Making a Round-Headed Pin (on Lathe Machine) - New Age ...

Making a Round-Headed Pin (on Lathe Machine) - New Age ... Making a Round-Headed Pin (on Lathe Machine) - New Age ...

Job No.: ME292/01 Date of Commencement: __________ Date of Submission: ______ INTRODUCTION 1

- Page 2 and 3: Job No.: ME292/01 Date of Commencem

- Page 4 and 5: Job No.: ME292/01 Date of Submissio

- Page 6 and 7: Job No.: ME292/01 Date of Submissio

- Page 8 and 9: Job No.: ME292/01 Date of Submissio

- Page 10 and 11: Job No.: ME292/02 Date of Commencem

- Page 12 and 13: Job No.: ME292/02 Date of Commencem

- Page 14 and 15: Job No.: ME292/02 Date of Submissio

- Page 16 and 17: Job No.: ME292/02 Date of Submissio

- Page 18 and 19: Job No.: ME292/03 Date of Commencem

- Page 20 and 21: Job No.: ME292/03 Date of Submissio

- Page 22 and 23: Job No.: ME292/03 Date of Submissio

- Page 24 and 25: Job No.: ME292/04 Date of Commencem

- Page 26 and 27: Job No.: ME292/04 Date of Commencem

- Page 28 and 29: Job No.: ME292/04 Date of Submissio

- Page 30 and 31: Job No.: ME292/04 Date of Submissio

- Page 32 and 33: Job No.: ME292/05 Date of Commencem

- Page 34 and 35: Job No.: ME292/05 Date of Submissio

- Page 36 and 37: Job No.: ME292/06 Date of Commencem

- Page 38 and 39: Job No.: ME292/06 Date of Commencem

- Page 40 and 41: Job No.: ME292/06 Date of Submissio

- Page 42 and 43: Job No.: ME292/06 Date of Submissio

- Page 44: Job No.: ME292/06 Date of Submissio

Job No.: ME292/01<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

INTRODUCTION<br />

1<br />

<str<strong>on</strong>g>Making</str<strong>on</strong>g> a <str<strong>on</strong>g>Round</str<strong>on</strong>g>-<str<strong>on</strong>g>Headed</str<strong>on</strong>g> <str<strong>on</strong>g>Pin</str<strong>on</strong>g><br />

(<strong>on</strong> <strong>Lathe</strong> <strong>Machine</strong>)<br />

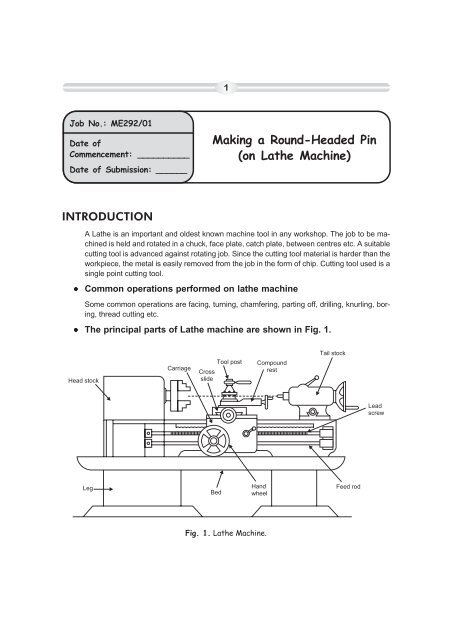

A <strong>Lathe</strong> is an important and oldest known machine tool in any workshop. The job to be machined<br />

is held and rotated in a chuck, face plate, catch plate, between centres etc. A suitable<br />

cutting tool is advanced against rotating job. Since the cutting tool material is harder than the<br />

workpiece, the metal is easily removed from the job in the form of chip. Cutting tool used is a<br />

single point cutting tool.<br />

• Comm<strong>on</strong> operati<strong>on</strong>s performed <strong>on</strong> lathe machine<br />

Some comm<strong>on</strong> operati<strong>on</strong>s are facing, turning, chamfering, parting off, drilling, knurling, boring,<br />

thread cutting etc.<br />

• The principal parts of <strong>Lathe</strong> machine are shown in Fig. 1.<br />

