- Page 1 and 2:

GROWING GOURMET and MEDICINAL MUSHR

- Page 3 and 4:

This book should help advance the c

- Page 5 and 6:

GROWING GOURMET AND MEDICINAL MUSHR

- Page 7 and 8:

GROWING GOURMET AND MEDICINAL MUSHR

- Page 9 and 10:

GROWING GOURMET AND MEDICINAL MUSHR

- Page 11 and 12:

GROWING GOURMET AND MEDICINAL MUSHR

- Page 13 and 14:

GROWING GOURMET AND MEDICINAL MUSHR

- Page 15 and 16:

GROWING GOURMET AND MEDICINAL MUSHR

- Page 17 and 18:

CHAPTER 1 Mushrooms, Civilization &

- Page 19 and 20:

Immortality (1976) where he postula

- Page 21 and 22:

CHAPTER 2 The Role of Mushrooms in

- Page 23 and 24:

tive species and planted in plots s

- Page 25 and 26:

ducing organ: the mushroom. Further

- Page 27 and 28:

fungi first to capture a twig, a bl

- Page 29 and 30:

The Global Environmental Shift and

- Page 31 and 32:

nm peroxidases and cellulases which

- Page 33 and 34:

CHAPTER 3 S electing a Candidate fo

- Page 35 and 36:

SELECTING A CANDIDATE FOR CULTIVATI

- Page 37 and 38:

N atural CHAPTER 4 Natural Culture:

- Page 39 and 40:

NATURAL CULTURE: CREATING MYCOLOGIC

- Page 41 and 42:

NATURAL CULTURE: CREATING MYCOLOGIC

- Page 43 and 44:

NATURAL CULTURE: CREATING MYCOLOGIC

- Page 45 and 46:

NATURAL CULTURE: CREATING MYCOLOGIC

- Page 47 and 48:

NATURAL CULTURE: CREATING MYCOLOGIC

- Page 49 and 50:

NATURAL CULTURE: CREATING MYCOLOGIC

- Page 51 and 52:

NATURAL CULTURE: CREATING MYCOLOGIC

- Page 53 and 54:

NATURAL CULTURE: CREATING MYCOLOGIC

- Page 55 and 56:

NATURAL CULTURE: CREATING MYCOLOGIC

- Page 57 and 58:

CHAPTER 5 The Stametsian Model: Per

- Page 59 and 60:

PERMACULTURE WITH A MYCOLOGICAL TWI

- Page 61 and 62:

PERMACULTURE WITH A MYCOLOGICAL TWI

- Page 63 and 64:

CHAPTER 6 Materials for Formulating

- Page 65 and 66:

MATERIALS FOR FORMULATING A FRUITIN

- Page 67 and 68:

MATERIALS FOR FORMULATING A FRUITIN

- Page 69 and 70:

MATERIALS FOR FORMULATING A FRUITIN

- Page 71 and 72:

MATERIALS FOR FORMULATING A FRUITIN

- Page 73 and 74:

CHAPTER 7 Biological Efficiency: An

- Page 75 and 76:

BIOLOGICAL EFFICIENCY: AN EXPRESSIO

- Page 77 and 78:

CHAPTER8 Home-made vs. Commercial S

- Page 79 and 80:

HOME-MADE VERSUS COMMERCIAL SPAWN 6

- Page 81 and 82:

CHAPTER 9 The Mushroom Life Cycle W

- Page 83 and 84:

Figure 44. Scanning electron microg

- Page 85 and 86:

scape, the inycosphere, will give r

- Page 87 and 88:

Figure 51. A fully mature basidium.

- Page 89 and 90:

posites. The method of spore ejecti

- Page 91 and 92:

C ultivating CHAPTER 10 The Six Vec

- Page 93 and 94:

floor. After a minute or two, the c

- Page 95 and 96:

The best one can hope is that conta

- Page 97 and 98:

Figure 60. Storing petri mobile cre

- Page 99 and 100:

S terile CHAPTER 11 Mind and Method

- Page 101 and 102:

MIND AND METHODS FOR MUSHROOM CULTI

- Page 103 and 104:

MIND AND METHODS FOR MUSHROOM CULTI

- Page 105 and 106:

CHAPTER 12 Culturing Mushroom Mycel

- Page 107 and 108:

CULTURING MUSHROOM MYCELIUM ON AGAR

- Page 109 and 110:

CULTURING MUSHROOM MYCELIUM ON AGAR

- Page 111 and 112:

CULTURING MUSHROOM MYCELIUM ON AGAR

- Page 113 and 114:

CULTURING MUSHROOM MYCELIUM ON AGAR

- Page 115 and 116:

CULTURING MUSHROOM MYCELIUM ON AGAR

- Page 117 and 118:

CULTURING MUSHROOM MYCELIUM ON AGAR

- Page 119 and 120:

E very CHAPTER 13 The Stock Culture

- Page 121 and 122:

If one has ten or more replicates,

- Page 123 and 124:

eads: FVITC P2 11/16/92 C # 0825905

- Page 125 and 126:

Figure 87. Rhizomorphic mycelium di

- Page 127 and 128:

exemplified by Laetiporus suiphureu

- Page 129 and 130:

molds belonging to Penicillium, Asp

- Page 131 and 132:

duce odors which humans can recogni

- Page 133 and 134:

CHAPTER 14 Evaluating a Mushroom St

- Page 135 and 136:

Figure 96. Healthy mushroom myceliu

- Page 137 and 138: EVALUATING sustained. Without secon

- Page 139 and 140: 14. Duration between 1st, 2nd and 3

- Page 141 and 142: substantially in flavor. The cultiv

- Page 143 and 144: G rain CHAPTER 15 Generating Grain

- Page 145 and 146: Figure 101. One memod for preparing

- Page 147 and 148: is added proportionately. Whereas t

- Page 149 and 150: grams. 4 cups is approximately a li

- Page 151 and 152: t .,..,..,,,.. ,'"'•• Figure 10

- Page 153 and 154: Figure 111. Grain inoculated with m

- Page 155 and 156: Figure 113. Gallon jars of 3rd gene

- Page 157 and 158: ag resembles those still widely in

- Page 159 and 160: Figure 116. Scanning electron nucro

- Page 161 and 162: F— GENERATING GRAIN SPAWN 145 Fig

- Page 163 and 164: Figure 120. Actively growing myceli

- Page 165 and 166: Figure 122. Inoculating mycelium in

- Page 167 and 168: the norm. The jars normally grow ou

- Page 169 and 170: Figure 124. (Jyster mushrooms out"

- Page 171 and 172: S awdust CHAPTER 16 Creating Sawdus

- Page 173 and 174: Figure 125. Sawdust spawn of Reishi

- Page 175 and 176: Figure 129. Dispersing the spawn th

- Page 177 and 178: CHAPTER 17 Growing Gourmet Mushroom

- Page 179 and 180: GROWING GOURMET MUSHROOMS ON ENRICH

- Page 181 and 182: GROWING GOURMET MUSHROOMS ON ENRICH

- Page 183 and 184: GROWING GOURMET MUSHROOMS ON ENRICH

- Page 185 and 186: GROWING GOURMET MUSHROOMS ON ENRICH

- Page 187: GROWING GOURMET MUSHROOMS ON ENRICH

- Page 191 and 192: GROWING GOURMET MUSHROOMS ON ENRICH

- Page 193 and 194: GROWING GOURMET MUSHROOMS ON ENRICH

- Page 195 and 196: GROWING GOURMET MUSHROOMS ON ENRICH

- Page 197 and 198: C H A P T E R 1 8 Cultivating Gourm

- Page 199 and 200: ice, oat and sorghum straws are the

- Page 201 and 202: Figure 146. A brick keeps the straw

- Page 203 and 204: Figure 149. Newly constructed, scre

- Page 205 and 206: spawn is gravity fed or hand broadc

- Page 207 and 208: C hoosing CHAPTER 19 Cropping Conta

- Page 209 and 210: onments typically ensue until the p

- Page 211 and 212: Figure 158. The Phoenix Oyster, Ple

- Page 213 and 214: Figure 162. The hinged wall-frame

- Page 215 and 216: Figure 167. Bouquets of Golden Oyst

- Page 217 and 218: Figure 171. By slamming the culumn

- Page 219 and 220: latedsubstrate.An 8-ft. longcolumn,

- Page 221 and 222: came a template for the cultivation

- Page 223 and 224: CROPPING CONTAINERS 207 Figures 182

- Page 225 and 226: CHAPTER 20 Casing: A Topsoil Promot

- Page 227 and 228: CHAPTER 21 Growth Parameters for Go

- Page 229 and 230: Figure 188. The Button mushroom (Ag

- Page 231 and 232: of the surface, the region supporti

- Page 233 and 234: other gourmet and medicinal mushroo

- Page 235 and 236: INDOOR GROWTH PARAMETERS The Gilled

- Page 237 and 238: Figure 193.20 days after inoculatio

- Page 239 and 240:

