Flygt Submersible Pumps Master Brochure PDF - Godwin Pumps

Flygt Submersible Pumps Master Brochure PDF - Godwin Pumps

Flygt Submersible Pumps Master Brochure PDF - Godwin Pumps

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

WATER & WASTEWATER<br />

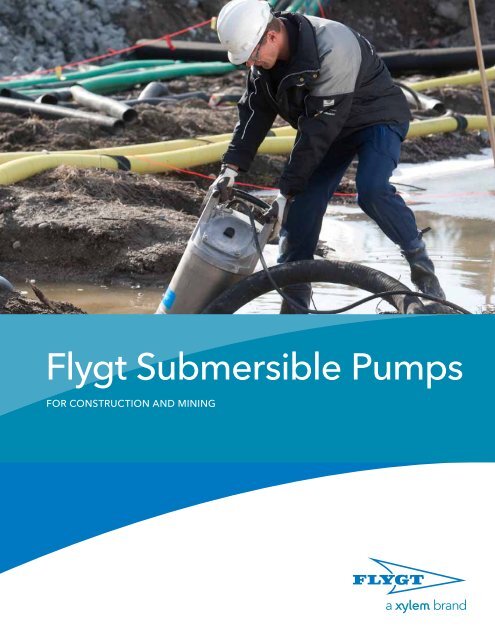

<strong>Flygt</strong> <strong>Submersible</strong> <strong>Pumps</strong><br />

FOR CONSTRUCTION aNd MINING

Over 60 years of dependable pumping<br />

Construction workers and miners have come to trust the<br />

compact, heavy-duty design of <strong>Flygt</strong> submersible pumps<br />

since they were developed more than sixty years ago.<br />

<strong>Flygt</strong> was the first to offer a practical, heavy-duty electric<br />

submersible pump that could withstand the severe<br />

demands of construction site and mine dewatering<br />

and yet still be portable. Over time these early<br />

submersibles became the prototype for a complete<br />

range of other hard-working <strong>Flygt</strong> submersible pumps,<br />

all built in the same tradition of dependability.<br />

We know from years of experience what it takes<br />

to design and manufacture the finest heavy-duty<br />

submersible equipment. The high tolerance machining<br />

is a standard manufacturing process for all parts that<br />

make up our products. We know from experience<br />

that it takes many precise steps, along with quality<br />

O-rings, to achieve the exceptional “fit” needed to<br />

keep a submersible motor dry. This includes critical<br />

sealing areas, such as where the power cable enters<br />

the pump. All parts are machined so the right amount<br />

of compression force is applied between the sealing<br />

grommet, cable and pump body, each and every time<br />

the cable entry bolts are tightened. The result is<br />

a dependable compression cable seal, which can<br />

easily be serviced in the field, and does not require<br />

epoxy sealers.<br />

Precision machining with the outer stator core<br />

diameter and inner motor housing surface allows us to<br />

precisely shrink-fit the motor stator core into the housing.<br />

This feature provides a uniform metal-to-metal contact<br />

between the heat producing motor and its housing,<br />

resulting in exceptional cooling without the need for<br />

messy, expensive cooling oil.<br />

2<br />

The original submersible<br />

pumps had a distinctive<br />

bell-like shape.<br />

Continuing its tradition of excellence, Xylem has<br />

recently introduced its latest generation of <strong>Flygt</strong> pumps.<br />

Designated the 2600 series, the new dewatering pump<br />

line features innovative hydraulics, fewer components,<br />

new materials and a practical, ergonomic design. The<br />

patented DuraSpin hydraulic system and newly<br />

designed impeller improves wear resistance and<br />

sustains performance over time. The wear-resistant<br />

closed impellers are made from high-chrome cast<br />

iron. A single screw enables fast and easy adjustment<br />

for maximum pump performance. During scheduled<br />

maintenance, a moderately worn hydraulic end can<br />

be quickly adjusted back to virtually full performance.<br />

The unique one-piece Plug-In seal incorporates two<br />

mechanical seals for double protection against liquid<br />

penetration.<br />

The results of these features together<br />

in one pump:<br />

• Unmatched wear resistance<br />

• Consistent long-term performance<br />

• Less downtime resulting in the lowest possible cost<br />

of ownership<br />

• Three times more wear-resistant compared to<br />

traditional dewatering pumps<br />

Xylem and <strong>Flygt</strong> continues to offer the most complete<br />

range of heavy-duty submersible pumps, backed by<br />

a nationwide network of service centers stocked with<br />

genuine <strong>Flygt</strong> pumps and parts. When dependability<br />

counts, specify the best… specify <strong>Flygt</strong> pumps.<br />

The earliest electric submersible dewatering pump, developed by <strong>Flygt</strong>,<br />

was called the “Parrot Cage” after its unusual look. In 1948 the first<br />

practical version, model B-80, went into full production and became the<br />

prototype for a complete line of other hard working submersibles, all<br />

built in the same tradition of dependability.

Table OF CONTeNTS<br />

Pump Features ........................................ 5<br />

bS / KS series dewatering pumps ............ 6<br />

Solids-handling dewatering pumps ........ 11<br />

VORTeX IMPelleRS<br />

Solids-handling dewatering pumps ........ 14<br />

ClOSed IMPelleRS<br />

Solids-handling dewatering pumps ........ 16<br />

N–IMPelleRS<br />

Stainless steel dewatering pumps .......... 19<br />

Solids-handling stainless steel<br />

dewatering pumps .................................... 20<br />

Heavy-duty dewatering pumps ............... 22<br />

Heavy-duty slurry pumps .......................... 23<br />

<strong>Flygt</strong> accessories ........................................ 26<br />

3

The pumps in the 2600 series cover almost any dewatering application at worksites of all sizes, including construction sites, mines,<br />

quarries and other harsh environments. The slim design allows the pumps to be installed in pipes used for active dewatering. High<br />

wear-resistance and ease of service make 2600 series pumps the clear choice for contractors.<br />

Compact <strong>Flygt</strong> pumps can be installed virtually anywhere dewatering<br />

is required. Multiple pumps equipped with high volume impellers<br />

allow large amounts of water to be pumped quickly. <strong>Flygt</strong>’s exclusive<br />

motor design places the heat producing stator in direct contact with<br />

the motor housing, which provides optimum cooling even under<br />

non-submerged conditions.<br />

4<br />

<strong>Flygt</strong> submersible pumps are routinely used to remove abrasive,<br />

dirty water from quarries with steep embankments and severe<br />

heights. When equipped with high-head impellers, check valves<br />

and optional tandem coupling kits, submersible pumps offer an<br />

excellent solution. Quarry installations can also include mounting the<br />

pump from a floating raft to keep it off the rough or soft bottom<br />

and accommodate varying water depths.

6<br />

5<br />

1<br />

4<br />

7<br />

Model BS 2640<br />

3<br />

8<br />

2<br />

1. Terminal board<br />

Additional barrier to water ingress. Screwless spring loaded<br />

terminal assures reliable connections and simplifies wiring.<br />

2. External oil and inspection plugs<br />

The external oil plug facilitates service, with no need to<br />

disassemble the pump to refill or check the condition of the oil,<br />

as well as providing easy access to the inspection chamber.<br />

3. Inspection chamber<br />

The inspection chamber provides early notification of any<br />

fluid buildup in case of seal leakage, minimizing the risk<br />

of expensive repair work.<br />

4. Plug-In Seal<br />

The special one-piece Plug-In seal incorporates two<br />

mechanical seals for double protection against liquid penetration.<br />

The unit enables faster and simpler replacement, and<br />

protects seal surfaces during disassembly and mounting.<br />

5. Spin-Out<br />

Unique to <strong>Flygt</strong> products, this patented design protects the<br />

outer seal and extends service life by expelling abrasive<br />

particles from the seal.<br />

6. Impeller<br />

* K impeller, optional<br />

The high-chrome closed impeller is our standard design, made<br />

to handle a high level of abrasives. Additionally, we have the<br />

high-chrome open *K impeller, designed to minimize the<br />

clogging associated with pumping large stringy solids.<br />

7. Single adjustment screw<br />

A single screw enables fast and easy impeller adjustment<br />

for optimal performance over a sustained period of time.<br />

8. Dura-Spin hydraulic system<br />

Spiral grooves on the suction cover, in combination with back<br />

vanes on the impeller, provide greatly increased durability by<br />

preventing abrasive particles from reaching the impeller neck.<br />

5

S/KS series dewatering pumps<br />

These are popular <strong>Flygt</strong> dewatering pumps, known for job site dependability. Most models have strong, lightweight<br />

aluminum and stainless steel body parts and feature hardened impellers with nitrile rubber adjustable wear parts for<br />

long life. These tough pumps do not require total submersion, and will operate under snore conditions if necessary.<br />