Head stock<br />

Leg<br />

Carriage<br />

Tool post<br />

Cross<br />

slide<br />

Bed<br />

Compound<br />

rest<br />

Hand<br />

wheel<br />

Fig. 1. <strong>Lathe</strong> <strong>Machine</strong>.<br />

Tail stock<br />

Feed rod<br />

Lead<br />

screw

Job No.: ME292/01<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

SCHEMATIC DIAGRAM<br />

Raw material: Mild steel bar of φ 35 mm<br />

All dimensi<strong>on</strong>s are in mm.<br />

Drawing: Not to scale.<br />

2 × 45°<br />

75<br />

25<br />

2<br />

<str<strong>on</strong>g>Making</str<strong>on</strong>g> a <str<strong>on</strong>g>Round</str<strong>on</strong>g>-<str<strong>on</strong>g>Headed</str<strong>on</strong>g> <str<strong>on</strong>g>Pin</str<strong>on</strong>g><br />

(<strong>on</strong> <strong>Lathe</strong> <strong>Machine</strong>)<br />

20<br />

Fig. 2<br />

TOOLS AND ACCESSORIES REQUIRED<br />

(i) <strong>Lathe</strong> <strong>Machine</strong><br />

(ii) 3-jaw Chuck<br />

(iii) Facing Tool<br />

(iv) Turning Tool<br />

(v) Chamfering Tool<br />

(vi) Marking and Measuring Tool<br />

f33

Job No.: ME292/01<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

(vii) Odd leg Caliper<br />

(viii) Outside Caliper<br />

(ix) Combinati<strong>on</strong> Drill<br />

(x) <strong>Lathe</strong> Dog<br />

PROCEDURE<br />

(i) Select the speed, feed and depth of cut for different operati<strong>on</strong>s.<br />

(ii) Load the job <strong>on</strong> three-jaw chuck.<br />

3<br />

(iii) Perform facing operati<strong>on</strong> <strong>on</strong> both ends of the job <strong>on</strong>e after another by a facing tool.<br />

(iv) Perform centre drilling operati<strong>on</strong> <strong>on</strong> both ends of the job by a combinati<strong>on</strong> drill.<br />

(v) Hold the job between centres using <strong>Lathe</strong> dog.<br />

(vi) Turn the job to reduce diameter to φ 25 mm over a length of 75 mm and to φ 33 mm over<br />

a length of 25 mm by a turning tool.<br />

(vii) Chamfer <strong>on</strong>e end by chamfering tool.<br />

(viii) Check the dimensi<strong>on</strong>s.<br />

DISCUSSIONS/CONCLUSIONS<br />

<str<strong>on</strong>g>Making</str<strong>on</strong>g> a <str<strong>on</strong>g>Round</str<strong>on</strong>g>-<str<strong>on</strong>g>Headed</str<strong>on</strong>g> <str<strong>on</strong>g>Pin</str<strong>on</strong>g><br />

(<strong>on</strong> <strong>Lathe</strong> <strong>Machine</strong>)<br />

Write your comments <strong>on</strong> the dimensi<strong>on</strong>s and quality of the job obtained and discuss about the<br />

discrepancies or errors, if any.<br />

Signature of the Teacher

Job No.: ME292/01<br />

Date of Submissi<strong>on</strong>:<br />

1. What is a machine tool?<br />

2. How is a lathe specified?<br />

4<br />

Assignments <strong>on</strong> <strong>Lathe</strong> <strong>Machine</strong><br />

Signature of the Teacher

Job No.: ME292/01<br />

Date of Submissi<strong>on</strong>:<br />

3. Explain the terms: cutting speed, feed, depth of cut in relati<strong>on</strong> to turning.<br />

4. Which materials are comm<strong>on</strong>ly used as cutting tool material?<br />

5<br />

Assignments <strong>on</strong> <strong>Lathe</strong> <strong>Machine</strong><br />

Signature of the Teacher

Job No.: ME292/01<br />

Date of Submissi<strong>on</strong>:<br />

5. Write functi<strong>on</strong>s of lead screw and feed rod of a lathe machine.<br />

6<br />

Assignments <strong>on</strong> <strong>Lathe</strong> <strong>Machine</strong><br />

6. Name and explain five operati<strong>on</strong>s that can be performed <strong>on</strong> a lathe machine.<br />

Signature of the Teacher

Job No.: ME292/01<br />

Date of Submissi<strong>on</strong>:<br />

1. What is a machine tool?<br />

2. How is a lathe specified?<br />

7<br />

Assignments <strong>on</strong> <strong>Lathe</strong> <strong>Machine</strong><br />

