OTHER WHISKEY MASH RECIPES

OTHER WHISKEY MASH RECIPES

OTHER WHISKEY MASH RECIPES

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

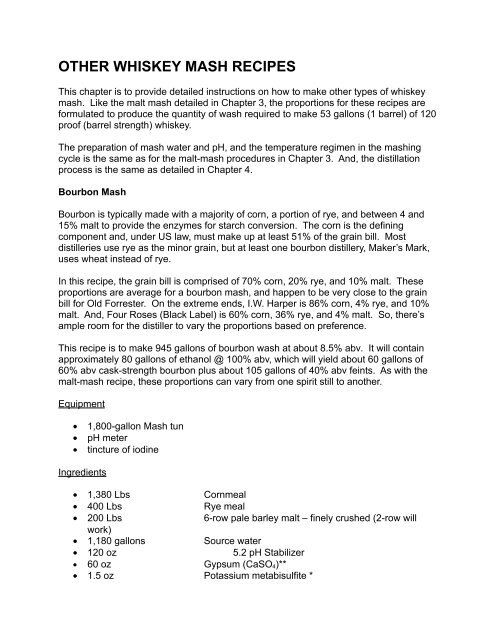

<strong>OTHER</strong> <strong>WHISKEY</strong> <strong>MASH</strong> <strong>RECIPES</strong><br />

This chapter is to provide detailed instructions on how to make other types of whiskey<br />

mash. Like the malt mash detailed in Chapter 3, the proportions for these recipes are<br />

formulated to produce the quantity of wash required to make 53 gallons (1 barrel) of 120<br />

proof (barrel strength) whiskey.<br />

The preparation of mash water and pH, and the temperature regimen in the mashing<br />

cycle is the same as for the malt-mash procedures in Chapter 3. And, the distillation<br />

process is the same as detailed in Chapter 4.<br />

Bourbon Mash<br />

Bourbon is typically made with a majority of corn, a portion of rye, and between 4 and<br />

15% malt to provide the enzymes for starch conversion. The corn is the defining<br />

component and, under US law, must make up at least 51% of the grain bill. Most<br />

distilleries use rye as the minor grain, but at least one bourbon distillery, Maker’s Mark,<br />

uses wheat instead of rye.<br />

In this recipe, the grain bill is comprised of 70% corn, 20% rye, and 10% malt. These<br />

proportions are average for a bourbon mash, and happen to be very close to the grain<br />

bill for Old Forrester. On the extreme ends, I.W. Harper is 86% corn, 4% rye, and 10%<br />

malt. And, Four Roses (Black Label) is 60% corn, 36% rye, and 4% malt. So, there’s<br />

ample room for the distiller to vary the proportions based on preference.<br />

This recipe is to make 945 gallons of bourbon wash at about 8.5% abv. It will contain<br />

approximately 80 gallons of ethanol @ 100% abv, which will yield about 60 gallons of<br />

60% abv cask-strength bourbon plus about 105 gallons of 40% abv feints. As with the<br />

malt-mash recipe, these proportions can vary from one spirit still to another.<br />

Equipment<br />

• 1,800-gallon Mash tun<br />

• pH meter<br />

• tincture of iodine<br />

Ingredients<br />

• 1,380 Lbs Cornmeal<br />

• 400 Lbs Rye meal<br />

• 200 Lbs 6-row pale barley malt – finely crushed (2-row will<br />

work)<br />

• 1,180 gallons Source water<br />

• 120 oz 5.2 pH Stabilizer<br />

• 60 oz Gypsum (CaSO4)**<br />

• 1.5 oz Potassium metabisulfite *

* The potassium metabisulfite is only required if the source water contains<br />

chloramines.<br />

** The gypsum is only required if the source water is low in calcium (i.e. less than 100<br />

ppm). The 60 oz of gypsum will raise the calcium level for this batch by 100 ppm. This<br />

amount can be adjusted accordingly to yield a mash water with between 100 and 250<br />

ppm calcium.<br />

The source water is assumed to be fairly soft municipal tap water. E.g.:<br />

• hardness level of 4<br />

• almost no iron<br />

• 100 ppm calcium<br />

• pH 8.5<br />

Method<br />

Since this recipe involves mashing un-malted cereal grains, the grain will have to be<br />

cooked at a higher temperature to gelatinize the starches before it’s cooled and the malt<br />

is added. Also, with cereal-grain mashes, the mash is not sparged. It’s fermented right<br />

on the grain bed, and the solids are separated out after fermentation.<br />

First, begin by preparing the mash water. With the entire quantity of source water in a<br />