Many are available in MSHA-certified, explosion-proof versions for use in mining or landfill dewatering.<br />

6<br />

KS 2610<br />

W<br />

bS/KS 2620<br />

W<br />

bS/KS 2630<br />

W<br />

H<br />

H<br />

H<br />

Model number: 2610.171<br />

Motor rating: 1ø: 1.3HP@3420RPM<br />

1ø: 1.8HP@3475RPM<br />

3ø: 1.9HP@3365RPM<br />

Voltage (1ø): 115V 230V<br />

Full load amps: 11A/15A 5.6A /7.4A<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 5.2A 2.6A 2A<br />

Versions: 2” Standard<br />

Imp. Code 235, 239 (1ø): 233 (3ø)<br />

Hose connection: Male NPT<br />

Pump dimensions: 7 3 /4” W (max.) x 23” H (max.)<br />

Max. weight (lbs.): 53<br />

Description: Aluminum and stainless steel<br />

construction; open non-clog<br />

impeller, rests on bottom strainer.<br />

Options: Warm liquid 70ºC version available;<br />

2610.082 MSHA approved version.<br />

Model number: 2620.171<br />

Motor rating: 1ø: 2.4HP@3420RPM<br />

3ø: 3.5HP@3410RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 9.9A<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 9.5A 4.7A 3.6A<br />

Versions: 3” Standard<br />

Imp. Code K235 (1ø), K236, B228 (3ø)<br />

Hose connection: Male NPT<br />

Pump dimensions: 9 1 /2” W (max.) x 24” H (max.)<br />

Max. weight (lbs.): 66<br />

Description: Aluminum and stainless steel<br />

construction; open non-clog (K)<br />

or extra wear resistant (B) closed<br />

impellers, rests on bottom strainer.<br />

Options: Warm liquid 70ºC version available;<br />

2620.082 MSHA approved version.<br />

Model number: 2630.180<br />

Motor rating: 5.9HP@3490RPM<br />

Voltage (3ø): 208V 230V 460V 575V<br />

Full load amps: 15A 14A 7.1A 5.8A<br />

Versions: 3” High head<br />

Imp. Code B253<br />

4” Standard<br />

Imp. Code K236, B228<br />

Hose connection: Male NPT<br />

Pump dimensions: 11” W (max.) x 30” H (max.)<br />

Max. weight (lbs.): 108<br />

Description: Aluminum and stainless steel<br />

construction; open non-clog (K)<br />

or extra wear resistant (B) closed<br />

impellers, rests on bottom strainer.<br />

Options: Warm liquid 70ºC version available;<br />

2630.081 MSHA approved version.<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

105<br />

90<br />

75<br />

60<br />

45<br />

30<br />

15<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

239<br />

235<br />

233<br />

0 50100 150 200 250<br />

K236<br />

K235<br />

FLOW GPM<br />

B228<br />

0 50100 150 200 250 300<br />

K236<br />

FLOW GPM<br />

B253<br />

B228<br />

0 100 200 300 400 500 600<br />

FLOW GPM

S/KS 2640<br />

bS 2660<br />

bS 2670<br />

W<br />

W<br />

W<br />

H<br />

H<br />

H<br />

Model number: 2640.180<br />

Motor rating: 1ø: 6 HP @ 3475 RPM<br />

3ø: 8.9HP@3495RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 17A<br />

Voltage (3ø): 208V 230V 460V 575V<br />

Full load amps: 24A 22A 11A 8.5A<br />

Versions: 3” High head<br />

Imp. Code B252 (1ø), B253 (3ø)<br />

4” Standard<br />

Imp. Code K235 (1ø), K236, B228 (3ø)<br />

Hose connection: Male NPT<br />

Pump dimensions: 11” W (max.) x 30” H (max.)<br />

Max. weight (lbs.): 112<br />

Description: Aluminum and stainless steel<br />

construction; open non-clog (K)<br />

or extra wear resistant (B) closed<br />

impellers, rests on bottom strainer.<br />

Options: Warm liquid 70ºC version available;<br />

2640.081 MSHA approved version.<br />

Model number: 2660.180<br />

Motor rating: 15HP@3495RPM<br />

Voltage (3ø): 208V 230V 460V 575V<br />

Full load amps: 39A 35A 18A 14A<br />

Versions: 3” High head<br />

Imp. Code 253 (HT), 278 (SH)<br />

4” & 6” Standard<br />

Imp. Code 228, 236<br />

Hose connection: Male NPT<br />

Pump dimensions: 14” W (max.) x 32” (35” SH) H (max.)<br />

Max. weight (lbs.): 172 (211 SH)<br />

Description: Aluminum and stainless steel<br />

construction; extra wear resistant<br />

closed impellers, rests on<br />

bottom strainer.<br />

Options: Warm liquid 70ºC version available;<br />

2660.081 MSHA approved version.<br />

Model number: 2670.180<br />

Motor rating: 27HP@3490RPM<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 61A 31A 25A<br />

Versions: 4” High head<br />

Imp. Code 253<br />

6” Standard<br />

Imp. Code 228<br />

Hose connection: Male NPT<br />

Pump dimensions: 16” W (max.) x 38” H (max.)<br />

Max. weight (lbs.): 309<br />

Description: Aluminum and stainless steel<br />

construction; extra wear resistant<br />

closed impellers; rests on<br />

bottom strainer.<br />

Options: Warm liquid 70ºC version available;<br />

2670.081 MSHA approved version.<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

B252<br />

B227<br />

B253<br />

B228<br />

K236<br />

0 100 200 300 400 500 600 700<br />

FLOW GPM<br />

B278SH<br />

B253HT<br />

B228MT<br />

K236MT<br />

0 200 400 600 800 1000 1200<br />

FLOW GPM<br />

240<br />

210<br />

180<br />

150<br />

120<br />

90<br />

60<br />

30<br />

253<br />

228<br />

0 250 500 750 1000 1250 1500<br />

FLOW GPM<br />

7

8<br />

bS 2071<br />

W<br />

bS 2075.324<br />

bS 2125<br />

W<br />

W<br />

H<br />

H<br />

H<br />

Model number: 2071.010<br />

Motor rating: 1ø: 4.1HP@3425RPM<br />

3ø: 6HP@3335RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 17A<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 16A 8.1A 6.5A<br />

Versions: 2” Standard (2 stage)<br />

Imp. Code 236 (1ø), 231 (3ø)<br />

3” High volume<br />

Imp. Code 216 (1ø), 212 (3ø)<br />

Hose connection: Male NPSM threaded<br />

Pump dimensions: 7 1 /4” W (max.) x 27” H (max.)<br />

Max. weight (lbs.): 68<br />

Description: Aluminum construction; open<br />

impeller, adjustable wear plate;<br />

rests on bottom strainer.<br />

Options: SS impellers<br />

Model number: 2075.324<br />

Motor rating: 3ø: 5.3 HP@3425RPM<br />

8.8 HP@3410RPM<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 14/23A 7.2/12A 5.8/9.4A<br />

Versions: 2” Super High head<br />

Imp. Code 272<br />

3” High head<br />

Imp. Code 234<br />

3” Standard<br />

Imp. Code 232<br />

Hose connection: Male NPSM threaded<br />

Pump dimensions: 12” W (max.) x 22” H (max.)<br />

Max. weight (lbs.): 88<br />

Description: Cast iron construction, open<br />

impeller, adjustable wear plate;<br />

rests on bottom strainer<br />

Model number: 2125.181<br />

Motor rating: 13HP@3470RPM<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 32A 16A 13A<br />

