Structure/Property Relationships in Irons and ... - ASM International

Structure/Property Relationships in Irons and ... - ASM International

Structure/Property Relationships in Irons and ... - ASM International

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Metals H<strong>and</strong>book Desk Edition, Second Edition<br />

J.R. Davis, Editor, p 153-173<br />

<strong>Structure</strong>/<strong>Property</strong><br />

<strong>Relationships</strong> <strong>in</strong> <strong>Irons</strong> <strong>and</strong> Steels<br />

THE PROPERTIES of irons <strong>and</strong> steels are<br />

l<strong>in</strong>ked to the chemical composition, process<strong>in</strong>g<br />

path, <strong>and</strong> result<strong>in</strong>g microstructure of the material;<br />

this correspondence has been known s<strong>in</strong>ce the<br />

early part of the twentieth century. For a particular<br />

iron <strong>and</strong> steel composition, most properties depend<br />

on microstructure. These properties are called<br />

Bruce L. Bramfitt, Homer Research Laboratories, Bethlehem Steel Corporation<br />

Basis of Material Selection ............................................... 153<br />

Role of Microstructure .................................................. 155<br />

Ferrite ............................................................. 156<br />

Pearlite ............................................................ 158<br />

Ferrite-Pearl ite ....................................................... 160<br />

Ba<strong>in</strong>ite ............................................................ 162<br />

Martensite .................................... ...................... 164<br />

Austenite ........................................................... 169<br />

Ferrite-Cementite ..................................................... 170<br />

Ferrite-Martensite .................................................... 171<br />

Ferrite-Austenite ..................................................... 171<br />

Graphite ........................................................... 172<br />

Cementite .......................................................... 172<br />

This Section was adapted from Materials 5election <strong>and</strong> Design, Volume 20, <strong>ASM</strong> H<strong>and</strong>book, 1997,<br />

pages 357-382. Additional <strong>in</strong>formation can also be found <strong>in</strong> the Sections on cast irons <strong>and</strong> steels which<br />

immediately follow <strong>in</strong> this H<strong>and</strong>book <strong>and</strong> by consult<strong>in</strong>g the <strong>in</strong>dex.<br />

structure-sensitive properties, for example, yield<br />

strength <strong>and</strong> hardness. The structure-<strong>in</strong>sensitive<br />

properties, for example, electrical conductivity,<br />

are not discussed <strong>in</strong> this Section. Process<strong>in</strong>g is a<br />

means to develop <strong>and</strong> control microstructure, for<br />

example, hot roll<strong>in</strong>g, quench<strong>in</strong>g, <strong>and</strong> so forth. In<br />

this Section, the role of these factors is described<br />

Copyright © 1998 <strong>ASM</strong> <strong>International</strong>®<br />

All rights reserved.<br />

www.asm<strong>in</strong>ternational.org<br />

<strong>in</strong> both theoretical <strong>and</strong> practical terms, with par-<br />

ticular focus on the role of microstructure.<br />

Basis of Material Selection<br />

In order to select a material for a particular<br />

component, the designer must have an <strong>in</strong>timate<br />

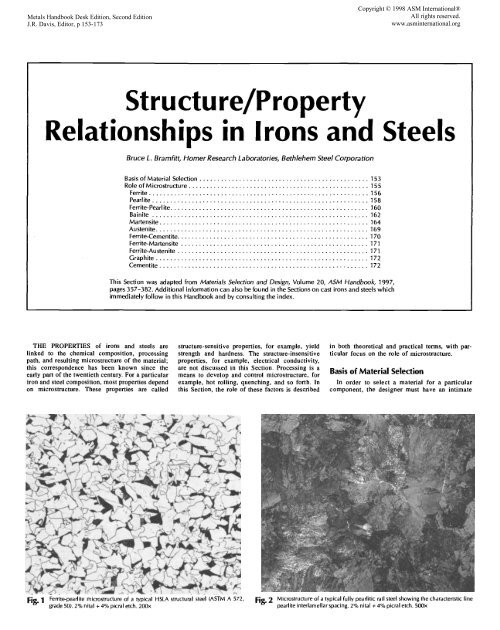

" "o" - grade 50). 2% nital + 4% picral etch. 200x Fig. :2 Microstructu<br />

repearlite <strong>in</strong>terlamellar°f a typicalspac<strong>in</strong>g.fUllY2%pearlitiCnital + 4%rail steelpicralShow<strong>in</strong>getch. 500xthe characteristic f<strong>in</strong>e

154/<strong>Structure</strong>/<strong>Property</strong> <strong>Relationships</strong> <strong>in</strong> <strong>Irons</strong> <strong>and</strong> Steels<br />

knowledge of what properties are required. Con-<br />

sideration must be given to the environment<br />

(corrosive, high temperature, etc.) <strong>and</strong> how the<br />

component will be fabricated (welded, bolted,<br />

etc.). Once these property requirements are es-<br />

tablished the material selection process can be-<br />

g<strong>in</strong>. Some of the properties to be considered<br />

are:<br />

Mechanical properties Other properties/<br />

Strength characteristics<br />

Tensile strength (ultimate Formability<br />

strength) Dmwability<br />

Yield strength Stretchability<br />

Compressive strength Bendability<br />

Hardness Wear resistance<br />

Toughness Abrasion resistance<br />

Notch toughness Gall<strong>in</strong>g resistance<br />

Fracture toughness Slid<strong>in</strong>g wear resistance<br />

Ductility Adhesive wear resistance<br />

Total elongation Mach<strong>in</strong>ability<br />

Reduction <strong>in</strong> area Weldability<br />

Fatigue resistance<br />

Table 1 lists mechanical properties of selected steels<br />

<strong>in</strong> various heat-treated or cold-worked conditions.<br />

In the selection process, what is required for<br />

one application may be totally <strong>in</strong>appropriate for<br />

another application. For example, steel beams for<br />

a railway bridge require a totally different set of<br />

properties than the steel rails that are attached to<br />

the wooden ties on the bridge deck. In design<strong>in</strong>g<br />

the bridge, the steel must have sufficient strength<br />

to withst<strong>and</strong> substantial applied loads. In fact,<br />

the designer will generally select a steel with<br />

higher strength than actually required. Also, the<br />

designer knows that the steel must have fracture<br />

toughness to resist the growth <strong>and</strong> propagation of<br />

cracks <strong>and</strong> must be capable of be<strong>in</strong>g welded so<br />

that structural members can be jo<strong>in</strong>ed without<br />

sacrific<strong>in</strong>g strength <strong>and</strong> toughness. The steel<br />

bridge must also be corrosion resistant. This can<br />

be provided by a protective layer of pa<strong>in</strong>t. If<br />

pa<strong>in</strong>t<strong>in</strong>g is not allowed, small amounts of certa<strong>in</strong><br />

alloy<strong>in</strong>g elements such as copper <strong>and</strong> chromium<br />

can be added to the steel to <strong>in</strong>hibit or reduce<br />

corrosion rates. Thus, the steel selected for the<br />

bridge would be a high-strength low-alloy<br />

(HSLA) structural steel such as ASTM A572,<br />

grade 50 or possibly a weather<strong>in</strong>g steel such as<br />

ASTM A588. A t);pical HSLA steel has a ferrite-<br />

pearlite microstructure as seen <strong>in</strong> Fig. 1 <strong>and</strong> is<br />

microalloyed with vanadium <strong>and</strong>/or niobium for<br />

strengthen<strong>in</strong>g. (Microalloy<strong>in</strong>g is a term used to<br />

describe the process of us<strong>in</strong>g small additions of<br />

carbonitride form<strong>in</strong>g elements--titanium, vana-<br />

dium, <strong>and</strong> niobium--to strengthen steels by gra<strong>in</strong><br />

ref<strong>in</strong>ement <strong>and</strong> precipitation harden<strong>in</strong>g.)<br />

On the other h<strong>and</strong>, the steel rails must have<br />

high strength coupled with excellent wear resis-<br />

tance. Modem rail steels consist of a fully pearli-<br />

tic microstructure with a f<strong>in</strong>e pearlite <strong>in</strong>terlamel-<br />

lar spac<strong>in</strong>g, as shown <strong>in</strong> Fig. 2. Pearlite is unique<br />

because it is a lamellar composite consist<strong>in</strong>g of<br />

88% soft, ductile ferrite <strong>and</strong> 12% hard, brittle<br />

cementite (Fe3C). The hard cementite plates pro-<br />

vide excellent wear resistance, especially when<br />

embedded <strong>in</strong> soft ferrite. Pearlitic steels have<br />

high strength <strong>and</strong> are fully adequate to support<br />

heavy axle loads of modem locomotives <strong>and</strong><br />

freight cars. Most of the load is applied <strong>in</strong> com-<br />

pression. Pearlitic steels also have relatively<br />

poor toughness <strong>and</strong> cannot generally withst<strong>and</strong><br />

