Replacing the Rotor Seal

Replacing the Rotor Seal

Replacing the Rotor Seal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

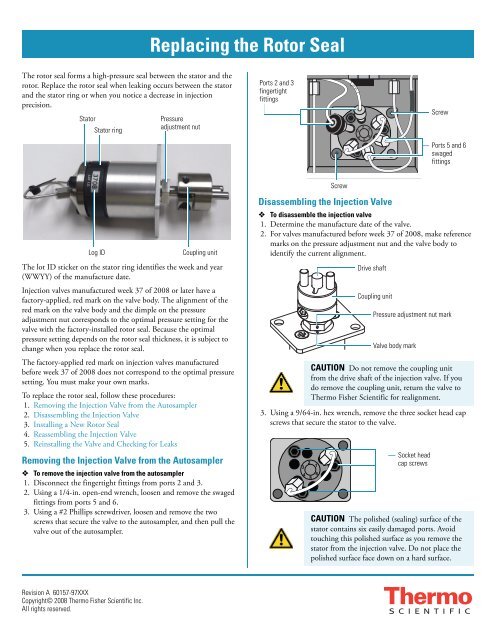

The rotor seal forms a high-pressure seal between <strong>the</strong> stator and <strong>the</strong><br />

rotor. Replace <strong>the</strong> rotor seal when leaking occurs between <strong>the</strong> stator<br />

and <strong>the</strong> stator ring or when you notice a decrease in injection<br />

precision.<br />

Stator<br />

Stator ring<br />

The lot ID sticker on <strong>the</strong> stator ring identifies <strong>the</strong> week and year<br />

(WWYY) of <strong>the</strong> manufacture date.<br />

Injection valves manufactured week 37 of 2008 or later have a<br />

factory-applied, red mark on <strong>the</strong> valve body. The alignment of <strong>the</strong><br />

red mark on <strong>the</strong> valve body and <strong>the</strong> dimple on <strong>the</strong> pressure<br />

adjustment nut corresponds to <strong>the</strong> optimal pressure setting for <strong>the</strong><br />

valve with <strong>the</strong> factory-installed rotor seal. Because <strong>the</strong> optimal<br />

pressure setting depends on <strong>the</strong> rotor seal thickness, it is subject to<br />

change when you replace <strong>the</strong> rotor seal.<br />

The factory-applied red mark on injection valves manufactured<br />

before week 37 of 2008 does not correspond to <strong>the</strong> optimal pressure<br />

setting. You must make your own marks.<br />

To replace <strong>the</strong> rotor seal, follow <strong>the</strong>se procedures:<br />

1. Removing <strong>the</strong> Injection Valve from <strong>the</strong> Autosampler<br />

2. Disassembling <strong>the</strong> Injection Valve<br />

3. Installing a New <strong>Rotor</strong> <strong>Seal</strong><br />

4. Reassembling <strong>the</strong> Injection Valve<br />

5. Reinstalling <strong>the</strong> Valve and Checking for Leaks<br />

Removing <strong>the</strong> Injection Valve from <strong>the</strong> Autosampler<br />

To remove <strong>the</strong> injection valve from <strong>the</strong> autosampler<br />

1. Disconnect <strong>the</strong> fingertight fittings from ports 2 and 3.<br />

2. Using a 1/4-in. open-end wrench, loosen and remove <strong>the</strong> swaged<br />

fittings from ports 5 and 6.<br />

3. Using a #2 Phillips screwdriver, loosen and remove <strong>the</strong> two<br />

screws that secure <strong>the</strong> valve to <strong>the</strong> autosampler, and <strong>the</strong>n pull <strong>the</strong><br />

valve out of <strong>the</strong> autosampler.<br />

Revision A 60157-97XXX<br />

Copyright© 2008 Thermo Fisher Scientific Inc.<br />

All rights reserved.<br />

<strong>Replacing</strong> <strong>the</strong> <strong>Rotor</strong> <strong>Seal</strong><br />

Pressure<br />

adjustment nut<br />

Log ID Coupling unit<br />

Ports 2 and 3<br />

fingertight<br />

fittings<br />

Screw<br />

Disassembling <strong>the</strong> Injection Valve<br />

20 µL<br />

2<br />

3 1<br />

4 6<br />

5<br />

Screw<br />

Ports 5 and 6<br />

swaged<br />

fittings<br />

To disassemble <strong>the</strong> injection valve<br />

1. Determine <strong>the</strong> manufacture date of <strong>the</strong> valve.<br />

2. For valves manufactured before week 37 of 2008, make reference<br />

marks on <strong>the</strong> pressure adjustment nut and <strong>the</strong> valve body to<br />

identify <strong>the</strong> current alignment.<br />

Drive shaft<br />

Coupling unit<br />

Pressure adjustment nut mark<br />

Valve body mark<br />

CAUTION Do not remove <strong>the</strong> coupling unit<br />

from <strong>the</strong> drive shaft of <strong>the</strong> injection valve. If you<br />

do remove <strong>the</strong> coupling unit, return <strong>the</strong> valve to<br />

Thermo Fisher Scientific for realignment.<br />

3. Using a 9/64-in. hex wrench, remove <strong>the</strong> three socket head cap<br />

screws that secure <strong>the</strong> stator to <strong>the</strong> valve.<br />

3<br />

2<br />

1<br />

4<br />

5<br />

6<br />

Socket head<br />

cap screws<br />

CAUTION The polished (sealing) surface of <strong>the</strong><br />

stator contains six easily damaged ports. Avoid<br />

touching this polished surface as you remove <strong>the</strong><br />

stator from <strong>the</strong> injection valve. Do not place <strong>the</strong><br />

polished surface face down on a hard surface.