Versions: 3” High head (2 stage)<br />

Imp. Code 234<br />

Hose connection: Male NPSM threaded, or slip-on<br />

Pump dimensions: 18” W (max.) x 33” H (max.)<br />

Max. weight (lbs.): 176<br />

Description: Aluminum construction; open<br />

impeller, adjustable wear plate;<br />

rests on bottom strainer.<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

200<br />

175<br />

150<br />

125<br />

100<br />

75<br />

50<br />

25<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

270<br />

240<br />

210<br />

180<br />

150<br />

120<br />

90<br />

60<br />

30<br />

236<br />

216<br />

231<br />

212<br />

0 50100 150 200 250 300 350<br />

B 272<br />

B 234<br />

FLOW GPM<br />

0 50100 150 200 250 300 350 400<br />

FLOW GPM<br />

234<br />

B 232<br />

0 50100 150 200 250 300 350 400<br />

FLOW GPM

S 2140<br />

W<br />

bS 2201<br />

W<br />

bS 2250<br />

W<br />

H<br />

H<br />

H<br />

Model number: 2140.010<br />

Motor rating: 19HP@3480RPM<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 46A 23A 18A<br />

Versions: 3” High head (2 stage)<br />

Imp. Code 234<br />

3” Standard<br />

Imp. Code 232<br />

Hose connection: Male NPSM threaded, or slip-on<br />

Pump dimensions: 18” W (max.) x 33” H (max.)<br />

Max. weight (lbs.): 186<br />

Description: Aluminum construction; open<br />

impeller, adjustable wear plate;<br />

rests on bottom strainer.<br />

Model number: 2201.011, 2201.320<br />

Motor rating: 58HP@3450RPM (High head, Std.)<br />

50HP@1760RPM (High volume)*<br />

Voltage: 460V 575V<br />

Full load amps: 66/65A 52/ 48A<br />

Versions: 4” High head, Imp. Code 234, 244<br />

6” & 8” Standard, Imp. Code 232<br />

6” & 8” High vol., Imp. Code 412<br />

Hose connection: 4” Male NPSM threaded<br />

6” & 8” Female NPT threaded<br />

Pump dimensions: 19” W (max.) x 48” H (max.)<br />

Max. weight (lbs.): 617 - Aluminum, 1000 - Cast iron<br />

Description: Aluminum (.011) or cast iron (.320)<br />

construction; open impeller(s),<br />

adjustable wear plate; rests on<br />

bottom strainer.<br />

Options: SS impellers<br />

2201.590 MSHA approved version.<br />

Model number: 2250.011<br />

Motor rating: 87HP@1770RPM<br />

Voltage (3ø): 460V 575V<br />

Full load amps: 103A 83A<br />

Versions: 6” High head<br />

Imp. Code 434<br />

8” & 10” Standard<br />

Imp. Code 432<br />

Hose connection: 6” & 8” Female NPT threaded<br />

10” Male NPT threaded<br />

Pump dimensions: 37” W (max.) x 49” H (max.)<br />

Max. weight (lbs.): 1190<br />

Description: Aluminum construction; open<br />

impeller, adjustable wear plate;<br />

rests on bottom strainer.<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

280<br />

240<br />

200<br />

160<br />

120<br />

80<br />

40<br />

B 234<br />

0 200 400 600 800 1000<br />

234<br />

412<br />

244<br />

232<br />

0 1000 2000 3000 4000<br />

434<br />

FLOW GPM<br />

FLOW GPM<br />

432<br />

0 1000 2000 3000 4000 5000<br />

FLOW GPM<br />

9

10<br />

bS 2290<br />

W<br />

bS 2400 HT<br />

W<br />

bS 2400 MT<br />

H<br />

H<br />

Model number: 2290.010<br />

Motor rating: 110HP@1775RPM<br />

Voltage (3ø): 460V 575V<br />

Full load amps: 131A 105A<br />

Versions: 6” High head<br />

Imp. Code 434<br />

8” & 10” Standard<br />

Imp. Code 432<br />

Hose connection: 6” & 8” Female NPT threaded<br />

10” Male NPT threaded<br />

Pump dimensions: 37” W (max.) x 49” H (max.)<br />

Max. weight (lbs.): 1190<br />

Description: Aluminum construction; open<br />

impeller, adjustable wear plate;<br />

rests on bottom strainer.<br />

Model number: 2400.402<br />

Motor rating: 140HP@3560RPM<br />

Voltage (3ø): 460V 575V<br />

Full load amps: 148A 118A<br />

Versions: 4” High head<br />

Imp. Code 244<br />

Discharge conn.: 250# Flange<br />

Pump dimensions: 27” W (max.) x 49” H (max.)<br />

Max. weight (lbs.): 1984<br />

Description: Cast iron construction; open (MT)<br />

or closed (HT) impeller, adjustable<br />

wear plates, strainer, rests on<br />

bottom.<br />

Options: SS impellers, SS wet end<br />

2400.490 MSHA approved version.<br />

H<br />

W<br />

* including stand<br />

Model number: 2400.402<br />

Motor rating: 140HP@3560RPM<br />

Voltage (3ø): 460V 575V<br />

Full load amps: 148A 118A<br />

Versions: 4” High head<br />

Imp. Code 244<br />

6” High volume<br />

Imp. Code 232<br />

Discharge conn.: 125# Flange<br />

Pump dimensions*: 30” W (max.) x 49” H (max.)<br />

Max. weight (lbs.)*: 2167<br />

Description: Cast iron construction; open (MT)<br />

or closed (HT) impeller, adjustable<br />

wear plates, strainer, rests on<br />

bottom.<br />

Options: SS impellers, SS wet end<br />

2400.490 MSHA approved version.<br />

* including stand<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

280<br />

240<br />

200<br />

160<br />

120<br />

80<br />

40<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

434<br />

432<br />

0 1000 2000 3000 4000 5000<br />

244<br />

FLOW GPM<br />

0 500 1000 1500 2000 2500<br />

FLOW GPM<br />

232<br />

0 500 1000 1500 2000 2500<br />

FLOW GPM

Solids-handling dewatering pumps<br />

VORTeX IMPelleRS<br />

<strong>Pumps</strong> equipped with a vortex impeller are suited for pumping water containing moderately abrasive or stringy<br />

solid materials which tend to clog conventional centrifugal impellers. The “open” impeller is located and turns at the<br />

top of the pump chamber, causing a powerful vortex that induces a pumping action in the water below it. Since most<br />

of the pumped water does not actually pass through the impeller, wear and clog-potential are minimized.<br />

dS 2620<br />

dS 2630<br />

dS 2640<br />

W<br />

W<br />

W<br />

H<br />

H<br />

H<br />

Model number: 2620.280<br />

Motor rating: 1ø: 2.4HP@3420RPM<br />

3ø: 3.5HP@3410 RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 9.9A<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 9.5A 4.7A 3.5A<br />

Versions: 3” Standard<br />

Imp. Code 235 (1ø), 236 (3ø)<br />

Discharge conn.: Male NPT threaded<br />

Pump dimensions: 15” W (max.) x 29” H (max.)<br />

Max. weight (lbs.): 75<br />

Description: DS: Aluminum and stainless<br />

steel construction; vortex<br />

type impeller with open inlet<br />

area. Rests on stand.<br />

Options: 2620.580 MSHA approved version.<br />

Model number: 2630.280<br />

Motor rating: 3ø: 6.0HP@1675RPM<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 18A 8.6A 6.9A<br />

Versions: 4” Standard<br />

Imp. 428MT<br />

Discharge conn.: Female NPT threaded<br />

Pump dimensions: 19” W (max.) x 34” H (max.)<br />

Max. weight (lbs.): 119<br />

Description: DS: Aluminum and stainless<br />

steel construction; vortex<br />

type impeller with open inlet<br />

area. Rests on stand.<br />

Model number: 2640.280<br />

Motor rating: 3ø: 2.7HP@3415RPM<br />

Voltage (3ø): 208V 230V 460V 575V<br />

Full load amps: 24A 22A 11A 8.4A<br />

Versions: 3” Standard<br />

Imp. Code 253 (HT), 228 (MT)<br />

Discharge conn.: NPT threaded, male<br />

Pump dimensions: 19” W (max.) x 34” H (max.)<br />

Max. weight (lbs.): 75<br />

Description: DS: Aluminum and stainless<br />

steel construction; vortex<br />

type impeller with open inlet<br />

area. Rests on stand.<br />

Options: 2640.580 MSHA approved version.<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

D235<br />

D236<br />

0 50 100 150 200 250<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0 100<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

