String Book - Logan Oil Tools

String Book - Logan Oil Tools

String Book - Logan Oil Tools

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>String</strong> <strong>Book</strong><br />

Keep Your <strong>String</strong> Together!

LOGAN OIL TOOLS manufactures<br />

a complete line of quality fishing tools and<br />

related products.<br />

Providing quality downhole fishing tools at<br />

a fair price has been our primary goal since<br />

1971. Decades of solid sales and service<br />

experience with fishing tools enables our<br />

staff to understand what service means to<br />

fishing tool operators, supervisors, and<br />

store managers.<br />

Recognized as a leading source of quality<br />

products delivered “stock to dock” for<br />

many of the largest fishing and rental tool<br />

companies throughout the world, our<br />

delivery capabilities are supported by our<br />

143,000-square-foot sales, engineering,<br />

manufacturing, and warehouse facilities<br />

strategically located in Houston, Texas.<br />

In addition to our eleven sales offices/stores<br />

located in California, Louisiana, Mississippi,<br />

North Dakota, Oklahoma, Pennsylvania,<br />

Texas, and Utah, we have four international<br />

stocking point facilities established in<br />

strategic locations around the globe —<br />

Edmonton, Canada; Aberdeen, Scotland;<br />

Dubai, United Arab Emirates; and Singapore<br />

— to maximize delivery needs.<br />

For more information about our extensive<br />

line of fishing tools and related<br />

products, please contact our Sales<br />

and Service Department at:<br />

Tel 281.219.6613<br />

sales@loganoiltools.com

DISCLAIMER<br />

<strong>Logan</strong> <strong>Oil</strong> <strong>Tools</strong> has published this engineering handbook for the benefit of its employees and to aid<br />

its customers in the selection of tools and equipment by providing engineering and dimensional data.<br />

<strong>Logan</strong> <strong>Oil</strong> <strong>Tools</strong> does not recommend using the information in this handbook for any other purpose.<br />

Information contained in this handbook has been obtained from sources <strong>Logan</strong> <strong>Oil</strong> <strong>Tools</strong> believes to be<br />

reliable and every effort has been extended to make this handbook complete and accurate. However,<br />

<strong>Logan</strong> <strong>Oil</strong> <strong>Tools</strong> does not guarantee the completeness or accuracy of any information published herein<br />

and shall not be responsible for any errors, omissions, or damages caused by the use of this information.<br />

This handbook is published with the understanding that <strong>Logan</strong> <strong>Oil</strong> <strong>Tools</strong> is supplying information but is<br />

not attempting to render engineering or other professional services. If such services are required, the<br />

assistance of an appropriate professional should be sought.<br />

1.5M Rev. 3/0611<br />

<strong>String</strong> <strong>Book</strong><br />

kEEp youR StRIng togEthER!

contentS<br />

StREngth, tESt, AnD toRQuE DAtA<br />

<strong>Logan</strong> Series 10 Sucker Rod Overshots ............................................................................................4–5<br />

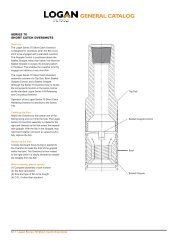

<strong>Logan</strong> Series 20 Short Catch Sucker Rod Overshots ........................................................................6–8<br />

<strong>Logan</strong> Series 70 Short Catch Overshots ..........................................................................................9–10<br />

<strong>Logan</strong> Series 150 Releasing & Circulating Overshots....................................................................11–15<br />

<strong>Logan</strong> Superior Hydraulic Fishing Jars.................................................................................................16<br />

<strong>Logan</strong> Superior Energizers ...................................................................................................................17<br />

<strong>Logan</strong> Surface Bumper Jars .................................................................................................................18<br />

<strong>Logan</strong> Lubricated Fishing Bumper Subs ..............................................................................................19<br />

tooL JoIntS<br />

API Numbered Rotary Shouldered Connections ..................................................................................20<br />

API Regular – Union Tool Regular ........................................................................................................21<br />

API Full Hole – Union Tool Full Hole ....................................................................................................22<br />

API Internal Flush – Hughes and Reed LF ...........................................................................................23<br />

American MT, AMT, and AMMT ............................................................................................................24<br />

PAC ......................................................................................................................................................25<br />

Hughes Xtra Hole & Reed Xtra Hole ....................................................................................................26<br />

Hughes Slim Hole .................................................................................................................................27<br />

Hughes Slimline H-90 ...........................................................................................................................28<br />

Hughes H-90 ..................................................................................................................................29–30<br />

Hydril Joints ..........................................................................................................................................31<br />

Tool Joint Dimensions – Recommended Maximum and Minimum ......................................................32<br />

pIpE AnD DRILL CoLLARS<br />

Seamless Drill Pipe Performance Properties .......................................................................................33<br />

New Drill Pipe Collapse and Internal Pressure Data ............................................................................34<br />

API Drill Collar and Joint Sizes .............................................................................................................35<br />

Recommended Procedure for Making Up Drill Collars with New Joints ...............................................36<br />

Drill Collar Torque Recommendations (ft-lbs) .................................................................................37–42<br />

Drill Collar Weights – Pounds per Foot ................................................................................................43<br />

30' Spiral Drill Collars – Approximate Weights .....................................................................................44<br />

Drill Collar Grooves for Elevators and Slips .........................................................................................45<br />

Elevator Bore Charts ............................................................................................................................46<br />

Web Wilson Forged Links .....................................................................................................................47<br />

Weld-on Type Tool Joints Make-up Torque .....................................................................................48–53<br />

Tubing Sizes – Threaded and Coupled Types ......................................................................................54<br />

Tubing Make-up Torque .................................................................................................................55–74<br />

Atlas Bradford Tubing Joints.................................................................................................................75<br />

Hydril Tubing Joints ..............................................................................................................................76<br />

Tubing Pressure Ratings ......................................................................................................................77<br />

Tubing Setting Depths – Tension and Collapse ....................................................................................78<br />

Pipe Sizes – Standard Steel Pipe and Line Pipe..................................................................................79<br />

Sucker Rod Connections ......................................................................................................................80<br />

Threaded and Coupled Casing Sizes – 4-1/2" to 7" .............................................................................81<br />

Threaded and Coupled Casing Sizes – 7-5/8" to 10-3/4" .....................................................................82<br />

Threaded and Coupled Casing Sizes – 11-3/4" to 20" .........................................................................83<br />

Casing Make-up Torque – Short Thread ........................................................................................84–86<br />

Casing Make-up Torque – Long Thread .........................................................................................87–91<br />

Drill Bit Specifications ...........................................................................................................................92

contentS<br />

CASIng DAtA – BIt SIzES AnD CLEARAnCES<br />

API Casing......................................................................................................................................93–94<br />

National Seamless Internal Upset Casing – Short Coupling with Light Upset......................................95<br />

National Seamless Internal Upset Casing – Short Coupling with Heavy Upset ...................................96<br />

Pittsburgh Special Acme Thread Casing – Internal Upset ....................................................................97<br />

Youngstown Speed Tite Casing with Hydril Two-Step Thread ..............................................................98<br />

Spang-Chalfant Extreme Line Casing .................................................................................................99<br />

J&L Integral Joint Seamless Casing – Light and Heavy Upset ..........................................................100<br />

Kelly Cross-Section Dimensions .......................................................................................................101<br />

Kelly Weights – Pounds per Foot .......................................................................................................102<br />

MISCELLAnEouS<br />

Buoyancy Factor for Steel Pipe ..........................................................................................................103<br />

Ring Joint – Flange Data ....................................................................................................................104<br />

Flange Dimensions – Studs, Nuts, and Ring Gaskets................................................................105–106<br />

Brinell Hardness Table ........................................................................................................................107<br />

Hardness Testing Conversion Table ...................................................................................................108<br />

Equivalency Chart – Fractions/Decimal/Metric ...................................................................................109<br />

Line Pull x Tong Lever Chart — Torque in Foot Pounds .....................................................................110<br />

Torque Output with Manual Tongs ......................................................................................................111<br />

Proper Placement of Torque Indicators ......................................................................................112–115<br />

Measuring Wear on Elevators, Tool Joints, Link Arms, and Link Ears ....................................... 116–118

<strong>Logan</strong> SerieS 10 SUcKer roD overShotS<br />

CALCuLAtED StREngthS<br />

Load Capacity @ yield point (lbs) Max. Make-up torque<br />

Bowl no. Max. Catch Size Catch Size 50% of yield (ft/lbs)<br />

<strong>Logan</strong> Bowen Spiral Basket o.D. Spiral Basket Without top Sub Bowl<br />

(in) grapple grapple (in) Stop to Bowl to guide<br />

B 00 17987 1-1/4 1-1/16 1-7/16 16,500 1-1/16 down 11,500 100 95<br />

B 00 5 16492 1-3/8 1-3/16 1-21/32 39,100 1-3/16 down to, but not including 1" 28,500 235 145<br />

1" down 18,000<br />

B 00 13942 1-1/2 1-5/16 1-25/32 39,500 1-5/16 down to, but not including 1" 28,500 315 170<br />

1" down 18,000<br />

B 00 9991 1-1/2 1-5/16 1-29/32 83,800 1-5/16 down 38,200 350 235<br />

B 00 9342 1-5/8 1-7/16 1-29/32 39,500 1-7/16 down to, but not including 1" 28,500 375 225<br />

1" down 18,000<br />

B 005 9881 1-5/8 1-7/16 2-5/16 138,100 1-7/16 down to, but not including 1" 93,900 1,750 535<br />

1" down 59,400<br />

B 005 36425 1-9/16 1-3/8 2-27/32 39,500 1-3/8 down to, but not including 1" 28,500 … …<br />

1" down 18,000<br />

B 005 27767 1-13/16 1-5/8 2-9/64 55,700 1-5/8 down to, but not including 1" 40,100 575 175<br />

1" down 25,400<br />

All strengths are calculated theoretical yield points and are accurate within 20%. All strengths assume straight, steady pull and full grapple engagement of a round fish.<br />

Anything less than full engagement or straight pulling, will reduce the listed strength.<br />

Tong marks or other damage to the bowl surface will also reduce the listed strength.<br />

All torque calculations are theoretical maximum tightening torques for the threaded connection and do not include clamping force. Clamping force is not considered<br />

due to the variety of devices used to tighten these connections.<br />

CAUTION: Due to the amount of torque applied to a connection and the type of device used to apply the torque, damage to the bowl, top sub, or guide may occur.