4. Pull <strong>the</strong> stator off <strong>the</strong> valve. Place it on its side on a clean surface.<br />

5. If <strong>the</strong> polished surface of <strong>the</strong> stator is scratched, replace <strong>the</strong> valve.<br />

6. Pull <strong>the</strong> stator ring off <strong>the</strong> valve.<br />

7. Pull <strong>the</strong> rotor seal off <strong>the</strong> three pins on <strong>the</strong> drive shaft.<br />

8. Inspect <strong>the</strong> valve components for contamination. Clean as<br />

necessary.<br />

Installing a New <strong>Rotor</strong> <strong>Seal</strong><br />

To install a new rotor seal<br />

Hold <strong>the</strong> rotor seal with <strong>the</strong> engraved flow passages facing away<br />

from <strong>the</strong> drive shaft and mount <strong>the</strong> rotor seal onto <strong>the</strong> drive<br />

shaft’s three alignment pins. The pins align with <strong>the</strong> rotor seal in<br />

only one way.<br />

Reassembling <strong>the</strong> Injection Valve<br />

To reassemble <strong>the</strong> injection valve<br />

1. Ensure that <strong>the</strong> drive shaft stop pin is positioned within <strong>the</strong> slot<br />

in <strong>the</strong> valve body.<br />

2. To mount <strong>the</strong> stator ring onto <strong>the</strong> valve body, align <strong>the</strong> body<br />

locating pin with <strong>the</strong> alignment hole in <strong>the</strong> valve body. Then<br />

insert <strong>the</strong> body locating pin into <strong>the</strong> alignment hole.<br />

Log ID<br />

sticker<br />

Drive shaft<br />

stop pin<br />

7715-00<br />

P/N<br />

Polished sealing surface<br />

Alignment hole<br />

<strong>Rotor</strong> seal with three grooves<br />

Alignment pins (for rotor seal)<br />

Stator ring<br />

Body locating pin<br />

Alignment hole in <strong>the</strong><br />

valve body<br />

Valve body<br />

3. To mount <strong>the</strong> stator onto <strong>the</strong> stator ring, hold <strong>the</strong> stator with its<br />

polished surface facing <strong>the</strong> stator ring. Align <strong>the</strong> alignment hole<br />

in <strong>the</strong> stator with <strong>the</strong> stator locating pin on <strong>the</strong> stator ring. Then<br />

insert <strong>the</strong> locating pin into <strong>the</strong> alignment hole.<br />

2<br />

Alignment<br />

hole in <strong>the</strong><br />

stator<br />

Stator locating<br />

pin<br />

7715-00<br />

P/N<br />

25 µL<br />

Socket head<br />

cap screws (3x)<br />

Stator ring<br />

4. Insert <strong>the</strong> three socket head cap screws into <strong>the</strong> stator.<br />

5. Using a 9/64-in. hex wrench, tighten each screw a little at a time,<br />

keeping <strong>the</strong> stator surface parallel to <strong>the</strong> stator ring surface.<br />

6. If you have an adjustable torque wrench with a 1/4-in. shaft and a<br />

hex driver attachment, evenly torque <strong>the</strong> three socket head cap<br />

screws to 20 inch-pounds.<br />

Reinstalling <strong>the</strong> Valve and Checking for Leaks<br />

To reinstall <strong>the</strong> injection valve and check for leaks<br />

1. Align <strong>the</strong> holes in <strong>the</strong> valve plate with <strong>the</strong> two small holes to <strong>the</strong><br />

left and right of <strong>the</strong> valve receptacle, and <strong>the</strong>n insert <strong>the</strong> valve<br />

drive shaft into <strong>the</strong> valve receptacle.<br />

20 µL<br />

Valve receptacle<br />

2. Using a #2 Phillips screwdriver, tighten <strong>the</strong> screws that secure <strong>the</strong><br />

valve to <strong>the</strong> autosampler.<br />

3. Reconnect <strong>the</strong> transfer tubing to port 2 and <strong>the</strong> waste tubing to<br />

port 3. Hand-tighten <strong>the</strong> fittings.<br />

4. Reconnect <strong>the</strong> heat exchanger outlet to port 5. Hand-tighten <strong>the</strong><br />

fitting, and <strong>the</strong>n tighten <strong>the</strong> fitting an additional 90 degrees<br />

(1/4 turn) with a 1/4-in. open-end wrench.<br />

5. If <strong>the</strong> valve leaks between <strong>the</strong> stator and <strong>the</strong> stator ring, remove<br />

<strong>the</strong> valve from <strong>the</strong> autosampler, and tighten <strong>the</strong> pressure<br />

adjustment nut an additional 30 degrees with a 9/16-in. openend<br />

wrench. Then reinstall <strong>the</strong> valve, and check for leaks.<br />

Pressure<br />

adjustment nut<br />

Pressure adjustment nut<br />

turned 30 degrees