when winding a bobbin and<br />

when not stitching.(Its use is discouraged in industrial <strong>sewing</strong> because it<br />

wastes time and energy).<br />

Presser foot A device that holds the fabric in place for stitching.<br />

Pressure regulator Control that regulates the amount of pressure on the (pressure dial)<br />

presser foot.<br />

Pretension A simple tension disc used to regulate the thread so that it will feed into<br />

the tension assembly evenly.<br />

Pulley The wheel attached to the motor. It transmits motion from the motor to<br />

the hand wheel <strong>by</strong> means of a leather belt.<br />

Rotary hook assembly The part that holds the bobbin case.<br />

Shuttle An oscillating device that carries the needle thread around the bobbin<br />

and forms the “lock” on the lockstitch.<br />

Slack thread regulator A metal hook or bar near the tension discs.<br />

Slide plate (slide or bed slide) A removable cover at the left of the <strong>machine</strong> bed that bed allows access<br />

to the lower mechanism.<br />

Sole (shoe or slipper) The bottom part of the presser foot that contracts the cloth.<br />

Stand A metal structure upon which the table is mounted.<br />

Stitch hole (needle hole) The hole in the throat plate. The needle carries the thread into the hole<br />

so that it can interlock with the bobbin thread.<br />

Stitch regulator A device that regulates stitch length.<br />

Switch (power switch) A key or button that turns the <strong>machine</strong> on and off.<br />

Page | 14

Table The cabinet upon which the bead rests, it generally has a drawer on the<br />

left side.<br />

Take-up lever The part that first loosens the top thread during the stitch formation,<br />

then removes any slack to set or lock the stitch.<br />

Take-up lever guard A piece of metal in front of the thread take-up lever.<br />

Tension discs Two concave discs that control the delivery of the upper thread from<br />

the spool to the needle.<br />

Thread guides (thread eyelets) The parts that guide the thread from the thread cone (thread eyelets) to<br />

the needle. They smooth the thread and protect it from abrasion.<br />

Thread retainer (pretension) A three-hole guide that applies a small amount of tension on the thread<br />

so it win flow into the tension discs uniformly.<br />

Thread stand A metal device that holds thread cones.<br />

Throat plate The smooth surface directly under the presser foot that includes the<br />

stitch hole and surrounds the feed dog. It protects the lower mechanism<br />

from a build-up of excess lint.<br />

Toes (Prongs) The front end of the presser foot, or the part that faces the oncoming<br />

cloth. It is frequently upturned. On feet such as the zipper foot, cording<br />

foot, and shirring foot, there is only one toe.<br />

Treadle (foot treadle) A metal platform on which the feet rest.(Note: In case of an accident,<br />

the clutch control releases the hand wheel so that it can be turned).<br />

Page | 15

5. MODERN INDUSTRIAL SEWING MACHINES<br />

A. MULTI – NEEDLE PLEAT GAUGE<br />

Imperial multi-needle pleat gauges for tuxedo front shirts - both men's<br />

and ladies'.<br />

Several pleat types are available; including exposed and covered types<br />

illustrated above.<br />

Attachments available for Union Special 54400 (type 401 stitch)<br />

<strong>machine</strong>s or 52 Class (type 101 stitch) <strong>machine</strong>.<br />

Exact finish size and samples are required. Please Submit Samples with<br />

Order.<br />

Both Union Special 54400 and Imperial 52 Class <strong>machine</strong>s also available.<br />

Page | 16

B. OVERLOCK MACHINE<br />

Type of stitch Lock stitch<br />

Machine speed 2500[s.p.m/r.p.m]<br />

Type of motor used Induction motor<br />

Type of lubrication Automatic<br />

Oil used G2<br />

Type of feed Different feed<br />

Type of needle DP X 5<br />

Type of bed Cylindrical bed<br />

Purpose of <strong>machine</strong> Loops attaching<br />

Power consumption 3/4HP<br />

Page | 17

C. BARTACK SEWING MACHINE<br />

Type of stitch Lock stitch<br />

Machine speed 2500[s.p.m/r.p.m]<br />

Type of motor used Induction motor<br />

Type of lubrication Automatic<br />

Oil used G2<br />

Type of feed Different feed<br />

Type of needle DP X 5<br />

Type of bed Cylindrical bed<br />

Purpose of <strong>machine</strong> Loops attaching<br />

Power consumption 3/4HP<br />

Page | 18

D. BUTTON SEWING MACHINE<br />

Type of stitch Lock stitch<br />

Machine speed 2500[s.p.m/r.p.m]<br />

Type of motor used Induction motor<br />

Type of lubrication Automatic<br />

Oil used G2<br />

Type of feed Different feed<br />

Type of needle DP X 17<br />

Type of bed Cylindrical bed<br />

Purpose of <strong>machine</strong> Button <strong>sewing</strong><br />

Power consumption 3/4HP<br />

Page | 19

E. BUTTON HOLE MACHINE<br />

Type of stitch Lock stitch [bobbin, bobbin case are used].<br />

Machine speed 3600 -4000[s.p.m/r.p.m]<br />

Type of motor used Induction motor<br />

Type of lubrication Automatic<br />

Oil used G1<br />

Type of needle DP X 5<br />

Type of bed Raised bed<br />

Purpose of <strong>machine</strong> Making button holes<br />

Power consumption 3/4HP<br />

Page | 20

F. FEED OF THE ARM<br />

Type of stitch Chine stitch<br />

Machine speed 4000[s.p.m/r.p.m]<br />

Type of motor used Clutch motor<br />

Type of lubrication Automatic & manuals<br />

Oil used G1<br />

Type of feed Needle feed<br />

Type of needle TV X 1orTV X 64<br />

Type of bed Cylindrical bed<br />

Purpose of <strong>machine</strong> Joining sleeves, side of trouser<br />

Power consumption 1/2 HP<br />

Page | 21

6. MEASURING TOOLS<br />

Fabric Scissors<br />

Paper Scissors<br />

Seam ripper Measuring Tape<br />

Trimmer<br />

Pencil & Eraser<br />

Tracing Wheel<br />

Measuring Scale<br />

Page | 22

CHAPTER-III<br />

SELECTION CRITERIA FOR SMO TRAINEES<br />

Page | 23

The Candidate for the SMO Training Programme must have the minimum<br />

qualification of 8 th Standard.<br />

The Candidate’s age preferably should be between 18 to 25 years.<br />

The objective of the program is to meet the skill requirements of the apparel<br />

industry and to create gainful employment opportunities for rural BPL families in<br />

apparel industry. So, keeping in view the requirements of the industry, the candidate<br />

for the SMO Programme has to pass through the following tests:<br />

1. PEG BOARD TEST<br />

The Peg Board Test is conducted to know the hand movement of the candidate. The Purdue<br />