Signature of the Teacher

Job No.: ME292/01<br />

Date of Submissi<strong>on</strong>:<br />

3. Explain the terms: cutting speed, feed, depth of cut in relati<strong>on</strong> to turning.<br />

4. Which materials are comm<strong>on</strong>ly used as cutting tool material?<br />

8<br />

Assignments <strong>on</strong> <strong>Lathe</strong> <strong>Machine</strong><br />

Signature of the Teacher

Job No.: ME292/01<br />

Date of Submissi<strong>on</strong>:<br />

5. Write functi<strong>on</strong>s of lead screw and feed rod of a lathe machine.<br />

6. Name and explain five operati<strong>on</strong>s that can be performed <strong>on</strong> a lathe machine.<br />

9<br />

Assignments <strong>on</strong> <strong>Lathe</strong> <strong>Machine</strong><br />

Signature of the Teacher

Job No.: ME292/02<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

INTRODUCTION<br />

10<br />

<str<strong>on</strong>g>Making</str<strong>on</strong>g> a Square Bar from a<br />

<str<strong>on</strong>g>Round</str<strong>on</strong>g> Bar (<strong>on</strong> Milling <strong>Machine</strong>)<br />

Milling machine is a machine tool in which metal is removed by means of a rotating cutter with<br />

multiple number of teeth (or multipoint). Each teeth has cutting edge which removes metal<br />

from workpiece.<br />

The feed and depth of cut to the job is provided by feeding the job to the cutter, l<strong>on</strong>gitudinally,<br />

transversely or vertically.<br />

• Up Milling and Down Milling<br />

When cutter rotates against the directi<strong>on</strong> of feed of job then it is called Up or C<strong>on</strong>venti<strong>on</strong>al<br />

milling.<br />

When cutter rotates in the same directi<strong>on</strong> as feed of job then it is called Down milling/Climb<br />

milling.<br />

• Comm<strong>on</strong> operati<strong>on</strong>s performed <strong>on</strong> Milling <strong>Machine</strong><br />

Plain milling, Face milling, Angular milling, Gear milling, Form milling, Milling slots, Keyways<br />

etc.<br />

• Principal parts of Milling machine are shown in Fig. 3.<br />

Column<br />

Motor<br />

Overarm<br />

Knee<br />

Elevating screw<br />

Fig. 3. Milling <strong>Machine</strong>.<br />

Milling cutter<br />

Arbor<br />

Table<br />

Saddle<br />

Base

Job No.: ME292/02<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

SCHEMATIC DIAGRAM<br />

Raw Material: Mild steel bar of φ 35 mm.<br />

All dimensi<strong>on</strong>s are in mm.<br />

Drawing: Not to scale (NTS).<br />

60<br />

11<br />

<str<strong>on</strong>g>Making</str<strong>on</strong>g> a Square Bar from a<br />

<str<strong>on</strong>g>Round</str<strong>on</strong>g> Bar (<strong>on</strong> Milling <strong>Machine</strong>)<br />

Fig. 4<br />

f 35<br />

TOOLS AND ACCESSORIES REQUIRED<br />

(i) Milling <strong>Machine</strong><br />

(ii) Vice/Clamping Device<br />

f 35

Job No.: ME292/02<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

(iii) Cylindrical Milling Cutter (Plain)<br />

(iv) Surface Plate, Gauge<br />

(v) Hammer, Try Square, V-Block, Punch<br />

PROCEDURE<br />

12<br />

(i) Select speed, feed, depth of cut of milling machine for operati<strong>on</strong>.<br />

(ii) Mark both ends of round bar as per the dimensi<strong>on</strong> required by using V-block, Surface<br />

gauge, Surface plate, Try square etc.<br />

(iii) Make the mark permanent by punch and hammer.<br />

(iv) Load the job <strong>on</strong> machine vice, keeping its axis perpendicular to the axis of cutter. Take<br />

help of surface gauge to set the job properly.<br />

(v) Remove material from the surface of job to produce <strong>on</strong>e plane of square bar to be produced.<br />

(vi) After completi<strong>on</strong> of <strong>on</strong>e plane follow the same procedure to cut other three planes.<br />