<strong>Logan</strong> SerieS 10 SUcKer roD overShotS<br />

CALCuLAtED StREngthS<br />

Load Capacity @ yield point (lbs) Max. Make-up torque<br />

Bowl no. Max. Catch Size Catch Size 50% of yield (ft/lbs)<br />

<strong>Logan</strong> Bowen Spiral Basket o.D. Spiral Basket Without top Sub Bowl<br />

(in) grapple grapple (in) Stop to Bowl to guide<br />

B 006 11482 1-13/16 1-5/8 2-5/16 118,100 1.660 down to, but not including 1-1/8" 85,100 1,050 445<br />

1-1/8" down 53,800<br />

B 007 16072 1-15/16 1-3/4 2-1/4 55,700 1-3/4 down to, but not including 1-1/8" 40,100 650 335<br />

1-1/8" down 25,400<br />

B 008 9402 2 1-13/16 2-5/16 55,700 1-13/16 down to, but not including 1-1/8" 40,100 740 240<br />

1-1/8" down 25,400<br />

B 009 9532 2 1-13/16 2-7/8 200,400 1-13/16 down to, but not including 1-1/8" 144,400 3,200 1,050<br />

1-1/8" down 91,300<br />

B 0 0 15861 2-3/8 2-3/16 2-27/32 70,000 2-3/16 down to, but not including 1-1/8" 51,100 1,850 500<br />

1-1/8" down 37,700<br />

All strengths are calculated theoretical yield points and are accurate within 20%. All strengths assume straight, steady pull and full grapple engagement of a round fish.<br />

Anything less than full engagement or straight pulling, will reduce the listed strength.<br />

Tong marks or other damage to the bowl surface will also reduce the listed strength.<br />

All torque calculations are theoretical maximum tightening torques for the threaded connection and do not include clamping force. Clamping force is not considered<br />

due to the variety of devices used to tighten these connections.<br />

CAUTION: Due to the amount of torque applied to a connection and the type of device used to apply the torque, damage to the bowl, top sub, or guide may occur.<br />

5

6<br />

SerieS 20 Short catch SUcKer roD overShotS<br />

CALCuLAtED StREngthS<br />

Maximum Catch Size (Basket) 7/8 1 1-1/4 1-3/8 1-1/2 1-3/4 1-13/16<br />

nominal overshot o.D. * 1-9/32 1-13/32 1-5/8 1-3/4 1-29/32 2-1/4 2-5/16<br />

Load Capacity @ yield point (lbs) 31,500 31,500 42,200 35,100 41,000 50,298 50,400<br />

Bowl <strong>Logan</strong> part no. B 0 B 0 B 0 B 0 B 0 5 B 0 55 B 0 6<br />

Bowen No. 17317 25782 28762 18357 11556 47465 17439<br />

Complete Assembly <strong>Logan</strong> part no. 0- 5-D 0- 8-D 0- 6 -D 0- 75-D 0- 9 -D 0- 5-D 0- -D<br />

Bowen No. 17315 25780 28760 18355 11555 47464 17438<br />

Maximum Catch Size (Basket) 2-1/8 2-1/8 2-3/8 2-1/2<br />

nominal overshot o.D. * 2-25/32 2-7/8 3-1/8 3-1/4<br />

Load Capacity @ yield point (lbs) 102,300 101,800 127,000 127,000<br />

Bowl <strong>Logan</strong> part no. B 0 7 B 0 8 B 0 9 B 0 0<br />

Bowen No. 18307 20171 20647 22272<br />

Complete Assembly <strong>Logan</strong> part no. 0- 78-D 0- 87-A 0- -D 0- 5-A<br />

Bowen No. 18305 20170 20645 22270<br />

Strengths are theoretical yield points that are accurate within 20%.<br />

Strengths assume full grapple engagement of a round fish and a straight, steady pull.<br />

Anything less than full engagement or steady, straight pulling will reduce the listed strength.<br />

* Check the actual tool OD if the tool is to be run through a tight clearance.

SerieS 20 Short catch SUcKer roD overShotS<br />

A<br />

W<br />

F N Rod O.D.<br />

P<br />

C<br />

Diameter of Bead<br />

Does Not Exceed “F”<br />

L<br />

DIMEnSIonS AnD CALCuLAtED StREngthS<br />

Rod Size — Inches 1/2 5/8 3/4 7/8 1 1-1/8<br />

A — pin Length 1 1-1/8 1-3/8 1-3/8 1-3/4 2<br />

C — Full Sized Coupling o.D. 1 1-1/2 1-5/8 1-13/16 2-3/16 or 2 * 2-3/8<br />

F — Shoulder o.D. 1 1-3/8 1-1/2 1-5/8 2 2-1/4<br />

L — Minimum Length 2-3/4 4 4 4 4 4-1/2<br />

n — Wrench Flat 5/8 7/8 1 1 1-5/16 1-1/2<br />

p — pin o.D. 3/4 15/16 1-1/16 1-3/16 1-3/8 1-9/16<br />

W — Coupling Wrench Flat Width 3/4 1-3/8 1-1/2 1-5/8 1-7/8 2-1/8<br />

thread 3/4 10 thd 15/16 10 thd 1-1/16 10 thd 1-3/16 10 thd 1-3/8 10 thd 1-9/16 10 thd<br />

* Used when running 1-inch rods in 2-7/8" tubing; 2-3/16" is standard.<br />

7

8<br />

SerieS 20 Short catch SUcKer roD overShotS<br />

StREngth tABLE<br />

Rod Size — Inches 1/2 5/8 3/4 7/8 1<br />

Rod Area 0.196 0.306 0.442 0.601 0.785<br />

Based on:<br />

J&L Type 7 with ultimate tensile strength Yield 16,000 21,400 30,900 42,100 55,000<br />

of 86,000 and yield of 70,000 psi Ultimate 20,000 26,300 38,000 51,700 67,500<br />

Torque * 70 140 171 381 570<br />

J&L Type 2 with ultimate tensile strength Yield … 19,900 28,700 39,100 51,000<br />

of 100,000 and yield of 65,000 psi Ultimate … 30,600 44,200 60,100 78,500<br />

Torque * 65 130 159 353 530<br />

J&L Type 1 with ultimate tensile strength Yield … 20,900 30,300 41,200 53,800<br />

of 100,000 and yield of 65,000 psi Ultimate … 30,600 44,200 60,100 78,500<br />

Torque * 68-1/2 136 168 372 560<br />

J&L Type 12 with ultimate tensile strength Yield … 29,400 42,300 57,700 75,300<br />

of 120,000 and yield of 96,000 psi Ultimate … 37,700 53,000 72,000 94,200<br />

Torque * 96 192 235 476 783<br />

* Torque based on rod O.D. @ yield.

<strong>Logan</strong> SerieS 70 Short catch overShotS<br />

CALCuLAtED StREngthS<br />

Maximum Catch Size (Basket) 1-5/8 2-1/2 2-5/8 3-1/16 3-1/16 3-1/16 3-3/8<br />

overshot o.D. 2-5/16 3-5/8 3-3/4 3-15/16 4-5/8 4-1/8 4-3/8<br />

Complete Assembly <strong>Logan</strong> part no. 70- -D 70- 6 -D 70- 75-D 70- 9 -D 70- 6 -A 70- -D 70- 8-D<br />

Bowen No. 38506 17615 13535 63892 11290 10434 C-11023<br />

Bowl <strong>Logan</strong> part no. C 000 C 00 C 00 C 00 5 C 00 C 00 C 00 5<br />

Bowen No. 38508 17617 13537 63894 11291 10436 B-11025<br />

Basket grapple Load Capacity @ yield point (lbs):<br />

Max. Capacity with Stop … … 239,800 … 398,100 212,700 …<br />

Min. Capacity Without Stop 85,200 263,600 239,800 224,600 398,100 212,700 250,300<br />

Max. Make-up torque 50% of yield (ft/lbs) 600 2,550 2,800 … … 4,000 4,600<br />

Maximum Catch Size (Basket) 3-21/32 3-21/32 3-3/4 3-3/4 4-1/4 4-3/4 5-1/4<br />

overshot o.D. 4-11/16 5-5/8 4-3/4 5-1/2 5-3/4 5-7/8 6-1/4<br />

Complete Assembly <strong>Logan</strong> part no. 70- 68-D 70-56 -A 70- 75-D 70-550-A 70-575-A 70-587-D 70-6 5-D<br />

Bowen No. 10543 11297 12645 12785 13065 10560 14805<br />

Bowl <strong>Logan</strong> part no. C 005 C 006 C 007 C 008 C 009 C 0 0 C 0 05<br />

Bowen No. 10545 11299 12646 12787 13067 10562 14807<br />

Basket grapple Load Capacity @ yield point (lbs):<br />

Max. Capacity with Stop 197,600 635,700 267,100 504,500 467,400 306,200 …<br />

Min. Capacity Without Stop 197,600 790,500 267,100 558,100 575,600 348,200 319,700<br />

Max. Make-up torque 50% of yield (ft/lbs) 5,000 … … … 7,400 … 8,100<br />

Notes:<br />

1) All strengths are calculated theoretical yield points and are accurate within 20%. All strengths assume a straight, steady pull and<br />

full grapple engagement of a round fish. Anything less than straight pulling or full engagement will substantially reduce the strength.<br />

2) No tong marks should be applied to the bowl. Tong marks and other surface damage to the bowl will also reduce the strength.<br />

3) Maximum recommended makeup torque is 50% of yield. Less torque may be used depending upon the situation.<br />

4) Jarring may amplify the pull load by a factor of 3 to 10.<br />

9

0<br />

<strong>Logan</strong> SerieS 70 Short catch overShotS<br />

CALCuLAtED StREngthS<br />

Maximum Catch Size (Basket) 4-3/4 6 6-1/4 6-1/2 7 7-3/4 8<br />

overshot o.D. 6-5/8 7-5/8 7-7/8 8-1/4 8-1/2 9-1/4 9-3/4<br />

Complete Assembly <strong>Logan</strong> part no. 70-66 -A 70-76 -A 70-787-A 70-8 5-A 70-850-A 70-9 5-A 70-975-A<br />

Bowen No. 11303 11630 16975 38939 20050 25030 20060<br />

Bowl <strong>Logan</strong> part no. C 0 C 0 C 0 C 0 C 0 5 C 0 6 C 0 7<br />

Bowen No. 11305 11632 16977 38941 20052 25032 20062<br />

Basket grapple Load Capacity @ yield point (lbs):<br />

Max. Capacity with Stop 579,400 358,000 349,200 … 285,100 … …<br />

Min. Capacity Without Stop 720,600 445,300 445,700 445,100 373,700 391,700 445,100<br />

Max. Make-up torque 50% of yield (ft/lbs) … 12,500 … 22,000 24,200 27,800 30,800<br />

Maximum Catch Size (Basket) 9 13-3/8<br />

overshot o.D. 11-1/4 16<br />

Complete Assembly <strong>Logan</strong> part no. 70- 5-A 70- 600-A<br />

Bowen No. 33878 …<br />

Bowl <strong>Logan</strong> part no. C 0 8 C 0 9<br />

Bowen No. 33880 …<br />

Basket grapple Load Capacity @ yield point (lbs):<br />

Max. Capacity with Stop … …<br />

Min. Capacity Without Stop 874,800 …<br />

Max. Make-up torque 50% of yield (ft/lbs) 42,000 55,500<br />

Notes:<br />

1) All strengths are calculated theoretical yield points and are accurate within 20%. All strengths assume a straight, steady pull and<br />

full grapple engagement of a round fish. Anything less than straight pulling or full engagement will substantially reduce the strength.<br />

2) No tong marks should be applied to the bowl. Tong marks and other surface damage to the bowl will also reduce the strength.<br />

3) Maximum recommended makeup torque is 50% of yield. Less torque may be used depending upon the situation.<br />

4) Jarring may amplify the pull load by a factor of 3 to 10.