Pegboard has been used extensively for various applications. It has two types of activity:<br />

one measures gross movements of the hands, fingers, and arms, and the other measures<br />

assembly or fingertip dexterity.<br />

The Peg Board Test consists of a rectangular board that holds cylindrical pegs. The pegs are<br />

approximately two inch (2.5 cm) in height, and are colored red on one side, black on the<br />

other. Two tests were chosen for this research. The peg board test requires subjects to<br />

transfer the pegs from one hole in the tray to another. The peg board test requires subjects<br />

to pick up a peg, transfer it to the other hand while turning it over, and replace it with the<br />

opposite side facing up.<br />

The operator will be given 80 sec of time to complete it. The operator has to complete the<br />

exercises given in the given span of period.<br />

Page | 24

2. COLOR BLINDNESS TEST<br />

The colour blindness test used test to check color vision deficiencies. There are different<br />

sets available which are often used for pilot, police officer and other job recruitments,<br />

where perfect colour vision is a precondition.<br />

This is a test plate in which everyone should see a "12".<br />

This plate is designed to separate the type of color defectives and the level to which they<br />

are observed. Most will see the number "26" clearly while some will only see a "2" or a "6"<br />

or no numerals at all.<br />

Can you trace a line from one "X" to the other? Someone with normal color vision will trace<br />

an orange/brown purple line and those with a slight deficiency will follow a different path.<br />

Page | 25

Some of the Examples are:<br />

The operator will be shown 10 figures. Each carries 5 sec of time. The operator must be able<br />

to recognize the Letter or Number which is in the Figure in the given span of time.<br />

Page | 26

3. VISUAL DEXTERITY TEST<br />

Example:<br />

Practice:<br />

Visual Dexterity test is the crucial one which plays major role in knowing the Eye<br />

Coordination of the operator.<br />

Eye coordination is a crucial skill involving how effective we are at translating what our eyes<br />

see into appropriate physical responses, such as anticipating the motion of a line in its way<br />

so that we could find out the exact destiny of the line. The operator will be given two<br />

exercises; each carries 30 sec of time to complete it. The operator has to complete the<br />

exercises given in the given span of period.<br />

8<br />

5<br />

3<br />

2<br />

7<br />

1<br />

6<br />

9<br />

4<br />

10<br />

Page | 27

CHAPTER-IV<br />

TRAINING OF SEWING MACHINE OPERATORS<br />

1. PAPER EXERCISES<br />

Page | 28

STOP<br />

A. Pedal Control at Maximum Velocity<br />

MACHINE: SNLS EXERCISE – 1 DURATION: 6 SECS<br />

Page | 29<br />

START

Machine: SNLS<br />

Exercise : Pedal Control at Maximum Velocity<br />

Starting Position:<br />

The apprentice should sit facing the <strong>sewing</strong> <strong>machine</strong> with<br />

both feet on the pedal and the right knee against the knee lift.<br />

Paper in starting position. No thread in <strong>machine</strong>.<br />

Methodology:<br />

Security<br />

The timekeeper starts the chronometer.<br />

Place paper under the <strong>machine</strong> so that the dotted<br />

line lies directly under the needle.<br />

Sew at maximum speed without leaving boundary.<br />

stop at the end of the column with the needle at top<br />

position (1 stitch tolerance).<br />

Raise the foot and slide the paper to the next<br />

column.<br />

Place paper under the <strong>machine</strong> so that the dotted<br />

line lies directly under the needle.<br />

Sew the second line until the end.<br />

Raise the foot and slide paper to the next column.<br />

Stop the chronometer when apprentice sets paper<br />

on the third column.<br />

Hold the paper with the thumb under the paper.<br />

Maintain fingers away from needle at all times.<br />

use glasses.<br />

Avoid using loose clothing and/or long and loose hair.<br />

Quality<br />

Do not tear paper.<br />

The stitch line should remain straight and within the<br />

column limits<br />

Ergonomics<br />

Sited in front of the <strong>sewing</strong> <strong>machine</strong>.<br />

Both feet on pedal<br />

Goal:<br />

6 Seconds<br />

Illustration:<br />

Exercise Number :<br />

Paper Exercise #1<br />

Page | 30

chair and Machine at a comfortable height.<br />

Back rest facing forward.<br />

Waste<br />

Throw away used paper. Use paper several times<br />

Abilities developed<br />

Pedal control<br />

Straight stitches centered at a 3/8” at maximum velocity.<br />

Use of knee lift to elevate <strong>machine</strong> foot.<br />

Necessary material<br />

SNLS without thread<br />

Paper exercise #1<br />

Page | 31

B. Precise stops at maximum speed<br />

MACHINE: SNLS EXERCISE – 2 DURATION: 6 SECS<br />

START<br />

STOP<br />

Page | 32

Machine: SNLS<br />

Exercise : Precise stops at maximum speed<br />

Starting Position:<br />

The apprentice should sit facing the <strong>sewing</strong> <strong>machine</strong><br />