Growth Parameters Spawn Run: Incuba

- Page 241 and 242:

Growth Parameters Spawn Run: Incuba

- Page 243 and 244:

Harvest Hints: Since this mushroom

- Page 245 and 246:

The Enoki Mushroom Fkxmmulina velut

- Page 247 and 248:

Growth Parameters Spawn Run: Incuba

- Page 249 and 250:

GROWTH PARAMETERS 233 aspen, willow

- Page 251 and 252:

GROWTH PARAMETERS 235 short period

- Page 253 and 254:

Introduction: Before the publicatio

- Page 255 and 256:

Growth Parameters Spawn Run: Incuba

- Page 257 and 258:

GROWTH PARAMETERS 24f doors, this m

- Page 259 and 260:

Growth Parameters Spawn Run: Incuba

- Page 261 and 262:

Figure 216. Inoculated logs of Kuri

- Page 263 and 264:

GROWTH PARAMETERS 247 spores of spe

- Page 265 and 266:

In Japan, H. tessulatus is marketed

- Page 267 and 268:

Growth Parameters Spawn Run: Incuba

- Page 269 and 270:

I Figure 224. Commercial cultivatio

- Page 271 and 272:

GROWTH PARAMETERS 255 Figures 226 a

- Page 273 and 274:

Growth Parameters Spawn Run: Incuba

- Page 275 and 276:

The Shiitake Mushroom of the Genus

- Page 277 and 278:

GROWTH PARAMETERS 261 Figure 231 &

- Page 279 and 280:

Figure 235. After soaking, logs can

- Page 281 and 282:

GROWTH PARAMETERS 265 Figure 240. A

- Page 283 and 284:

Growth Parameters Spawn Run: Incuba

- Page 285 and 286:

GROWTH PARAMETERS 269 This species

- Page 287 and 288:

Figure 249. The "Donko" form of Shi

- Page 289 and 290:

When I was a impoverished, near-sta

- Page 291 and 292:

GROWTH PARAMETERS 275 nated) for 24

- Page 293 and 294:

The Nameko Mushroom of the Genus Ph

- Page 295 and 296:

Growth Parameters Spawn Run: Incuba

- Page 297 and 298:

GROWTH PARAMETERS 281 Natural Metho

- Page 299 and 300:

The Oyster Mushrooms of the Genus P

- Page 301 and 302:

Introduction: Few mushrooms are as

- Page 303 and 304:

259. Bottle culture of P. cttrtnopl

- Page 305 and 306:

Figure 262. A beautiful clustered b

- Page 307 and 308:

oom Kit. ri Pertecti's oyster Musn-

- Page 309 and 310:

Growth Parameters Spawn Run: Incuba

- Page 311 and 312:

Figure Wild fruiting of P cystidios

- Page 313 and 314:

Pleurotus djamor (Fries) Boedjin se

- Page 315 and 316:

GROWTH PARAMETERS 299 studies are c

- Page 317 and 318:

Growth Parameters Spawn Run: Incuba

- Page 319 and 320:

Medicinal Properties: Not known to

- Page 321 and 322:

Figure 275 and 276. P. eryngii frui

- Page 323 and 324:

Growth Parameters Spawn Run: Incuba

- Page 325 and 326:

GROWTH PARAMETERS 309 Pleurotus euo

- Page 327 and 328:

Growth Parameters Spawn Run: Incuba

- Page 329 and 330:

GROWTH PARAMETERS 313 Pleurotus ost

- Page 331 and 332:

Figure 282. A sporeless strain of P

- Page 333 and 334:

Suggested Agar Culture Media: MYPA,

- Page 335 and 336:

Spawn Run: Temperature: 75° F. (24

- Page 337 and 338:

Plate 1. Fruiting culture of Agrocy

- Page 339 and 340:

Plate 7. Flammulina velutipes, the

- Page 341 and 342:

Plates 14. Shiitake mushrooms, Lent

- Page 343 and 344:

Plate 22. Pleurotus eryngii, the Ki

- Page 345 and 346:

PDF compression, OCR, web-optimizat

- Page 347 and 348:

PDF compression, OCR, web-optimizat

- Page 349 and 350:

Plate 44. Two strains of Ganoderma

- Page 351 and 352:

Plate 51. Succulent bouquet of .Mai

- Page 353 and 354:

Pleurotuspulmonarius (Fries) Quelet

- Page 355 and 356:

Figure 287. F. pulmonarius fruiting

- Page 357 and 358:

Growth Parameters Spawn Run: Incuba

- Page 359 and 360:

GROWTH PARAMETERS 327 The Caramel C

- Page 361 and 362:

GROWTH PARAMETERS 329 Psilocybe whi

- Page 363 and 364:

Growth Parameters Spawn Run: Incuba

- Page 365 and 366:

dicinal properties, instead focusin

- Page 367 and 368:

The King Stropharia of the Genus St

- Page 369 and 370:

Figure 297. Azureus Stamets holding

- Page 371 and 372:

Growth Parameters Spawn Run: Incuba

- Page 373 and 374:

GROWTH PARAMETERS 341 room can also

- Page 375 and 376:

GROWTH PARAMETERS 343 The Paddy Str

- Page 377 and 378:

Figure 303. Soaked straw is thrown

- Page 379 and 380:

Growth Parameters Spawn Run: Incuba

- Page 381 and 382:

GROWTH PARAMETERS 349 Figure 312—

- Page 383 and 384:

INDOOR GROWTH PARAMETERS T he The P

- Page 385 and 386:

GROWTH PARAMETERS 353 tude sickness

- Page 387 and 388:

GROWTH PARAMETERS 355 Ganoderma luc

- Page 389 and 390:

figure 318. U. lucidum (F'orintek's

- Page 391 and 392:

Natural Habitat: An annual mushroom

- Page 393 and 394:

GROWTH PARAMETERS 361 Figure 323—

- Page 395 and 396:

GROWTH PARAMETERS 363 Figures 327

- Page 397 and 398:

Growth Parameters Spawn Run: Incuba

- Page 399 and 400:

GROWTH PARAMETERS 367 Natural Metho

- Page 401 and 402:

GROWTH PARAMETERS 369 Comments: A s

- Page 403 and 404:

GROWTH PARAMETERS 371 form. Microsc

- Page 405 and 406:

Iligure 335. Maitake usually truits

- Page 407 and 408:

Growth Parameters Spawn Run: Incuba

- Page 409 and 410:

GROWTH PARAMETERS 377 1992, dried M

- Page 411 and 412:

GROWTH PARAMETERS 379 Fruitbody dev

- Page 413 and 414:

Figure 341. Sclerotia of North Amer

- Page 415 and 416:

Growth Parameters Spawn Run: Incuba

- Page 417 and 418:

GROWTH PARAMETERS 385 placed into a

- Page 419 and 420:

INDOOR GROWTH PARAMETERS The Lion's

- Page 421 and 422:

GROWTH PARAMETERS 389 Description:

- Page 423 and 424:

Growth Parameters Spawn Run: Incuba

- Page 425 and 426:

GROWTH PARAMETERS 393 Figure 349. W

- Page 427 and 428:

INDOOR GROWTH PARAMETERS The Wood E

- Page 429 and 430:

GROWTH PARAMETERS 397 A. polytricha

- Page 431 and 432:

Growth Parameters Spawn Run: Incuba

- Page 433 and 434:

INDOOR GROWTH PARAMETERS M orels Th

- Page 435 and 436:

GROWTH PARAMETERS 403 Figure 357. T

- Page 437 and 438:

GROWTH PARAMETERS 405 thousands per

- Page 439 and 440:

Figure 363. A Morel primordium form

- Page 441 and 442:

Common Names: The Black Morel The C

- Page 443 and 444:

GROWTH PARAMETERS 413 Figure 372 &

- Page 445 and 446:

T e m p e r a U r e (°C) Profile o

- Page 447 and 448:

Figure 375. This mycological experi

- Page 449 and 450:

Growth Parameters* Spawn Run: Incub

- Page 451 and 452:

CHAPTER 22 Maximizing the Substrate

- Page 453 and 454:

dergoes another 50% reduction in ma

- Page 455 and 456:

CHAPTER 23 Harvesting, Storing, and

- Page 457 and 458:

Figure 378. Bouquets of Pleurotus o

- Page 459 and 460:

Figure 380. An example of poor pack

- Page 461 and 462:

P. a large blower located at one en

- Page 463 and 464:

CHAPTER 24 Mushroom Recipes: Enjoyi

- Page 465 and 466:

MUSHROOM RECIPES 433 Jack Czarnecki

- Page 467 and 468:

MUSHROOM RECIPES 435 Hope & Orson M

- Page 469 and 470:

MUSHROOM RECIPES 437 Robert Roselli

- Page 471 and 472:

Andrew Weil's Shiitake Teriyaki MUS

- Page 473 and 474:

MUSHROOM RECIPES 441 Recommended Mu

- Page 475 and 476:

T his CHAPTER 25 Cultivation Proble

- Page 477 and 478:

TROUBLESHOOTING 445 small tree frog

- Page 479 and 480:

Contaminants localized to point of

- Page 481 and 482:

TROUBLESHOOTING 449 PROBLEM CAUSE S

- Page 483 and 484:

TROUBLESHOOTING 451 PROBLEM CAUSE S

- Page 485 and 486:

TROUBLESHOOTING 453 PROBLEM CAUSE S

- Page 487 and 488:

APPENDIX I Descriptions of Environm

- Page 489 and 490:

proof electrical fixtures are essen

- Page 491 and 492:

neer systems with mushroom preserva

- Page 493 and 494:

APPENDIX II Designing and Building

- Page 495 and 496:

DESIGNING AND BUILDING A SPAWN LABO

- Page 497 and 498:

DESIGNING AND BUILDING A SPAWN LABO

- Page 499 and 500:

DESIGNING AND BUILDING A SPAWN LABO

- Page 501 and 502:

APPENDIX III The Growing Room: An E

- Page 503 and 504:

MOUTH MUSHROOM-CAVE NEAR PARI& THE

- Page 505 and 506:

Many farms employ pass-through curt

- Page 507 and 508:

move debris from the feet and enhan

- Page 509 and 510:

changes per hour required during th

- Page 511 and 512:

After washing, the growing room fee

- Page 513 and 514:

APPENDIX IV Resource Directory T he

- Page 515 and 516:

Mushroom Book Suppliers Fungi Perfe

- Page 517 and 518:

Mushroom Cultivation Seminars & Tra

- Page 519 and 520:

RESOURCE DIRECTORY 487 Chibougamau

- Page 521 and 522:

RESOURCE DIRECTORY 489 Nutmeg Mycol

- Page 523 and 524:

Centre for Land & Biological Resear

- Page 525 and 526:

J. B. Swayne Spawn (215) 444-0888 8

- Page 527 and 528:

RESOURCE DIRECTORY 495 The Mushroom

- Page 529 and 530:

Material APPENDIX V Analysis of Bas

- Page 531 and 532:

Material ANALYSIS OF B ASIC MAT ERI

- Page 533 and 534:

Material ANALYSIS OF BASI C M ATERI

- Page 535 and 536:

Material ANALYSIS OF B ASI C M ATER

- Page 537 and 538:

Material ANALYSIS OF BASI C M ATERI

- Page 539 and 540:

Material ANALYSIS OF BASI C MATERIA

- Page 541 and 542:

Material ANALYSIS OF BASI C MATERIA

- Page 543 and 544:

Material ANALYSIS OF BASI C M AT ER

- Page 545 and 546:

APPENDIX VI Data Conversion Tables

- Page 547 and 548:

1°F. = •5550 Kelvin 1° F = (.55

- Page 549 and 550:

DATA CONVERSION TABLES 517 Miscella

- Page 551 and 552:

Glossary A agar: a product derived

- Page 553 and 554:

droplets of spore bundles on relati

- Page 555 and 556:

mycophagist: a person or animal tha

- Page 557 and 558:

metabolic heat released as fungi, b

- Page 559 and 560:

Bibliography Adachi, K., H. Nanba,

- Page 561 and 562:

BIBLIOGRAPHY 529 Chang, S.T. &W.A.

- Page 563 and 564:

______ BIBLIOGRAPHY 531 Gormanson,D

- Page 565 and 566:

_____1995. BIBLIOGRAPHY 533 Ito, T.

- Page 567 and 568:

wheat straw. Mushroom Journal of th

- Page 569 and 570:

_____J.A. 1991. Manual on mushmom c

- Page 571 and 572:

_____1987b. BIBLIOGRAPHY 539 Royse,

- Page 573 and 574:

_____,A. BIBLIOGRAPHY 541 Stijve, T

- Page 575 and 576:

543 1993. Boost immunity with medic

- Page 577 and 578:

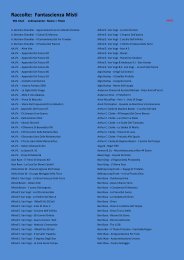

A agaricum 351 agarikon 351 agar me

- Page 579 and 580:

ganoderic acids 368 Ganoderma 353,

- Page 581 and 582:

N Nuematoloma N. capnoides 237 N. f

- Page 583 and 584:

spore germination 100 spore load 24

- Page 585 and 586:

Alan Bessette Figures 52, 53 Julie