String Book - Logan Oil Tools

String Book - Logan Oil Tools

String Book - Logan Oil Tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6<br />

recommenDeD proceDUre for maKing Up<br />

DriLL coLLarS With neW jointS<br />

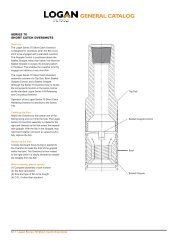

Connector Sub or Drill Collar<br />

Suggested Marking<br />

1. Thoroughly clean with distillate, pin and box threads and shoulder. After cleaning, the joint must<br />

be dried before lubricant is applied.<br />

2. Coat all areas of the pin and box threads and shoulders with a thin even coat of a good grade<br />

lubricant from a covered or newly opened can. A molydisulfide lubricant is recommended.<br />

3. Extreme care should be used when stabbing the joints to avoid stabbing wounds. If drill collar<br />

connecting subs are used, it is preferred that the subs be applied by hand rather than with lifting<br />

equipment.<br />

4. Make up joints manually with chain tongs as far as possible and then use cathead to the full<br />

recommended torque as shown on attached chart.<br />

5. Scribe vertical chalk line across joint make-up line of box and pin faces.<br />

6. Break joint, clean and dry threads. Inspect the threads and joint faces carefully for evidence<br />

of galling or “hair like” slivers of steel. Stone or file all rough spots and remove slivers. Be careful<br />

not to remove chalk line across joint face.<br />

7. Again make up joints manually with chain tongs as far as possible and then with cathead using<br />

full recommended torque. The joint must make up to the chalk mark or father. If the joint does not<br />

make up to this line, again break the joint, dry and clean. Inspect the threads and joint faces care-<br />

fully and in general proceed as under 6 above.<br />

8. If the joints make up to the chalk line or farther, a center punch mark shall be made on both the<br />

box and pin halves, adjacent to the shoulder, as permanent inspection mark. After each run, these<br />

match making spots should be inspected and as long as there is no creep between the two marks,<br />

the joints should be left unbroken if possible (nonworking joints). As the drill collars wear, it is<br />

recommended that the center punch marks be deepened so that they will always be in evidence.<br />

When it is noted that creep has occurred on the nonworking joints, they should be broken apart,<br />

inspected and if necessary recut.