FLOW GPM<br />

D 428<br />

200 300<br />

FLOW GPM<br />

D 253<br />

D 228<br />

400<br />

500<br />

0 50 100 150 200 250 300<br />

FLOW GPM<br />

11

12<br />

dS 3045<br />

W<br />

bS 3068<br />

W<br />

dS 3068<br />

W<br />

H<br />

H<br />

H<br />

Model number: 3045.181<br />

Motor rating: 1ø: 1.1Hp @ 3350 RPM<br />

3ø: 1.8Hp @ 33900 RPM<br />

Voltage (1ø): 115V 230V<br />

Full load amps: 10A 5A<br />

Voltage (3ø): 200V 230V 460V 575V<br />

Full load amps: 5.4A 5.2A 2.6A 2A<br />

Versions: 2” Standard<br />

Imp. Code 236 (1ø), 234 (3ø)<br />

Discharge conn.: Female NPT threaded<br />

Pump dimensions: 11 1 /2” W (max.) x 18 1 /2” H (max.)<br />

Max. weight (lbs.): 62<br />

Description: Cast iron construction; open<br />

impeller, rests on stand.<br />

Options: Explosion proof (FM approval)<br />

variant 3045.091<br />

Model number: 3068.250<br />

Motor rating: 1ø: 2.3HP@3330RPM<br />

3ø: 2.7HP@3330RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 10A<br />

Voltage (3ø): 200V 230V 460V 575V<br />

Full load amps: 8.5A 7.5A 3.7A 2.9A<br />

Versions: 1 1 /2” High head<br />

Imp. Code 253 (1ø), 251 (3ø)<br />

Discharge conn.: Female NPT threaded<br />

Pump dimensions: 12 3 /4” W (max.) x 18 1 /2” H (max.)<br />

Max. weight (lbs.): 75<br />

Description: Cast iron construction; open<br />

impeller, rests on stand.<br />

Options: Warm liquid versions available<br />

FM version 3068.590<br />

Model number: 3068.250<br />

Motor rating: 1ø: 2.3HP@3300RPM<br />

3ø: 2.7HP@3415RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 10A<br />

Voltage (3ø): 200V 230V 460V 575V<br />

Full load amps: 8.5A 7.5A 3.7A 2.9A<br />

Versions: 1 1 /2” Standard<br />

Imp. Code 283 (1ø), 281 (3ø)<br />

Discharge conn.: Female NPT threaded<br />

Pump dimensions: 12 3 /4” W (max.) x 19” H (max.)<br />

Max. weight (lbs.): 75<br />

Description: DS: Cast iron construction;<br />

vortex type impeller with open<br />

inlet area. Rests on stand.<br />

Options: Explosion proof (FM approved)<br />

variant 3068.590<br />

Warm liquid version available<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

236<br />

253<br />

234<br />

0 20 40 60 80 100 120 140<br />

FLOW GPM<br />

251<br />

0 25 50 75 100 125 150<br />

FLOW GPM<br />

281<br />

283<br />

0 20 40 60 80 100<br />

FLOW GPM

dF/dS 3068<br />

W<br />

dF 3057<br />

W<br />

W<br />

dS 3085<br />

H<br />

H<br />

H<br />

Model number: 3068.180<br />

Motor rating: 1ø: 2.0HP@1670RPM<br />

3ø: 2.4, 3.2HP@1670RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 9.4A<br />

Voltage (3ø): 200V 230V 460V 575V<br />

Full load amps: 8.5/11A 7.8/10A 3.6/4.7A 2.9/3.8A<br />

Versions: 3” Standard<br />

Imp. Code 473 (1ø), 471, 472 (3ø)<br />

Hose connection: Slip-on<br />

Pump dimensions: 20 1 /4” W (max.) x 23 1 /2” H (max.)<br />

Max. weight (lbs.): 115<br />

Description: DF/DS - Cast iron construction;<br />

vortex type impeller with open<br />

inlet area. DF: Rests on legs;<br />

DS: Rests on stand.<br />

Options: Explosion proof (FM approved)<br />

variant 3068.090<br />

Warm liquid version available<br />

Model number: 3057.181<br />

(Abrasion resistant version)<br />

Motor rating: 3.8HP@3460RPM<br />

Voltage (3ø): 200V 230V 460V 575V<br />

Full load amps: 12A 10A 5.2A 4A<br />

Versions: 2” Standard<br />

Imp. Code 272, 274<br />

Hose connection: Female NPT threaded<br />

Pump dimensions: 12” W (max.) x 18 1 /2” H (max.)<br />

Max. weight (lbs.): 70<br />

Description: Cast iron construction with vortex<br />

type impeller, hardened volute<br />

and impeller for high abrasion<br />

resistance, rests on legs.<br />

Model number: 3085.182<br />

Motor rating: 1ø: 2.4HP & 3ø: 3HP@1750RPM<br />

1ø: 2.9HP & 3ø: 4HP@3450RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 10/12A<br />

Voltage (3ø): 200V 230V 460V 575V<br />

Full load amps: 10/12A 9/10A 4.5/5A 3.6/4A<br />

Versions: 3” Standard<br />

Imp. Code 473 (1ø), 475 (3ø)<br />

3” High head<br />

Imp. Code 284 (1ø), 280 (3ø)<br />

Hose connection: Male NPSM threaded, or slip-on<br />

Pump dimensions: 17 3 /4” W (max.) x 24” H (max.)<br />

Max. weight (lbs.): 125<br />

Description: Cast iron construction; vortex type<br />

impeller, open inlet area, rests on<br />

stand.<br />

Options: Explosion proof (FM approved)<br />

variant 3085.092<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

72<br />

64<br />

56<br />

48<br />

40<br />

32<br />

24<br />

16<br />

8<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

284<br />

475<br />

280<br />

473<br />

274<br />

272<br />

0 30 60 90 120 150 180 210<br />

FLOW GPM<br />

473<br />

0 50 100 150 200 250 300 350 400<br />

FLOW GPM<br />

471<br />

472<br />

0 50 100 150 200 250 300<br />

FLOW GPM<br />

13

Solids-handling dewatering pumps<br />

ClOSed IMPelleRS<br />

CS models feature closed wastewater impellers designed for pumping typical wastewater solids as found in many<br />

sewage applications. Usually, a stationary brass or nitrile rubber wear ring is set into the volute bottom, surrounding<br />

the lower part of the impeller, to prevent wear and maintain hydraulic efficiency. Larger models may also utilize a<br />

stainless steel rotating ring, tightly fitted around the lower part of the impeller, to further reduce wear.<br />

14<br />

CF 3068<br />

W<br />

CS 3085<br />

W<br />

H<br />

H<br />

Model number: 3068.180<br />

Motor rating: 1ø: 2.3HP@3300RPM<br />

3ø: 2.7, 3.8HP@3300RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 10A<br />

Voltage (3ø): 200V 230V<br />

Full load amps: 8.5/12A 7.5/10.4A<br />

460V 575V<br />

3.7/5.2A 2.9/4A<br />

Versions: 2” High head<br />

Imp. Code 255 (1ø), 253 (3ø)<br />

Hose connection: Female NPT, Slip-on (optional)<br />

Pump dimensions: 14 1 /8” W (max.) x 22 3 /8” H (max.)<br />

Max. weight (lbs.): 84<br />

Description: Cast iron construction; closed<br />

solids handling impeller with<br />

thrulet, rests on legs.<br />

Options: Explosion proof (FM approved)<br />

variant 3068.090<br />

Model number: 3085.183<br />

Motor rating: 1ø: 2.4HP@1750RPM<br />

3ø: 2.2, 3HP@1750RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 10A<br />

Voltage (3ø): 200V 230V<br />

Full load amps: 7.8/10A 6.7/9A<br />

460V 575V<br />

3.4/4.5A 2.7/3.6A<br />

Versions: 3” Std., Imp. Code 436 (1ø, 3ø)<br />

434 (3ø, 3HP only)<br />

Hose connection: NPSM threaded, or slip-on<br />

Pump dimensions: 19” W (max.) x 23 3 /4” H (max.)<br />

Max. weight (lbs.): 175<br />

Description: Cast iron construction; closed<br />

solids handling impeller with<br />

thrulet, wear ring; rests on stand.<br />

Options: Explosion proof (FM approved)<br />

variant 3085.092<br />

Warm liquid versions available<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