with both feet on the pedal and the right knee against<br />

the knee lift. Paper in starting position. No thread in<br />

<strong>machine</strong>.<br />

Methodology:<br />

Security<br />

The timekeeper starts the chronometer.<br />

Place paper under the <strong>machine</strong> so that the<br />

dotted line lies directly under the needle.<br />

Sew at maximum speed without leaving<br />

boundary.<br />

stop at the end of the 1 st column with the<br />

needle at top position (1 stitch tolerance).<br />

Raise the foot and slide the paper to the next<br />

column.<br />

Place paper under the <strong>machine</strong> so that the<br />

dotted line lies directly under the needle.<br />

Sew the second line until the end.<br />

Raise the foot and slide paper to the next<br />

column.<br />

Stop the chronometer when apprentice sets<br />

paper on the third column.<br />

Hold the paper with the thumb under the paper.<br />

Maintain fingers away from needle at all times.<br />

use glasses.<br />

Avoid using loose clothing and/or long and loose hair.<br />

Quality<br />

Do not tear paper.<br />

The stitch line should remain straight and within the<br />

column limits<br />

Ergonomics<br />

Sited in front of the <strong>sewing</strong> <strong>machine</strong>.<br />

Both feet on pedal<br />

Goal: 6 Seconds<br />

Illustration:<br />

Exercise Number :<br />

Paper exercise # 2<br />

Page | 33

chair and Machine at a comfortable height.<br />

Back rest facing forward.<br />

Waste<br />

Throw away used paper. Use paper several times<br />

Abilities developed<br />

Pedal control<br />

Straight stitches centered at a 3/8” at maximum<br />

velocity.<br />

Use of knee lift to elevate <strong>machine</strong> foot.<br />

Necessary material<br />

SNLS without thread<br />

Paper exercise #2<br />

Page | 34

STOP<br />

C. Straight stitches at maximum velocity<br />

MACHINE: SNLS EXERCISE – 3 DURATION: 10 SECS<br />

Page | 35<br />

START

Machine: SNLS<br />

Exercise : Straight stitches at maximum velocity<br />

Starting Position:<br />

The apprentice should sit facing the <strong>sewing</strong> <strong>machine</strong> with<br />

both feet on the pedal and the right knee against the knee lift.<br />

Paper in starting position. No thread in <strong>machine</strong>.<br />

Methodology:<br />

The timekeeper starts the chronometer.<br />

Place paper under the <strong>machine</strong> so that the dotted<br />

line lies directly under the needle.<br />

Sew at maximum speed in a straight line within<br />

boundaries.<br />

Stop with the pedal at the end of the rectangle with<br />

the needle at the top position.<br />

Make sure the stitches do not leave the rectangle.<br />

Lift the <strong>machine</strong>’s foot and slide paper so that the<br />

second dotted line lies directly under the needle.<br />

Sew at maximum speed in a straight line within<br />

boundaries.<br />

Stop with the pedal once the apprentice has<br />

reached the end of the rectangle, keeping the<br />

needle in the<br />

top position.<br />

Lift the <strong>machine</strong>’s foot and slide paper so that the<br />

third dotted line lies directly under the needle.<br />

The chronometer is stopped once the paper is<br />

placed under the third dotted line.<br />

Note: Each cycle includes two lines<br />

Security<br />

Hold the paper with the thumb under the paper.<br />

Maintain fingers away from needle at all times.<br />

Use glasses.<br />

Avoid using loose clothing and/or long and loose hair.<br />

Quality<br />

Do not tear paper.<br />

The stitch line should remain straight and within<br />

Boundaries.<br />

Ergonomics<br />

Sited in front of the <strong>sewing</strong> <strong>machine</strong>.<br />

Both feet on pedal<br />

Chair and Machine at a comfortable height.<br />

Goal : 10 Seconds Exercise Number :<br />

Illustration:<br />

Paper exercise #3<br />

Page | 36

Back rest facing forward.<br />

Waste<br />

Throw away used paper. Use paper several times<br />

Abilities developed<br />

Exact Stops<br />

Straight stitches at maximum velocity centered at<br />

118” margin.<br />

Use of knee lift to elevate <strong>machine</strong> foot.<br />

Necessary material<br />

SNLS without thread<br />

Paper exercise #3<br />

Page | 37

D. Change of Direction with Needle Down<br />

MACHINE:SNLS EXERCISE – 4 DURATION: 10 SECS<br />

Page | 38<br />

START<br />

STOP

Machine: SNLS<br />

Exercise : Change of Direction with Needle Down<br />

Starting Position:<br />

The apprentice should sit facing the <strong>sewing</strong> <strong>machine</strong><br />

with both feet on the pedal and the right knee against<br />

the knee lift. Paper in starting position. No thread in<br />

<strong>machine</strong>.<br />

Methodology:<br />

The timekeeper starts the chronometer.<br />

Place paper under the <strong>machine</strong> so that the<br />

dotted line lies directly under the needle.<br />

Sew at maximum speed in a straight line so<br />

that stitches lie over doffed line.<br />

Stop with needle in down position when the<br />

apprentice reaches the square.<br />

Make sure the stitches do not leave the<br />

square.<br />

Lift the foot and turn the paper 90° clockwise.<br />

Lower <strong>machine</strong>s foot and sew towards next<br />

square.<br />

Stop with needle in down position when the<br />

apprentice reaches square.<br />

Lift the foot and turn the paper 90° clockwise.<br />

Sew at maximum speed in a straight line so<br />

that stitches lie over dotted line and stop<br />

when the last<br />

square is reached.<br />

Lift foot and place paper to start second cycle<br />

Place paper under the <strong>machine</strong> so that the<br />

dotted line lies directly under the needle.<br />

Lower <strong>machine</strong>s foot.<br />

stop chronometer when the <strong>machine</strong>’s foot is<br />

lowered<br />

Note: Each cycle contains 3 lines and 2 90° turns.<br />

SECURITY<br />

Hold the paper with the thumb under the paper.<br />

Maintain fingers away from needle at all times.<br />

use glasses. -]<br />

Avoid using lo6se clothing and/or long and loose hair.<br />

QUALITY<br />

Do not tear paper.<br />

Make turns with needle at down position and within<br />

Goal: 10 Seconds<br />

Illustration:<br />

Exercise Number :<br />

Paper exercise:4<br />

Page | 39

square<br />

limits.<br />

1/16’ Misalignment with dotted line.<br />

ERGONOMICS<br />

Sited in front of the <strong>sewing</strong> <strong>machine</strong>.<br />

Both feet on pedal<br />

chair and Machine at a comfortable height.<br />

Back rest facing forward.<br />

WASTE<br />

Throw away used paper. Use paper several times<br />

ABILITIES DEVELOPED<br />

Exact Stops<br />

Straight stitches at maximum velocity.<br />

Use of push button to control <strong>machine</strong>s foot.<br />

NECESSARY MATERIALS<br />

SNLS without thread<br />

Paper exercise #4<br />

Page | 40

STOP<br />

E. Sewing Curve with One Hand<br />

MACHINE: SNLS EXERCISE – 5 DURATION: 6 SECS<br />

Page | 41<br />

START

Machine: SNLS<br />

Exercise : Sewing Curve with One Hand<br />

Starting Position:<br />

The apprentice should sit facing the <strong>sewing</strong> <strong>machine</strong> with<br />