<strong>Logan</strong> SerieS 150 reLeaSing & circULating overShotS<br />

CALCuLAtED StREngthS<br />

Maximum Load Capacity @ yield point (lbs)<br />

Complete <strong>Logan</strong> Bowen Catch Size w/ overshot Spiral Basket grapple<br />

Assembly Bowl no. Bowl no. Spiral grapple o.D. (in) grapple w/o Stop w/ Stop<br />

150-231-D A1950 B-8921 2 2-5/16 50,400 36,300 28,900<br />

150-263-D A2000 B-10201 2-1/8 2-5/8 101,600 86,400 61,000<br />

150-313-E A2001 9306 2-3/8 3-1/8 193,500 173,200 118,000<br />

150-350-A A2002 B-4743 2-3/8 3-1/2 309,000 265,500 167,000<br />

150-412-B A20025 1446 2-3/8 4-1/8 455,000 390,000 265,000<br />

150-338-D A2003 B-5088 2-1/2 3-3/8 258,000 213,300 163,500<br />

150-363-A A2004 B-5082 2-1/2 3-5/8 346,200 307,700 219,800<br />

150-363-E A2005 9271 2-7/8 3-5/8 193,500 157,400 78,700<br />

150-375-D A20055 37587 3-1/16 3-3/4 217,700 221,200 179,700<br />

150-388-D A20056 B-1836 3-1/8 3-7/8 155,100 144,200 98,000<br />

150-376-D A20057 B-1828 2-7/8 3-3/4 214,000 192,800 121,400<br />

150-400-A A2006 B-4738 2-7/8 4 304,000 221,500 199,000<br />

150-393-D A2007 B-5103 3-1/16 3-15/16 265,400 219,000 160,100<br />

150-419-A A2008 B-5100 3-1/16 4-3/16 291,800 263,000 118,200<br />

150-400-D A2009 B-5106 3-1/8 4 262,900 217,000 125,100<br />

150-413-A A2010 9107 3-1/8 4-1/8 310,200 255,000 170,000<br />

150-412-A A20105 8223 3-1/8 4-1/8 310,200 255,000 170,000<br />

150-425-A A2011 B-4824 3-1/8 4-1/4 291,800 263,000 118,200<br />

150-413-D A2012 B-5117 3-1/4 4-1/8 225,000 202,000 127,500<br />

150-438-A A2013 B-5114 3-1/4 4-3/8 254,000 234,200 147,500<br />

150-388-E A20135 21302 3-3/8 3-7/8 102,500 97,500 66,500<br />

150-425-D A2014 B-5128 3-3/8 4-1/4 262,900 217,000 116,800<br />

150-4375-A A20145 9637 3-3/8 4-3/8 281,500 249,400 167,900<br />

150-450-A A2015 B-5125 3-3/8 4-1/2 320,000 280,000 176,000<br />

150-438-D A2016 B-4621 3-1/2 4-3/8 267,400 220,700 144,300<br />

150-482-A A2017 B-4734 3-1/2 4-13/16 456,000 396,000 286,000

<strong>Logan</strong> SerieS 150 reLeaSing & circULating overShotS<br />

CALCuLAtED StREngthS<br />

Maximum Load Capacity @ yield point (lbs)<br />

Complete <strong>Logan</strong> Bowen Catch Size w/ overshot Spiral Basket grapple<br />

Assembly Bowl no. Bowl no. Spiral grapple o.D. (in) grapple w/o Stop w/ Stop<br />

150-451-D A20161 A-3795 3-1/2 4-1/2 271,000 226,000 146,500<br />

150-450-D A20175 17203 3-21/32 4-17/32 260,400 233,400 170,500<br />

150-456-D A2018 B-5153 3-21/32 4-9/16 276,400 228,100 157,900<br />

150-469-C A2019 9111 3-21/32 4-11/16 332,000 279,000 199,500<br />

150-500-A A2020 B-5150 3-21/32 5 394,000 338,000 210,000<br />

150-463-D A2021 B-5131 3-3/4 4-5/8 270,600 218,000 150,900<br />

150-468-C A20215 9121 3-3/4 4-11/16 261,300 233,000 138,000<br />

150-444-D A20217 B-9775 3-13/16 4-7/16 137,500 118,000 44,800<br />

150-513-A A2022 B-4688 3-3/4 5-1/8 489,000 447,000 354,000<br />

150-525-A A2023 9517 3-7/8 5-1/4 451,000 389,500 276,500<br />

150-462-D A20235 B-6232 3-7/8 4-5/8 186,800 166,700 104,200<br />

150-488-D A2024 B-5156 4 4-7/8 385,000 241,000 167,000<br />

150-531-A A2025 B-5144 4 5-5/16 402,000 351,000 273,000<br />

150-500-D A2026 B-5430 4-1/8 5 296,000 258,500 201,000<br />

150-544-A A2027 B-5427 4-1/8 5-7/16 547,600 435,500 277,100<br />

150-512-D A20285 4717 4-1/4 5-1/8 312,500 264,000 196,000<br />

150-513-D A2028 B-5164 4-1/4 5-1/8 356,800 301,000 232,200<br />

150-556-A A2029 5898 4-1/4 5-9/16 526,600 494,300 362,500<br />

150-555-A A20295 B-4821 4-1/4 5-9/16 439,200 396,000 286,000<br />

150-538-D A2030 B-5167 4-1/2 5-3/8 279,000 258,000 186,200<br />

150-581-A A2031 B-4816 4-1/2 5-13/16 439,200 396,000 286,000<br />

150-550-D A20315 B-4971 4-5/8 5-1/2 297,000 258,000 186,200<br />

150-563-A A2032 5700 4-5/8 5-5/8 420,000 378,500 273,000<br />

150-594-A A2033 5735 4-5/8 5-15/16 514,100 421,300 297,400<br />

150-563-D A2034 B-5170 4-3/4 5-5/8 360,400 308,400 234,500<br />

150-575-A A2035 8977 4-3/4 5-3/4 432,900 411,600 303,275

<strong>Logan</strong> SerieS 150 reLeaSing & circULating overShotS<br />

CALCuLAtED StREngthS<br />

Maximum Load Capacity @ yield point (lbs)<br />

Complete <strong>Logan</strong> Bowen Catch Size w/ overshot Spiral Basket grapple<br />

Assembly Bowl no. Bowl no. Spiral grapple o.D. (in) grapple w/o Stop w/ Stop<br />

150-606-A A2036 B-4831 4-3/4 6-1/16 431,000 381,000 275,500<br />

150-575-D A2037 B-7098 4-7/8 5-3/4 273,500 230,700 178,000<br />

150-613-A A20375 905 4-7/8 6-1/8 405,000 367,000 298,000<br />

150-619-A A2038 B-7095 4-7/8 6-3/16 404,500 341,200 282,700<br />

1150-588-D A2039 B-5173 5 5-29/32 323,500 283,500 218,500<br />

150-612-C A20395 7788 5 6-1/8 468,000 440,000 322,000<br />

150-663-A A2040 B-4827 5 6-5/8 637,000 574,300 462,000<br />

150-576-D A20402 B-11825 5-1/8 5-3/4 135,000 115,000 71,500<br />

150-638-D A20405 4503 5-1/4 6-3/8 403,000 356,000 256,000<br />

150-650-D A20407 9205 5-3/8 6-1/2 385,500 325,000 232,000<br />

150-663-D A2041 8617 5-1/2 6-5/8 386,000 325,000 232,000<br />

150-713-A A2042 B-2791 5-1/2 7-1/8 637,500 574,300 462,000<br />

150-688-D A2043 8980 5-3/4 6-7/8 367,000 332,000 253,000<br />

150-738-A A2044 B-3522 5-3/4 7-3/8 637,500 574,300 462,000<br />

150-763-A A2045 7574 6 7-5/8 611,300 532,600 404,300<br />

150-725-D A2046 B-5208 6-1/8 7-1/4 435,000 392,000 298,000<br />

150-775-A A2047 B-4218 6-1/8 7-3/4 637,000 574,300 462,000<br />

150-738-D A2048 9694 6-1/4 7-3/8 450,400 427,283 327,900<br />

150-762-C A20485 1875 6-1/4 7-5/8 542,468 479,044 364,490<br />

150-763-C A2049 1641 6-1/4 7-5/8 502,100 449,900 363,200<br />

150-777-A A20495 1657 6-1/4 7-7/8 627,600 542,400 395,000<br />

150-788-A A2050 B-2109 6-1/4 7-7/8 586,800 515,600 413,700<br />

150-750-D A2051 9011 6-3/8 7-1/2 479,000 454,000 339,000<br />

150-775-C A2052 9164 6-3/8 7-3/4 385,500 325,000 232,000<br />

150-763-D A2053 9862 6-1/2 7-5/8 418,200 396,700 322,900<br />

150-813-A A2054 B-3711 6-1/2 8-1/8 586,500 515,500 413,500

<strong>Logan</strong> SerieS 150 reLeaSing & circULating overShotS<br />

CALCuLAtED StREngthS<br />

Maximum Load Capacity @ yield point (lbs)<br />

Complete <strong>Logan</strong> Bowen Catch Size w/ overshot Spiral Basket grapple<br />