(vii) Check dimensi<strong>on</strong>s of job.<br />

DISCUSSIONS/CONCLUSIONS<br />

<str<strong>on</strong>g>Making</str<strong>on</strong>g> a Square Bar from a<br />

<str<strong>on</strong>g>Round</str<strong>on</strong>g> Bar (<strong>on</strong> Milling <strong>Machine</strong>)<br />

Write your comments <strong>on</strong> the dimensi<strong>on</strong>s and quality of the job obtained and discuss about<br />

dimensi<strong>on</strong>al errors, if any.<br />

Signature of the Teacher

Job No.: ME292/02<br />

Date of Submissi<strong>on</strong>:<br />

1. How is a milling machine specified?<br />

13<br />

2. Differentiate between Up milling and Down milling.<br />

Assignments<br />

(<strong>on</strong> Milling <strong>Machine</strong>)<br />

Signature of the Teacher

Job No.: ME292/02<br />

Date of Submissi<strong>on</strong>:<br />

14<br />

3. Name few cutters used in milling machine.<br />

Assignments<br />

(<strong>on</strong> Milling <strong>Machine</strong>)<br />

Signature of the Teacher

Job No.: ME292/02<br />

Date of Submissi<strong>on</strong>:<br />

1. How is a milling machine specified?<br />

15<br />

2. Differentiate between Up milling and Down milling.<br />

Assignments<br />

(<strong>on</strong> Milling <strong>Machine</strong>)<br />

Signature of the Teacher

Job No.: ME292/02<br />

Date of Submissi<strong>on</strong>:<br />

3. Name few cutters used in milling machine.<br />

16<br />

Assignments<br />

(<strong>on</strong> Milling <strong>Machine</strong>)<br />

Signature of the Teacher

Job No.: ME292/03<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

INTRODUCTION<br />

17<br />

<str<strong>on</strong>g>Making</str<strong>on</strong>g> a V-Block<br />

(<strong>on</strong> Shaper)<br />

Shaper is a reciprocating type machine tool which is primarily intended to produce flat surfaces.<br />

The surfaces may be horiz<strong>on</strong>tal, vertical <strong>on</strong> inclined. This machine involves the use of<br />

a single point cutting tool similar to a tool used in lathe machine.<br />

Tool is held in the tool post mounted at the end of ram. Workpiece is held in a vice or clamed<br />

directly <strong>on</strong> table. The ram reciprocates in to and fro directi<strong>on</strong> and cutting of material takes<br />

place during forward stroke while the return stroke is idle. Return stroke time is less as compared<br />

to forward stroke and this is obtained by a quick return mechanism. Feed is provided by<br />

moving job relative to tool in a directi<strong>on</strong> perpendicular to the movement of ram. Depth of cut is<br />

adjusted by moving tool downward towards the workpiece.<br />

• Principal parts of a Shaper machine are shown in Fig. 5.<br />

Table<br />

Base<br />

Clapper box<br />

Tool post<br />

Cross rail<br />

Tool<br />

Lock<br />

Fig. 5. Shaper <strong>Machine</strong>.<br />

Body<br />

Ram<br />

Motor and drive system

Job No.: ME292/03<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

SCHEMATIC DIAGRAM<br />

18<br />

Raw material: Cast ir<strong>on</strong> block—50 mm × 50 mm × 50 mm.<br />

All dimensi<strong>on</strong>s are in mm.<br />

Drawing: Not to scale (NTS).<br />

10<br />

10<br />

4 20<br />

25<br />

45<br />

10<br />

45<br />

45<br />

Fig. 6<br />

TOOLS AND ACCESSORIES REQUIRED<br />

(i) Shaper<br />

(ii) <strong>Machine</strong> Vice/Clamping Device<br />

(iii) Surface Plate<br />

<str<strong>on</strong>g>Making</str<strong>on</strong>g> a V-Block<br />

(<strong>on</strong> Shaper)