both feet on the pedal the right knee against the knee lift.<br />

Paper in starting position. No thread in <strong>machine</strong>.<br />

Methodology:<br />

Security:<br />

The timekeeper starts the chronometer.<br />

Place paper under the <strong>machine</strong> so that the line lies<br />

directly under the needle.<br />

Sew at maximum speed following the curved line<br />

using only the LH on the paper, turning the wrist.<br />

Stop at the end of the line with the needle on the<br />

top position.<br />

Slide the paper with the LH while the <strong>machine</strong> foot<br />

is at the uppermost position.<br />

Place paper under the <strong>machine</strong> so that the line lies<br />

directly under the needle to start the second cycle.<br />

The chronometer is stopped when the apprentice is<br />

set for the next cycle.<br />

Hold the paper with the thumb under the paper.<br />

Maintain fingers away from needle at all times.<br />

Use glasses.<br />

Avoid using loose clothing and/or long and loose hair.<br />

Quality:<br />

Do not tear paper.<br />

Maintain margin at +/-1/16" with respect to line.<br />

Sew without stopping.<br />

Goal: 6 seconds<br />

Illustration:<br />

Exercise Number :<br />

Paper exercise # 5<br />

Page | 42

Ergonomics:<br />

Sited in front of the <strong>sewing</strong> <strong>machine</strong>.<br />

Both feet on pedal<br />

Chair and Machine at a comfortable height.<br />

Back rest facing forward.<br />

Waste:<br />

Throw away used paper. Use paper several times<br />

Abilities Developed:<br />

Sewing curved lines at a constant margin.<br />

Changing direction without stopping.<br />

Use of push button to control <strong>machine</strong>s foot.<br />

Necessary Materials:<br />

SNLS without thread<br />

Paper exercise #5<br />

Page | 43

F. Sewing in Circles<br />

MACHINE: SNLS EXERCISE – 6 DURATION: 34 SECS<br />

START STOP<br />

Page | 44

Machine: SNLS<br />

Exercise : Sewing in Circles<br />

Starting Position:<br />

The apprentice should sit facing the <strong>sewing</strong> <strong>machine</strong> with<br />

both feet on the pedal and the right knee against the knee lift.<br />

Paper in starting position. No thread in <strong>machine</strong>.<br />

Methodology:<br />

Security<br />

The timekeeper starts the chronometer.<br />

Place paper under the <strong>machine</strong> so that the line lies<br />

directly under the needle.<br />

Sew at maximum speed following the curved line<br />

without stopping, turning the paper to form an<br />

eight.<br />

Use index fingers to pivot paper.<br />

stop at the end with the needle on the top position.<br />

Turn and slide the paper while the <strong>machine</strong> foot is<br />

at the uppermost position towards the next cycle.<br />

Place paper under the <strong>machine</strong> so that the line lies<br />

directly under the needle.<br />

The chronometer is stopped when the apprentice is<br />

set for the next cycle.<br />

Hold the, paper with the thumb under the paper.<br />

Maintain fingers away from needle at all times.<br />

Use glasses.<br />

Avoid using loose clothing and/or long and loose hair.<br />

Quality<br />

Do not tear paper.<br />

Maintain margin at ÷/-l/16” with respect to line.<br />

Sew without stopping.<br />

Ergonomics<br />

Sited in front of the <strong>sewing</strong> <strong>machine</strong>.<br />

Both feet on pedal<br />

chair and Machine at a comfortable height.<br />

Goal: 14 seconds Exercise Number :<br />

Illustration:<br />

Paper exercise # 6<br />

Page | 45

Back rest facing forward.<br />

Waste<br />

Throw away used paper. Use paper several times<br />

Abilities developed<br />

Sewing curved lines at a constant margin.<br />

Changing direction without stopping.<br />

Use of push button to control <strong>machine</strong> foot.<br />

Necessary<br />

SNLS without thread<br />

Paper exercise # 6<br />

Page | 46

G. Judging changes of direction<br />

MACHINE: SNLS EXERCISE – 7 DURATION: 20 SECS<br />

Page | 47

Machine: SNLS<br />

Exercise : Judging changes of direction.<br />

Starting Position: The apprentice should sit facing the <strong>sewing</strong><br />

<strong>machine</strong> with both feet on the pedal and the right knee against<br />

the knee lift. Paper in starting position. No thread in <strong>machine</strong>.<br />