Assembly Bowl no. Bowl no. Spiral grapple o.D. (in) grapple w/o Stop w/ Stop<br />

150-775-D A2055 9134 6-5/8 7-3/4 422,000 400,000 318,000<br />

150-825-A A2056 B-3034 6-5/8 8-1/4 637,500 574,300 462,000<br />

150-788-D A2057 B-5224 6-3/4 7-7/8 531,900 467,300 375,000<br />

150-838-A A2058 277 6-3/4 8-3/8 637,000 542,250 408,250<br />

150-800-D A20587 M-8997 6-7/8 8 436,000 406,900 350,000<br />

150-814-D A20590 9817 7 8-1/8 453,000 429,500 329,500<br />

150-813-D A2059 9219 7 8-1/8 453,000 429,500 329,500<br />

150-812-D A20595 B-3264 7 8-1/8 439,200 395,800 318,400<br />

150-837-D A20598 17209 7 8-3/8 587,977 557,764 428,051<br />

150-863-A A2060 B-3819 7 8-5/8 637,000 574,300 462,000<br />

150-825-D A20605 9571 7-1/8 8-1/4 422,000 400,000 307,300<br />

150-838-D A2061 B-5356 7-1/4 8-3/8 430,000 385,000 295,000<br />

150-888-A A2062 M-1026-1 7-1/4 8-7/8 586,900 515,600 426,500<br />

150-850-D A2063 9233 7-3/8 8-1/2 422,000 400,000 309,000<br />

150-900-A A2064 B-5232 7-3/8 9 637,000 574,300 462,000<br />

150-863-D A2065 B-7103 7-1/2 8-5/8 436,000 385,000 309,000<br />

150-913-A A2066 B-4516 7-1/2 9-1/8 637,000 574,300 462,000<br />

150-875-D A2067 9239 7-5/8 8-3/4 458,000 435,000 333,000<br />

150-762-A A20675 B-5243 7-5/8 9-1/4 657,000 578,000 465,000<br />

150-888-D A2068 9852 7-3/4 8-7/8 458,000 435,000 333,000<br />

150-889-D A2069 B-5259 7-3/4 8-7/8 430,000 385,000 295,000<br />

150-937-A A20695 1283 7-3/4 9-3/8 637,000 542,250 408,250<br />

150-938-A A2070 B-1501 7-3/4 9-3/8 592,000 520,000 340,000<br />

150-913-D A2071 B-5267 8 9-1/8 396,000 347,500 236,000<br />

150-963-A A2072 266 8 9-5/8 602,700 510,750 398,600<br />

150-950-D A2073 9062 8-3/8 9-1/2 447,500 424,500 325,500

<strong>Logan</strong> SerieS 150 reLeaSing & circULating overShotS<br />

CALCuLAtED StREngthS<br />

Maximum Load Capacity @ yield point (lbs)<br />

Complete <strong>Logan</strong> Bowen Catch Size w/ overshot Spiral Basket grapple<br />

Assembly Bowl no. Bowl no. Spiral grapple o.D. (in) grapple w/o Stop w/ Stop<br />

150-1006-A A2074 B-1231 8-3/8 10-1/16 637,500 574,300 462,000<br />

150-963-D A2075 B-5286 8-1/2 9-5/8 419,500 376,000 341,000<br />

150-1013-A A2076 8962 8-1/2 10-1/8 602,700 492,000 391,000<br />

150-1025-D A2077 B-5299 8-5/8 10-1/4 657,000 578,000 465,000<br />

150-1050-A A2078 B-5307 8-7/8 10-1/2 586,600 515,400 413,600<br />

150-1063-A A2079 B-5323 9 10-5/8 586,800 515,600 426,500<br />

150-1125-A A2080 B-12824 9-5/8 11-1/4 586,800 515,600 413,700<br />

150-1138-A A2081 26257 9-3/4 11-3/8 565,900 502,900 380,000<br />

150-1175-A A2082 5331 10-1/8 11-3/4 616,000 528,000 435,000<br />

150-1275-A A2083 15802 11-1/4 12-3/4 605,000 562,250 444,000<br />

150-1375 A2084 33008 12 13-3/4 1,022,314 745,564 …<br />

150-1600 A2085 68030 14 16 1,164,000 1,175,000 …<br />

150-1675 A2086 64555 14-3/4 16-3/4 1,197,674 1,226,777 …<br />

150-2075 A2087 31655 16-3/4 20-1/4 … 1,479,060 1,344,600<br />

Notes:<br />

1) All strengths are calculated theoretical yield points and are accurate within 20%. All strengths assume a straight, steady pull and<br />

full grapple engagement of a round fish. Anything less than straight pulling or full engagement will substantially reduce the strength.<br />

2) No tong marks should be applied to the bowl. Tong marks and other surface damage to the bowl will also reduce the strength.<br />

5

6<br />

<strong>Logan</strong> SUperior hyDraULic fiShing jarS<br />

Mandrel Extension to Washpipe<br />

Mandrel to Mandrel Extension<br />

(internal connection)<br />

(internal connection)<br />

Connector<br />

Mandrel Spline Body<br />

Balance Body Body Pressure Body<br />

Washpipe Body<br />

Floater Body<br />

StREngth AnD tESt DAtA<br />

Complete Assembly 6 - 06 6 - 6 - 6 - 75 6 - 76 6 - 5 6 - 50 6 - 75 6 -6 5 6 -775<br />

outside Diameter (in) 3-1/16 3-1/8 3-1/8 3-3/4 3-3/4 4-1/4 4-1/2 4-3/4 6-1/4 7-3/4<br />

Jar tester Low test pull Load — Min (lbs) 7,000 9,000 7,000 12,000 12,000 12,000 12,000 15,000 18,000 18,000<br />

JAR tEStER LoW tESt puD — Max (lbs)<br />

12,000 12,000 12,000 16,000 16,000 16,000 16,000 20,000 26,000 26,000<br />

Jar tester Standard pull test (lbs) 18,000 30,000 18,000 35,000 35,000 35,000 30,000 50,000 100,000 100,000<br />

Field Load — Max pull Load 36,000 55,000 36,000 72,000 51,000 75,000 60,000 100,000 200,000 275,000<br />

Lift Load After Jarring, Jar Fully Extended<br />

185,000 253,000 185,000 330,000 285,000 375,000 360,000 505,000 1,000,000 1,600,000<br />

tensile @ yield (lbs)<br />

torque @ yield (ft-lbs) 4,200 7,500 4,200 14,500 9,650 18,500 12,000 18,100 40,800 79,000<br />

MAXIMuM RECoMMEnDED tIghtEnIng toRQuES (Ft-LBS)<br />

Spline Body to Balance Body 2,100 2,700 2,100 3,500 3,650 5,000 3,500 9,090 20,000 39,000<br />

Balance Body to Connector Body 2,100 2,700 2,100 3,500 3,650 5,000 3,500 9,090 20,000 39,000<br />

Connector Body to pressure Body 2,100 2,700 2,100 3,500 3,650 5,000 3,500 9,090 20,000 39,000<br />

Mandrel to Mandrel Extension 700 800 700 800 800 1,700 900 1,800 7,000 12,500<br />

pressure Body to Floater Body 2,100 2,700 2,100 3,500 3,650 5,000 3,500 9,090 20,000 39,000<br />

Mandrel Extension to Washpipe 600 700 600 700 700 1,500 800 1,000 4,800 10,500<br />

Floater Body to Washpipe Body 2,100 2,700 2,100 3,500 3,650 5,000 3,500 9,090 20,000 39,000

<strong>Logan</strong> SUperior energizerS<br />

Mandrel to Mandrel Extension<br />

Mandrel Extension to Washpipe<br />

(internal connection)<br />

(internal connection)<br />

Connector<br />

Mandrel Spline Body<br />

Balance Body Body<br />

Pressure Body Washpipe Body<br />

StREngth AnD tESt DAtA<br />

Complete Assembly 6 - 06 6 - 6 - 6 - 75 6 - 76 6 - 5 6 - 50 6 - 75 6 -6 5 6 -775<br />

outside Diameter (in) 3-1/16 3-1/8 3-1/8 3-3/4 3-3/4 4-1/4 4-1/2 4-3/4 6-1/4 7-3/4<br />

Jar tester Low test pull Load — Min (lbs) 7,000 9,000 7,000 12,000 12,000 12,000 12,000 15,000 18,000 18,000<br />

Jar tester Low test pull Load — Max (lbs) 12,000 12,000 12,000 16,000 16,000 16,000 16,000 20,000 26,000 26,000<br />

Jar tester Standard pull test (lbs) 18,000 30,000 18,000 35,000 35,000 35,000 30,000 50,000 100,000 100,000<br />

Field Load — Max pull Load 36,000 55,000 36,000 72,000 51,000 75,000 60,000 100,000 200,000 275,000<br />

Lift Load After Jarring, Jar Fully Extended,<br />

185,000 253,000 185,000 330,000 285,000 375,000 360,000 505,000 1,000,000 1,600,000<br />

tensile @ yield (lbs)<br />

torque @ yield (ft-lbs) 4,200 7,500 4,200 14,500 9,650 18,500 12,000 18,100 40,800 79,000<br />

MAXIMuM RECoMMEnDED tIghtEnIng toRQuES (Ft-LBS)<br />

Spline Body to Balance Body 2,100 2,700 2,100 3,500 3,500 5,000 5,000 9,090 20,000 39,000<br />

Mandrel to Mandrel Extension 700 800 700 800 700 1,700 1,500 1,800 7,000 12,500<br />

Balance Body to Connector Body 2,100 2,700 2,100 3,500 3,500 5,000 5,000 9,090 20,000 39,000<br />

Connector Body to pressure Body 2,100 2,700 2,100 3,500 3,500 5,000 5,000 9,090 20,000 39,000<br />

Mandrel Extension to Washpipe 600 700 600 700 700 1,500 1,500 1,000 4,800 10,500<br />

pressure Body to Washpipe Body 2,100 2,700 2,100 3,500 3,500 5,000 5,000 9,090 20,000 39,000<br />