impact loads without failure. The rail steel could<br />

not meet the requirements of the bridge builder,<br />

Table I Mechanical properties of selected steels<br />

Tensile Yield<br />

strength strength<br />

Steel Condition MPa ksi MPa kd<br />

Elongation<br />

iaS0muma, Reduction Hardness,<br />

Carbon steel bar(a)<br />

1006 Hot rolled 295 43 165 24 30 55 86<br />

Colddrawn 330 48 285 41 20 45 95<br />

1008 Hot rolled 305 44 170 24.5 30 55 86<br />

Colddrawn 340 49 285 41.5 20 45 95<br />

1010 Hot rolled 325 47 180 26 28 50 95<br />

Cold drawn 365 53 305 44 20 40 105<br />

1012 Hot rolled 330 48 185 26.5 28 50 95<br />

Colddrawn 370 54 310 45 19 40 105<br />

1015 Hot rolled 345 50 190 27.5 28 50 101<br />

Cold drawn 385 56 325 47 18 40 111<br />

1016 Hot rolled 380 55 205 30 25 50 110<br />

Cold dmwn 420 61 350 51 18 40 121<br />

1017 Hot rolled 365 53 200 29 26 50 105<br />

Cold drawn 405 59 340 49 18 40 116<br />

1018 Hot rolled 400 58 220 32 25 50 116<br />

Cold drawn 440 64 370 54 15 40 126<br />

1019 Hot rolled 405 59 225 32.5 25 50 116<br />

Cold drawn 455 66 380 55 15 40 131<br />

1020 Hot rolled 380 55 205 30 25 50 l 1 l<br />

Cold drawn 420 61 350 51 15 40 121<br />

1021 Hot rolled 420 61 230 33 24 48 116<br />

Colddrawn 470 68 395 57 15 40 131<br />

1022 Hot rolled 425 62 235 34 23 47 121<br />

Colddrawn 475 69 400 58 15 40 137<br />

1023 Hot rolled 385 56 215 31 25 50 111<br />

Cold drawn 425 62 360 52.5 15 40 121<br />

1524 Hot rolled 510 74 285 41 20 42 149<br />

Cold drawn 565 82 475 69 12 35 163<br />

1025 Hot rolled 400 58 220 32 25 50 116<br />

Colddrawn 440 64 370 54 15 40 126<br />

1026 Hot rolled 440 64 240 35 24 49 126<br />

Colddrawn 490 71 415 60 15 40 143<br />

1527 Hot rolled 515 75 285 41 18 40 149<br />

Colddmwn 570 83 485 70 12 35 163<br />

1030 Hot rolled 470 68 260 37.5 20 42 137<br />

Cold drawn 525 76 440 64 12 35 149<br />

1035 Hot rolled 495 72 270 39.5 18 40 143<br />

Colddrawn 550 80 460 67 12 35 163<br />

1536 Hot rolled 570 83 315 45.5 16 40 163<br />

COld drawn 635 92 535 77.5 12 35 187<br />

1037 Hot rolled 510 74 280 40.5 18 40 143<br />

Cold drawn 565 82 475 69 12 35 167<br />

1038 Hot rolled 515 75 285 41 18 40 149<br />

Colddrawn 570 83 485 70 12 35 163<br />

1039 Hot rolled 545 79 300 43.5 16 40 156<br />

Cold drawn 605 88 510 74 12 35 179<br />

1040 Hot rolled 525 76 290 42 18 40 149<br />

Colddrawn 585 85 490 71 12 35 170<br />

1541 Hot rolled 635 92 350 51 15 40 187<br />

Cold drawn 705 102.5 600 87 10 30 207<br />

Annealed, cold drawn 650 94 550 80 10 45 184<br />

1042 Hot rolled 550 80 305 44 16 40 163<br />

Colddrawn 6!5 89 515 75 12 35 179<br />

Normalized, cold drawn 585 85 505 73 12 45 179<br />

1043 Hot rolled 565 82 310 45 16 40 163<br />

Cold drawn 625 91 530 77 12 35 179<br />

Normalized, cold drown 600 87 515 75 12 45 179<br />

1044 Hot rolled 550 80 305 44 16 40 163<br />

1045 Hot rolled 565 82 310 45 16 40 163<br />

Colddmwn 625 91 530 77 12 35 179<br />

Annealed, cold drawn 585 85 505 73 12 45 170<br />

1046 Hot rolled 585 85 325 47 15 40 170<br />

Cold drawn 650 94 545 79 12 35 187<br />

Annealed, cold drawn 620 90 515 75 12 45 179<br />

1547 Hot rolled 650 94 360 52 15 30 192<br />

Cold drawn 710 103 605 88 10 28 207<br />

Annealed, cold drawn 655 95 585 85 10 35 187<br />

1548 Hot rolled 660 96 365 53 14 33 197<br />

Colddrawn 735 106.5 615 89.5 10 28 217<br />

Annealed, cold drawn 645 93.5 540 78.5 10 35 192<br />

(cont<strong>in</strong>ued)<br />

(a) All values are estimated m<strong>in</strong>imum values; type 1100 series steels are rated on the basis of 0.10% max Si or coarse-gra<strong>in</strong> melt-<br />

<strong>in</strong>g practice; the mechanical properties shown are expected m<strong>in</strong>imums for the sizes rang<strong>in</strong>g from 19 to 31.8 mm (0.75 to 1.25<br />

<strong>in</strong>.). (b) Most data are for 25 mm (1 <strong>in</strong>.) diam bar. Source: Ref 1

Table I (cont<strong>in</strong>ued)<br />

Tensile Yield<br />

strength strength<br />

Steel Condition MPa ksi MPa ksi<br />

<strong>Structure</strong>/<strong>Property</strong> <strong>Relationships</strong> <strong>in</strong> <strong>Irons</strong> <strong>and</strong> Steels / 155<br />

Elongation<br />

<strong>in</strong> 50 ram, Reduction Hardness,<br />

% ~a area, % HB<br />

Carbon steel bar(a) (cont<strong>in</strong>ued)<br />

1049 Hot rolled 600 87 330 48 15 35 179<br />

Cold drawn 670 97 560 81.5 10 30 197<br />

Annealed, cold drawn 635 92 530 77 10 40 187<br />

1050 Hot roned 620 90 340 49.5 15 35 179<br />

Cold da'awn 690 100 580 84 10 30 197<br />

Annealed, cold drawn 655 95 550 80 10 40 189<br />

1552 Hot rolled 745 108 410 59.5 12 30 217<br />

Annealed, cold drawn 675 98 570 83 10 40 193<br />

1055 Hot rolled 650 94 355 51.5 12 30 192<br />

Annealed, cold drawn 660 96 560 81 10 40 197<br />

1060 Hot rolled 675 98 370 54 12 30 201<br />

Spheroidized annealed, cold drawn 620 90 485 70 10 45 183<br />

1064 Hot rolled 670 97 370 53.5 12 30 201<br />

Spheroidized annealed, cold drawn 615 89 475 69 10 45 183<br />

1065 Hot rolled 690 100 380 55 12 30 207<br />

Spheroidized annealed, cold drawn 635 92 490 71 10 45 187<br />

1070 Hot rolled 705 102 385 56 12 30 212<br />

Spheroidized annealed, cold drawn 640 93 495 72 10 45 192<br />

1074 Hot rolled 725 105 400 58 12 30 217<br />

Spheroidized annealed, cold drawn 650 94 505 73 10 40 192<br />

1078 Hot rolled 690 1130 380 55 12 30 207<br />

Spheroidized annealed, cold drawn 650 94 500 72.5 10 40 192<br />

1080 Hot rolled 770 112 425 61.5 10 25 229<br />

Spheroidized annealed, cold drawn 675 98 515 75 10 40 192<br />

1084 Hot rolled 820 119 450 65.5 10 25 241<br />

Spheroidized annealed, cold drawn 690 100 530 77 10 40 192<br />

1085 Hot rolled 835 121 460 66.5 10 25 248<br />

Spheroidized annealed, cold drawn 695 100.5 540 78 10 40 192<br />

1086 Hot rolled 770 112 425 61.5 10 25 229<br />

Spheroidized aimealed, cold drawn 670 97 510 74 10 40 192<br />

1090 Hot rolled 840 122 460 67 10 25 248<br />

Spheroidized annealed, cold drawn 695 101 540 78 10 40 197<br />

1095 Hot rolled 825 120 455 66 10 25 248<br />

Spheroidized annealed, cold drawn 680 99 525 76 10 40 197<br />

1211 Hot rolled 380 55 230 33 25 45 121<br />

Colddrawn 515 75 400 58 10 35 163<br />

1212 Hot rolled 385 56 230 33.5 25 45 121<br />

Cold drawn 540 78 415 60 10 35 167<br />

1213 Hot rolled 385 56 230 33.5 25 45 121<br />

Cold drawn 540 78 415 60 10 35 167<br />

12L14 Hot rolled 395 57 235 34 22 45 121<br />

Cold drawn 540 78 415 60 10 35 163<br />

1108 Hot roUed 345 50 190 27.5 30 50 101<br />

Colddrawn 385 56 325 47 20 40 121<br />

1109 Hot rolled 345 50 190 27.5 30 50 101<br />

Cold drawn 385 56 325 47 20 40 121<br />

11i7 Hot roned 425 62 235 34 23 47 121<br />

Colddrawn 475 69 400 58 15 40 137<br />

1118 Hot rolled 450 65 250 36 23 47 131<br />

Colddrawn 495 72 420 61 15 40 143<br />

1119 Hot roned 425 62 235 34 23 47 121<br />

Colddrawn 475 69 400 58 15 40 137<br />

1132 Hot roUed 570 83 315 45.5 16 40 167<br />

Cold drawn 635 92 530 77 12 35 183<br />

~1137 Hot roiled 605 88 330 48 15 35 179<br />

Colddrawn 675 98 565 82 10 30 197<br />

1140 Hot rolled 545 79 300 43.5 16 40 156<br />

Colddrawn 605 88 510 74 12 35 170<br />

1141 Hot roned 650 94 355 51.5 15 35 187<br />

Colddrawn 725 105.1 605 88 10 30 212<br />

1144 Hot rolled 670 97 365 53 15 35 197<br />

Colddrawn 745 108 620 90 10 30 217<br />

1145 Hot rolled 585 85 325 47 15 40 170<br />

Colddrawn 650 94 550 80 12 35 187<br />

1146 Hot roUed 585 85 325 47 15 40 170<br />

Cold drawn 650 94 550 80 12 35 187<br />

1151 Hot rolled 635 92 350 50.5 15 35 187<br />

Colddrawn 705 102 595 86 10 30 207<br />

(cont<strong>in</strong>ued)<br />

(a) All values are estimated m<strong>in</strong>imum values; type 1100 series steels are rated on the basis of 0.10% max Si or coarse-gra<strong>in</strong> melt-<br />

<strong>in</strong>g practice; the mechanical properties shown are expected m<strong>in</strong>imums for the sizes rang<strong>in</strong>g from 19 to 31.8 mm (0.75 to 1.25<br />

<strong>in</strong>.). (b) Most data are for 25 mm (1 <strong>in</strong>.) diam bar. Source: Ref 1<br />