Job No.: ME292/03<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

(iv) Try square, Surface gauge<br />

(v) Scriber, Punch, Hammer<br />

(vi) Cutter<br />

PROCEDURE<br />

19<br />

(i) Select stroke length, speed, feed and depth of cut.<br />

(ii) Load the job <strong>on</strong> machine vice.<br />

(iii) Remove material from <strong>on</strong>e face to make it plain.<br />

<str<strong>on</strong>g>Making</str<strong>on</strong>g> a V-Block<br />

(<strong>on</strong> Shaper)<br />

(iv) By following above procedure remove material from other five surfaces, obtain a block of<br />

dimensi<strong>on</strong>s 45 mm × 45 mm × 45 mm.<br />

(v) Check corners by Try square to ensure that all three edges from corner are perpendicular<br />

to each other.<br />

(vi) Unload the job from machine.<br />

(vii) Mark the job as per drawing using surface plate, gauge, scale, scriber etc.<br />

(viii) Make the mark permanent by punch and hammer.<br />

(ix) Again load the job <strong>on</strong> vice.<br />

(x) Remove material to produce V-shape by titling the tool to required angle of inclinati<strong>on</strong>.<br />

(xi) Cut a slot at the bottom of V groove.<br />

(x) Cut another slot at the bottom of block.<br />

(xi) Measure dimensi<strong>on</strong>s of job.<br />

DISCUSSIONS/CONCLUSIONS<br />

Write your comments <strong>on</strong> dimensi<strong>on</strong>al error and surface quality of job obtained and discuss<br />

the reas<strong>on</strong>s of dimensi<strong>on</strong>al errors, if any.

Job No.: ME292/03<br />

Date of Submissi<strong>on</strong>:<br />

1. How is a shaper specified?<br />

2. Explain the functi<strong>on</strong> of Clapper box.<br />

20<br />

Assignments <strong>on</strong> Shaper<br />

Signature of the Teacher

Job No.: ME292/03<br />

Date of Submissi<strong>on</strong>:<br />

3. What are the different types of quick return mechanism used in Shaper machine?<br />

21<br />

4. Explain any <strong>on</strong>e quick return mechanism with a neat sketch.<br />

Assignments <strong>on</strong> Shaper<br />

Signature of the Teacher

Job No.: ME292/03<br />

Date of Submissi<strong>on</strong>:<br />

1. How is a shaper specified?<br />

2. Explain the functi<strong>on</strong> of Clapper box.<br />

22<br />

Assignments <strong>on</strong> Shaper<br />

Signature of the Teacher

Job No.: ME292/03<br />

Date of Submissi<strong>on</strong>:<br />

3. What are the different types of quick return mechanism used in Shaper machine?<br />

23<br />

4. Explain any <strong>on</strong>e quick return mechanism with a neat sketch.<br />

Assignments <strong>on</strong> Shaper<br />

Signature of the Teacher

Job No.: ME292/04<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

INTRODUCTION<br />

• Drilling <strong>Machine</strong><br />

24<br />

Drilling machine is used to produce or generate a round hole in the workpiece. The tool used<br />

for drilling holes is called Drill. The Drill is placed in the chuck of the machine which rotates<br />

about its axis. The linear moti<strong>on</strong> is given to the drill towards the workpiece.<br />

• Taps<br />

A tap is a tool used for making internal threads. The taps are provided with cutting edges and<br />

three or four flutes cut across it, so that when it is screwed into a hole, it cuts an internal<br />

thread. These are made in sets of three. First use taper tap, then medium tap and then<br />

bottoming or plug tap. These are made of high carb<strong>on</strong> steel or high speed steel and hardened<br />

and tempered.<br />

OPERATIONS PERFORMED ON DRILLING MACHINE<br />

The comm<strong>on</strong> operati<strong>on</strong>s performed <strong>on</strong> drilling machine are drilling, boring, reaming, tapping,<br />

counter boring etc.<br />

Principal parts of the drilling machine are shown in Fig. 7.<br />

Pulley<br />

Hand wheel<br />

Sleeve<br />

Spindle<br />

Drill bit<br />

Table<br />

Drilling Three Holes and<br />

Cutting BSW Thread<br />

(Drilling and Tapping)<br />

Belt<br />

Fig. 7. Drilling <strong>Machine</strong>.<br />

Column<br />

Motor<br />

Base

Job No.: ME292/04<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

SCHEMATIC DIAGRAM<br />

25<br />

Drilling Three Holes and<br />

Cutting BSW Thread<br />

(Drilling and Tapping)<br />

Raw Material: Mild steel plate of dimensi<strong>on</strong> 80 mm × 50 mm × 10 mm.<br />