105<br />

90<br />

75<br />

60<br />

45<br />

30<br />

15<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

436<br />

255<br />

253<br />

0 50 100 150 200 250 300<br />

FLOW GPM<br />

434<br />

0 100 200 300 400 500 600 700<br />

FLOW GPM

CS 3102<br />

W<br />

CS 3127<br />

W<br />

CS 3300<br />

W<br />

H<br />

H<br />

H<br />

Model number: 3102.181<br />

Motor rating: 1ø: 3.9HP@1730RPM<br />

3ø: 5HP@1730RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 16A<br />

Voltage (3ø): 200V 230V 460V 575V<br />

Full load amps: 15A 13A 6.6A 5.3A<br />

Versions: 4” Standard<br />

Imp. Code 433 (1ø, 3ø), 432 (3ø)<br />

Hose connection: NPSM threaded, or slip-on<br />

Pump dimensions: 24” W (max.) x 27 3 /4” H (max.)<br />

Max. weight (lbs.): 245<br />

Description: Cast iron construction; closed<br />

solids handling impeller with<br />

thrulet, wear ring; rests on stand.<br />

Options: Explosion proof (FM approved)<br />

variant 3102.090<br />

Warm liquid version available<br />

Model number: 3127.181<br />

Motor rating: 1ø: 7.5HP@1730RPM<br />

3ø: 10HP@1730RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 30A<br />

Voltage (3ø): 200V 230V 460V 575V<br />

Full load amps: 29A 26A 13A 10A<br />

Versions: 4” High head<br />

Imp. Code 462 (1ø), 483 (3ø)<br />

6” Std., Imp. Code 433 (1ø), 432 (3ø)<br />

8” Std., Imp. Code 412 (1ø), 411 (3ø)<br />

Hose connection: 4” & 6” NPSM threaded, or<br />

4”, 6” & 8” slip-on<br />

Pump dimensions: 31 1 /2” W (max.) x 30 3 /4” H (max.)<br />

Max. weight (lbs.): 400<br />

Description: Cast iron construction; closed<br />

solids handling impeller with<br />

thrulet, wear ring; rests on stand.<br />

Options: Explosion proof (FM approved)<br />

variant 3127.090<br />

Warm liquid version available<br />

Model number: 3300.181<br />

Motor rating: 60HP@1170RPM & 875RPM<br />

45HP@875RPM<br />

75HP, 88HP@1170RPM<br />

Voltage (3ø, 60HP): 460V 575V<br />

Full load amps: 73/80A 58/ 65A<br />

Voltage (3ø,<br />

45/75/88HP): 460V 575V<br />

Full load amps: 60/91/108A 48/ 73/86A<br />

Versions: 6” High head, Imp. Code 464 (88HP)<br />

8” Standard<br />

Imp. Code 646 (60HP), 642 (75HP)<br />

10” High volume<br />

Imp. Code 807 (45HP), 804 (60HP)<br />

Hose connection: Slip-on<br />

Pump dimensions: 66” W (max.) x 75 3 /4” H (max.)<br />

Max. weight (lbs.): 1915<br />

Description: Cast iron construction; closed<br />

solids handling impeller with<br />

thrulet, wear ring; rests on stand.<br />

Options: Explosion proof (FM approved)<br />

variant 3300.091<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

54<br />

48<br />

42<br />

36<br />

30<br />

24<br />

18<br />

12<br />

6<br />

90<br />

75<br />

60<br />

45<br />

30<br />

15<br />

225<br />

200<br />

175<br />

150<br />

125<br />

100<br />

75<br />

50<br />

25<br />

412<br />

464<br />

807<br />

462<br />

483<br />

433<br />

433<br />

646<br />

432<br />

0 100 200 300 400 500 600 700 800<br />

FLOW GPM<br />

642<br />

432<br />

804<br />

411<br />

0 400 800 1200 1600 2000<br />

FLOW GPM<br />

0 1500 3000 4500 6000 7500 9000<br />

FLOW GPM<br />

15

Solids-handling dewatering pumps<br />

N–IMPelleRS<br />

All NS series pumps are equipped with <strong>Flygt</strong>’s innovative “self-cleaning” N-impeller. The open impeller works<br />

with a special relief groove at the bottom of the volute to continually keep it free from solids build-up. This<br />

proven design not only reduces clogging but also ensures continued long-term efficiencies, which significantly<br />

reduce electrical operating costs. An excellent choice where troublesome solids are present in the water to<br />

be pumped.<br />

16<br />

NS 3085<br />

W<br />

NS 3102<br />

W<br />

H<br />

H<br />

Model number: 3085.183<br />

Motor rating: 1ø: 2.4HP@1750RPM<br />

3ø: 2.2, 3HP@1750RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 10A<br />

Voltage (3ø): 200V 230V<br />

Full load amps: 7.8/10A 6.7/9A<br />

460V 575V<br />

3.4/4.5A 2.7/3.6A<br />

Versions: 3” Standard<br />

Imp. Code 463 (1ø, 3ø), 462 (3ø)<br />

Hose connection: NPSM threaded, or slip-on<br />

Pump dimensions: 17 3 /4” W (max.) x 24 1 /4” H (max.)<br />

Max. weight (lbs.): 175<br />

Description: Cast iron construction; semi-open,<br />

backswept multi-vane, self-cleaning<br />

impeller; rests on stand.<br />

Options: Explosion proof (FM approved)<br />

variant 3085.092<br />

Warm liquid version available<br />

Model number: 3102.181<br />

Motor rating: 5HP@1730RPM<br />

Voltage (3ø): 200V 230V 460V 575V<br />

Full load amps: 15A 13A 6.6A 5.3A<br />

Versions: 4” & 6” High volume<br />

Imp. Code 422, 423<br />

Hose connection: NPSM threaded, or slip-on<br />

Pump dimensions: 27” W (max.) x 28 1 /2” H (max.)<br />

Max. weight (lbs.): 118<br />

Description: Cast iron construction; semi-open,<br />

backswept multi-vane, self-cleaning<br />

impeller; rests on stand.<br />

Options: Explosion proof (FM approved)<br />

variant 3102.090<br />

Warm liquid version available<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