<strong>and</strong> the HSLA structural steel could not meet the<br />

requirements of the civil eng<strong>in</strong>eer who designed<br />

the bridge or the rail system.<br />

A similar case can be made for the selection of<br />

cast irons. A cast mach<strong>in</strong>e hous<strong>in</strong>g on a large<br />

lathe requires a material with adequate strength,<br />

rigidity, <strong>and</strong> durability to support the applied<br />

load <strong>and</strong> a certa<strong>in</strong> degree of damp<strong>in</strong>g capacity <strong>in</strong><br />

order to rapidly attenuate (dampen) vibrations<br />

from the rotat<strong>in</strong>g parts of the lathe. The cast iron<br />

jaws of a crusher require a material with substan-<br />

tial wear resistance. For this application, a cast-<br />

<strong>in</strong>g is required because wear-resistant steels are<br />

very difficult to mach<strong>in</strong>e. For the mach<strong>in</strong>e hous-<br />

<strong>in</strong>g, gray cast iron is selected because it is rela-<br />

tively <strong>in</strong>expensive, can be easily cast, <strong>and</strong> has the<br />

ability to dampen vibrations as a result of the<br />

graphite flakes present <strong>in</strong> its microstructure.<br />

These flakes are dispersed throughout the ferrite<br />

<strong>and</strong> pearlite matrix (Fig. 3). The graphite, be<strong>in</strong>g a<br />

major nonmetallic constituent <strong>in</strong> the gray iron,<br />

provides a tortuous path for sound to travel<br />

through the material. With so many flakes, sound<br />

waves are easily reflected <strong>and</strong> the sound damp-<br />

ened over a relatively short distance. However,<br />

for the jaw crusher, damp<strong>in</strong>g capacity is not a<br />

requirement. In this case, an alloy white cast iron<br />

is selected because of its high hardness <strong>and</strong> wear<br />

resistance. The white cast iron microstructure<br />

shown <strong>in</strong> Fig. 4 is graphite free <strong>and</strong> consists of<br />

martensite <strong>in</strong> a matrix of cementite. Both of these<br />

constituents are very hard <strong>and</strong> thus provide the<br />

required wear resistance. Thus, <strong>in</strong> this example<br />

the gray cast iron would not meet the require-<br />

ments for the jaws of a crusher <strong>and</strong> the white cast<br />

iron would not meet the requirements for the<br />

lathe hous<strong>in</strong>g.<br />

Role of Microstructure<br />

In steels <strong>and</strong> cast irons, the microstructural<br />

constituents have the names ferrite, pearlite,<br />

ba<strong>in</strong>ite, martensite, cementite, <strong>and</strong> austenite. In<br />

most all other metallic systems, the constituents<br />

are not named, but are simply referred to by a<br />

Greek letter (ct, 13, Y, etc.) derived from the loca-<br />

tion of the constituent on a phase diagram. Fer-<br />

rous alloy constituents, on the other h<strong>and</strong>, have<br />

been widely studied for more than 100 years. In<br />

the early days, many of the <strong>in</strong>vestigators were<br />

petrographers, m<strong>in</strong><strong>in</strong>g eng<strong>in</strong>eers, <strong>and</strong> geologists.<br />

Because m<strong>in</strong>erals have long been named after<br />

their discoverer or place of orig<strong>in</strong>, it was natural<br />

to similarly name the constituents <strong>in</strong> steels <strong>and</strong><br />

cast irons.<br />

It can be seen that the four examples described<br />

above have very different microstructures: the<br />

structural steel has a ferrite plus pearlite micro-<br />

structure; the rail steel has a fully pearlitic mi-<br />

crostructure; the mach<strong>in</strong>e hous<strong>in</strong>g (lathe) has a<br />

ferrite plus pearlite matrix with graphite flakes;<br />

<strong>and</strong> the jaw crusher microstructure conta<strong>in</strong>s<br />

martensite <strong>and</strong> cementite. In each case, the mi-<br />

crostructure plays the primary role <strong>in</strong> provid<strong>in</strong>g<br />

the properties desired for each application. From<br />

these examples, one can see how material proper-<br />

ties can be tailored by microstructural manipula-<br />

tion or alteration. Knowledge about microstruc-<br />

ture is thus paramount <strong>in</strong> component design <strong>and</strong><br />

alloy development. In the paragraphs that follow,<br />

each microstructural constituent is described<br />

with particular reference to the properties that<br />

can be developed by appropriate manipulation of<br />

the microstructure through deformation (e.g., hot<br />

<strong>and</strong> cold roll<strong>in</strong>g) <strong>and</strong> heat treatment. Further de-

156 / <strong>Structure</strong>/<strong>Property</strong> <strong>Relationships</strong> <strong>in</strong> <strong>Irons</strong> <strong>and</strong> Steels<br />

tails about these microstructural constituents can<br />

be found <strong>in</strong> Ref 2 to 6.<br />

Ferrite<br />

A wide variety of steels <strong>and</strong> cast irons fully<br />

exploit the properties of ferrite. However, only a<br />

few commercial steels are completely ferritic. An<br />

example of the microstructure of a fully ferritic,<br />

ultralow carbon steel is shown <strong>in</strong> Fig. 5.<br />

Ferrite is essentially a solid solution of iron<br />

conta<strong>in</strong><strong>in</strong>g carbon or one or more alloy<strong>in</strong>g ele-<br />

ments such as silicon, chromium, manganese,<br />

<strong>and</strong> nickel. There are two types of solid solu-<br />

tions: <strong>in</strong>terstitial <strong>and</strong> substitutional. In an <strong>in</strong>ter-<br />

stitial solid solution, elements with small atomic<br />

diameter, for example, carbon <strong>and</strong> nitrogen, oc-<br />

cupy specific <strong>in</strong>terstitial sites <strong>in</strong> the body-cen-<br />

tered cubic (bcc) iron crystall<strong>in</strong>e lattice. These<br />

sites are essentially the open spaces between the<br />

larger iron atoms. In a substitutional solid solu-<br />

tion, elements of similar atomic diameter replace<br />

or substitute for iron atoms. The two types of<br />

solid solutions impart different characteristics to<br />

ferrite. For example, <strong>in</strong>terstitial elements like<br />

carbon <strong>and</strong> nitrogen can easily diffuse through<br />

the open bcc lattice, whereas substitutional ele-<br />

ments like manganese <strong>and</strong> nickel diffuse with<br />

great difficulty. Therefore, an <strong>in</strong>terstitial solid<br />

solution of iron <strong>and</strong> carbon responds quickly dur-<br />

<strong>in</strong>g heat treatment, whereas substitutional solid<br />

solutions behave sluggishly dur<strong>in</strong>g heat treat-<br />

ment, such as <strong>in</strong> homogenization.<br />

Accord<strong>in</strong>g to the iron-carbon phase diagram<br />

(Fig. 6a), very little carbon (0.022% C) can dis-<br />

solve <strong>in</strong> ferrite (ctFe), even at the eutectoid tem-<br />

perature of 727 °C (1330 °F). (The iron-carbon<br />

phase diagram <strong>in</strong>dicates the phase regions that<br />

exist over a wide carbon <strong>and</strong> temperature range.<br />

The diagram represents equilibrium conditions.<br />

Figure 6(b) shows an exp<strong>and</strong>ed iron-carbon dia-<br />

gram with both the euteetoid <strong>and</strong> eutectic re-<br />

gions.) At room temperature, the solubility is an<br />

order of magnitude less (below 0.005% C). How-<br />

ever, even at these small amounts, the addition of<br />

carbon to pure iron <strong>in</strong>creases the room-tempera-<br />

ture yield strength of iron by more than five<br />

times, as seen <strong>in</strong> Fig. 7. If the carbon content<br />

exceeds the solubility limit of 0.022%, the car-<br />

bon forms another phase called cementite (Fig.<br />

8). Cementite is also a constituent of pearlite, as<br />

seen <strong>in</strong> Fig. 9. The role of cementite <strong>and</strong> pearlite<br />

on the mechanical properties of steel is discussed<br />

below.<br />

The <strong>in</strong>fluence of solid-solution elements on the<br />

yield strength of ferrite is shown <strong>in</strong> Fig. 10. Here<br />

one can clearly see the strong effect of carbon on<br />

<strong>in</strong>creas<strong>in</strong>g the strength of ferrite. Nitrogen, also<br />

an <strong>in</strong>terstitial element, has a similar effect. Phos-<br />

phorus is also a ferrite strengthener. In fact, there<br />

are commercially available steels conta<strong>in</strong><strong>in</strong>g<br />

phosphorus (up to 0.12% P) for strengthen<strong>in</strong>g.<br />

These steels are the rephosphorized steels (type<br />

1211 to 1215 series). Mechanical property data<br />

for these steels can be found <strong>in</strong> Table 1.<br />

In Fig. 10, the substitutional solid solution ele-<br />

ments of silicon, copper, manganese, molybde-<br />

num, nickel, alum<strong>in</strong>um, <strong>and</strong> chromium are shown<br />

to have far less effect as ferrite strengtheners<br />

than the <strong>in</strong>terstitial elements. In fact, chromium,<br />

nickel, <strong>and</strong> alum<strong>in</strong>um <strong>in</strong> solid solution have very<br />