7

8<br />

<strong>Logan</strong> SUrface BUmper jarS<br />

Washpipe to Bottom Sub<br />

(internal connection)<br />

Bowl Bottom Sub<br />

Top Sub to Main Mandrel<br />

Main Mandrel to Friction Mandrel<br />

(internal connection)<br />

(internal connection)<br />

Knocker Sub<br />

Top Sub Bowl Extension<br />

StREngth AnD tESt DAtA<br />

Complete Assembly 609-00<br />

outside Diameter (in) 7<br />

Bowl outside Diameter (in) 9<br />

Max torque @ yield (ft-lbs) 33,800<br />

Max tensile Load @ yield (ft-lbs) 845,000<br />

Max pump pressure (psi) 8,000<br />

Setting Load (tons) 0 – 50<br />

MAXIMuM RECoMMEnDED tIghtEnIng toRQuES (Ft-LBS)<br />

top Sub to Main Mandrel 16,900<br />

knocker Sub Bowl Extension 16,900<br />

Bowl Extension to Bowl 17,900<br />

Main Mandrel to Friction Mandrel 2,700<br />

Washpipe to Bottom Sub 2,700<br />

Bowl to Bottom Sub 17,900

<strong>Logan</strong> LUBricateD fiShing BUmper SUBS<br />

Mandrel to Washpipe<br />

(internal connection)<br />

Knocker to Mandrel<br />

(internal connection)<br />

Washpipe Body<br />

Mandrel Mandrel Body<br />

Middle Body<br />

StREngth AnD tESt DAtA<br />

Complete Assembly 607-181 607-225 607-312 607-375 607-376 607-377 607-425 607-450 607-475 607-476 607-600 607-625 607-675 607-775<br />

outside Diameter (in) 1-13/16 2-1/4 3-1/8 3-3/4 3-3/4 3-3/4 4-1/4 4-1/2 4-3/4 4-3/4 6 6-1/4 6-3/4 7-3/4<br />

tensile Strength (lbs) 75,400 116,415 239,070 363,780 300,750 291,735 397,650 388,650 484,650 433,000 622,295 777,150 1,130,400 1,276,950<br />

Bumper Sub yield torque (ft-lbs) 480 1,740 3,400 7,100 7,100 4,920 9,260 7,100 11,030 15,000 23,000 32,600 43,200 62,400<br />

Max operating torque (ft-lbs) 240 870 1,700 3,550 3,550 2,460 4,630 3,550 5,518 7,500 11,500 16,300 21,600 31,200<br />

MAXIMuM RECoMMEnDED tIghtEnIng toRQuES (Ft-LBS)<br />

Mandrel to Mandrel Body 240 … … … … … … … … … … … … …<br />

Mandrel Body to Middle Body 370 870 1,700 3,550 3,550 2,460 4,630 3,550 7,500 7,500 11,500 16,300 21,600 31,200<br />

knocker to Mandrel … 90 430 580 410 330 670 370 1,100 1,000 2,270 3,120 3,000 7,690<br />

Mandrel to Washpipe … 140 660 500 490 1,220 730 1,450 1,690 1,500 3,800 9,750 13,300 21,000<br />

Middle Body to Washpipe Body 370 870 1,700 3,550 3,550 2,460 4,630 3,550 7,500 7,500 13,500 16,300 22,600 31,200<br />

9

0<br />

0.625<br />

45° 1/2 Max.<br />

0.62R<br />

D L<br />

D LF<br />

C<br />

api nUmBereD<br />

rotary ShoULDereD connectionS<br />

L PC<br />

See Note<br />

0.625<br />

D S Q C<br />

See Note<br />

Note: Extent of bevel on pin and box starting thread is optional with manufacturer.<br />

Thread Thread Lg. Dia. Flat Sm. Dia Box Pin Box<br />

Form, Taper, Pitch Dia. of Pin, on Pin of Pin Depth Length Counterbore<br />

Conn. Inch Thds. In/Ft @ Gauge Pt. Reference DLF DS LBC LPC QC<br />

No. * Radius Per In on Dia. C DL ± 1/64 +0 –3/8 +0 –3/8 +0 –1/8 +1/32 –0<br />

23 0.038 4 2 2.355 2.563 2.437 2.063 3-5/8 3 2-5/8<br />

26 ** 0.038 4 2 2.668 2.876 2.750 2.376 3-5/8 3 2-15/16<br />

31 ** 0.038 4 2 3.183 3.391 3.266 2.808 4-1/8 3-1/2 3-29/64<br />

35 0.038 4 2 3.531 3.739 3.625 3.114 4-3/8 3-3/4 3-13/16<br />

38 ** 0.038 4 2 3.808 4.016 3.891 3.349 4-5/8 4 4-5/64<br />

40 ** 0.038 4 2 4.072 4.280 4.156 3.630 5-1/8 4-1/2 4-11/32<br />

44 0.038 4 2 4.417 4.625 4.499 8.875 5-1/8 4-1/2 4-11/16<br />

46 ** 0.038 4 2 4.626 4.834 4.709 4.084 5-1/8 4-1/2 4-29/32<br />

50 ** 0.038 4 2 5.0417 5.250 5.125 4.500 5-1/8 4-1/2 5-5/16<br />

56 0.038 4 3 5.616 5.876 5.703 4.626 5-5/8 5 5-15/16<br />

61 0.038 4 3 6.178 6.438 6.266 6.063 6-1/8 5-1/2 6-1/2<br />

70 0.038 4 3 7.053 7.313 7.141 6.813 6-5/8 6 7-3/8<br />

77 0.038 4 3 7.741 8.000 7.828 6.376 7-1/8 6-1/2 8-1/16<br />

All dimensions are in inches.<br />

* The connection number is the diameter of the connection at the gauge point rounded to units<br />

and tenths of inches.<br />

** See Table 12 below for interchangeability of numbered rotary shouldered connections with rotary<br />

shouldered connections of Table 9.1.<br />

taBLe 12<br />

IntERChAngEABILIty oF nuMBERED RotARy ShouLDERED ConnECtIonS<br />

WIth tABLE 9. RotARy ShouLDERED ConnECtIonS<br />

45°<br />

numbered Connection Equivalent Connection of table 9.<br />

26 2-3/8 IF<br />

31 2-7/8 IF<br />

38 3-1/2 IF<br />

40 4 FH<br />

46 4 IF<br />

50 4-1/2 IF<br />

L BC

api regULar — Union tooL regULar<br />

G<br />

A<br />

5 Thd. 3 TPF .118<br />

5 Thd. 2 TPF .119<br />

4 Thd. 3 TPF .147<br />

4 Thd. 2 TPF .148<br />

ApI REguLAR — unIon tooL REguLAR<br />

Size A B C D E F g h k<br />

2-3/8 3 3-1/8 2-5/8 1-7/8 2-11/16 3-3/8 1 5 3<br />

2-7/8 3-1/2 3-3/4 3 2-1/8 3-1/16 3-7/8 1-1/4 5 3<br />

3-1/2 3-3/4 4-1/4 3-1/2 2-9/16 3-9/16 4-1/8 1-1/2 5 3<br />

4-1/2 4-1/4 5-1/2 * 4-5/8 3-9/16 4-11/16 4-5/8 2-1/4 5 3<br />

5-1/2 4-3/4 6-3/4 5-33/64 4-21/64 5-37/64 5-1/8 2-3/4 4 3<br />

6-5/8 ** 5 7-3/4 6 5-5/32 6-1/16 5-3/8 3-1/2 4 2<br />

7-5/8 5-1/4 8-7/8 7 5-11/16 7-1/16 5-5/8 4 4 3<br />

8-5/8 5-3/8 10 7-61/64 6-39/64 8-1/64 5-3/4 4-3/4 4 3<br />

* 5-3/4 O.D. is optional.<br />

** Threaded portion same as 5-1/2 Union Tool Full Hole.<br />

H - Threads per Inch<br />

F<br />

K - Incl. Taper 5/8 C’Bore<br />

D<br />

.015R<br />

C<br />

B<br />

E<br />

.020R - 5 Thd.<br />

.025R - 4 Thd.<br />

.040 Flat - 5 Thd.<br />

30° 30° .050 Flat - 4 Thd.<br />

90°<br />

.200 5 Thd.<br />

.250 4 Thd.<br />

.015R<br />

G<br />

30°

api fULL hoLe — Union tooL fULL hoLe<br />

G<br />

4 Thd. 3 TPF<br />

A<br />

.147<br />

4 Thd. 2 TPF<br />

.148<br />

5 Thd. 3 TPF<br />

.118<br />

Size A B C D E F g h k<br />

2-7/8 * 3-1/2 4-1/4 3-5/8 2-3/4 3-11/16 3-9/16 2-1/8 5 3<br />

3-1/2 3-3/4 4-5/8 4 3-1/16 4-3/64 4-3/8 2-1/8 ** 5 3<br />

4 4-1/2 5-1/4 4-9/32 3-17/32 4-11/32 5-1/8 2-13/16 4 † 2<br />

4-1/2 4 5-3/4 4-51/64 3-51/64 4-7/8 4-5/8 3 5 3<br />

5-1/2 5 7 5-53/64 5 5-29/32 5-5/8 4 4 2<br />

6-5/8 5 8 6-3/4 5-59/64 6-27/32 5-5/8 5 4 2<br />

* Not API Standard.<br />

** I.D. changed from 2-7/16", May 1979 (API)<br />

† Thread form same as API-IF joint.<br />

H - Threads per Inch<br />

K - Incl. Taper 5/8<br />

D<br />

.015R<br />

C<br />

ApI FuLL hoLE — unIon tooL FuLL hoLE<br />

B<br />

E<br />

.020R - 5 Thd.<br />

.025R - 4 Thd.<br />

30° 30°<br />

90°<br />

.200<br />

.250<br />

5 Thd.<br />

4 Thd.<br />

.015R<br />

Perf. Thd.<br />

F<br />

.040 Flat - 5 Thd.<br />

.050 Flat - 4 Thd.<br />

G<br />

30°

api internaL fLUSh — hUgheS anD reeD Lf<br />

A<br />

G<br />

.015R<br />

30°<br />

H - Threads per Inch<br />

K - Incl. Taper<br />

ApI IntERnAL FLuSh — hughES AnD REED LF<br />

Size A B C D E F g h k<br />

2-3/8 3 3-3/8 2-7/8 2-3/8 2-15/16 3-3/8 1-3/4 4 2<br />

2-7/8 3-1/2 4-1/8 3-25/64 2-13/16 3-29/64 3-7/8 2-1/8 4 2<br />

3-1/2 4 4-3/4 4-1/64 3-11/32 4-5/64 4-3/8 2-11/16 4 2<br />

4 4-1/2 5-3/4 4-53/64 4-5/64 4-29/32 4-7/8 3-1/4 4 2<br />

4-1/2 4-1/2 6-1/8 5-1/4 4-1/2 5-5/16 4-7/8 3-3/4 4 2<br />

5-1/2 5 7-3/8 6-25/64 5-9/16 6-29/64 5-3/8 4-13/16 4 2<br />

Threaded portion same as 2-7/8" Hughes Slim Hole.<br />

Threaded portion same as 3-1/2" Hughes Slim Hole.<br />

Threaded portion same as 4-1/2" Hughes Slim Hole.<br />

D<br />

.250<br />

90°<br />

30°<br />

Threaded portion same as 4-1/2" Hughes Xtra Hole, 5" Reed Double Streamline,<br />