single container, add the 120 oz of 5.2 pH Stabilizer and the 60 oz of gypsum to it, and<br />

mix thoroughly. This can be done in the mash tun with the agitator on. If the source<br />

water contains chloramines then add the 1.5 oz of potassium metabisulfite, otherwise<br />

leave this out.<br />

The water chemistry should now have a suitable level of calcium and sulfate ions, and<br />

the pH will be buffered to 5.2 for the duration of the mashing cycle.<br />

After the water is prepared, place it in the mash tun, turn on the agitator, and begin<br />

heating it until the water temperature reaches near boiling (212 o F). Next, turn off the<br />

heat but leave the agitator running. Add the 1,380 Lbs of cornmeal and the 400 Lbs of<br />

rye meal. The temperature should come to rest at about 180 or 190 o F. Let the mash<br />

gelatinize for 20 minutes with the agitator running.<br />

At this point, the mash should be a thick porridge (i.e. the starches have gelatinized).<br />

Next, force cool the mash to 152 o F. This is normally done by running water through<br />

cooling coils in the mash tun with the agitator running.<br />

After the mash is down to 152 o F, with the agitator still running, add the 200 Lbs of finelycrushed<br />

barley malt. The temperature should come to rest at about 149 o F. The mash<br />

temperature should then be adjusted to 145 o F.

While maintaining a conversion temperature of 145 o F, leave the mash covered and<br />

agitating for 90 minutes for the starches to convert to sugars.<br />

After 90-minutes, the conversion should be complete. This can be tested by the iodine<br />

starch test described in Chapter 3.<br />

After it’s confirmed that the starch conversion is complete, the mash can be force<br />

cooled to the fermentation temperature, 80 o F, and then transferred to the fermentation<br />

tank.<br />

Since the mash is not sparged the way malt mash is, and all the solids are left in the<br />

mash, then at this point you will have about 1,600 gallons of bourbon mash with a SG of<br />

about 1.060 or more at 80 o F ready for the fermentation stage.<br />

Fermentation Procedure<br />

Equipment<br />

• 1,800-gallon fermentation vessel with aeration equipment<br />

• SG and temperature measuring equipment<br />

Ingredients<br />

• 1,600 gallons Bourbon mash from the mashing step<br />

• 15 oz Safwhiskey M-1 malt whiskey yeast (from Lesaffre) or<br />

Red Star bourbon whiskey yeast (from Lesaffre)<br />

Method<br />

The mash will be in the fermenter. The Originating Gravity (OG) and the temperature<br />

should be measured. The OG is expected to be about 1.060 or more, and the<br />

temperature should be 80 o F. If the OG is more than 1.060, it should be adjusted<br />

downward by the addition of mash water so that it’s 1.060.<br />

The mash will now require aeration since the heat from the mashing process will have<br />

driven off all the dissolved oxygen. The 15 oz of whiskey yeast can be added either<br />

before or after the aeration process. This will depend mostly on the type of aeration<br />

equipment used.<br />

After the aeration is finished and the yeast has been added, the temperature should be<br />

controlled so that it’s kept between 75 and 85 o F.<br />

After 30 minutes the yeast will have hydrated in the liquid and can be thoroughly mixed<br />

in. Within four or five hours of pitching the yeast, vigorous fermentation should be<br />

evident. Leave the mash to ferment for 72 hours. The mash should be roused for ten<br />

minutes every four hours or so.

After 72 hours the fermentation will either be complete and the activity will have<br />

diminished to a slow spurious bubbling, or the fermentation will still be active and only<br />

have slowed down slightly.<br />

If the latter is the case, monitor it every six hours or so until the bubbling is very slow<br />

and the fermentation is therefore, finished. Fermentation shouldn’t take more than 96<br />

hours.<br />

When the fermentation is complete and the yeast has had 12 hours or so to settle, the<br />

Terminating Gravity (TG) can be measured.<br />

With the OG and the TG, the alcohol percentage can be calculated using the formula:<br />

1000(OG - TG) / 7.4 = % abv<br />

At this point, the mash is now called “wash”, and the next step is to distill it in the beerstripping<br />

still. If the beer-stripper is equipped with jacketed steam heat and an agitator,<br />

then the wash can be distilled with all the solids left in. Not all bourbon distilleries do<br />

this, but some contend that it makes for a better flavor.<br />

If the boiler is not equipped with jacketed steam heat and an agitator, or if the distiller<br />

simply decides to remove the mash solids from the wash before distilling it, then the<br />

wash will have to be processed through solids-separating equipment to render the clear<br />

liquid for distillation.<br />

After the completion of this fermentation step, you will have about 945 gallons of liquid<br />

bourbon wash at about 8.5% abv. If the solids are left in the wash, then the volume of<br />

wash will be about 1,600 gallons.<br />

You are now ready to proceed to the beer-stripping step, and then the spirit run. For<br />

this please follow the instructions in Chapter 4 to distill the wash.