little <strong>in</strong>fluence on the strength of ferrite.<br />

In addition to carbon (<strong>and</strong> other solid-solution<br />

elements), the strength of a ferritic steel is also<br />

]'able 1 (cont<strong>in</strong>ued)<br />

Steel Condition<br />

Low-alloy steels(b)<br />

1340 Normalized at 870 °C (1600 °F) 834<br />

Annealed at 800 °C (1475 °F) 703<br />

3140 Normalized at 870 °C (1600 oF) 889<br />

Annealed at 815 °C (1500 °F) 690<br />

4130 Normalized at 870 °C (1600 °F) 670<br />

Annealed at 865 °C (1585 °F) 560<br />

Water quenched from 855 °C (1575 °F) 1040<br />

<strong>and</strong> tempered at 540 °C (1000 °F)<br />

4140 Normalized at 870 °C (1600 oF) 1020<br />

Annealed at 815 °C (1500 °F) 655<br />

Water quenched from 845 °C ( 1550 °F) 1075<br />

<strong>and</strong> tempered at 540 °C (1000 °F)<br />

4150 Normalized at 870 °C ( 1600 °F) 1160<br />

Annealed at 830 °C (1525 °F) 731<br />

oil quenched from 830 °C (1525 °F) 1310<br />

<strong>and</strong> tempered at 540 °C (1000 °F)<br />

4320 Normalized at 895 °C (1640 oF) 793<br />

Annealed at 850 °C (1560 °F) 580<br />

4340 Normalized at 870 °C (1600 oF) 1282<br />

Annealed at 810 °C (1490 oF) 745<br />

Oil quenched from 800 °C (1475 °F) 1207<br />

<strong>and</strong> tempered at 540 °C (1000 °F)<br />

4419 Normalized at 955 °C (1750 oF) 515<br />

Annealed at 915 °C (1675 °F) 450<br />

4620 Normalized at 900 °C (1650 oF) 570<br />

Annealed at 855 °C (1575 oF) 510<br />

4820 Normalized at 860 °C (1580 oF) 758<br />

Annealed at 815 °C (1500 °F) 685<br />

5140 Normalized at 870 °C (1600 oF) 793<br />

Annealed at 830 °C (1525 °F) 570<br />

Oil quenched from 845 °C (1550 °F) 972<br />

<strong>and</strong> tempered at 540 °C (1000 °F)<br />

5150 Normalized at 870 °C (1600 oF) 869<br />

Annealed at 825 °C (1520 oF) 675<br />

Oil quenched from 830 °C (1525 °F) 1055<br />

<strong>and</strong> tempered at 540 °C (1000 °F)<br />

5160 Normalized at 855 °C (1575 oF) 1025<br />

Annealed at 815 °C (1495 oF) 724<br />

Oil quenched from 830 °C (1525 °F) 1145<br />

<strong>and</strong> tempered at 540 °C (1000 oF)<br />

6150 Normalized at 870 °C (1600 oF) 938<br />

Annealed at 815 °C (1500 oF) 670<br />

Oil quenched from 845 °C (1550 °F) 1200<br />

<strong>and</strong> tempered at 540 °C (1000 oF)<br />

8620 Normalized at 915 °C 0675 °F) 635<br />

Annealed at 870 °C (1600 oF) 540<br />

8630 Normalized at 870 °C (1600 oF) 650<br />

Annealed at 845 °C (1550 °F) 565<br />

Water quenched from 845 °C (1550 °F) 931<br />

<strong>and</strong> tempered at 540 °C (1000 °F)<br />

8650 Normalized at 870 °C (1600) 1025<br />

Annealed at 795 °C ( 1465 °F) 715<br />

oil quenched from 800 °C (1475 °F) 1185<br />

<strong>and</strong> tempered at 540 °C ( 1000 °F)<br />

8740 Normalized at 870 °C (1600 oF) 931<br />

Annealed at 815 °C (1500 oF) 696<br />

Oil quenched from 830 °C ( 1525 °F) 1225<br />

<strong>and</strong> tempered at 540 °C (1000 oF)<br />

9255 Normalized at 900 °C ( 1650 oF) 931<br />

Annealed at 845 °C (1550 oF) 779<br />

Oil quenched from 885 °C (1625 °F) 1130<br />

<strong>and</strong> tempered at 540 °C ( 1000 oF)<br />

9310 Normalized at 890 °C (1630 °F) 910<br />

Annealed at 845 °C (1550 oF) 820<br />

Ferritie sta<strong>in</strong>less steels(b)<br />

405 Annealed bar<br />

Cold draw n bar<br />

409 Annealed bar<br />

430 Annealed bar<br />

Tensile Yield<br />

strength strength<br />

MPa ksi MPa ksi<br />

Elongatba<br />

<strong>in</strong>SOnma, l~lt~tion Hardm~<br />

% ~a area, % lib<br />

121 558 81 22.0 63 248<br />

102 434 63 25.5 57 207<br />

129 600 87 19.7 57 262<br />

100 420 61 24.5 51 197<br />

97 435 63 25.5 59.5 197<br />

81 460 67 21.5 59.6 217<br />

151 979 142 18.1 63.9 302<br />

148 655 95 17.7 46.8 302<br />

95 915 60 25.7 56,9 197<br />

156 986 143 15.5 56,9 311<br />

168 731 106 11.7 30,8 321<br />

106 380 55 20.2 40,2 197<br />

190 1215 176 13.5 47.2 375<br />

115 460 67 20.8 51 235<br />

84 425 62 29.0 58 163<br />

186 862 125 12.2 36.3 363<br />

108 470 68 22.0 50.0 217<br />

175 1145 166 14.2 45.9 352<br />

75 350 51 32.5 69.4 143<br />

65 330 48 31.2 62.8 121<br />

83 365 53 29.0 66.7 174<br />

74 370 54 31.3 60.3 149<br />

110 485 70 24.0 59.2 229<br />

99 460 67 22.3 58.8 197<br />

115 470 68 22.7 59.2 229<br />

83 290 42 28.6 57.3 167<br />

141 841 122 18.5 58.9 293<br />

126 530 77 20.7 58.7 255<br />

98 360 52 22.0 43.7 197<br />

159 1000 145 16.4 52.9 311<br />

149 650 94 18.2 50.7 285<br />

105 275 40 17.2 30.6 197<br />

166 1005 146 14.5 45.7 341<br />

136 615 89 21.8 61.0 269<br />

97 415 60 23.0 48.4 197<br />

174 1160 168 14.5 48.2 352<br />

92 360 52 26.3 59.7 183<br />

78 385 56 31.3 62.1 149<br />

94 425 62 23.5 53.5 187<br />

82 370 54 29.0 58.9 156<br />

135 850 123 18.7 59.6 269<br />

149 690 100 14 45.0 302<br />

104 385 56 22.5 46.0 212<br />

172 1105 160 14.5 49.1 352<br />

135 605 88 16.0 47.9 269<br />

101 415 60 22.2 46.4 201<br />

178 1130 164 16.0 53.0 352<br />

135 580 84 19.7 43.4 269<br />

113 485 70 21.7 41.1 229<br />

164 924 134 16.7 38.3 321<br />

132 570 83 18.8 58.1 269HRB<br />

119 450 65 17.3 42.1 241HRB<br />

483 70 276 40 30 60 150<br />

586 85 483 70 20 60 185<br />

450 65 240 35 25 75HRB<br />

517 75 310 45 30 --65" 155<br />

(confnued)<br />

(a) All values are estimated m<strong>in</strong>imum values; type 1100 series steels are rated on the basis of 0.10% max Si or coarse-gra<strong>in</strong> melt-<br />

<strong>in</strong>g practice; the mechanical properties shown are expected m<strong>in</strong>imums for the sizes rang<strong>in</strong>g from 19 to 31.8 mm (0.75 to 1.25<br />

<strong>in</strong>.). (b) Most data are for 25 mm (1 <strong>in</strong>.) diam bar. Source: Ref I