and 4-1/2" Reed Xtra Hole.<br />

Threaded portion same as 5-1/2" Reed Double Streamline, 5" Hughes Xtra Hole,<br />

and 5" Reed Xtra Hole.<br />

C<br />

B<br />

E<br />

.056<br />

5/8<br />

.015R<br />

.065<br />

.1114<br />

Axis<br />

Perf. Thd.<br />

F<br />

30°<br />

G

.31<br />

american mt, amt, anD ammt *<br />

.015 R Typ<br />

Perf. Thd.<br />

A<br />

L<br />

.047<br />

45°<br />

Diameter of flat<br />

Max. cone diameter at shoulder<br />

.166<br />

30°<br />

.44<br />

G M D J C B E O<br />

90°<br />

Axis of Joint<br />

.055<br />

AMERICAn Mt, AMt, AnD AMMt<br />

Perf. Thd.<br />

N<br />

F<br />

45°<br />

.056<br />

G<br />

45°<br />

H - Threads per Inch<br />

K - Incl. Taper<br />

Size A B C D E F G H J K L M N O<br />

(in) (in) (in) (in) (in) (in) (in) (TPI) (in) (TPF) (in) (in) (in) (in)<br />

1 1-1/2 1-9/16 1.281 1.093 1.301 1-1/2 3/4 6 1.233 1-1/2 1-1/8 61/64 2 1.183<br />

1-1/4 2 1-3/4 1.469 1.218 1.489 2 3/4 6 1.421 1-1/2 1-5/8 1-3/32 2-1/2 1.371<br />

1-1/2 2 2 1.668 1.418 1.688 2 1 6 1.621 1-1/2 1-5/8 1-9/32 2-1/2 1.570<br />

* MT is Macaroni Tubing; AMT is American Macaroni Tubing;<br />

AMMT is American Mining Macaroni Tubing

A<br />

pac<br />

.38<br />

G D J C B E<br />

Diameter of straight<br />

Max. cone diameter at shoulder<br />

.015 R Typ<br />

.067<br />

pAC<br />

.250<br />

30°<br />

90°<br />

Axis of Joint<br />

Perf. Thd.<br />

F<br />

G<br />

H - Threads per Inch<br />

K - Incl. Taper<br />

Size A B C D E F g h J k<br />

(in) (in) (in) (in) (in) (in) (in) (tpI) (in) (tpF)<br />

2-3/8 2-3/8 2-7/8 2-23/64 2-1/16 2-27/64 2-1/2 1-3/8 4 2-5/16 1-1/2<br />

2-7/8 2-3/8 3-1/8 2-17/32 2-15/64 2-19/32 2-1/2 1-1/2 4 2-31/64 1-1/2<br />

3-1/2 3-1/4 3-3/4 3-3/64 2-41/64 3-7/64 3-3/8 2 4 3 1-1/2<br />

.076<br />

.093<br />

30°<br />

5

6<br />

hUgheS Xtra hoLe & reeD eXtra hoLe<br />

A<br />

H - Threads per Inch<br />

K - Incl. Taper<br />

G D C<br />

hughES XtRA hoLE & REED EXtRA hoLE<br />

Size A B C D E F g h J k<br />

2-7/8 3-7/8 4-1/4 3-21/64 2-11/16 3-23/64 4-1/2 1-7/8 4 3-15/64 2<br />

3-1/2 3-3/8 4-3/4 3-13/16 3-1/4 3-7/8 3-15/16 2-7/16 4 … 2<br />

4-1/2 4-3/8 6 4-53/64 4-7/64 4-29/32 4-15/16 3-1/4 4 … 2<br />

5 4-1/2 6-1/4 5-1/4 4-1/2 5-5/16 4-7/8 3-3/4 4 … 2<br />

Threaded portion same as 2-7/8" Reed Xtra Hole, 3-1/2" Reed Double Streamline,<br />

and 3-1/2" Hughes Double Streamline.<br />

J<br />

30° 30°<br />

.065<br />

.250<br />

Threaded portion same as 4-1/2" Hughes External Flush, 4-1/2" FH Reed External Flush,<br />

4" Hughes Slim Hole, and 3-1/2" Reed Xtra Hole.<br />

90°<br />

Threaded portion same as 4" API-IF, 5" Reed Double Sreamline, and 4-1/2" Reed Xtra Hole.<br />

Threaded portion same as 4-1/2" API-IF, 5-1/2" Reed Double Sreamline, and 5" Reed Xtra Hole.<br />

B<br />

.056<br />

E<br />

1/64 R<br />

1/64 R<br />

.1114<br />

Perf. Thd.<br />

F<br />

5/8<br />

35°<br />

Max. cone diameter at shoulder<br />

Diameter of straight section<br />

30°<br />

G

hughES SLIM hoLE<br />

Size A B C D E F g h k<br />

2-3/8 2-7/8 2-7/8 2-7/16 1-31/32 2-1/2 3-1/4 1-1/4 4 2<br />

2-7/8 2-7/8 3-3/8 2-7/8 2-25/64 2-15/16 3-1/4 1-3/4 4 2<br />

3-1/2 3-3/8 4 3-25/64 2-53/64 3-29/64 3-3/4 2-1/8 4 2<br />

4 3-3/8 4-1/2 3-13/16 3-1/4 3-7/8 3-3/4 2-9/16 4 2<br />

4-1/2 3-7/8 5 4-1/64 3-3/8 4-5/64 4-1/4 2-11/16 4 2<br />

Threaded portion same as 2-3/8" API-IF.<br />

Threaded portion same as 2-7/8" API-IF.<br />

Threaded portion same as 3-1/2" Hughes Xtra Hole, 3-1/2" Reed Xtra Hole,<br />

4-1/2" Hughes External Flush, and 4-1/2" Reed External Flush.<br />

Threaded portion same as 3-1/2" API-IF.<br />

A<br />

1/32 R<br />

G<br />

.015 R<br />

hUgheS SLim hoLe<br />

H - Threads per Inch<br />

K - Incl. Taper<br />

D<br />

C<br />

B<br />

30° 30°<br />

90°<br />

.250<br />

E<br />

.056<br />

F<br />

.065<br />

21/32<br />

.1114<br />

Perf. Thd.<br />

30°<br />

G<br />

7

8<br />

3/64 R<br />

N<br />

60°<br />

3/16<br />

.047<br />

G<br />

A<br />

45°<br />

hUgheS SLimLine h-90<br />

1/32<br />

Diameter straight<br />

1/8 R<br />

30°<br />

1/32 R<br />

2-3/8 Size<br />

H - Threads per Inch<br />

Perf. Thd.<br />

F<br />

K - Incl. Taper 3/8<br />

D<br />

Diameter straight<br />

.015 R<br />

.030 R<br />

J<br />

45°<br />

C<br />

45°<br />

B E<br />

Max. cone diameter at shoulder<br />

.3333<br />

90°<br />

hughES SLIMLInE h-90<br />

.041<br />

.090<br />

Size A B C D E F g h J k L M n<br />

2-3/8 2-3/4 3-1/8 2.725 2.439 2-49/64 3-1/16 1-1/2 3 2-43/64 1-1/4 3-1/16 2-1/4 2-5/8<br />

3-1/4 3-3/16<br />

3-3/4 2-1/8 – 2-1/4 3-5/8<br />

3-7/8 2-1/8 – 2-1/4 3-23/32<br />

2-7/8 2-7/8 4 3.196 2.897 3-15/64 3-3/8 2-1/8 – 2-1/4 3 3-5/32 1-1/4 3-13/16 2-45/64 3-3/32<br />

4 2 3-13/16<br />

4-1/8 1-3/4 – 2 3-29/32<br />

4-1/4 1-1/2 – 1-3/4 4<br />

4-5/8 2-3/8 – 2-3/4 4-7/16<br />

4-3/4 2-1/2 – 2-3/4 4-17/32<br />

3-1/2 3-1/8 4-7/8 3.835 3.509 3-7/8 3-3/8 2-5/8 3 3-25/32 3-5/8 4-5/8 3-11/32 3-47/64<br />

4-7/8 2-3/8 – 2-1/2 4-5/8<br />

5 2 – 2-3/8 4-23/32<br />

5-1/8 1-3/4 – 2-1/8 4-13/16<br />

L<br />

1/32 R<br />

.068<br />

M<br />

.084<br />

Axis of joint<br />

G<br />

30°

.1000<br />

.0461<br />

1/8 R<br />

45°<br />

.015R<br />

A<br />

hUgheS h-90<br />

H - Threads per Inch<br />

K - Incl. Taper<br />

G D J C L B E<br />

Diameter straight<br />

.28571<br />

45°<br />

.050<br />

.030R<br />

90°<br />

.034<br />

Axis of joint<br />

hughES h-90<br />

1/32 R<br />

Size A B C D E F g h J k L<br />

5 … … … … 2-5/8 – 2-3/4 … … … 4-13/16<br />

5-1/8 … … … … 2-1/2 – 2-3/4 … … … 4-13/16<br />

3-1/2 3-7/8 5-1/4 4-1/8 3-31/64 4-3/16 4-7/16 2 – 2-5/8 3-1/2 3-15/16 2 5<br />

5-3/8 … … … … 2 – 2-1/4 … … … 5<br />

5-1/2 … … … … 2 – 2-1/8 … … … 5<br />

5-1/2 … … … … 2-7/8 – 3 … … … 5-5/16<br />

5-5/8 … … … … 2-1/2 – 2-7/8 … … … 5-5/16<br />

4 4-1/8 5-3/4 4-1/2 3-13/16 4-9/16 4-11/16 2-1/4 – 2-7/8 3-1/2 4-5/16 2 5-1/2<br />

5-7/8 … … … … 2 – 2-3/4 … … … 5-1/2<br />

6 … … … … 2 – 2-1/2 … … … 5-1/2<br />

6 … … … … 3 – 3-1/4 … … … 5-3/4<br />

6-1/8 … … … … 2-3/4 – 3 … … … 5-3/4<br />

4-1/2 4-3/8 6-1/4 4-53/64 4-7/64 4-29/32 4-15/16 2-1/2 – 3 3-1/2 4-41/64 2 6<br />