463<br />

(1ø, 3ø)<br />

462<br />

(3ø)<br />

0 100 200 300 400 500 600 700<br />

FLOW GPM<br />

422<br />

423<br />

0 200 400 600 800 1000<br />

FLOW GPM

NS 3127<br />

W<br />

NS 3153<br />

W<br />

NS 3171<br />

W<br />

H<br />

H<br />

H<br />

Model number: 3127.181<br />

Motor rating: 1ø: 7.5HP@1730RPM<br />

3ø: 10HP@1740RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 30A<br />

Voltage (3ø): 200V 230V 460V 575V<br />

Full load amps: 29A 26A 13A 10A<br />

Versions: 4” & 8” Standard<br />

Imp. Code 420 (1ø), 438 3ø)<br />

8” High volume<br />

Imp. Code 422 (1ø), 421 3ø)<br />

Hose connection: 4” & 6”NPSM threaded, or slip-on<br />

4”, 6” & 8” Slip-on<br />

Pump dimensions: 31 1 /2” W (max.) x 30 3 /4” H (max.)<br />

Max. weight (lbs.): 400<br />

Description: Cast iron construction; semi-open,<br />

backswept multi-vane, self-cleaning<br />

impeller; rests on stand.<br />

Options: Explosion proof (FM approved)<br />

variant 3127.090<br />

Warm liquid version available<br />

Model number: 3153.181<br />

Motor rating: 20HP@1755RPM<br />

23HP@3510RPM<br />

Voltage (3ø): 200V 230V 460V 575V<br />

Full load amps: 59A 52A 26A 21A<br />

Versions: 4” Super high head, Imp. Code 273<br />

4” High head, Imp. Code 461<br />

6” Standard, Imp. Code 433<br />

8” High volume, Imp. Code 413<br />

Hose connection: 4”, 6” & 8” Slip-on<br />

Pump dimensions: 42” W (max.) x 47 1 /4” H (max.)<br />

Max. weight (lbs.): 840 - High volume, 530 - Standard<br />

Description: Cast iron construction; semi-open,<br />

backswept multi-vane, self-cleaning<br />

impeller; rests on bottom strainer.<br />

Options: Explosion proof (FM approved)<br />

variant 3153.091<br />

Model number: 3171.181<br />

Motor rating: 25HP@1160RPM<br />

30HP@1740RPM<br />

Voltage (3ø): 230V 460V<br />

Full load amps: 64/74 32/37<br />

575V<br />

25/30/31A<br />

Versions: 6” Standard, Imp. Code 433<br />

10” High volume, Imp. Code 613<br />

Hose connection: 6” & 10” Slip-on<br />

Pump dimensions: 45 1 /2” W (max.) x 51 1 /4” H (max.)<br />

Max. weight (lbs.): 1060 - High volume, 770 - Standard<br />

Description: Cast iron construction; semi-open,<br />

backswept multi-vane, self-cleaning<br />

impeller; rests on bottom strainer.<br />

Options: Explosion proof (FM approved)<br />

variant 3171.091<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

270<br />

240<br />

210<br />

180<br />

150<br />

120<br />

90<br />

60<br />

30<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

422<br />

438<br />

439<br />

0 300 600 900 1200 1500 1800<br />

461<br />

273<br />

413<br />

FLOW GPM<br />

433<br />

421<br />

0 700 1400<br />

FLOW GPM<br />

2100 2800<br />

433<br />

613<br />

0 1000 2000 3000 4000 5000<br />

FLOW GPM<br />

17

18<br />

NS 3171 (Continued)<br />

W<br />

NS 3202<br />

W<br />

NS 3301<br />

W<br />

H<br />

H<br />

H<br />

Model number: 3171.181<br />

Motor rating: 30HP@1740RPM<br />

35HP@3525RPM<br />

Voltage (3ø): 230V 460V<br />

Full load amps: 74/79A 37/40A<br />

575V<br />

25/30/31A<br />

Versions: 4” Super high head<br />

Imp. Code 274<br />

4” High head<br />

Imp. Code 454<br />

Hose connection: 4”, 6” & 10” Slip-on<br />

Pump dimensions: 45 1 /2” W (max.) x 51 1 /4” H (max.)<br />

Max. weight (lbs.): 1060 - High volume, 770 - Standard<br />

Description: Cast iron construction; semi-open,<br />

backswept multi-vane, self-cleaning<br />

impeller; rests on bottom strainer.<br />

Options: Explosion proof (FM approved)<br />

variant 3171.091<br />

Model number: 3202.180<br />

Motor rating: 60HP@1170RPM & 1775RPM<br />

70HP@1775RPM<br />

Voltage (3ø): 460V 575V<br />

Full load amps: 72/68/80A 58/55/63A<br />

Versions: 6” High head<br />

Imp. Code 456<br />

8” Standard<br />

Imp. Code 640<br />

10” High volume<br />

Imp. Code 614<br />

Hose connection: 6”, 8” & 10” Slip-on<br />

Pump dimensions: 52 1 /2” W (max.) x 62” H (max.)<br />

Max. weight (lbs.): 1985 - High volume<br />

1340 - Standard<br />

Description: Cast iron construction; semi-open,<br />

backswept multi-vane, self-cleaning<br />

impeller; rests on bottom strainer.<br />

Options: Explosion proof (FM approved)<br />

variant 3202.090<br />

Model number: 3301.180<br />

Motor rating: 85HP@1185RPM<br />

105HP@1780RPM<br />

Voltage (3ø): 460V 575V<br />

Full load amps: 109/121A 88/97A<br />

Versions: 6” High head<br />

Imp. Code 454<br />

10” Standard<br />

Imp. Code 634<br />

12” High volume<br />

Imp. Code 624<br />

Hose connection: 6”, 10” & 12” Slip-on<br />

Pump dimensions: 56 3 /4” W (max.) x 67 1 /4” H (max.)<br />

Max. weight (lbs.): 1985 - High volume<br />

1340 - Standard<br />

Description: Cast iron construction; semi-open,<br />

backswept multi-vane, self-cleaning<br />

impeller; rests on bottom strainer.<br />

Options: Explosion proof (FM approved)<br />

variant 3301.090<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

275<br />

200<br />

175<br />

150<br />

125<br />

100<br />

75<br />

50<br />

25<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

274<br />

454<br />

0 200 400 600 800 1000 1200 1400 1600<br />

456<br />

FLOW GPM<br />

640<br />

614<br />

0 2000 4000<br />

FLOW GPM<br />

6000 8000<br />

454<br />

634<br />

624<br />

0 2000 4000 6000 8000 10000<br />

FLOW GPM

Stainless steel dewatering pumps<br />

These submersible pumps are designed for pumping low pH and other corrosive liquids. The CS models feature a<br />

closed impeller for handling solids, making them excellent for industrial or environmental cleanup applications.<br />

All models are equipped with a hose connection and lift handle and operate on a stand or strainer bottom.<br />

bS 2720 (SS)<br />

W<br />

bS 2740 (SS)<br />

W<br />

bS 2750 (SS)<br />

W<br />

H<br />

H<br />

H<br />

Model number: 2720.390<br />

Motor rating: 3.1HP@3315RPM<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 8.5 4.2 3.4<br />

Versions: 3” Standard<br />

Imp. Code 242<br />

Discharge conn.: Male NPT<br />

Pump dimensions: 9 3 /8” W x 23 3 /4” H<br />

Max. weight (lbs.): 97<br />

Description: Stainless steel construction; open<br />

impeller; rests on bottom strainer.<br />

Model number: 2740.390<br />

Motor rating: 9HP@3455RPM<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 21A 11A 8.6A<br />

Versions: 3” High head<br />

Imp. Code 267<br />

4” Standard<br />

Imp. Code 242<br />

Hose connection: Male NPT<br />

Pump dimensions: 11” W (max.) x 28 3 /4” H (max.)<br />

Max. weight (lbs.): 165<br />

Description: Stainless steel construction;<br />

open impellers; rests on<br />

bottom strainer.<br />

Model number: 2750.390<br />

Motor rating: 13HP@3455RPM<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 31A 15A 12A<br />

Versions: 3” High head<br />

Imp. Code 267<br />

4” Standard<br />

Imp. Code 242<br />

Hose connection: Male NPT<br />

Pump dimensions: 11” W (max.) x 31” H (max.)<br />

Max. weight (lbs.): 198<br />

Description: Stainless steel construction;<br />

open impellers; rests on<br />

bottom strainer.<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

240<br />

210<br />

180<br />

150<br />

120<br />

90<br />

60<br />

30<br />

473<br />

0 50 100 150 200 250 300 350 400<br />

267<br />

FLOW GPM<br />

242<br />

0 100 200 300 400 500 600 700<br />

267<br />

FLOW GPM<br />

242<br />

0 125 250 375 500 625 750 875 1000<br />

FLOW GPM<br />

19

Solids-handling stainless steel dewatering pumps<br />

20<br />

dS 2720 (SS)<br />

dS 2730 (SS)<br />

W<br />

W<br />

dS 2740 (SS)<br />

W<br />

H<br />

H<br />

H<br />

Model number: 2720.280<br />

Motor rating: 3.1HP@3315RPM<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 8.5 4.2 3.4<br />

Versions: 3” Standard<br />

Imp. Code 242<br />

Hose connection: Standard<br />

Pump dimensions: 16 1/2’ W x 28 H<br />

Max. weight (lbs.): 111<br />

Description: Stainless steel construction; open<br />

impeller; rests on bottom strainer.<br />

Model number: 2730.280<br />

Motor rating: 6HP@1675RPM<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 18A 9A 7.3A<br />

Versions: 4” Standard<br />

Imp. Code 442<br />

Hose connection: Male NPT<br />

Pump dimensions: 16 1 /2” W (max.) x 28 3 /8” H (max.)<br />

Max. weight (lbs.): 209<br />

Description: Stainless steel construction; vortex<br />

impeller; rests on bottom stand.<br />

Model number: 2740.280<br />

Motor rating: 9HP@3455RPM<br />

Voltage (3ø): 230V 460V 575V<br />

Full load amps: 21A 11A 8.6A<br />

Versions: 3” High head<br />

Imp. Code 244<br />

Hose connection: Male NPT<br />

Pump dimensions: 16 1 /2” W (max.) x 28 3 /8” H (max.)<br />

Max. weight (lbs.): 209<br />

Description: Stainless steel construction; vortex<br />

impeller; rests on bottom stand.<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