Table 1 (cont<strong>in</strong>ued)<br />

Tensile<br />

strength<br />

Steel Ccmdition MPa ksi<br />

Ferritic sta<strong>in</strong>less steels(b) (cont<strong>in</strong>ued)<br />

430 (cont'd) Annealed <strong>and</strong> cold drawn 586 85<br />

442 Annealed bar 515 75<br />

Annealed at 815 °C (1500 °F) <strong>and</strong> cold 545 79<br />

worked<br />

446 Annealed bar 550 80<br />

Annealed at 815 °C (1500 °F) <strong>and</strong> cold 607 88<br />

drawn<br />

Martensilic sta<strong>in</strong>less steels(b)<br />

403 Annealed bar 515 75<br />

Tempered bar 765 111<br />

410 Oil quenched from 980 °C ( 1800 °F); 1085 158<br />

tempered at 540 °C (1000 °F);.16 nun<br />

(0.625 <strong>in</strong>.) bar<br />

Oil quenched from 980 °C (1800 °F); 1525 221<br />

tempered at 40 °C (104 °F); 16 mm<br />

(0.625 <strong>in</strong>.) bar<br />

414 Annealed bar 795 115<br />

Cold drawn bar 895 130<br />

Oil quenched from 980 °C (1800 °F); 1005 146<br />

tempered at 650 °C (1200 oF)<br />

420 Annealed bar 655 95<br />

Annealed <strong>and</strong> cold drawn 760 110<br />

431 Annealed bar 860 125<br />

Annealed <strong>and</strong> cold drawn 895 130<br />

Oil quenched from 980 °C (1800 °F); 831 121<br />

tempered at 650 °C (1200 oF)<br />

Oil quenched from 980 °C (1800 °F); 1435 208<br />

tempered at 40 °C (104 °F)<br />

440C Annealed bar 760 110<br />

Annealed <strong>and</strong> cold drawn bar 860 125<br />

Hardened <strong>and</strong> tempered at 315 °C 1970 285<br />

(6OO °F)<br />

Austenitle sta<strong>in</strong>less steels(b)<br />

201 Annealed 760 110<br />

50% hard 1035 150<br />

Full hard 1275 185<br />

Extra hard 1550 225<br />

202 Annealed bar 515 75<br />

Annealed sheet 655 95<br />

50% hard sheet 1030 150<br />

301 Annealed 725 105<br />

50% hard 1035 150<br />

Full hard 1415 205<br />

302 Annealed strip 620 90<br />

25% hard strip 860 125<br />

Annealed bar 585 85<br />

303 Annealed bar 620 90<br />

Colddrawn 690 100<br />

304 Annealed bar 585 85<br />

Annealed <strong>and</strong> cold drawn 690 100<br />

Cold-drawn high tensile 860 125<br />

305 Annealed sheet 585 85<br />

308 Annealed bar 585 85<br />

309 Annealed bar 655 95<br />

310 Annealed sheet 620 90<br />

Annealed bar 655 95<br />

314 Annealed bar 689 100<br />

316 Annealed sheet 580 84<br />

Annealed bar 550 80<br />

Annealed <strong>and</strong> cold-drawn bar 620 90<br />

317 Annealed sheet 620 90<br />

Annealed bar 585 85<br />

321 Annealed sheet 620 90<br />

Annealed bar 585 85<br />

Annealed <strong>and</strong> cold-drawn bar 655 95<br />

330 Annealed sheet 550 80<br />

Annealed bar 585 85<br />

347 Annealed sheet 655 95<br />

Annealed bar 620 90<br />

(cont<strong>in</strong>ued)<br />

Yield<br />

strength<br />

MPa ksi<br />

Elongation<br />

<strong>in</strong> 50ram,<br />

%<br />

483 70 20 65 185<br />

310 45 30 50 160<br />

427 62 35.5 79 92HRC<br />

345 50 25 45 86HRB<br />

462 67 26 64 96HRB<br />

275 40 35 70 82HRB<br />

585 85 23 67 97HRB<br />

1005 146 13 70 ...<br />

1225 178 15 64 45HRB<br />

620 90 20 60 235<br />

795 115 15 58 270<br />

800 116 19 58 ...<br />

345 50 25 55 195<br />

690 100 14 40 228<br />

655 95 20 55 260<br />

760 110 15 35 270<br />

738 107 20 64 ...<br />

1140 166 17 59 45HRC<br />

450 65 14 25 97HRB<br />

690 100 7 20 260<br />

1900 275 2 10 580<br />

380 55 52 ... 87HRB<br />

760 ll0 12 ... 32HRC<br />

965 140 8 ... 41HRC<br />

1480 215 1 ... 43HRC<br />

275 40 40 ......<br />

310 45 40 ......<br />

760 110 10 _ ...<br />

275 40 60 70' ...<br />

655 95 54 61 ...<br />

1330 193 6 ...<br />

275 40 55 ... 80HRB<br />

515 75 12 _ 25HRC<br />

240 35 60 70" 80HRB<br />

240 35 50 55 160<br />

415 60 40 53 228<br />

235 34 60 70 149<br />

415 60 45 ... 212<br />

655 95 25 ... 275<br />

260 38 50 _ 80HRB<br />

205 30 55 65' 150<br />

275 40 45 65 83HRB<br />

310 45 45 _ 85HRB<br />

275 40 45 65' 160<br />

345 50 45 60 180<br />

290 42 50 _ 79HRB<br />

240 35 60 70" 149<br />

415 60 45 65 190<br />

275 40 45 ... 85HRB<br />

275 40 50 ... 160<br />

240 35 45 _ 80HRB<br />

240 35 55 65' 150<br />

415 60 40 60 185<br />

260 38 40 ... ...<br />

290 42 45 ... 80HRB<br />

275 40 45 _ 85HRB<br />

240 35 50 65" 160<br />

(a) All values are estimated m<strong>in</strong>imum values; type 1100 series steels are rated on the basis of 0.10% max Si or coarse-gra<strong>in</strong> melt-<br />

<strong>in</strong>g practice; the mechanical properties shown are expected m<strong>in</strong>imums for the sizes rang<strong>in</strong>g from 19 to 31.8 mm (0.75 to 1.25<br />

<strong>in</strong>.). (b) Most data are for 25 mm (1 <strong>in</strong>.) diam bar. Source: Ref 1<br />

<strong>Structure</strong>/<strong>Property</strong> <strong>Relationships</strong> <strong>in</strong> <strong>Irons</strong> <strong>and</strong> Steels / 157<br />

determ<strong>in</strong>ed by its gra<strong>in</strong> size accord<strong>in</strong>g to the<br />

Hall-Petch relationship:<br />

Reduction Hardness, Gy = Go + kyd -1/2 (Eq 1)<br />

<strong>in</strong> area, % HB<br />

where Oy is the yield strength (<strong>in</strong> MPa), ~o is a<br />

constant, ky is a constant, <strong>and</strong> d is the gra<strong>in</strong> diame-<br />

ter (<strong>in</strong> mm).<br />

The gra<strong>in</strong> diameter is a measurement of size of<br />

the ferrite gra<strong>in</strong>s <strong>in</strong> the microstructure, for exam-<br />

ple, note the gra<strong>in</strong>s <strong>in</strong> the ultralow carbon steel <strong>in</strong><br />

Fig. 5. Figure 11 shows the Hall-Petch relation-<br />

ship for a low-carbon fully ferritic steel. This<br />

relationship is extremely important for under-<br />

st<strong>and</strong><strong>in</strong>g structure-property relationships <strong>in</strong><br />

steels. Control of gra<strong>in</strong> size through ther-<br />

momechanical treatment, heat treatment, <strong>and</strong>/or<br />

microalloy<strong>in</strong>g is vital to the control of strength<br />

<strong>and</strong> toughness of most steels. The role of gra<strong>in</strong><br />

size is discussed <strong>in</strong> more detail below.<br />

There is a simple way to stabilize ferrite,<br />

thereby exp<strong>and</strong><strong>in</strong>g the region of ferrite <strong>in</strong> the<br />

iron-carbon phase diagram, namely by the addi-<br />

tion of alloy<strong>in</strong>g elements such as silicon, chro-<br />

mium, <strong>and</strong> molybdenum. These elements are<br />

called ferrite stabilizers because they stabilize<br />

ferrite at room temperature through reduc<strong>in</strong>g the<br />

amount of y solid solution (austenite) with the<br />

formation of what is called a y-loop as seen at the<br />

far left <strong>in</strong> Fig. 12. This iron-chromium phase dia-<br />

gram shows that ferrite exists up above 12% Cr<br />

<strong>and</strong> is stable up to the melt<strong>in</strong>g po<strong>in</strong>t (liquidus<br />

temperature). An important fully ferritic family<br />

of steels is the iron-chromium ferritic sta<strong>in</strong>less<br />

steels. These steels are resistant to corrosion, <strong>and</strong><br />

are classified as type 405, 409, 429, 430, 434,<br />

436, 439, 442, 444, <strong>and</strong> 446 sta<strong>in</strong>less steels.<br />

These steels range <strong>in</strong> chromium content from 11<br />

to 30%. Additions of molybdenum, silicon, nio-<br />

bium, alum<strong>in</strong>um, <strong>and</strong> titanium provide specific<br />

properties. Ferritic sta<strong>in</strong>less steels have good<br />

ductility (up to 30% total elongation <strong>and</strong> 60%<br />

reduction <strong>in</strong> area) <strong>and</strong> formability, but lack<br />

strength at elevated temperatures compared with<br />

austenitic sta<strong>in</strong>less steels. Room-temperature<br />

yield strengths range from 170 to about 440 MPa<br />

(25 to 64 ksi), <strong>and</strong> room-temperature tensile<br />

strengths range from 380 to about 550 MPa (55<br />

to 80 ksi). Table 1 lists the mechanical properties<br />

of some of the ferritic sta<strong>in</strong>less steels. Type 409<br />

sta<strong>in</strong>less steel is widely used for automotive ex-<br />

haust systems. Type 430 free-mach<strong>in</strong><strong>in</strong>g sta<strong>in</strong>less<br />

steel has the best mach<strong>in</strong>ability of all sta<strong>in</strong>less<br />

steels other than that of a low-carbon, free-ma-<br />

ch<strong>in</strong><strong>in</strong>g martensitic sta<strong>in</strong>less steel (type 41.6).<br />

Another family of steels utiliz<strong>in</strong>g a ferrite sta-<br />

bilizer (y-loop) are the iron-silicon ferritic alloys<br />

conta<strong>in</strong><strong>in</strong>g up to about 6.5% Si (carbon-free).<br />

These steels are of commercial importance be-<br />

cause they have excellent magnetic permeability<br />

<strong>and</strong> low core loss. High-efficiency motors <strong>and</strong><br />

transformers are produced from these iron-sili-<br />

con electrical steels (alum<strong>in</strong>um can also substi-<br />

tute for silicon <strong>in</strong> them).<br />

Over the past 20 years or so, a new breed of<br />

very-low-carbon fully ferritic sheet steels has<br />

emerged for applications requir<strong>in</strong>g exceptional<br />

formability (see Fig. 5). These are the <strong>in</strong>tersti-<br />

tial-free (IF) steels for which carbon <strong>and</strong> nitro-<br />

gen are reduced <strong>in</strong> the steelmak<strong>in</strong>g process to<br />

very low levels, <strong>and</strong> any rema<strong>in</strong><strong>in</strong>g <strong>in</strong>terstitial<br />

carbon or nitrogen is tied up with small amounts<br />

of alloy<strong>in</strong>g elements (e.g., titanium or niobium)<br />

that form preferentially carbides <strong>and</strong> nitrides.

158/<strong>Structure</strong>/<strong>Property</strong> <strong>Relationships</strong> <strong>in</strong> <strong>Irons</strong> <strong>and</strong> Steels<br />

Table I (cont<strong>in</strong>ued)<br />

qI~mBe Yield<br />

st~ngth strength<br />

Sted C<strong>and</strong>~laa MPa k~ MPa I~<br />

Austenilic sta<strong>in</strong>less steels(b) (cont<strong>in</strong>ued)<br />

347 (eont'd) Annealed<strong>and</strong>colddrawnbar 690<br />

384 Annealed wire 1040 °C (1900 °F) 515<br />

Marag<strong>in</strong>g steels(b)<br />

18Ni(250) Annealed 965<br />

Aged bar 32 mm (1.25 <strong>in</strong>.) 1844<br />

Aged sheet 6 mm (0.25 <strong>in</strong>.) 1874<br />

18Ni(300) Annealed 1034<br />

Aged bar 32 mm (1.25 <strong>in</strong>.) 2041<br />

Aged sheet 6 mm (0.25 <strong>in</strong>.) 2169<br />

18Ni(350) Annealed 1140<br />

Aged bar 32 mm (l.25 <strong>in</strong>.) 2391<br />

Aged sheet 6 mm (0.25 <strong>in</strong>.) 2451<br />

Elongation<br />

<strong>in</strong>S0mm, Reduction Hardness,<br />

% <strong>in</strong> area, % liB<br />

100 450 65 40 60 212<br />

75 240 35 55 72 70HRB<br />

140 655 95 17 75 30 HRC<br />

269 1784 259 11 56.5 51.8 HRC<br />

272 1832 266 8 40.8 50.6HRC<br />

150 758 110 18 72 32HRC<br />

296 2020 293 11.6 55.8 54.7 HRC<br />

315 2135 310 7.7 35 55.1HRC<br />

165 827 120 18 70 35 HRC<br />

347 2348 341 7.6 33.8 58.4 HRC<br />

356 2395 347 3 15.4 57.7 HRC<br />

(a) All values are estimated m<strong>in</strong>imum values; type 1100 series steels ate rated on the basis of 0.10% max Si or coarse-gra<strong>in</strong> melt-<br />