6-3/8 … … … … 2 – 3 … … … 6<br />

6-1/2 … … … … 2 – 2-3/4 … … … 6<br />

21/32<br />

Max. cone diameter at shoulder<br />

E<br />

Perf. Thd.<br />

F<br />

45°<br />

13/32<br />

30°<br />

Shoulder Details<br />

for 7, 7-5/8, and 8-5/8 Connections<br />

G<br />

9

0<br />

hUgheS h-90<br />

Size A B C D E F g h J k L<br />

6-1/2 2-7/8 – 3-1/4 6-1/8<br />

6-5/8 2-1/2 – 3 6-1/8<br />

5 4-5/8 6-3/4 5-7/64 4-21/64 5-11/64 5-3/16 2-1/4 – 3 3-1/2 4-59/64 2 6-3/8<br />

6-7/8 2-1/4 – 2-3/4 6-3/8<br />

7 2-1/2 6-3/8<br />

6-3/4 3-1/8 – 3-3/8 6-3/8<br />

6-7/8 3 – 3-1/4 6-5/8<br />

7 2-3/4 – 3-1/4 6-5/8<br />

5-1/2 4-5/8 7-1/8 5-3/8 4-29/64 5-7/16 5-3/16 2-1/4 – 3-1/4 3-1/2 5-3/16 2 6-5/8<br />

7-1/4 2-1/4 – 3 6-3/8<br />

7-3/8 2-1/4 – 2-3/4 6-5/8<br />

7-1/2 2-1/4 – 2-1/2 6-5/8<br />

7-5/8 3-3/8 – 3-5/8 7-1/4<br />

7-3/4 3-1/4 – 3-1/2 7-1/2<br />

6-5/8 4-7/8<br />

7-7/8<br />

8<br />

6 5-3/16 6-1/16 5-11/16<br />

3 – 3-1/2<br />

2-1/2 – 3-1/2<br />

3-1/2 5-13/16 2<br />

7-1/2<br />

7-1/2<br />

8-1/8 2-1/2 – 3-1/4 7-1/2<br />

8-1/4 2-1/2 – 3 7-1/2<br />

8-1/4 3-1/2 – 3-3/4 8<br />

8-3/8 2-3/4 – 3-3/4 8<br />

7 5-3/8 8-1/2 6-1/2 5-5/32 5-15/16 2-3/4 – 3-3/4 3-1/2 6-3/8 3 8-1/4<br />

8-5/8 2-3/4 – 3-1/2 8-1/4<br />

8-3/4 2-3/4 – 3-1/4 8-1/4<br />

9 2-3/4 – 3 8-5/8<br />

9-1/2 3-1/2 – 4 9-1/4<br />

9-5/8 3 – 4 9-1/4<br />

7-5/8 6<br />

9-3/4<br />

9-7/8<br />

7-25/64 5-57/64 6-9/16<br />

3 – 4<br />

3 – 4<br />

3-1/2 7-17/64 3<br />

9-1/4<br />

9-5/8<br />

10 3 – 3-3/4 9-5/8<br />

10-1/4 3 – 3-1/4 9-5/8<br />

10-3/4 3-1/2 – 4 10-1/2<br />

8-5/8 6-1/2 11 8-17/64 6-41/64 1-1/16 3 – 4 3-1/2 8-9/64 3 10-1/2<br />

11-1/4 3 – 4 10-3/4<br />

11-1/2 3 – 3-1/4 10-3/4<br />

For drill collar ODs less than 8-5/8", E = 6.563<br />

For drill collar ODs 8-5/8" or more, E = 7.125<br />

For drill collar ODs less than 9-3/4", E = 7.453<br />

For drill collar ODs 9-3/4" or more, E = 8.000<br />

For drill collar ODs less than 10-3/4", E = 8.343<br />

For drill collar ODs 10-3/4" or more, E = 9.375

30°<br />

G<br />

A<br />

hyDriL jointS<br />

H - Threads per Inch<br />

K - Incl. Taper<br />

D<br />

C<br />

type Size A B C D E g h k u<br />

IF 2-3/8 – 6.65 3-15/16 3-3/8 2-13/16 2-21/64 2-13/16 1-3/4 3 1/2 3-59/64<br />

IF 2-7/8 – 10.4 3-57/64 3-7/8 2-3/16 2-45/64 3-3/16 2-7/64 3 1/2 3-59/64<br />

IF 2-7/8 – 11.8 3-57/64 3-7/8 2-3/16 2-45/64 3-3/16 2 3 1/2 3-59/64<br />

IF 3-1/2 – 13.3 3-61/64 4-1/2 2-27/32 3-23/64 3-27/32 2-3/4 3 1/2 3-31/32<br />

IF 3-1/2 – 15.5 3-61/64 4-1/2 2-27/32 3-23/64 3-27/32 2-9/16 3 1/2 3-31/32<br />

IF 4-1/2 – 16.6 4 6 2-13/64 4-35/64 5-7/32 3-3/4 3 1/2 4-1/64<br />

IF 4-1/2 – 20.0 4 6 2-13/64 4-35/64 5-7/32 3-3/4 3 1/2 4-1/64<br />

IF 5 – 20.5 4-23/32 6-5/8 5-25/32 5-1/64 5-51/64 4-3/16 2 1/2 4-3/4<br />

F 2-3/8 2-5/8 2-3/8 1-59/64 1-43/64 1-15/16 1 4 1/2 2-15/32<br />

F 2-7/8 3-21/32 2-7/8 2-23/64 1-29/32 2-3/8 1-1/16 4 1/2 3-1/2<br />

F 3-1/2 4-1/16 3-1/2 2-13/16 2-21/64 2-13/16 1-1/2 3 1/2 3-59/64<br />

F 4 3-59/64 4-1/16 3-5/16 2-55/64 3-11/32 2 3 1/2 3-29/32<br />

F 4-1/2 3-61/64 4-1/2 3-27/32 3-23/64 3-27/32 2-3/16 3 1/2 3-31/32<br />

F 5 4-5/16 5 4-3/16 3-35/64 4-13/64 2-5/16 3 1/2 4<br />

F 5-1/2 4-1/4 5-9/16 4-21/32 4-1/64 4-43/64 2-3/4 3 1/2 4-1/32<br />

F 6-5/8 5-5/16 6-5/8 5-11/16 4-29/32 5-45/64 3-1/2 2 1/2 5-1/8<br />

EIU 3-1/2 4-1/4 4-5/8 3-47/64 3-17/64 3-3/4 2-7/16 3 1/2 4<br />

EIU 4 4-5/16 5-9/16 4-21/64 4-1/64 4-43/64 3-1/8 3 1/2 4-1/32<br />

EIU 4-1/2 4-7/16 5-3/4 4-47/64 3-3/32 4-3/4 3-5/32 3 1/2 4-1/8<br />

EIU 5-1/2 5-1/2 7 5-53/64 5-1/16 5-27/32 4 2 1/2 5-1/8<br />

EIU 6-5/8 5-1/2 8 6-7/8 6-7/64 6-57/64 5 2 1/2 5-1/8<br />

B<br />

E<br />

30°<br />

U<br />

G

tooL joint DimenSionS<br />

A<br />

RECoMMEnDED MAXIMuM AnD MInIMuM<br />

nom. nom. “A” “B” “C” “C”<br />

Joints o.D. o.D. Max. Max. Min. Max.<br />

API Reg 3-1/8 1 1-1/8 1-5/8 2-15/16 3-1/4<br />

2-3/8 API IF 3-3/8 1-3/4 1-3/4 2 3-3/16 3-5/8<br />

Hydril IF 3-3/8 1-3/4 1-3/4 1-7/8 3-1/8 3-5/8<br />

API Reg 3-3/4 1-1/4 1-3/8 1-7/8 3-1/2 4<br />

FH 4-1/4 2-1/8 2-1/8 2-3/8 4-1/16 4-5/8<br />

2-7/8 API IF 4-1/8 2-1/8 2-1/8 2-1/2 3-7/8 4-3/8<br />

Hydril IF 3-7/8 2-1/8 2-3/16 2-3/16 3-5/8 4-1/8<br />

Hughes Xtra Hole 4-1/4 1-7/8 1-7/8 2-1/8 4 4-5/8<br />

3 Union Tool (UT) 4-1/4 1-1/2 1-1/2 2-1/8 3-3/4 4-1/2<br />

API Reg 4-1/4 1-1/2 1-3/4 2-1/4 4 4-5/8<br />

API FH 4-5/8 2-7/16 2-7/16 2-3/4 4-1/2 5<br />

3-1/2 API IF 4-3/4 2-11/16 2-11/16 3 4-1/2 5<br />

Hydril IF 4-1/2 2-3/4 2-3/4 2-13/16 4-3/8 4-7/8<br />

Hughes Xtra Hole 4-3/4 2-7/16 2-7/16 2-3/4 4-1/2 5<br />

API FH 5-1/4 2-13/16 2-13/16 3-1/4 5 5-3/8<br />

4 API IF 5-3/4 3-1/4 3-5/16 3-1/2 5-1/2 6<br />

Union Tool 5-3/4 2-1/4 2-7/8 3-1/2 5-3/8 6<br />

API Reg 5-3/4 2-1/4 2-5/8 3-1/4 5-3/8 6<br />

API FH 5-3/4 3 3-5/32 3-1/2 5-1/2 6<br />

4-1/2 API IF 6-1/8 3-3/4 3-3/4 4-1/8 5-7/8 6-1/2<br />

Hydril IF 6 3-3/4 3-7/8 4 5-13/16 6-1/4<br />

Hughes Xtra Hole 6 3-1/4 3-1/4 3-3/8 5-5/8 6-1/4<br />

API Reg or UT 6-3/4 2-3/4 3-1/4 3-7/8 6-3/8 7<br />

5-1/2 API FH 7 4 4 4-1/2 6-1/2 7-1/4<br />

API IF 7-3/8 4-13/16 4-13/16 5-1/4 7-1/8 7-7/8<br />

API Reg or UT 7-3/4 3-1/2 4 4-3/4 7-1/8 7-7/8<br />

6-5/8 API FH 8 5 5 5-1/2 7-1/2 8-1/4<br />

IF 8-1/2 5-29/32 5-29/32 6-1/4 8-3/8 9<br />

7-5/8 Reg 8-7/8 4 4-1/4 5-1/4 8-1/8 9<br />

8-5/8 Reg 10 4-3/4 5-1/4 6-1/4 9 10-1/8<br />

C<br />

B

SeamLeSS DriLL pipe performance propertieS<br />

nEW DRILL pIpE — DIMEnSIonAL, toRSIonAL, AnD tEnSILE DAtA<br />

Nominal Section Polar<br />

Weight Plain Wall Area Sectional Torsional Data * Tensile Data Based on Minimum Values<br />

