ASTM F732-82 Recip Pin on Flat Joint Prostheses ... - CETR

ASTM F732-82 Recip Pin on Flat Joint Prostheses ... - CETR ASTM F732-82 Recip Pin on Flat Joint Prostheses ... - CETR

Evaluation of Friction and Wear Properties of Polymeric Materials for Use in Total Joint Prostheses Using Micro-Tribometer mod. CETR-UMT 2

Evaluati<strong>on</strong> of Fricti<strong>on</strong> and Wear Properties of Polymeric Materials for Use in<br />

Total <strong>Joint</strong> <strong>Prostheses</strong> Using Micro-Tribometer mod. <strong>CETR</strong>-UMT 2<br />

<str<strong>on</strong>g>ASTM</str<strong>on</strong>g> <str<strong>on</strong>g>F732</str<strong>on</strong>g>-<str<strong>on</strong>g>82</str<strong>on</strong>g> (reapproved 1991)<br />

Summary of Test Method:<br />

This test method is used to evaluate the fricti<strong>on</strong> and wear properties of combinati<strong>on</strong>s of materials that are<br />

being c<strong>on</strong>sidered for use as the bearing surfaces of human total joint replacement prostheses. The test method<br />

utilizes a flat-ended polymer cylinder upper specimen and a flat stainless steel lower counterface that is<br />

immersed in bovine blood serum. The load is applied downward <strong>on</strong>to the cylinder specimen. The flat lower<br />

specimen slides linearly, back and forth under the cylinder specimen. The test parameters are listed below.<br />

Test Parameters<br />

Lubricant Temperature Applied Load Stroke Length Osc. Frequency Durati<strong>on</strong><br />

Bovine blood serum 37º C 225 N 1 inch 1.0 Hz 70 hrs.<br />

Polymer Specimen: length 13 mm, diameter 9 mm.<br />

Counterface surface finish: 0.026 to 0.05 µm.<br />

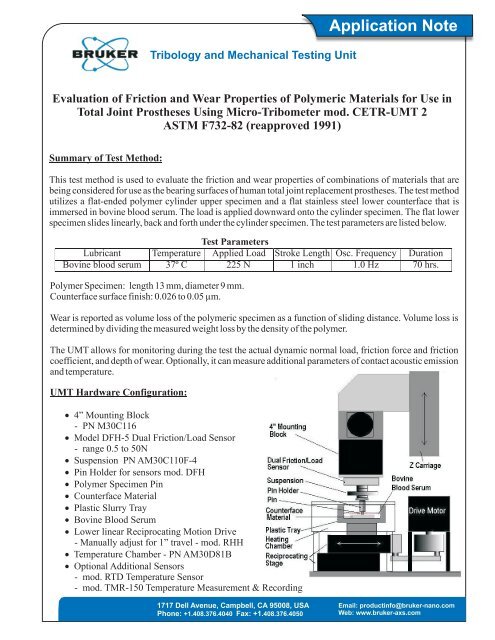

UMT Hardware C<strong>on</strong>figurati<strong>on</strong>:<br />

Tribology and Mechanical Testing Unit<br />

Wear is reported as volume loss of the polymeric specimen as a functi<strong>on</strong> of sliding distance. Volume loss is<br />

determined by dividing the measured weight loss by the density of the polymer.<br />

The UMT allows for m<strong>on</strong>itoring during the test the actual dynamic normal load, fricti<strong>on</strong> force and fricti<strong>on</strong><br />

coefficient, and depth of wear. Opti<strong>on</strong>ally, it can measure additi<strong>on</strong>al parameters of c<strong>on</strong>tact acoustic emissi<strong>on</strong><br />

and temperature.<br />

4” Mounting Block<br />

- PN M30C116<br />

Model DFH-5 Dual Fricti<strong>on</strong>/Load Sensor<br />

- range 0.5 to 50N<br />

Suspensi<strong>on</strong> PN AM30C110F-4<br />

<str<strong>on</strong>g>Pin</str<strong>on</strong>g> Holder for sensors mod. DFH<br />

Polymer Specimen <str<strong>on</strong>g>Pin</str<strong>on</strong>g><br />

Counterface Material<br />

Plastic Slurry Tray<br />

Bovine Blood Serum<br />

Lower linear <str<strong>on</strong>g>Recip</str<strong>on</strong>g>rocating Moti<strong>on</strong> Drive<br />

- Manually adjust for 1” travel - mod. RHH<br />

Temperature Chamber - PN AM30D81B<br />

Opti<strong>on</strong>al Additi<strong>on</strong>al Sensors<br />

- mod. RTD Temperature Sensor<br />

- mod. TMR-150 Temperature Measurement & Recording<br />

1717 Dell Avenue, Campbell, CA 95008, USA<br />

Ph<strong>on</strong>e: +1.408.376.4040 Fax: +1.408.376.4050<br />

Applicati<strong>on</strong> Note<br />

Email: productinfo@bruker-nano.com<br />

Web: www.bruker-axs.com

Applicati<strong>on</strong> Note<br />

UMT Software Test Setup:<br />

UMT Opti<strong>on</strong>s File:<br />

Load the opti<strong>on</strong>s file which c<strong>on</strong>tains settings for the Linear <str<strong>on</strong>g>Recip</str<strong>on</strong>g>rocating Moti<strong>on</strong> drive and the 500 N force/load<br />

sensor.<br />

Test Sequence:<br />

The Test Sequence should c<strong>on</strong>sist of 2 sheets.<br />

Sheet 1 is for settling time for the carriage to establish the initial normal load.<br />

Carriage - applies a 225 N C<strong>on</strong>stant Force for a Durati<strong>on</strong> of 10 sec.<br />

Spindle Velocity is 0 revs/min.<br />

Slider is idle.<br />

Sheet 2 is for the actual sliding test.<br />

Carriage - applies a 225 N C<strong>on</strong>stant Force for a Durati<strong>on</strong> of 70 hours.<br />

Spindle Velocity is 60 revs/min, Move-C<strong>on</strong>tinuous, and Directi<strong>on</strong>- Clockwise<br />

Slider is idle.<br />

Data Collecti<strong>on</strong>:<br />

The following should be checked under DataFile:<br />

Fx Fricti<strong>on</strong> Force<br />

Fz Normal Force<br />

T Time<br />

Z1 Carriage Positi<strong>on</strong> (Used to determine Wear Depth)<br />

Te input Temperature (opti<strong>on</strong>al)<br />

Report:<br />

Use the Viewer program to plot test results.<br />

Select the parameters to be displayed by checking<br />

the appropriate box under Parameters <strong>on</strong> the Viewer screen.<br />

For viewing COF plots of reciprocating tests check the Fz box, click <strong>on</strong> the Symmetry butt<strong>on</strong>, click <strong>on</strong> the Peak Detect<br />

butt<strong>on</strong>, and then check the COF box.<br />

Multiple test results can be viewed at the same time as in the example below.<br />

Page 2<br />

Tribology and Mechanical Testing Unit<br />

1717 Dell Avenue, Campbell, CA 95008, USA<br />

Ph<strong>on</strong>e: +1.408.376.4040 Fax: +1.408.376.4050<br />

Email: productinfo@bruker-nano.com<br />

Web: www.bruker-axs.com