APPENDIX A<br />

HOW TO MAKE MOONSHINE<br />

Whiskey can be made on a small scale at home with a hobby still. All you need to know<br />

is how to make beer. Whether you join a homebrew club to learn how to make beer,<br />

take home brewing classes, buy the book How to Brew by John Palmer, or just buy a<br />

homebrew kit and follow the instructions, the main thing is to make some beer.<br />

Whiskey, by definition, is simply distilled beer. And beer is defined as fermented grain.<br />

Before the distilling part, the process of making moonshine is the same as making beer.<br />

You have to make, what brewers call, “wort”. Distillers have a different word for wort,<br />

they call it “mash”. It’s the same substrate, however mash has no hops and there’s no<br />

kettle boil. The mash is just fermented, and then distilled immediately following the<br />

high-krausen stage of the fermentation.<br />

Moonshine Recipe<br />

From your local homebrew shop, buy 90 pounds of flaked brewers’ corn and 15 pounds<br />

of crushed pale barley malt. Put 30 pounds of flaked corn and 5 pounds of crushed<br />

barley malt in three bags for three mashes.<br />

Mashing and Fermentation: Make three mashes. If you don’t have the equipment, you<br />

can just make one mash at a time. In a 15-gallon fermenter, or camp cooler, pour in 12<br />

gallons of near boiling water. When the water temperature is down to about 165 o F, add<br />

the 30 pounds of flaked corn and the 5 pounds of barley malt, and stir thoroughly.<br />

Cover, and let stand until the temperature is down to about 90 o F or less. Stir it<br />

thoroughly every 10 or 15 minutes for the first 90 minutes or so. After two hours from<br />

when the grain is added, you can force cool the mash with a wort chiller to 90 o F if you<br />

want.<br />

When the mash is 90 o F or less, it needs to be aerated before yeast is added. An easy<br />

way to do this is to place a fish aquarium aeration stone in the mash and turn the air<br />

pump on and let it bubble for about 30 minutes. Alternatively, you could take about 5<br />

gallons at a time and pour it from one pail to another five or six times. After aerating it,<br />

add 3 teaspoons of Red Star yeast. Bread yeast works, too, but Red Star is real<br />

whiskey yeast and produces a better flavor. Let the mash ferment to completion, which<br />

is about seven days.<br />

Make up the other two batches the same way.

When the fermentation is complete, the liquid needs to be strained out of the spent<br />

grain. This can be done by suspending a strainer or colander over a large plastic pail<br />

and using a large nylon straining bag to strain the mash.<br />

Incidentally, you could take a shortcut and make up each batch by just dissolving 15<br />

pounds of Dried Malt Extract (DME) in 10 gallons of hot tap water, and adding the yeast<br />

when the temperature is 90 o F or less. This mash would not require straining, it would<br />

just need to be siphoned off the sediment. Of course, this would make a malt whiskey<br />

instead of corn whiskey.<br />

After all three batches are made you will have about 30 gallons of 9% abv wash ready<br />

to be distilled.<br />

Distilling (three 10-gallon batches): The strained wash should be left to settle for about<br />

12 hours or so and then siphoned off the sediment to eliminate the last of the<br />

suspended solids.<br />

Run 1 – Distill the three 10-gallon batches of wash. Each batch should yield 2 or more<br />

gallons of 40 abv. On each run, do a small heads and tails cut of about ½ cup each. Be<br />

sure to store the spirits in glass or stainless steel. The total moonshine collected is<br />

about 6 gallons.<br />

If you decide to drink your moonshine, don’t. The key to really good moonshine is<br />

double distilling.<br />

Double Distilling – Combine the three first runs and make one 6-gallon second run.<br />

Again, cut the heads and tails. The cuts can be done by taste this time. The hearts of<br />

the second run should yield 2½ gallons of 70% abv. Now, cut the moonshine with 1 7/8<br />

gallons of distilled water (Cosco). The final yield will be about 4 3/8 gallons of 40%<br />

moonshine.<br />

To make the moonshine into whiskey, buy a small barrel or some wooden staves from a<br />

local homebrew shop. Infuse the staves in the moonshine, or place the moonshine in<br />

the small barrel, and in a few weeks you’ll have whiskey.<br />

Drink it right away, or if you can wait, let it infuse with the oak for three weeks. For good<br />

whiskey, age for 1 to 3 years with oak.<br />

Enjoy!