<strong>in</strong>g practice; the mechanical properties shown are expected m<strong>in</strong>imums for the sizes rang<strong>in</strong>g from 19 to 31.8 mm (0.75 to 1.25<br />

<strong>in</strong>.). (b) Most data are for 25 mm (1 <strong>in</strong>.) diam bar. Some: Ref 1<br />

These steels have very low strength, but are used<br />

to produce components that are difficult or im-<br />

possible to form from other steels. Very-low-car-<br />

bon, fully ferritic steels (0.001% C) are now be-<br />

<strong>in</strong>g manufactured for automotive components<br />

that harden dur<strong>in</strong>g the pa<strong>in</strong>t-cur<strong>in</strong>g cycle. These<br />

steels are called bake-harden<strong>in</strong>g steels <strong>and</strong> have<br />

controlled amounts of carbon <strong>and</strong> nitrogen that<br />

comb<strong>in</strong>e with other elements, such as titanium<br />

<strong>and</strong> niobium, dur<strong>in</strong>g the bak<strong>in</strong>g cycle (175 °C, or<br />

350 °F, for 30 m<strong>in</strong>). The process is called ag<strong>in</strong>g,<br />

<strong>and</strong> the strength derives from the precipitation of<br />

titanium/niobium carbonitrides at the elevated<br />

temperature.<br />

Another form of very-low-carbon, fully ferritic<br />

steel is motor lam<strong>in</strong>ation steel. The carbon is re-<br />

moved from these steels by a process known as<br />

decarburization. The decarburized (carbon-free)<br />

ferritic steel has good permeability <strong>and</strong> suffi-<br />

ciently low core loss (not as low as the iron-sili-<br />

con alloys) to be used for electric motor lam<strong>in</strong>a-<br />

tions, that is, the stacked steel layers <strong>in</strong> the rotor<br />

<strong>and</strong> stator of the motor.<br />

As noted previously, a number of properties<br />

are exploited <strong>in</strong> fully ferritic steels:<br />

• Iron-silicon steels: Exceptional electrical<br />

properties<br />

• Iron-chromium steels: Good corrosion resis-<br />

tance<br />

• Interstitial-free steels: Exceptional forma-<br />

bility<br />

• Bake-harden<strong>in</strong>g steels: Strengthens dur<strong>in</strong>g<br />

pa<strong>in</strong>t cure cycle<br />

• Lam<strong>in</strong>ation steels: Good electrical properties<br />

PearlRe<br />

As the carbon content of steel is <strong>in</strong>creased be-<br />

yond the solubility limit (0.02% C) on the iron-<br />

carbon b<strong>in</strong>ary phase diagram, a constituent called<br />

pearlite forms. Pearlite is formed by cool<strong>in</strong>g the<br />

steel through the eutectoid temperature (the tem-<br />

perature of 727 °C <strong>in</strong> Fig. 6) by the follow<strong>in</strong>g<br />

reaction:<br />

Austenite ~ cementite + ferrite ffXl2)<br />

The cementite <strong>and</strong> ferrite form as parallel plates<br />

called lamellae (Fig. 13). This is essentially a<br />

composite microstructure consist<strong>in</strong>g of a very<br />

hard carbide phase, cementite, <strong>and</strong> a very soft <strong>and</strong><br />

ductile ferrite phase. A fully pearlitic microstruc-<br />

ture is formed at the eutectoid composition of<br />

0.78% C. As can be seen <strong>in</strong> Fig. 2 <strong>and</strong> 13, pearlite<br />

forms as colonies where the lamellae are aligned<br />

<strong>in</strong> the same orientation. The properties of fully<br />

pearlitic steels are determ<strong>in</strong>ed by the spac<strong>in</strong>g be-<br />

tween the ferrite-cementite lamellae, a dimension<br />

called the <strong>in</strong>terlamellar spac<strong>in</strong>g, X, <strong>and</strong> the colony<br />

size. A simple relationship for yield strength has<br />

been developed by Heller (Ref 10) as follows:<br />

fly = -85.9 + 8.3 (X -t/2) (Eq 3)<br />

where fly is the 0.2% offset yield strength (<strong>in</strong><br />

MPa) <strong>and</strong> X is the <strong>in</strong>terlamellar spac<strong>in</strong>g (<strong>in</strong> mm).<br />

Figure 14 shows Heller's plot of strength versus<br />

<strong>in</strong>terlamellar spac<strong>in</strong>g for fully pearlitic eutectoid<br />

steels.<br />

It has also been shown by Hyzak <strong>and</strong> Bernste<strong>in</strong><br />

(Ref 11) that strength is related to <strong>in</strong>terlamellar<br />

spac<strong>in</strong>g, pearlite colony size, <strong>and</strong> prior-austenite<br />

gra<strong>in</strong> size, accord<strong>in</strong>g to the follow<strong>in</strong>g relation-<br />

ship:<br />

YS = 52.3 + 2.18 (~-1/2) -0.4 (de -L'2) -2.88 (d-1/2)(Eq 4)<br />

where YS is the yield strength (<strong>in</strong> MPa), d e is the<br />

pearlite colony size (<strong>in</strong> mm), <strong>and</strong> d is the prior-<br />

austenite gra<strong>in</strong> size (<strong>in</strong> mm). From Eq 3 <strong>and</strong> 4, it<br />

can be seen that the steel composition does not<br />

have a major <strong>in</strong>fluence on the yield strength of a<br />

fully pearlitic eutectoid steel. There is some solid-<br />

Fig, 3 Microstructure of a gray cast iron with a ferrite-pearlite matrix. Note the graphite Fig. 4 Microstructure of an alloy white cast iron. White constituent is cementite <strong>and</strong> the<br />

flakes dispersed throughout the matrix. 4% picral etch. 320x. Courtesy of A.O. darker constituent is martensite with some reta<strong>in</strong>ed austenite. 4% picral etch.<br />

Benscoter, Lehigh University 250x. Courtesy ofA.O. Benscoter, Lehigh University

Fig. 5 Microstructure of a fully ferritic, ultralow carbon<br />

steel. Marshalls etch + HF, 300x. Courtesy of<br />

A.O. Benscoter, Lehigh University<br />

solution strengthen<strong>in</strong>g of the ferrite <strong>in</strong> the lamel-<br />

lar structure (see Fig. 10).<br />

The thickness of the cementite lamellae can<br />

also <strong>in</strong>fluence the properties of pearlite. F<strong>in</strong>e ce-<br />

mentite lamellae can be deformed, compared<br />

with coarse lamellae, which tend to crack dur<strong>in</strong>g<br />

deformation.<br />

Although fully pearlitic steels have high<br />

strength, high hardness, <strong>and</strong> good wear resis-<br />

tance, they also have poor ductility <strong>and</strong> tough-<br />

ness. For example, a low-carbon, fully ferritic<br />

¢D<br />

O.<br />

E<br />

1180<br />

1140<br />

1100<br />

1060<br />

1020<br />

980<br />

940<br />

900<br />

86O<br />

820<br />

780<br />

740<br />

700 /<br />

66O<br />

Fe<br />

steel will typically have a total elongation of<br />

more than 50%, whereas a fully pearlitic steel<br />

(e.g., type 1080) will typically have a total elon-<br />

gation of about 10% (see Table 1). A low-carbon<br />

fully ferritic steel will have a room-temperature<br />

Charpy V-notch impact energy of about 200 J<br />

(150 ft. lbf), whereas a fully pearlitic steel will<br />

have room-temperature impact energy of under<br />

10 J (7 ft. lbf). The transition temperature (i.e.,<br />

the temperature at which a material changes from<br />

ductile fracture to brittle fracture) for a fully<br />

pearlitic steel can be approximated from the fol-<br />

low<strong>in</strong>g relationship (Ref 11):<br />

TT = 217.84 - 0.83 (de -1/2) - 2.98(d -1"~) (Eq5)<br />

where TT is the transition temperature (<strong>in</strong> °C).<br />

From Eq 5, one can see that both the prior-<br />

austenite gra<strong>in</strong> size <strong>and</strong> pearlite colony size con-<br />

trol the transition temperature of a pearlitic steel.<br />

Unfortunately, the transition temperature of a<br />

fully pearlitic steel is always well above room<br />

temperature. This means that at room tempera-<br />

ture the general fracture mode is cleavage, which<br />

is associated with brittle fracture. Therefore,<br />

fully pearlitic steels should not be used <strong>in</strong> appli-<br />

cations where toughness is important. Also, pear-<br />

litic steels with carbon contents slightly or mod-<br />

erately higher than the eutectoid composition<br />

(called hypereutectoid steels) have even poorer<br />

toughness.<br />

From Eq 4 <strong>and</strong> 5, one can see that for pearlite,<br />

strength is controlled by <strong>in</strong>terlamellar spac<strong>in</strong>g,<br />

colony size, <strong>and</strong> prior-austenite gra<strong>in</strong> size, <strong>and</strong><br />

toughness is controlled by colony size <strong>and</strong> prior-<br />

Carbon, at.%<br />

1 2 3 4 5 6<br />

I I I I I I<br />

Fe-C equilibrium (experimental)<br />

- - Fe-Fe3C equilibrium (experimental)<br />

(~Fe)<br />

auatenite<br />

~912 °C , / "<br />

~ ~0¢F.) ferrite . ,-~<br />

%~ 770 °C (Curie temperature) -*°~<br />

.../<br />

.................. ~- - -'-~ 0.68 7<br />

I ~ 0.0206 ~ ~, .'°"<br />

0.0218 I<br />

I Ferrite + cementite<br />

I I I I<br />

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4<br />

Carbon, wt%<br />

<strong>Structure</strong>/<strong>Property</strong> <strong>Relationships</strong> <strong>in</strong> <strong>Irons</strong> <strong>and</strong> Steels/159<br />

austenite gra<strong>in</strong> size. Unfortunately, these three<br />

factors are rather difficult to measure. To deter-<br />

m<strong>in</strong>e <strong>in</strong>terlamellar spac<strong>in</strong>g, a scann<strong>in</strong>g electron<br />

microscope (SEM), or a transmission electron<br />

microscope (TEM) is needed <strong>in</strong> order to resolve<br />

the spac<strong>in</strong>g, Generally, a magnification of<br />

10,000x is adequate, as seen <strong>in</strong> Fig. 13. Special<br />

statistical procedures have been developed to de-<br />

term<strong>in</strong>e an accurate measurement of the spac<strong>in</strong>g<br />