242<br />

0 50 100 150 200 250 300 350 400<br />

FLOW GPM<br />

442<br />

0 100 200 300 400 500 600<br />

FLOW GPM<br />

244<br />

0 30 60 90 120 150 180 210 240<br />

FLOW GPM

CS/dS 3060 (SS)<br />

W<br />

CS 3201 (SS)<br />

W<br />

CS 3300 (SS)<br />

W<br />

H<br />

H<br />

H<br />

Model number: 3060.390<br />

Motor rating: 1ø: 2.5HP@3400RPM<br />

3ø: 3.7HP@3300RPM<br />

Voltage (1ø): 230V<br />

Full load amps: 11A<br />

Voltage (3ø): 200V 230V 460V 575V<br />

Full load amps: 10.8A 9.4A 4.7A 3.8A<br />

Versions: CS: 3” Standard<br />

Imp. Code 226 (1ø), 222 (3ø)<br />

DS: 3” Vortex<br />

Imp. Code 276 (1ø), 274 (3ø)<br />

Hose connection: Slip-on<br />

Pump dimensions: 16 1 /2” W (max.) x 23 1 /2” H (max.)<br />

Max. weight (lbs.): 95<br />

Description: CS/DS: Stainless steel<br />

construction; rests on bottom<br />

strainer. CS: Open impeller, with<br />

diffuser. DS: Vortex type impeller.<br />

Model number: 3201.280<br />

Motor rating: 30HP@860RPM<br />

35HP@1170RPM<br />

47HP@1760RPM<br />

Voltage (3ø): 230V<br />

Full load amps: 82/94/116A<br />

460V 575V<br />

41/47/58A 33/38/46A<br />

Versions: 6” High hd., Imp. Code 452 (47HP)<br />

8” Std., Imp. Code 636 (35HP)<br />

10” High volume<br />

Imp. Code 821 (30HP)<br />

Hose connection: Slip-on<br />

Pump dimensions: 56” W (max.) x 63” H (max.)<br />

Max. weight (lbs.): 1600<br />

Description: Stainless steel construction;<br />

closed, solids handling impeller,<br />

wear rings; rests on bottom stand.<br />

Options: Explosion proof (FM approved)<br />

variant 3201.290<br />

Model number: 3300.280<br />

Motor rating: 60HP@1170RPM & 875RPM<br />

45HP@875RPM<br />

77, 88HP@1170RPM<br />

Voltage (3ø, 60HP): 460V 575V<br />

Full load amps: 73/80A 58/ 65A<br />

Voltage (3ø,<br />

45/77/88HP): 460V 575V<br />

Full load amps: 60/91/108A 48/ 73/86A<br />

Versions: 6” High hd., Imp. Code 464 (88HP)<br />

8” Standard<br />

Imp. Code 646 (60HP), 642 (77HP)<br />

10” High volume<br />

Imp. Code 807 (45HP), 804 (60HP)<br />

Hose connection: Slip-on<br />

Pump dimensions: 56 3 /4” W (max.) x 75 3 /4” H (max.)<br />

Max. weight (lbs.): 2590<br />

Description: Stainless steel construction;<br />

closed, solids handling impeller,<br />

wear rings; rests on bottom stand.<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

105<br />

90<br />

75<br />

60<br />

45<br />

30<br />

15<br />

175<br />

150<br />

125<br />

100<br />

75<br />

50<br />

25<br />

225<br />

200<br />

175<br />

150<br />

125<br />

100<br />

75<br />

50<br />

25<br />

276<br />

274<br />

226<br />

222<br />

0 50100 150 200 250 300<br />

821<br />

452<br />

FLOW GPM<br />

636<br />

0 1300 2600 3900 5200 6500<br />

464<br />

807<br />

FLOW GPM<br />

646<br />

642<br />

804<br />

0 1500 3000 4500 6000 7500 9000<br />

FLOW GPM<br />

21

Heavy-duty dewatering pumps<br />

All heavy duty models are specially designed for pumping liquids or slurries that contain abrasives, such as those<br />

found in tunneling, quarries or other industrial applications. They feature high chromium cast iron, solids handling<br />

impellers, with rubber clad wear plates for extended life. All models are transportable, equipped with large lift<br />

handle and heavy duty stand, and are available in explosion proof, Factory Mutual approved versions if required.<br />

22<br />

HS 3000 SeRIeS<br />

W<br />

W<br />

H<br />

H<br />

Model number: 3127.181<br />

Motor HP (1ø): 7.6<br />

Motor RPM: 1730<br />

Motor HP (3ø): 10<br />

Motor RPM: 1745<br />

Voltage (1ø): 230V<br />

Full load amps: 30A<br />

Voltage (3ø): 200V 230/460V 575V<br />

Full load amps: 29A 26/13A 10A<br />

Discharge conn: 4” Male NPSM threaded, or slip-on<br />

Impeller code: 468<br />

Pump dimensions: 21 5 /8” W (max.) x 29 1 /8” H (max.)<br />

Max. weight (lbs.): 319<br />

Major<br />

castings material: Cast iron<br />

Model number: 3152.181 3201.180<br />

Motor HP (3ø): 20 47<br />

Motor RPM: 1750 1760<br />

Voltage (3ø): 200V 200V<br />

Full load amps: 60A 133A<br />

230/460V 230/460V<br />

52/26A 116/58V<br />

575V 575V<br />

21A 46A<br />

Discharge conn: 6” 6”<br />

Impeller code: 462 462<br />

Pump dimensions: 33 1 /4” W, 41 3 42<br />

/8” W,<br />

7 /8” H 57 1 /4” H<br />

Max. weight (lbs.): 698<br />

Major<br />

1100<br />

castings material: Cast iron Cast iron<br />

Stainless steel<br />

Options<br />

(all models): FM approved variants<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

135<br />

120<br />

105<br />

90<br />

75<br />

60<br />

45<br />

30<br />

15<br />

468<br />

0 100 200 300 400 500 600<br />

FLOW GPM<br />

462<br />

(3152)<br />

462<br />

(3201)<br />

0 400 800 1200 1600 2000<br />

FLOW GPM

Heavy-duty slurry pumps<br />

HS 5100/5500 series pumps will easily handle extremely abrasive slurries containing sand, gravel, grit or ash, without<br />

damage. Both the impeller and pump casing are made of high chrome alloyed cast iron, for maximum abrasion<br />

resistance. The HS 5100 series pumps use a one-piece pump casing, while the HS 5500 series have a replaceable liner<br />

of high chrome alloyed cast iron. Heavy-duty mechanical seals are protected by a unique expeller and pressure isolation<br />

chamber. The optional agitator, when attached to the shaft, resuspends particles around the pump inlet.<br />

HS 5100.211<br />

W<br />

HS 5100.251<br />

W<br />

H<br />

H<br />

Model number: 5100.211<br />

Motor rating: 15HP@1150RPM<br />

20HP@1755RPM<br />

Voltage (3ø): 230V<br />

Full load amps: 46/52A<br />

460V 575V<br />

22/26A 17/21A<br />

Versions: 4” Std., Imp.<br />

4” High vol., Imp.<br />

Discharge conn: 4” Victaulic<br />

Pump dimensions: 23 1 /2” W (max.),<br />

45 1 /4” H (max.)<br />

Max. weight (lbs.): 555<br />

Description: Cast iron construction with high<br />

chrome volute; highchrome<br />

multi-vane closed impeller; rests<br />

on stand.<br />

Options: Agitator;<br />

Explosion proof (FM approved)<br />

variant 5100.221<br />

Model number: 5100.251<br />

Motor rating: 25HP@1160RPM<br />

34HP@1760RPM<br />

Voltage (3ø): 230V<br />

Full load amps: 64/81A<br />

460V 575V<br />

32/40A 25/32A<br />

Versions: 4” Std., Imp.<br />

4” High vol., Imp.<br />

Discharge conn: 4” Victaulic<br />

Pump dimensions: 23 1 /2” W (max.),<br />

50 1 /4” H (max.)<br />

Max. weight (lbs.): 710<br />

Description: Cast iron construction with high<br />

chrome volute; high chrome<br />

multi-vane closed impeller; rests<br />

on stand.<br />

Options: Agitator;<br />

Explosion proof (FM approved)<br />

variant 5100.261<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

632 x<br />

0 200 400<br />

630 x<br />

432<br />

600 800 1000 1200 1400<br />

FLOW GPM<br />

x Optional Agitator Version<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

