String Book - Logan Oil Tools

String Book - Logan Oil Tools

String Book - Logan Oil Tools

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

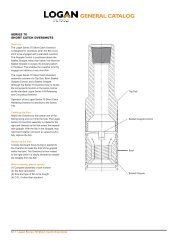

eLevator anD tooL joint inSpection gaUge<br />

Determining if an elevator is safe or unsafe, satisfactory for use or ready for repair, should not be entrusted to the eye!<br />

Such determinations require accurate measurements of the critical elevator parts.<br />

Link Arm<br />

Dimension<br />

to MEASuRE AngLE oF 8° tApER ELEVAtoRS: Place body of gauge<br />

on top of elevator bore, and drop sliding arm into the bore. Bring tapered<br />

edge of slide (marked “Elevator Taper”) against tapered surface of the bore.<br />

Read true taper angle of elevator bore at “H.” Percentage of remaining rated<br />

capacity is given opposite the reading. Tapers of 13° and less require factory<br />

reconditioning, or retirement from service. NOTE: Bores do not wear evenly.<br />

Use the smallest angle found.<br />

to MEASuRE AngLE oF 8° tApER tooL JoIntS: Place body of gauge<br />

on top shoulder of tool joint “box.” Sliding arm is adjusted so that the tapered<br />

edge (marked “Tool Joint Taper”) is in contact with the tapered surface of the<br />

tool joint. The true angle is read at “H.” Percentage of remaining rated capacity<br />

of the elevator is given opposite the reading. Again, use the smallest angle<br />

found. Tool joints of less than 13° should be repaired or replaced.<br />

WARNING: Even though the elevator may be in perfect condition,<br />

a worn tool joint taper reduces its rated capacity!<br />

While inspecting the tool joint, lay any straight edge of the gauge along the 18°<br />

taper to check that the angle of taper has not been violated by hardbanding.<br />

Should hardbanding extend onto the taper, such banding should be removed;<br />

and the elevator that was used with such a tool joint should be inspected for<br />

damaging wear.<br />

to MEASuRE WoRn CoLLAR SuRFACES oF SQuARE ShouLDER<br />

ELEVAtoRS: Place body of gauge on top surface of elevator. Using nontapered<br />

end of sliding arm, drop arm end into the worn area. Depth of wear is<br />

read on the “1/4-inch” scale where body and sliding arm cross. Shoulders worn<br />

more than 1/16 inch should be re-faced by machining. Any rolling of the edge<br />

into the bore should be removed so that it will not interfere with the closing of<br />

the elevator.<br />

to ChECk SQuARE ShouLDER tooL JoIntS: Use end of gauge body<br />

marked “90°.” Corner has been removed to permit this measurement. Joints<br />

out-of-square by more than 1/16 inch should be re-machined to 90°.<br />

LInk ARM WEAR ChARt FoR ChAMpIon ELEVAtoRS<br />

Collar type 8° taper type<br />

Elevator Link Arm Link Arm Elevator Link Arm Link Arm<br />

Size Cap. (ton) Dim. (in) Size Cap. (ton) Dim. (in)<br />

100 3 100 4<br />

C-100<br />

90<br />

79<br />

2-3/4<br />

2-1/2<br />

T-100<br />

91<br />

82<br />

3-3/4<br />

3-1/2<br />

69 2-1/4 72 3-1/4<br />

150 4 150 4-3/4<br />

C-150<br />

136<br />

122<br />

3-3/4<br />

3-1/2<br />

T-150<br />

138<br />

126<br />

4-1/2<br />

4-1/4<br />

108 3-1/4 114 4<br />

250 4-3/4 250 5<br />

C-250<br />

230<br />

210<br />

4-1/2<br />

4-1/4<br />

T-250<br />

232<br />

214<br />

4-3/4<br />

4-1/2<br />

190 4 198 4-1/4<br />

350 5 400 5-1/4<br />

322 4-3/4 368 5<br />

C-350 300 4-1/2 T-400 338 4-3/4<br />

276 4-1/4 311 4-1/2<br />

250 4 286 4-1/4<br />

7