All dimeni<strong>on</strong>s are in mm.<br />

Drawing: Not to scale.<br />

25<br />

15<br />

f 5<br />

9/16 BSW<br />

25 25 15<br />

Fig. 8<br />

TOOLS AND ACCESSORIES REQUIRED<br />

(i) Drilling <strong>Machine</strong><br />

(ii) Drills of size 5 mm and 12 mm<br />

(iii) Bench Vice<br />

f 5<br />

10<br />

50

Job No.: ME292/04<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

26<br />

Drilling Three Holes and<br />

Cutting BSW Thread<br />

(Drilling and Tapping)<br />

(iv) Try Square, Steel Rule, Centre Punch, Hammer, Surface Plate, Odd leg Caliper<br />

(v) BSW tap set<br />

(vi) Tap Wrench<br />

(vii) File<br />

(viii) Tool maker’s Vice<br />

(ix) Odd leg Caliper<br />

PROCEDURE<br />

(i) Clamp the workpiece in bench vice and file sides of the workpiece by flat file.<br />

(ii) Check corners by try square.<br />

(iii) Mark centre of holes to be produced as per drawing using surface plate, odd leg caliper.<br />

(iv) Make the marking permanent by punch and hammer.<br />

(v) Load the workpiece in tool maker vice <strong>on</strong> drilling machine table.<br />

(vi) Clamp the required drill and produce 2 holes of diameter 5 mm and 1 hole of diameter φ<br />

12 mm. Apply cutting oil during operati<strong>on</strong>.<br />

(vii) Unload the job from machine table.<br />

(viii) Load the job <strong>on</strong> bench vice.<br />

(ix) Fix the taper top in tap wrench and insert taper tap into the hole of φ 12 mm positi<strong>on</strong>ed<br />

perpendicular to the surface of the job.<br />

(x) Cut the thread by rotating the top wrench in clockwise directi<strong>on</strong> by applying a little downward<br />

force <strong>on</strong> it.<br />

(ix) Use medium tap and fine tap to complete the thread.<br />

DISCUSSIONS/CONCLUSIONS<br />

Write your comments <strong>on</strong> dimensi<strong>on</strong>al error and surface quality of job obtained and discuss<br />

about reas<strong>on</strong>s of dimensi<strong>on</strong>al errors, if any.

Job No.: ME292/04<br />

Date of Submissi<strong>on</strong>:<br />

1. How do you specify a drilling machine?<br />

27<br />

Assignments <strong>on</strong> Drilling<br />

and Tapping<br />

2. Draw the sketch of a taper shank twist drill and show its different parts.<br />

Signature of the Teacher

Job No.: ME292/04<br />

Date of Submissi<strong>on</strong>:<br />

28<br />

3. What are the comm<strong>on</strong>ly used drill bit materials?<br />

Assignments <strong>on</strong> Drilling<br />

and Tapping<br />

4. Name and explain different taps used to cut internal thread with neat sketch.<br />

Signature of the Teacher

Job No.: ME292/04<br />

Date of Submissi<strong>on</strong>:<br />

1. How do you specify a drilling machine?<br />

29<br />

Assignments <strong>on</strong> Drilling<br />

and Tapping<br />

2. Draw the sketch of a taper shank twist drill and show its different parts.<br />

Signature of the Teacher

Job No.: ME292/04<br />

Date of Submissi<strong>on</strong>:<br />

30<br />

3. What are the comm<strong>on</strong>ly used drill bit materials?<br />

Assignments <strong>on</strong> Drilling<br />

and Tapping<br />

4. Name and explain different taps used to cut internal thread with neat sketch.<br />

Signature of the Teacher

Job No.: ME292/05<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

INTRODUCTION<br />

31<br />

Grinding Four Corners of<br />

Job No. ME292/04 (Grinding)<br />

Grinding is generally called as finishing operati<strong>on</strong> which removes material from the surface of<br />

the job by means of a rotating grind wheel. Grinding is useful in removing unwanted material<br />

from workpiece, rounding corners of workpiece, sharpening cutting tools etc.<br />

In grinding, the work is held pressed against the high speed rotating grinding wheel to remove<br />

material by abrasi<strong>on</strong>.<br />

Grinding wheel is generally made from abrasives (like silic<strong>on</strong> carbide, aluminium oxide etc)<br />

embedded in the b<strong>on</strong>d (like Resinoid, Rubber, Vitrified etc).<br />