Methodology:<br />

The timekeeper starts the chronometer.<br />

Place paper under the <strong>machine</strong> so that the dotted line<br />

lies directly under the needle.<br />

Sew at maximum speed in a V- shape line so that<br />

stitches lie over doffed line.<br />

Stop with needle in down position when the apprentice<br />

reaches the V- shape.<br />

Make sure the stitches do not leave the V- shape.<br />

Lift the foot and turn the paper 90° clockwise.<br />

Lower <strong>machine</strong>s foot and sew towards next V- shape .<br />

Stop with needle in down position when the apprentice<br />

reaches V- shape .<br />

Lift the foot and turn the paper 60° clockwise.<br />

Sew at maximum speed in a straight line so that stitches<br />

lie over dotted line and stop when the last<br />

V- shape is reached.<br />

Lift foot and place paper to start second cycle<br />

Place paper under the <strong>machine</strong> so that the dotted line<br />

lies directly under the needle.<br />

Lower <strong>machine</strong>s foot.<br />

stop chronometer when the <strong>machine</strong>’s foot is lowered<br />

Note: Each cycle contains 8 lines and 7 60° turns.<br />

Security<br />

Hold the paper with the thumb under the paper.<br />

Maintain fingers away from needle at all times.<br />

use glasses. -]<br />

Avoid using lo6se clothing and/or long and loose hair.<br />

Quality<br />

Do not tear paper.<br />

Make turns with needle at down position and within square<br />

limits.<br />

1/16’ Misalignment with dotted line.<br />

Ergonomics<br />

Sited in front of the <strong>sewing</strong> <strong>machine</strong>.<br />

Goal: 20<br />

Seconds<br />

Illustration:<br />

Exercise Number :<br />

Paper exercise # 7<br />

Page | 48

Both feet on pedal<br />

chair and Machine at a comfortable height.<br />

Back rest facing forward.<br />

Waste<br />

Throw away used paper. Use paper several times<br />

Abilities developed<br />

Exact Stops<br />

Straight stitches at maximum velocity.<br />

Use of push button to control <strong>machine</strong>s foot.<br />

Necessary material<br />

SNLS without thread<br />

Paper exercise # 7<br />

Page | 49

H. Sewing curves<br />

MACHINE: SNLS EXERCISE – 8 DURATION: 20 SECS<br />

Page | 50

Machine: SNLS<br />

Exercise : Sewing curves<br />

Starting Position:<br />

The apprentice should sit facing the <strong>sewing</strong> <strong>machine</strong><br />

with both feet on the pedal and the right knee against<br />

the knee lift. Paper in starting position. No thread in<br />

<strong>machine</strong>.<br />

Methodology:<br />

Security<br />

The timekeeper starts the chronometer.<br />

Place paper under the <strong>machine</strong> so that the line<br />

lies directly under the needle.<br />

Sew at maximum speed following the curved<br />

line without stopping.<br />

Use index fingers to pivot paper.<br />

Stop at the end with the needle on the top<br />

position..<br />

Place paper under the <strong>machine</strong> so that the line<br />

lies directly under the needle.<br />

The chronometer is stopped when the<br />

apprentice is set for the next curve.<br />

Hold the, paper with the thumb under the paper.<br />

Maintain fingers away from needle at all times.<br />

Use glasses.<br />

Avoid using loose clothing and/or long and loose hair.<br />

Quality<br />

Do not tear paper.<br />

Maintain margin at ÷/-l/16” with respect to line.<br />

Sew without stopping.<br />

Ergonomics<br />

Sited in front of the <strong>sewing</strong> <strong>machine</strong>.<br />

Both feet on pedal<br />

chair and Machine at a comfortable height.<br />

Back rest facing forward.<br />

Goal: 20 Seconds<br />

Illustration:<br />

Exercise Number :<br />

Paper exercise # 8<br />

Page | 51

Waste<br />

Throw away used paper. Use paper several times<br />

Abilities developed<br />

Sewing curved lines at a constant margin.<br />

Changing direction without stopping.<br />

Use of push button to control <strong>machine</strong> foot.<br />

Necessary materials<br />

SNLS without thread<br />

Paper exercise # 8<br />

Page | 52

I. O / L Sewing straight line<br />

MACHINE: O/L EXERCISE – 9 DURATION: 10 SECS<br />

Page | 53

Machine: O / L<br />

Exercise : O / L Sewing straight line<br />

Starting Position:<br />

The apprentice should sit facing the <strong>sewing</strong> <strong>machine</strong> with<br />

left feet on the pedal and the right feet on the lifter. Paper<br />

in starting position. No thread in <strong>machine</strong>.<br />

Methodology:<br />

Security<br />

The timekeeper starts the chronometer.<br />

Place paper under the <strong>machine</strong> so that the line<br />

lies directly under the pressure foot.<br />

Sew at maximum speed in a straight line within<br />

boundaries.<br />

Stop with the pedal at the end of the rectangle<br />

with the needle at the top position.<br />

Make sure the stitches do not leave the rectangle.<br />

Lift the <strong>machine</strong>’s foot and slide paper so that the<br />

second line lies directly under the pressure foot.<br />

Sew at maximum speed in a straight line within<br />

boundaries.<br />

Stop with the pedal once the apprentice has<br />

reached the end of the rectangle, keeping the<br />

needle in the<br />

top position.<br />

Lift the <strong>machine</strong>’s foot and slide paper so that the<br />

third dotted line lies directly under the needle.<br />

The chronometer is stopped once the paper is<br />

placed under the third dotted line.<br />

Hold the paper with the thumb under the paper.<br />

Maintain fingers away from needle at all times.<br />

Use glasses.<br />

Avoid using loose clothing and/or long and loose hair.<br />

Quality<br />

Do not tear paper.<br />

The stitch line should remain straight and within<br />

Boundaries.<br />

Ergonomics<br />

Sited in front of the <strong>sewing</strong> <strong>machine</strong>.<br />

Left feet on pedal & right feet on lifter.<br />

Chair and Machine at a comfortable height.<br />

Goal: 10 Seconds<br />

Illustration:<br />

Exercise Number :<br />

Paper exercise # 9<br />

Page | 54

Back rest facing forward.<br />

Waste<br />

Throw away used paper. Use paper several times<br />

Abilities developed<br />

Exact Stops<br />

Straight stitches at maximum velocity centered at<br />

118” margin.<br />

Use of knee lift to elevate <strong>machine</strong> foot.<br />

Necessary material<br />

O / L without thread<br />

Paper exercise #9<br />

Page | 55

J. O / L Exact stop<br />

MACHINE: O/L EXERCISE – 10 DURATION: 20 SECS<br />

Page | 56

Machine: O / L<br />

Exercise : O / L Exact stop<br />

Starting Position:<br />

The apprentice should sit facing the <strong>sewing</strong> <strong>machine</strong> with<br />