(Ref 12). The colony size <strong>and</strong> especially the<br />

prior-austenite gra<strong>in</strong> size are very difficult to<br />

measure <strong>and</strong> require a skilled metallographer us-<br />

<strong>in</strong>g the light microscope or SEM <strong>and</strong> special<br />

etch<strong>in</strong>g procedures.<br />

Because of poor ductility/toughness, there are<br />

only a few applications for fully pearlitic steels,<br />

<strong>in</strong>clud<strong>in</strong>g railroad rails <strong>and</strong> wheels <strong>and</strong> high-<br />

strength wire. By far, the largest tonnage applica-<br />

tion is for rails. A fully pearlitic rail steel pro-<br />

vides excellent wear resistance for railroad<br />

wheel/rail contact. Rail life is measured <strong>in</strong> mil-<br />

lions of gross tons (MGT) of travel <strong>and</strong> current<br />

rail life easily exceeds 250 MGT. The wear resis-<br />

tance of pearlite arises from the unique morphol-<br />

ogy of the ferrite-cementite lamellar composite<br />

where a hard constituent is embedded <strong>in</strong>to a soft-<br />

ductile constituent. This means that the hard ce-<br />

mentite plates do not abrade away as easily as the<br />

rounded cementite particles found <strong>in</strong> other steel<br />

microstructures, that is, tempered martensite <strong>and</strong><br />

ba<strong>in</strong>ite, which is discussed later. Wear resistance<br />

of a rail steel is directly proportional to hardness.<br />

This is shown <strong>in</strong> Fig. 15, which <strong>in</strong>dicates less<br />

weight loss as hardness <strong>in</strong>creases. Also, wear re-<br />

sistance (less weight loss) <strong>in</strong>creases as <strong>in</strong>ter-<br />

lamellar spac<strong>in</strong>g decreases, as shown <strong>in</strong> Fig. 16.<br />

7 8 9<br />

1154°C - ~...~ 2125<br />

2.08 I ~ J., "'" ~1,,/ 8 °C-'~ 2050<br />

.o"Y 211 -- 1975<br />

• *' Y<br />

• .~ -- 1900<br />

-- 1825<br />

-- 1750<br />

AUS tenite + cementite -- 1700<br />

-- 1625<br />

-- 1550<br />

-- 1475<br />

738 °C - 1400<br />

I --<br />

727 °C<br />

1325<br />

I - 1250<br />

1.5 1.6 1.7 1.8 1.9 2.0 2.1 2.2<br />

Fig. 6(a) Iron-carbon phase diagram show<strong>in</strong>g the austenite (y Fe) <strong>and</strong> ferrite (ocFe) phase regions <strong>and</strong> eutectoid composition <strong>and</strong> temperature. Dotted l<strong>in</strong>es represent iron-graphite equi-<br />

librium conditions <strong>and</strong> solid l<strong>in</strong>es represent iron-cementite equilibrium conditions. Only the solid l<strong>in</strong>es are important with respect to steels. Source: Ref 2<br />

u- o<br />

E

160/<strong>Structure</strong>/<strong>Property</strong> <strong>Relationships</strong> <strong>in</strong> <strong>Irons</strong> <strong>and</strong> Steels<br />

Thus, the most important microstructural pa-<br />

rameter for controll<strong>in</strong>g hardness <strong>and</strong> wear resis-<br />

tance is the pearlite <strong>in</strong>terlamellar spac<strong>in</strong>g. Fortu-<br />

nately, <strong>in</strong>terlamellar spac<strong>in</strong>g is easy to control<br />

<strong>and</strong> is dependent solely on transformation tem-<br />

perature.<br />

Figure 17 shows a cont<strong>in</strong>uous cool<strong>in</strong>g transfor-<br />

mation (CCT) diagram for a typical rail steel. A<br />

CCT diagram is a time versus temperature plot<br />

show<strong>in</strong>g the regions at which various constitu-<br />

cnts--ferdte, pearlite, ba<strong>in</strong>ite, <strong>and</strong> martensite--<br />

form dur<strong>in</strong>g the cont<strong>in</strong>uous cool<strong>in</strong>g of a steel<br />

component. Usually several cool<strong>in</strong>g curves are<br />

shown with the associated start <strong>and</strong> f<strong>in</strong>ish trans-<br />

formation temperatures of each constituent.<br />

These diagrams should not be confused with iso-<br />

thermal transformation (IT or TTT) diagrams,<br />

which are derived by rapidly quench<strong>in</strong>g very th<strong>in</strong><br />

specimens to various temperatures, <strong>and</strong> ma<strong>in</strong>ta<strong>in</strong>-<br />

<strong>in</strong>g that temperature (isothermal) until the speci-<br />

mens beg<strong>in</strong> to transform, partially transform, <strong>and</strong><br />

fully transform, at which time they are quenched<br />

to room temperature. An IT diagram does not<br />

represent the transformation behavior <strong>in</strong> most<br />

processes where steel parts are cont<strong>in</strong>uously<br />

cooled, that is, air cooled, <strong>and</strong> so forth.<br />

As shown <strong>in</strong> Fig. 17, the peadite transforma-<br />

tion temperature (<strong>in</strong>dicated by the pearlite-start<br />

curve, Ps) decreases with <strong>in</strong>creas<strong>in</strong>g cool<strong>in</strong>g rate.<br />

The hardness of peaflite <strong>in</strong>creases with decreas-<br />

<strong>in</strong>g transformation temperature. Thus, <strong>in</strong> order to<br />

provide a rail steel with the highest hardness <strong>and</strong><br />

wear resistance, one must cool the rail from the<br />

austenite at the fastest rate possible to obta<strong>in</strong> the<br />

lowest transformation temperature. This is done<br />

<strong>in</strong> practice by a process known as head harden-<br />

<strong>in</strong>g, which is simply an accelerated cool<strong>in</strong>g proc-<br />

ess us<strong>in</strong>g forced air or water sprays to achieve<br />

the desired cool<strong>in</strong>g rate (Ref 15). Because only<br />

the head of the rail contacts the wheel of the<br />

railway car <strong>and</strong> locomotive, only the head re-<br />

quires the higher hardness <strong>and</strong> wear resistance.<br />

Another application for a fully pearlitic steel is<br />

high-strength wire (e.g., piano wire). Aga<strong>in</strong>, the<br />

composite morphology of lamellar ferrite <strong>and</strong> ce-<br />

mentite is exploited, this time dur<strong>in</strong>g wire draw-<br />

<strong>in</strong>g. A fully pearlitic steel rod is heat treated by a<br />

process known as patent<strong>in</strong>g. Dur<strong>in</strong>g patent<strong>in</strong>g,<br />

1~ M 3270<br />

1~ 3090<br />

1 ! 2730<br />

GFe<br />

1~ 2550<br />

11 2010<br />

lC 1830 ~<br />

E<br />

i ~ E 1470<br />

7 1290<br />

-~ 930<br />

4 750<br />

3 570<br />

I P_~<br />

30<br />

Fe 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0<br />

Carbon, wt%<br />

Fig. 6(b) Exp<strong>and</strong>ed iron-carbon phase diagram show<strong>in</strong>g both the eutectoid (shown <strong>in</strong> Fig. 6a) <strong>and</strong> eutectic regions.<br />

Dotted l<strong>in</strong>es represent iron-graphite equilibrium conditions <strong>and</strong> solid l<strong>in</strong>es represent iron-cementite equilib-<br />

rium conditions. The solid l<strong>in</strong>es at the eutectic are important to white cast irons <strong>and</strong> the dotted l<strong>in</strong>es are important to gray<br />

cast irons. Source: Ref 2<br />

2910<br />

2370<br />

2190<br />

rILE[<br />

the rod is transformed at a temperature of about<br />

540 °C (1000 °F) by pass<strong>in</strong>g it through a lead or<br />

salt bath at this temperature. This develops a<br />

microstructure with a very f<strong>in</strong>e pearlite <strong>in</strong>ter-<br />

lamellar spac<strong>in</strong>g because the transformation<br />

takes place at the nose of the CCT diagram, that<br />

is, at the lowest possible pearlite transformation<br />

temperature (see Fig. 17). The rod is then cold<br />

drawn to wire. Because of the very f<strong>in</strong>e <strong>in</strong>ter-<br />

lamellar spac<strong>in</strong>g, the ferrite <strong>and</strong> cementite lamel-<br />

lae become aligned along the wire axis dur<strong>in</strong>g<br />

the deformation process. Also, the f<strong>in</strong>e ccmentite<br />

lamella tend to bend <strong>and</strong> deform as the wire is<br />

elongated dur<strong>in</strong>g draw<strong>in</strong>g. The result<strong>in</strong>g wire is<br />

one of the strongest commercial products avail-<br />

able; for example, a commercial 0.1 mm (0.004<br />

<strong>in</strong>.) diam wire can have a tensile strength <strong>in</strong> the<br />

range of 3.0 to 3.3 GPa (439 to 485 ksi), <strong>and</strong> <strong>in</strong><br />

special cases a tensile strength as high as 4.8<br />

GPa (696 ksi) can be obta<strong>in</strong>ed. These wires are<br />

used <strong>in</strong> musical <strong>in</strong>struments because of the sound<br />

quality developed from the high tensile stresses<br />

applied <strong>in</strong> str<strong>in</strong>g<strong>in</strong>g a piano <strong>and</strong> viol<strong>in</strong> <strong>and</strong> are<br />

also used <strong>in</strong> wire rope cables for suspension<br />

bridges.<br />

Ferrite-Pearlite<br />

The most common structural steels produced<br />

have a mixed ferrite-pearlite microstructure.<br />

Their applications <strong>in</strong>clude beams for bridges <strong>and</strong><br />

high-rise build<strong>in</strong>gs, plates for ships, <strong>and</strong> re<strong>in</strong>-<br />

forc<strong>in</strong>g bars for roadways. These steels are rela-<br />

tively <strong>in</strong>expensive <strong>and</strong> are produced <strong>in</strong> large ton-<br />

nages. They also have the advantage of be<strong>in</strong>g<br />

able to be produced with a wide range of proper-<br />

ties. The microstructure of typical ferrite-pearlite<br />

steels is shown <strong>in</strong> Fig. 18.<br />

In most ferrite-pearlite steels, the carbon con-<br />

tent <strong>and</strong> the gra<strong>in</strong> size determ<strong>in</strong>e the micro-<br />

structure <strong>and</strong> result<strong>in</strong>g properties. For example,<br />