Different parts of a bench Grinder are shown in Fig. 9.<br />

Motor Grinding wheel<br />

Fig. 9. Grinding <strong>Machine</strong>.<br />

Base<br />

Work rest

Job No.: ME292/05<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

SCHEMATIC DIAGRAM<br />

Raw material: Job No. ME292/04.<br />

All dimensi<strong>on</strong>s are in mm.<br />

Drawing: Not to scale (NTS).<br />

R12<br />

32<br />

R5 R12<br />

Grinding Four Corners of<br />

Job No. ME292/04 (Grinding)<br />

Fig. 10<br />

TOOLS AND ACCESSORIES REQUIRED<br />

(i) Steel Rule<br />

(ii) Odd Leg Caliper<br />

R5

Job No.: ME292/05<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

(iii) Divider<br />

(iv) Surface Plate<br />

(v) Centre Punch<br />

(vi) Ball Peen Hammer<br />

(vii) Bench Grinder<br />

PROCEDURE<br />

33<br />

Grinding Four Corners of<br />

Job No. ME292/04 (Grinding)<br />

(i) Place the job <strong>on</strong> the surface plate and locate four centres of arc to be produced by grinding<br />

as per drawing.<br />

(ii) Mark centres by centre punch and hammer<br />

(iii) Draw arcs from centres with required radii by divider.<br />

(iv) Make some punch mark <strong>on</strong> arcs.<br />

(v) Hold the job tightly by both hands/t<strong>on</strong>gs and press it against the rotating grinding wheel to<br />

produce round corners as per drawing.<br />

DISCUSSIONS/CONCLUSIONS<br />

Write comments <strong>on</strong> dimensi<strong>on</strong>al error and surface quality of job obtained and discuss about<br />

the probable reas<strong>on</strong>s of dimensi<strong>on</strong>al error, if any.<br />

Signature of the Teacher

Job No.: ME292/05<br />

Date of Submissi<strong>on</strong>:<br />

1. Write short notes <strong>on</strong><br />

(a) Rough Grinding<br />

(b) Precisi<strong>on</strong> Grinding<br />

2. How is a grinding wheel specified?<br />

34<br />

Assignments <strong>on</strong> Grinder<br />

Signature of the Teacher

Job No.: ME292/05<br />

Date of Submissi<strong>on</strong>:<br />

1. Write short notes <strong>on</strong><br />

(a) Rough Grinding<br />

(b) Precisi<strong>on</strong> Grinding<br />

2. How is a grinding wheel specified?<br />

35<br />

Assignments <strong>on</strong> Grinder<br />

Signature of the Teacher

Job No.: ME292/06<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

INTRODUCTION<br />

36<br />

<str<strong>on</strong>g>Making</str<strong>on</strong>g> a Rectangular Tray<br />

(Tin Smithy and Soldering)<br />

Working of thin metallic sheets with the help of hand tools and some simple machines is<br />

known as sheet metal work. It is very important to know that for efficiently working in sheet<br />

metal <strong>on</strong>e should have knowledge about c<strong>on</strong>structi<strong>on</strong>al features and working principle of<br />

hand tools and machines. Also it is necessary to have knowledge of development of surfaces,<br />

properties of metal sheets etc.<br />

Many engineering articles made of sheet metal find their applicati<strong>on</strong> in decorative articles,<br />

machinery, household products etc.<br />

Types of Sheet Metal<br />

Galvanised Sheets<br />

(Coated)<br />

Ferrous Sheets<br />

Sheet metal Working <strong>Machine</strong>s<br />

Sheets<br />

Plain Sheets<br />

(Uncoated)<br />

<strong>Machine</strong>s generally used to carry out different sheet metal operati<strong>on</strong>s are:<br />

N<strong>on</strong>-Ferrous Sheets<br />

Rolling and bending machine, cutting machine, grooving machine, shearing machine, swaging<br />

machine etc.<br />

Sheet Metal Joints<br />

Many different types of joints are used in sheet metal work. Comm<strong>on</strong>ly used form of joints are<br />

lap joint, seam joint, hem (single, double), wired edge, cup etc.