left feet on the pedal and the right feet on the lifter.<br />

Paper in starting position. No thread in <strong>machine</strong>.<br />

Methodology:<br />

Security<br />

The timekeeper starts the chronometer.<br />

Place paper under the <strong>machine</strong> so that the line<br />

lies directly under the pressure foot.<br />

Sew at maximum speed in a line within<br />

boundaries.<br />

Stop with the pedal at the end of the straight<br />

line with the needle and turn to 120° and stitch<br />

correspondingly..<br />

Make sure the stitches do not leave the<br />

rectangle.<br />

Lift the <strong>machine</strong>’s foot and slide paper so that<br />

the second line lies directly under the pressure<br />

foot.<br />

Stop with the pedal once the apprentice has<br />

reached the end of the line, keeping in the top<br />

position.<br />

Lift the <strong>machine</strong>’s foot and slide paper so that<br />

the third dotted line lies directly under the<br />

pressure foot.<br />

The chronometer is stopped once the paper is<br />

placed under the third dotted line.<br />

Hold the paper with the thumb under the paper.<br />

Maintain fingers away from needle at all times.<br />

Use glasses.<br />

Avoid using loose clothing and/or long and loose hair.<br />

Quality<br />

Do not tear paper inside of the lines..<br />

The stitch line should remain straight and within<br />

Boundaries.<br />

Ergonomics<br />

Sited in front of the <strong>sewing</strong> <strong>machine</strong>.<br />

Left feet on pedal & right feet on lifter.<br />

Chair and Machine at a comfortable height.<br />

Back rest facing forward.<br />

Goal: 20 Seconds<br />

Illustration:<br />

Exercise Number :<br />

Paper exercise # 10<br />

Page | 57

Waste<br />

Throw away used paper. Use paper several times<br />

Abilities developed<br />

Exact Stops<br />

Straight stitches at maximum velocity centered<br />

at 118” margin.<br />

Use of knee lift to elevate <strong>machine</strong> foot.<br />

Necessary material<br />

O / L without thread<br />

Paper exercise #9<br />

Page | 58

K. Sewing curves<br />

MACHINE: O/L EXERCISE – 11 DURATION: 15 SECS<br />

Page | 59

Machine: SNLS<br />

Exercise : Sewing curves<br />

Starting Position:<br />

The apprentice should sit facing the <strong>sewing</strong> <strong>machine</strong> with left<br />

feet on the pedal and the right feet on the lifter. Paper in<br />

starting position. No thread in <strong>machine</strong>.<br />

Methodology:<br />

Security<br />

The timekeeper starts the chronometer.<br />

Place paper under the <strong>machine</strong> so that the line lies<br />

directly under the pressure foot.<br />

Sew at maximum speed in a line within boundaries.<br />

Stop with the pedal at the end of the straight line<br />

with the needle and turn to 120° and stitch<br />

correspondingly..<br />

Make sure the stitches do not leave the rectangle.<br />

Lift the <strong>machine</strong>’s foot and slide paper so that the<br />

second line lies directly under the pressure foot.<br />

Stop with the pedal once the apprentice has<br />

reached the end of the line, keeping in the top<br />

position.<br />

Lift the <strong>machine</strong>’s foot and slide paper so that the<br />

third dotted line lies directly under the pressure<br />

foot.<br />

The chronometer is stopped once the paper is<br />

placed under the third dotted line.<br />

Hold the paper with the thumb under the paper.<br />

Maintain fingers away from needle at all times.<br />

Use glasses.<br />

Avoid using loose clothing and/or long and loose hair.<br />

Quality<br />

Do not tear paper inside of the lines..<br />

The stitch line should remain straight and within<br />

Boundaries.<br />

Ergonomics<br />

Sited in front of the <strong>sewing</strong> <strong>machine</strong>.<br />

Left feet on pedal & right feet on lifter.<br />

Chair and Machine at a comfortable height.<br />

Back rest facing forward.<br />

Goal: 20 Seconds<br />

Illustration:<br />

Exercise Number :<br />

Paper exercise # 11<br />

Page | 60

Waste<br />

Throw away used paper. Use paper several times<br />

Abilities developed<br />

Exact Stops<br />

Straight stitches at maximum velocity centered at<br />

118” margin.<br />

Use of knee lift to elevate <strong>machine</strong> foot.<br />

Necessary material<br />

O / L without thread<br />

Paper exercise #8<br />

Page | 61

2. THREADING OF MACHINE (Single needle lock stitch <strong>machine</strong>)<br />

Page | 62

A. Thread the Machine and Draw up the Bobbin Thread<br />

1. Turn the <strong>machine</strong> off and remove your feet from the treadle. If there is no needle in the<br />

<strong>machine</strong>, run the <strong>machine</strong> out. Then insert a new needle. Check to be sure there is no lint or<br />

dust between the tensions discs or in the thread guide.<br />

2. Raise the thread take-up lever to its highest point.<br />

3. Place the thread on the thread stand. Then pass the thread over the guide at the top of the<br />

thread stand and through the hole in the spool pin(s).<br />

4. Guide the thread into the right (or top) hole of the needle-thread retainer. Then, guide it<br />

through the center hole and, finally the bottom (or left) hole.<br />

5. Guide the thread between the tension discs. Pull it into the check spring and under the slack<br />

thread retainer or vertical bar.<br />

6. Guide the thread from right to left into the eye of the take-up lever.<br />

7. Guide the thread through the remaining guides. The last thread guide is located directly<br />

above the long groove on the needle.<br />

8. Trim the thread end as needed and thread it into the eye of the needle from left to right.<br />

Note: The thread always threads from the long eye or groove on one side of the needle to<br />

the short eye on the other<br />

9. Pull the thread end about 3” (15cm) and hold the thread loosely in your left band.<br />

10. Release the brake and turn the hand wheel so that the needle moves down and up again to<br />

catch the bobbin thread. If the thread doesn’t come up, check the <strong>machine</strong> threading.<br />

Remove the bobbin case, rethread, and insert again<br />

Note: If you continue to turn the hand wheel, you may create a thread jam.<br />

11. Pull the needle thread taut to bring the bobbin thread up through the needle hole.<br />

12. Pull both threads between the prongs or toes of the foot, and then under the presser foot to<br />

the back of the <strong>machine</strong> leaving a 5” (15cm) tail.<br />

13. Draw the thread path for a lockstitch <strong>machine</strong>.<br />

Page | 63

B. Threading the bobbin case<br />

1. Removing the bobbin case<br />

Raise the bobbin case latch to remove the bobbin case<br />

2. Threading the bobbin case<br />

Pass the thread through the slit 1 in the bobbin case and route it under tension<br />

spring 2<br />

Hold the large of the bobbin case and set the bobbin case into the hook.<br />

Place the bobbin in the case taking care of the winding direction of the thread.(The<br />

bobbin should turn in the direction of arrow B when the thread is pulled in the<br />

direction of arrow A)<br />

Page | 64

C. Bobbin winding<br />

1) Route the thread in the order of A, B, and C, and then wind it round the bobbin several times.<br />