632 x<br />

0 200 400<br />

630 x<br />

432 x<br />

600 800 1000 1200 1400<br />

FLOW GPM<br />

x Optional Agitator Version<br />

430<br />

23

24<br />

HS 5100.300<br />

W<br />

HS 5150.300<br />

W<br />

HS 5150.350<br />

W<br />

H<br />

H<br />

H<br />

Model number: 5100.300<br />

Motor rating: 45HP@1170RPM<br />

70HP@1775RPM<br />

Voltage (3ø): 460V 575V<br />

Full load amps: 55/72/80A 44/58/63A<br />

Versions: 4” Standard<br />

Imp. Code 430, 432<br />

4” High volume<br />

Imp. Code 630, 632<br />

Discharge conn: 4” Victaulic<br />

Pump dimensions: 23 1 /2” W (max.),<br />

57 3 /4” H (max.)<br />

Max. weight (lbs.): 1095<br />

Description: Cast iron construction with high<br />

chrome volute; high chrome<br />

multi-vane closed impeller; rests<br />

on stand.<br />

Options: Agitator;<br />

Explosion proof (FM approved)<br />

variant 5100.310<br />

Model number: 5150.300<br />

Motor rating: 60HP@1775RPM<br />

Voltage (3ø): 460V 575V<br />

Full load amps: 68/80A 55/63A<br />

Versions: 6” Standard<br />

Imp. Code 432, 434<br />

Discharge conn: 6” Victaulic<br />

Pump dimensions: 34 1 /2” W (max.),<br />

65 1 /4” H (max.)<br />

Max. weight (lbs.): 1465<br />

Description: Cast iron construction with high<br />

chrome volute; high chrome<br />

multi-vane closed impeller; rests<br />

on stand.<br />

Options: Agitator;<br />

Explosion proof (FM approved)<br />

variant 5150.310<br />

Model number: 5150.350<br />

Motor rating: 85HP@1775RPM<br />

Voltage (3ø): 460V 575V<br />

Full load amps: 101/125A 80/101A<br />

Versions: 6” Standard<br />

Imp. Code 430, 432, 434,<br />

436, 438<br />

Discharge conn: 6” Victaulic<br />

Pump dimensions: 34 1 /2” W (max.),<br />

70 1 /4” H (max.)<br />

Max. weight (lbs.): 2005<br />

Description: Cast iron construction with high<br />

chrome volute; high chrome<br />

multi-vane closed impeller; rests<br />

on stand.<br />

Options: Agitator;<br />

Explosion proof (FM approved)<br />

variant 5150.360<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

632 x<br />

0 200 400<br />

630 x<br />

432 x<br />

600 800 1000 1200 1400<br />

FLOW GPM<br />

x Optional Agitator Version<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0 500 1000<br />

434 x<br />

FLOW GPM<br />

x Optional Agitator Version<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0 500 1000<br />

430 x<br />

432 x<br />

1500 2000 2500 3000 3500<br />

430 x<br />

438 x<br />

432 x<br />

1500 2000 2500 3000 3500<br />

FLOW GPM<br />

x Optional Agitator Version<br />

434 x<br />

436 x

HS 5520<br />

HS 5530<br />

W<br />

HS 5570<br />

W<br />

W<br />

H<br />

H<br />

H<br />

Model number: 5520.180<br />

Motor rating: 5HP@1735RPM<br />

Voltage (3ø): 460V<br />

Full load amps: 6.6A<br />

Discharge conn: 4” Flange<br />

Impeller code: 436<br />

Pump dimensions: 29 1 /2” W (max.),<br />

33 1 /2” H (max.)<br />

Max. weight (lbs.): 380<br />

Stator and pump<br />

housing material: Cast iron<br />

Options: FM approved variant;<br />

Warm liquid version available<br />

Model number: 5530.180<br />

Motor rating: 10HP@1740RPM<br />

Voltage (3ø): 460V<br />

Full load amps: 13A<br />

Discharge conn: 6” Flange<br />

Impeller code: 436<br />

Pump dimensions: 42 1 /2” W (max.),<br />

40” H (max.)<br />

Max. weight (lbs.): 680<br />

Stator and pump<br />

housing material: Cast iron<br />

Options: Agitator;<br />

FM approved variant;<br />

Warm liquid version available<br />

Model number: 5570.180<br />

Motor rating: 335HP@1760RPM<br />

280HP@1185RPM<br />

Voltage (3ø): 460V 575V<br />

Full load amps: 365/345A 300/266A<br />

Discharge conn: 8” Flange<br />

Impeller code: 470, 670<br />

Pump dimensions: 59” W (max.),<br />

80 1 /4” H (max.)<br />

Max. weight (lbs.): 3230<br />

Stator and pump<br />

housing material: Cast iron<br />

Options: Agitator;<br />

FM approved variant;<br />

Warm liquid version available<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

TOTAL HEAD FEET<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

436<br />

0 100 200 300 400 500 600 700<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

FLOW GPM<br />

436<br />

0 200 400 600 800 1000 1200<br />

320<br />

280<br />

240<br />

200<br />

160<br />

120<br />

80<br />

40<br />

FLOW GPM<br />

670<br />

470<br />

0 1000 2000 3000 4000 5000 6000<br />

FLOW GPM<br />

25

26<br />

<strong>Flygt</strong> accessories<br />

Automatic Level Control Systems<br />

<strong>Flygt</strong> offers a family of automatic controls that allow unattended operation of <strong>Flygt</strong><br />

portable pumps. They are available with either two <strong>Flygt</strong> ENM-10 level sensors or<br />

with FPC 100 controller. The FPC 100 allows for automatic pump operation without<br />

using floats or level sensors.<br />

Manual Control for Medium and Large Portable <strong>Pumps</strong><br />

Manual Control for Small, Portable <strong>Flygt</strong> <strong>Pumps</strong>:<br />

Zinc Anodes<br />

A complete range of manual controls are available for medium and large <strong>Flygt</strong><br />

portable submersible pumps. Each NEMA 4X enclosure is equipped with the<br />

correct circuit breaker/overload for pump protection of the model involved.<br />

These strong, rugged units allow easy manual control and full electrical<br />

protection for smaller <strong>Flygt</strong> portable submersibles. <strong>Flygt</strong> short-circuit and<br />

overload protection, along with starting components for single phase models,<br />

housed in a NEMA 4X watertight and corrosion resistant enclosure.<br />

High grade zinc anode kits are available for most <strong>Flygt</strong> submersible pumps to<br />

help protect against the damaging effects of galvanic corrosion. The anodes are<br />

easily mounted to the pump with the stainless steel hardware provided. Specify<br />

exact pump model when ordering.

Tandem Coupling Kits<br />

<strong>Flygt</strong> FPC100 Pump Controller<br />

<strong>Flygt</strong> Pump Flotation Modules<br />

Low Suction Collar<br />

Tandem connections are available for most models, allowing the pump to be<br />

connected in series with another <strong>Flygt</strong> submersible to help overcome severe<br />

vertical heights. Easily installed after the strainer is removed, allowing the connecting<br />

hose from another pump to be attached with clamps. Consult your nearest <strong>Flygt</strong><br />

supplier for pressure limitations and other application requirements.<br />

The <strong>Flygt</strong> FPC 100 Automatic Controller is used primarily for dewatering pumps in<br />

construction and mining applications where ordinary level sensors are not the best<br />

choice. The FPC 100 offers entirely automatic pump control without the need for<br />

components built into the pump or separate level sensor arrangements.<br />

<strong>Flygt</strong> pump flotation modules (PFM) have been developed to provide a light-weight<br />

and cost-effective alternative to traditional steel pontoons. The flotation modules<br />

are prefabricated from strong polyethylene with foam filling. The pump floats close<br />

to the surface, increasing the pump’s service life and reducing maintenance since<br />

the pump is no longer working in a high solids environment.<br />

The <strong>Flygt</strong> low suction collar removes unwanted water down to very low levels<br />

when required for emergency services. This works with models 2610, 2620<br />

and 2640.<br />

27

Xylem<br />

|’zīl m|<br />

e<br />

1. The tissue in plants that brings water upward from the roots<br />

2. A leading global water technology company<br />

We’re 12,000 people unified in a common purpose: creating innovative solutions<br />

to meet our world’s water needs. Developing new technologies that will improve<br />

the way water is used, conserved, and re-used in the future is central to our work.<br />

We move, treat, analyze, and return water to the environment, and we help people<br />

use water efficiently, in their homes, buildings, factories and farms. In more than<br />

150 countries, we have strong, long-standing relationships with customers who<br />

know us for our powerful combination of leading product brands and applications<br />

expertise, backed by a legacy of innovation.<br />

For more information on how Xylem can help you, go to xyleminc.com<br />

Dewatering Solutions<br />

Bridgeport, NJ • Telephone +1 (856) 467-3636<br />

<strong>Flygt</strong> is a brand of Xylem. For the latest version of this<br />

document, more information about <strong>Flygt</strong> products and<br />

the nearest office location or distributor near you visit<br />

www.godwinpumps.com<br />

<strong>Flygt</strong> <strong>Submersible</strong> <strong>Brochure</strong>. <strong>Master</strong> 01.2013