Job No.: ME292/06<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

Soldering<br />

37<br />

<str<strong>on</strong>g>Making</str<strong>on</strong>g> a Rectangular Tray<br />

(Tin Smithy and Soldering)<br />

It is a process of joining two or more metals by applicati<strong>on</strong> of a low melting point temperature<br />

alloy called solder in liquid state. Solder is essentialy <strong>on</strong> alloy of lead and tin. it is widely used<br />

in sheet metal work, electr<strong>on</strong>ic circuit etc.<br />

SCHEMATIC DIAGRAM<br />

120<br />

50<br />

Raw Material: G.I. sheet (26 SWG), G.I. wire φ 3 mm.<br />

Drawing: Not to scale (NTS).<br />

10<br />

200 50<br />

Fig. 11. Layout of job. Fig. 12. Job.<br />

TOOLS AND ACCESSORIES REQUIRED<br />

(i) Mallet<br />

(ii) Ball peen hammer<br />

10<br />

15

Job No.: ME292/06<br />

Date of<br />

Commencement: __________<br />

Date of Submissi<strong>on</strong>: ______<br />

(iii) Stake<br />

(iv) Snip<br />

(v) Steel Rule<br />

(vi) Steel Square<br />

(vii) Scriber, Divider<br />

(viii) Straight edge soldering ir<strong>on</strong>, Solder.<br />

PROCEDURE<br />

(i) Flaten the metal sheet by mallet.<br />

38<br />

<str<strong>on</strong>g>Making</str<strong>on</strong>g> a Rectangular Tray<br />

(Tin Smithy and Soldering)<br />

(ii) Develop the surface <strong>on</strong> given sheet as per drawing by the help of divider, steel rule, steel<br />

square, scriber etc.<br />

(iii) Cut the sheet as per the lay out.<br />

(iv) Fold and bend different porti<strong>on</strong> as per requirement by stake and mallet.<br />

(v) Make the joints with soldering ir<strong>on</strong> and solder.<br />

(vi) Place wire of φ 3 mm at the outer surface of edges and form edges round-shaped keeping<br />

the wire inside it, with the help of suitable hammer, stake etc.<br />

DISCUSSIONS/CONCLUSIONS<br />

Write comments <strong>on</strong> dimensi<strong>on</strong>al error and quality of the joint obtained, if any.<br />

Signature of the Teacher

Job No.: ME292/06<br />

Date of Submissi<strong>on</strong>:<br />

39<br />

Assignments <strong>on</strong> Tin Smithy<br />

and Soldering<br />

1. What is edge forming in sheet metal work? State functi<strong>on</strong>s of it.<br />

2. What are the different types of solders? State their compositi<strong>on</strong> and applicati<strong>on</strong>.<br />

Signature of the Teacher

Job No.: ME292/06<br />

Date of Submissi<strong>on</strong>:<br />

40<br />

3. What are the advantages of soldering over other joining processes?<br />

4. Name three sheets that are used in sheet metal.<br />

Assignments <strong>on</strong> Tin Smithy<br />

and Soldering<br />

Signature of the Teacher

Job No.: ME292/06<br />

Date of Submissi<strong>on</strong>:<br />

5. How is sheet metal specified?<br />

41<br />

Assignments <strong>on</strong> Tin Smithy<br />

and Soldering<br />

6. Name and briefly explain various hand tools used in sheet metal work.<br />

Signature of the Teacher

Job No.: ME292/06<br />

Date of Submissi<strong>on</strong>:<br />

42<br />

Assignments <strong>on</strong> Tin Smithy<br />

and Soldering<br />

1. What is edge forming in sheet metal work? State functi<strong>on</strong>s of it.<br />

2. What are the different types of solders? State their compositi<strong>on</strong> and applicati<strong>on</strong>.<br />

Signature of the Teacher

Job No.: ME292/06<br />

Date of Submissi<strong>on</strong>:<br />

43<br />

Assignments <strong>on</strong> Tin Smithy<br />

and Soldering<br />

3. What are the advantages of soldering over other joining processes?<br />

4. Name three sheets that are used in sheet metal.<br />

Signature of the Teacher

Job No.: ME292/06<br />

Date of Submissi<strong>on</strong>:<br />

5. How is sheet metal specified?<br />

44<br />

Assignments <strong>on</strong> Tin Smithy<br />

and Soldering<br />

6. Name and briefly explain various hand tools used in sheet metal work.<br />

Signature of the Teacher