2) Set bobbin presser 1 down to make the winder come in contact with the belt.<br />

3) Adjust adjustment screw 2 of the amount of bobbin thread to be wound round the bobbin so that<br />

the<br />

bobbin is wound with thread about 80%.Turn the adjustment screw 2 clockwise to increase the<br />

bobbin<br />

thread amount or counterclockwise to decrease it.<br />

4) If thread is wound unevenly, move winder tension adjust base 3 to the right or left until it is<br />

correctly<br />

positioned.<br />

5) The moment the bobbin has been wound up, the bobbin presser is released, and the bobbin<br />

winder will<br />

stop automatically.<br />

Page | 65

3. FABRIC EXERCISES<br />

TRAINING OF SEWING MACHINE OPERATORS<br />

Page | 66

A. Sewing 6”x 6” Sewing off the material<br />

MACHINE: SNLS EXERCISE: SEW 6” X 6”, SEWING OFF<br />

6”<br />

6” X 6”<br />

Seam Type<br />

DURATION: 15 SECS<br />

Page | 67<br />

6”

Machine: SNLS<br />

Exercise: Sewing 6”x 6” Sewing off the material.<br />

Starting Position:<br />

The apprentice should sit facing the <strong>sewing</strong> <strong>machine</strong> with<br />

Both feet on the pedal and the right knee against the knee lift.<br />

Place material close to the apprentice.<br />

Methodology:<br />

Security<br />

The timekeeper starts the chronometer.<br />

Take fabric with LH and scissors with RH<br />

simultaneously.<br />

Move fabric to the front, and lift <strong>machine</strong> toot.<br />

Place fabric under foot and up to guide at a 1/4"<br />

margin.<br />

Sew at maximum speed until the first edge,<br />

respecting the margin of 1/4".<br />

Stop when fabric leaves the <strong>machine</strong> and cut threads.<br />

Lift <strong>machine</strong> foot and turn fabric counterclockwise,<br />

Place fabric under foot and up to guide at a 1/4”<br />

margin.<br />

Lower <strong>machine</strong> foot.<br />

Sew at maximum speed until the second edge,<br />

respecting the margin of V..<br />

Stop when fabric leaves the <strong>machine</strong> and cut threads.<br />

Lift <strong>machine</strong> foot.<br />

Place fabric under foot and up to guide at a 1/4"<br />

margin.<br />

Lower <strong>machine</strong> foot.<br />

Sew at maximum speed until the third edge,<br />

respecting the margin of 1/4"<br />

Stop when fabric leaves the <strong>machine</strong> and cut threads.<br />

Lift <strong>machine</strong> foot and tum cloth counterclockwise.<br />

Place fabric under foot and up to guide at a 1/4"<br />

margin.<br />

Lower <strong>machine</strong> foot.<br />

Sew at maximum speed until the fourth edge,<br />

respecting the margin 1/4"<br />

Stop when fabric leaves the <strong>machine</strong> and cut threads.<br />

Take fabric with LH and scissors with RH and cut<br />

threads.<br />

The apprentice must be careful not to prick himself with<br />

The needle.<br />

Quality<br />

Maintain a margin of 1/4” (+-1/16).<br />

Ergonomics<br />

chair and Machine at a comfortable height. Back rest facing<br />

Goal:15 Seconds Exercise Number :<br />

Illustration:<br />

Fabric Exercise #1<br />

Page | 68

forward.<br />

Waste<br />

Use fabric various times while practicing.<br />

Abilities Developed<br />

Sewing in a straight line at maximum speed.<br />

Pedal control.<br />

Consistency in margins.<br />

Necessary Materials<br />

SNLS<br />

2 thread cone<br />

2 bobbins.<br />

6” x 6” fabric<br />

Scissors<br />

Page | 69

B. Sewing 6”x 6” Staying Within Material<br />

MACHINE: SNLS<br />

EXERCISE: SEW 6” X 6”, STAYING WITH IN<br />

6<br />

Seam Type<br />

6” X 6”<br />

DURATION: 18 SECS<br />

Page | 70<br />

6”

Machine: SNLS<br />

Exercise : Sewing 6”x 6” Staying Within Material<br />

Starting Position:<br />

The apprentice should sit facing the <strong>sewing</strong> <strong>machine</strong> with both<br />