Fig. 19 shows the effect of carbon on tensile <strong>and</strong><br />

impact properties. The ultimate tensile strength<br />

steadily <strong>in</strong>creases with <strong>in</strong>creas<strong>in</strong>g carbon con-<br />

tent. This is caused by the <strong>in</strong>crease <strong>in</strong> the volume<br />

fraction of pearlite <strong>in</strong> the microstructure, which<br />

has a strength much higher than that of ferrite.<br />

Thus, <strong>in</strong>creas<strong>in</strong>g the volume fraction of pearlite<br />

has a profound effect on <strong>in</strong>creas<strong>in</strong>g tensile<br />

strength.<br />

However, as seen <strong>in</strong> Fig. 19, the yield strength<br />

is relatively unaffected by carbon content, ris<strong>in</strong>g<br />

from about 275 MPa (40 ksi) to about 415 MPa<br />

(60 ksi) over the range of carbon content shown.<br />

This is because yield<strong>in</strong>g <strong>in</strong> a ferrite-pearlite steel<br />

is controlled by the fcrrite matrix, which is gen-<br />

erally considered to be the cont<strong>in</strong>uous phase (ma-<br />

"~ 35 241 ~:<br />

-'~ 25 ~' ..... 172<br />

"N,<br />

/ 103=<br />

0<br />

o~ 10 ~<br />

o.<br />

o<br />

0 0.001 0.002 0.003<br />

Carbon, wt%<br />

0.004 0.005 o<br />

6<br />

Fig, 7 Increase <strong>in</strong> room-temperature yield strength of<br />

iron with small additions of carbon. Source: Ref 7<br />

O3

Fig. 8 Photomic.rograph of an annealed low-carbon sheet steel with gra<strong>in</strong>-boundary ce-<br />

mentite. 2% nital + 4% picral etch. 1000x<br />

trix) <strong>in</strong> the microstructure. Therefore, pearlite<br />

plays only a m<strong>in</strong>or role <strong>in</strong> yield<strong>in</strong>g behavior.<br />

From Fig. 19, one can also see that ductility, as<br />

represented by reduction <strong>in</strong> area, steadily de-<br />

creases with <strong>in</strong>creas<strong>in</strong>g carbon content. A steel<br />

with 0.10% C has a reduction <strong>in</strong> area of about<br />

75%, whereas a steel with 0.70% C has a reduc-<br />

tion <strong>in</strong> area of only 25%. Percent total elongation<br />

would show a similar trend, however, with values<br />

much less than percent reduction <strong>in</strong> area.<br />

Much work has been done to develop empirical<br />

equations for ferrite-pearlite steels that relate<br />

strength <strong>and</strong> toughness to microstructural fea-<br />

tures, for example, gra<strong>in</strong> size <strong>and</strong> percent of<br />

pearlite as well as composition. One such equa-<br />

tion for ferrite-pearlitc steels under 0.25% C is as<br />

follows (Ref 16):<br />

YS = 53.9 + 32.34 (Mn) + 83.2(Si)<br />

+ 354.2(Nf) + 17.4(d-U2) (Eq 6)<br />

where Mn is the manganese content (%), Si is the<br />

silicon content (%), Nf is the free nitrogen content<br />

(%), <strong>and</strong> d is the ferrite gra<strong>in</strong> size (<strong>in</strong> mm). Equa-<br />

tion 6 shows that carbon content (percent pearlite)<br />

4-375<br />

+225<br />

.--~_m+150<br />

"~ +75<br />

o 0<br />

-75<br />

I<br />

C <strong>and</strong> N<br />

/<br />

y -- Ni <strong>and</strong> AI<br />

0 0.5 1.0 1.5 2.0 2.5 3.0<br />

Alloy content, wt%<br />

Fig, 10 Influence of solid-solution elements on the<br />

changes <strong>in</strong> yield stress of low-carbon ferritic<br />

steels. Source: Ref 5<br />

Si<br />

has no effect on yield strength, whereas the yield<br />

strength <strong>in</strong> Fig. 19 <strong>in</strong>creases somewhat with car-<br />

bon content. Accord<strong>in</strong>g to Eq 6, manganese, sili-<br />

con, <strong>and</strong> nitrogen have a pronounced effect on<br />

yield strength, as does gra<strong>in</strong> size. However, <strong>in</strong><br />

most ferrite-pearlite steels nitrogen is quite low<br />

(under 0.010%) <strong>and</strong> thus has m<strong>in</strong>imal effect on<br />

yield strength. In addition, as discussed below,<br />

nitrogen has a detrimental effect on impact prop-<br />

erties.<br />

The regression equation for tensile strength for<br />

the same steels is as follows (Ref 16):<br />

TS = 294,1 + 27.7(Mn) + 83.2(Si)<br />

+ 3.9(P) + 7.7(d -lt2) (F-4 7)<br />

where TS is the tensile strength (<strong>in</strong> MPa) <strong>and</strong> P is<br />

pearlite content (%). Thus, <strong>in</strong> dist<strong>in</strong>ction to yield<br />

strength, the percentage of pearlite <strong>in</strong> the micro-<br />

structure has an important effect on tensile<br />

strength.<br />

Toughness of ferrite-pearlite steels is also an<br />

important consideration <strong>in</strong> their use. It has long<br />

been known that the absorbed energy <strong>in</strong> a Charpy<br />

V-notch test is decreased by <strong>in</strong>creas<strong>in</strong>g carbon<br />

content, as seen <strong>in</strong> Fig. 20. In this graph of im-<br />

Fig. 11<br />

&<br />

600<br />

500<br />

400<br />

~ 300<br />

200<br />

100<br />

<strong>Structure</strong>/<strong>Property</strong> <strong>Relationships</strong> <strong>in</strong> <strong>Irons</strong> <strong>and</strong> Steels / 161<br />

Fig. 9 Photomicrograph of pearlite (dark constituent) <strong>in</strong> a low-carbon steel sheet. 2% ni-<br />

tal + 4% picral etch. 1000x<br />

pact energy versus test temperature, the shelf en-<br />

ergy decreases from about 200 J (150 ft • lbf) for<br />

a 0.11% C steel to about 35 J (25 ft. lbf) for a<br />

0.80% C steel. Also, the transition temperature<br />

<strong>in</strong>creases from about -50 to 150 °C (-60 to 300<br />

°F) over this same range of carbon content. The<br />

effect of carbon is due ma<strong>in</strong>ly to its effect on the<br />

percentage of pearlite <strong>in</strong> the microstructurc. This<br />

is reflected <strong>in</strong> the regression equation for transi-<br />

tion temperature below (Ref 16):<br />

TT = -19 + 44(Si) + 700(N~/2)<br />

+ 2.2(P) - 11.5 (d -1/2) (F_.q 8)<br />

It can be seen <strong>in</strong> all these relationships that<br />

ferrite gra<strong>in</strong> size is an important parameter <strong>in</strong><br />

improv<strong>in</strong>g both strength <strong>and</strong> toughness. It can<br />

also be seen that while pearlite is beneficial for<br />

<strong>in</strong>creas<strong>in</strong>g tensile strength <strong>and</strong> nitrogen is benefi-<br />

cial for <strong>in</strong>creas<strong>in</strong>g yield strength, both are harm-<br />

ful to toughness. Therefore, methods to control<br />

the gra<strong>in</strong> size of ferrite-pearlite steels have rap-<br />

idly evolved over the past 25 years. The two most<br />

important methods to control gra<strong>in</strong> size are con-<br />

trolled roll<strong>in</strong>g <strong>and</strong> microalloy<strong>in</strong>g. In fact, these<br />

I I I I I I I I I I I I<br />

0 1 2 3 4 5 6 7 8 9 10 11 12<br />

Gra<strong>in</strong> diameter (d-l~), mm -1~<br />

Hall-Petch relationship <strong>in</strong> low-carbon ~mtic steels, souse: Ref 8<br />

80<br />

80<br />

"N.<br />

20 |

162 / <strong>Structure</strong>/<strong>Property</strong> <strong>Relationships</strong> <strong>in</strong> <strong>Irons</strong> <strong>and</strong> Steels<br />

Fig. 12<br />

oo<br />

(9<br />

¢:L<br />

E<br />

Chromium, at.%<br />

0 10 20 30 40 50 60 70<br />

20OO<br />

1800<br />

1600<br />

1400 - 1394 °C<br />

I I<br />

1538 °C 1516 °: ~ ......<br />

1200 - ~ (~Fe,Cr)<br />

1000 _(~Fe)//_12. 7<br />

oc/I<br />

21<br />

8001:-- -.7<br />

I -/ ( o I<br />

~nn I Magnetic "~ • "---- ..... I , "* ".<br />

oc<br />

80 90 100<br />

Itransformabon.-<br />

/<br />

o.'. ..................<br />

,, :<br />

475 o C<br />

=.." ...........................<br />

"-..<br />

".,..<br />

400 i r'1 °° I I I I I I I t "'~<br />

0 10 20 30 40 50 60 70 80 90<br />

Fe Chromium, wt%<br />

Iron-chromium phase diagram. Source: Ref 9<br />

methods are used <strong>in</strong> conjunction to produce<br />

strong, tough ferrite-pearlite steels.<br />

Controlled roll<strong>in</strong>g is a thermomechanical<br />

treatment <strong>in</strong> which steel plates are rolled below<br />

the recrystailization temperature of aastcnite.<br />

This process results <strong>in</strong> elongation of the austenite<br />

gra<strong>in</strong>s. Upon further roll<strong>in</strong>g <strong>and</strong> subsequent cool-<br />

<strong>in</strong>g to room temperature, the austenite-to-ferrite<br />

transformation takes place. The ferrite gra<strong>in</strong>s are<br />