feet on the pedal and the right knee against the knee lift, Place<br />

fabric close to the apprentice.<br />

Methodology:<br />

Security<br />

The timekeeper starts the chronometer.<br />

Take fabric with LH and scissors with RH<br />

simultaneously.<br />

Move fabric to the front, and lift <strong>machine</strong> foot. Place<br />

fabric under foot and up to guide at a ¼” margin.<br />

Lower <strong>machine</strong> foot,<br />

Sew at maximum speed until the first edge, respecting<br />

the margin of ¼” (+-1/16).<br />

Stop with the needle at the lowest position exactly<br />

1/4” from the edge.<br />

Lift <strong>machine</strong> foot and turn fabric counterclockwise.<br />

Lower <strong>machine</strong> foot.<br />

Sew at maximum speed until the second edge,<br />

respecting the margin of 1/4“ (+-1/16”).<br />

Stop with the needle at the lowest position exactly ¼”<br />

from the edge.<br />

Lift <strong>machine</strong> foot and turn fabric counterclockwise,<br />

Lower <strong>machine</strong> foot.<br />

Sew at maximum speed until the third edge,<br />

respecting the margin of ¼”(+-1/16”).<br />

stop with the needle at the lowest position exactly %“<br />

from the edge,<br />

Lift <strong>machine</strong> foot and turn cloth counterclockwise,<br />

Lower <strong>machine</strong> foot.<br />

Sew at maximum speed until the fourth edge,<br />

respecting the margin of ¼” (+-1/16”)<br />

Stop when fabric leaves the <strong>machine</strong> and cut threads.<br />

Take fabric with LH and scissors with RH and cut<br />

threads,<br />

Timekeeper stops the chronometer.<br />

The apprentice must be careful not to prick himself with<br />

the needle.<br />

Quality<br />

Maintain a margin of 1/4” (+-1/16).<br />

Ergonomics<br />

chair and Machineat a comfortable height. Back rest facing<br />

forward.<br />

Goal: 18 Seconds Exercise Number :<br />

Illustration:<br />

Fabric Exercise #2<br />

Page | 71

Waste<br />

Use fabric various times while practicing.<br />

Abilities Developed<br />

Sewing in a straight line at maximum speed.<br />

Pedal control.<br />

Consistency in margins.<br />

Exact stops.<br />

Necessary Materials<br />

SNLS<br />

2 thread cone<br />

2 bobbins.<br />

6” x 6” fabric<br />

Scissors<br />

Page | 72

C. Sewing 6 x 6 back tack<br />

MACHINE: SNLS EXERCISE: SEW 6” X 6”, BACKTACK DURATION: 21 SECS<br />

6”<br />

Seam Type<br />

Page | 73<br />

6”

Machine: SNLS<br />

Exercise : Sewing 6 x 6 back tack<br />

Starting Position:<br />

Sit straight with two feet on the treadle. Keep the trimmer so<br />

as to access easily.<br />

Methodology:<br />

Security<br />

Pick two pieces of the fabrics one with each hand.<br />

Align the fabric while moving to the needle.<br />

Place the fabric under the needle! 1/4” from its top &<br />

1/4” from its side. Start <strong>sewing</strong>, with back tack<br />

Stop <strong>sewing</strong> at 1/4” from the bottom edge with<br />

needle down. Turn the fabric CCW 90 deg & start<br />

<strong>sewing</strong> in the same way for next 3 sides.<br />

When <strong>sewing</strong> the 4th side! Stop where the stitch has<br />

started & back tack (3 to 4 stitches).<br />

Keep away fingers from the needle.<br />

Quality<br />

Perfect alignment & regular stitch margin of 1/4’ Sharp corners.<br />

Number of back tack stitches. Avoid fullness.<br />

Ergonomics<br />

Keep two bundles one on each side of the body.<br />

Waste<br />

Abilities Developed<br />

Completely set SNLS <strong>machine</strong>.6 x 6 fabric pieces.<br />

Goal: 12 Seconds Exercise Number :<br />

Illustration:<br />

Fabric Exercise #3<br />

Page | 74

Necessary Materials<br />

SNLS<br />

2 Thread cone<br />

2 Bobbins<br />

6” x 6” fabric<br />

scissors<br />

Page | 75

D. Sew Over 3 Sides 6”x 12”<br />

MACHINE: SNLS EXERCISE: SEW 3 SIDES 6” X 12” DURATION: 21 SECS<br />

6”<br />

Seam Type<br />

Page | 76<br />

12”

Machine: SNLS<br />

Exercise : Sew Over 3 Sides 6”x 12”<br />

Starting Position:<br />

The apprentice should sit facing the <strong>sewing</strong> <strong>machine</strong> with both<br />

feet on the pedal and the right knee against the knee lift, Place<br />

fabric close to the operator.<br />

Methodology:<br />

Security<br />

The timekeeper starts the chronometer.<br />

Take corners of fabric with both hands.<br />

Lift <strong>machine</strong> root.<br />

Place fabric under foot and up to guide at a ¼”<br />

margin.<br />

Lower <strong>machine</strong> foot.<br />

Sew at maximum speed until the first edge, respecting<br />

the margin of ¼” (+-1/16”)).<br />

Stop with the needle at the lowest position exactly ¼”<br />

from the edge.<br />

Lift <strong>machine</strong> foot and turn fabric counterclockwise<br />

with LH.<br />

Lower <strong>machine</strong> foot.<br />

Sew at maximum speed until the second edge,<br />

respecting the margin of ¼” (+-1/16”)<br />

Stop with the needle at the lowest position exactly<br />

1/4” from the edge.<br />

Lift <strong>machine</strong> foot and turn fabric counterclockwise.<br />

Lower <strong>machine</strong> foot.<br />

Sew at maximum speed until the third edge,<br />

respecting the margin of’ 1/4” (+.l/16”).<br />

Stop when fabric leaves the <strong>machine</strong> and cut threads.<br />

Take fabric with LH and scissors with RH and cut<br />

threads.<br />

Timekeeper stops the chronometer.<br />

The apprentice must be careful not to prick himself with<br />

the needle.<br />

Use safety glasses.<br />

Avoid using loose clothing and/or long and loose hair.<br />

Quality<br />

Maintain a margin of 1/4” (+-1/16).<br />

Ergonomics<br />

chair and Machine at a comfortable height. Back rest facing<br />

forward.<br />

Goal:14 Seconds Exercise Number :<br />

Illustration:<br />

Fabric Exercise #4<br />

Page | 77

Waste<br />

Use fabric various times while practicing.<br />

Abilities Developed<br />

Sewing in a straight line at maximum speed.<br />

Pedal control.<br />

Consistency in margins.<br />

Exact stops.<br />

Joining and handling of large pieces<br />

Necessary Materials<br />

SNLS<br />

2 thread cone<br />

2 bobbins.<br />

6” x 6” fabric<br />

Scissors<br />

Page | 78

E. 12 X 6 Top stitch<br />

MACHINE: SNLS EXERCISE: 6” X 12” TOP STITCH DURATION: 14 SECS<br />

6”<br />

Seam Type<br />

Page | 79<br />

12”

Machine: SNLS<br />

Exercise : 12 X 6 Top stitch<br />

Starting Position:<br />

With both legs on treadle, pressure foot up.<br />

Methodology:<br />

Security<br />

Pick up the fabric from the side at the corners facing<br />

towards you with both hands.<br />

Keep RH side open corner near (under) the needle<br />

make sure of the stitch margin (1/4”) using the scale<br />