Size Threads & End Thick- Body of Modulus Torsional Yield Strength (ft-Ibs) Load at the Minimum Yield (lbs)<br />

O.D. Couplings Weight ness I.D. Pipe Z<br />

(in) (lb/ft) (lb/ft) (in) (in) (sq in) (cu in) D E 95 105 135 D E 95 105 135<br />

2-3/8 4.85 4.43 .190 1.995 1.3042 1.320 … 4760 6020 6660 … … 97820 123900 136940 176070<br />

6.65 6.26 .280 1.815 1.8429 1.734 4580 6240 7900 8740 … 101360 138220 175080 193500 248790<br />

2-7/8 6.85 6.16 .217 2.441 1.8120 2.242 … 8070 10220 11300 … … 135900 172140 190260 244620<br />

10.40 9.72 .362 2.151 2.8579 3.204 8460 11530 14610 16150 20760 157190 214340 271500 300080 385820<br />

9.50 8.81 .254 2.992 2.5902 3.922 … 14120 17890 19770 25420 … 194260 246070 271970 349680<br />

3-1/2 13.30 12.31 .368 2.764 3.6209 5.144 13580 18520 23460 25930 33330 199160 271570 343990 380190 488820<br />

15.50 14.63 .449 2.602 4.3037 5.846 15440 21050 26660 29470 37890 236720 322780 408850 451890 581000<br />

11.85 10.46 .262 3.476 3.0767 5.400 … 19440 24620 27220 34990 … 230750 292290 323050 415360<br />

4 14.00 12.93 .330 3.340 3.8048 6.458 17050 23250 29450 32550 41840 209280 285360 361460 399500 513650<br />

15.70 14.69 .380 3.240 4.3216 7.156 18890 25760 32630 36070 46380 237710 324150 410590 453810 583420<br />

13.75 12.24 .271 3.958 3.6004 7.184 … 25860 32760 36210 46550 … 270030 342040 378050 486060<br />

4-1/2 16.60 14.98 .337 3.826 4.4074 8.542 22550 30750 38950 43050 55350 242380 330560 418700 462780 595000<br />

20.00 18.69 .430 3.640 5.4981 10.232 27010 36840 46660 51570 66300 302390 412360 522320 577300 742240<br />

16.25 14.87 .296 4.408 4.3743 9.718 … 34980 44310 48970 62970 … 328070 415560 459300 590530<br />

5 19.50 17.93 .362 4.276 5.2746 11.416 30135 41090 52050 57530 73970 290100 395600 501090 553830 712070<br />

25.60 24.03 .500 4.000 7.0686 14.490 38250 52160 66070 73030 93900 388770 530140 671520 742200 954260<br />

19.20 16.87 .304 4.892 4.9624 12.222 … 44180 55960 61850 79520 … 372180 471430 521050 669920<br />

5-1/2 21.90 19.81 .361 4.778 5.8282 14.062 37120 50620 64120 70870 91120 320550 437120 553680 611960 786810<br />

24.70 22.54 .415 4.670 6.6296 15.688 41410 56470 71530 79060 101650 364630 497220 629810 696110 895000<br />

6-5/8 25.20 22.19 .330 5.965 6.5262 19.572 51740 70550 89360 98770 … 358930 489460 619990 685250 881040<br />

* Based on the shear strength equal to 57.7% of minimum yield strength and nominal wall thickness.

neW DriLL pipe coLLapSe anD internaL preSSUre Data<br />

nom. Weight<br />

Collapse pressure Based on Internal pressure at<br />

Size threads &<br />

Minimum Values (psi) Minimum yield Strength (psi)<br />

o.D. Couplings<br />

(in) (lb) D E 95 05 5 D E 95 05 5<br />

2-3/8 4.85 8100 11040 13980 15460 19070 … 10500 13300 14700 18900<br />

6.65 11440 15600 19760 21840 28080 11350 15470 19600 21660 27850<br />

2-7/8 6.85 7680 10470 12930 14010 17060 … 9910 12550 13870 17830<br />

10.40 12110 16510 20910 23110 29720 12120 16530 20930 23140 29750<br />

9.50 7400 10040 12060 13050 15780 … 9520 12070 13340 17150<br />

3-1/2 13.30 10350 14110 17880 19760 25400 10120 13800 17480 19320 24840<br />

15.50 12300 16770 21250 23480 30190 12350 16840 21330 23570 30310<br />

11.85 6590 8410 9960 10700 12650 … 8600 10890 12040 15480<br />

4 14.00 8330 11350 14380 15900 20170 7940 10830 13720 15160 19490<br />

15.70 9460 12900 16340 18050 23210 9140 12470 15790 17460 22440<br />

13.75 5720 7200 8400 8950 10310 … 7900 10010 11070 14230<br />

4-1/2 16.60 7620 10390 12750 13820 16800 7210 9830 12450 13760 17690<br />

20.00 9510 12960 16420 18150 23330 9200 12540 15890 17560 22580<br />

16.25 5560 6970 8090 8610 9860 … 7770 9840 10880 13990<br />

5 19.50 7390 10000 12010 12990 15700 6970 9500 12040 13300 17110<br />

25.60 9900 13500 17100 18900 24300 9620 13120 16620 18380 23620<br />

19.20 4910 6070 6930 7300 8120 … 7250 9190 10160 13060<br />

5-1/2 21.90 6610 8440 10000 10740 12710 6320 8610 10910 12060 15510<br />

24.70 7670 10460 12920 14000 17050 7260 9900 12540 13860 17830<br />

6-5 /8 25.20 4010 4810 5310 5490 6040 4790 6540 1 8280 9150 11770

api DriLL coLLar anD joint SizeS<br />

±1/32<br />

1"<br />

45°<br />

M +0 / –1/32"<br />

1/4" R<br />

Length Bevel Bending<br />

Drill Outside Bore Ft. Dia. Strength<br />

Collar Dia. +1/16 –0 ± 6 in. ± 1/64 Ratio<br />

Number * D d L DF M F<br />

NC 23–31 (tentative) 3-1/8 1-1/4 … 30 3 2.57:1 † †<br />

NC 26–35 (2-3/8 IF) 3-1/2 1-1/2 … 30 3-17/64 2.42:1 † †<br />

NC 31–41 (2-7/8 IF) 4-1/8 2 … 30 3-61/64 2.43:1 † †<br />

NC 35–47 4-3/4 2 … 30 4-33/64 2.58:1 3-15/64 3-3/8<br />

NC 38–50 (3-1/2 IF) 5 2-1/4 … 30 4-49/64 2.38:1 3-33/64 3-5/8<br />

… 5-3/4 2-1/4 NC 40 (4 FH) 30 or 31 5-13/32 3.10:1 3-25/32 4-1/8<br />

… 5-3/4 2-13/16 4-1/2 FH 30 or 31 5-17/32 2.22:1 4-13/64 3-5/8<br />

NC 44–60 6 2-1/4 … 30 or 31 5-11/16 2.49:1 4-3/16 4-1/8<br />

NC 44–60 6 2-13/16 … 30 or 31 5-11/16 2.84:1 4-3/16 4-1/8<br />

NC 44–62 6-1/4 2-1/4 … 30 or 31 5-7/8 2.91:1 4-3/16 4-1/8<br />

… 6-1/4 2-1/4 NC 46 (4 IF) 30 or 31 5-23/32 2.16:1 2-21/64 4-1/8<br />

NC 41–62 (4 IF) 6-1/4 2-13/16 … 30 or 31 5-29/32 2.63:1 4-21/64 4-1/8<br />

NC 46–65 (4 IF) 6-1/2 2-1/4 … 30 or 31 6-3/32 2.76:1 4-21/64 4-1/8<br />

NC 46–65 (4 IF) 6-1/2 2-13/16 … 30 or 31 6-3/32 3.05:1 4-21/64 4-1/8<br />

NC 46–67 (4 IF) 6-3/4 2-1/4 … 30 or 31 6-9/32 3.18:1 4-21/64 4-1/8<br />

… 6-3/4 2-13/16 NC 50 (4-1/2 IF) 30 or 31 6-25/32 2.35:1 4-3/4 4-1/8<br />

NC 50–70 (4-1/2 IF) 7 2-1/4 … 30 or 31 6-31/64 2.54:1 4-3/4 4-1/8<br />

NC 50–70 (4-1/2 IF) 7 2-13/16 … 30 or 31 6-31/64 2.73:1 4-3/4 4-1/8<br />

NC 50–72 (4-1/2 IF) 7-1/4 2-13/16 … 30 or 31 6-43/64 3.12:1 4-3/4 4-1/8<br />

NC 56–77 7-3/4 2-13/16 … 30 or 31 7-19/64 2.70:1 5-19/64 4-5/8<br />

… 7-3/4 3 6-5/8 Reg 30 or 31 7-21/64 2.37:1 5-27/64 4-5/8<br />

NC 56–80 8 2-13/16 … 30 or 31 7-31/64 3.02:1 5-19/64 4-5/8<br />

6-5/8 Reg 8-1/4 2-13/16 … 30 or 31 7-45/64 2.93:1 5-27/64 4-5/8<br />

NC 61–90 9 2-13/16 … 30 or 31 8-3/8 3.17:1 5-55/64 5-1/8<br />

7-5/8 Reg 9-1/2 3 … 30 or 31 8-13/16 2.81:1 6-13/32 4-7/8<br />

NC 70–97 9-3/4 3 … 30 or 31 9-5/32 2.57:1 6-47/64 5-5/8<br />

NC 70–100 10 3 … 30 or 31 9-11/32 2.81:1 6-47/64 5-5/8<br />

NC 77–110 (tentative) 11 3 … 30 or 31 10-17/64 2.78:1 7-27/64 6-1/8<br />

* The drill collar number (first column) consists of two parts separated by a hyphen. The first part is<br />

the connectlon number in the NC style. The second part, consisting of 2 (or 3) digits, indicates the<br />

drill collar outside diameter in units and tenths of inches. The connections shown in parentheses in<br />

the first column a not a part of the drill collar number; they indicate interchangeability of drill collars<br />

made with the standard (NC) connections as shown. If the connections shown in parentheses in<br />

the first column are made with the V-0.038 R thread form (as provided in Par. 9.4) the connections,<br />

and drill collars, are identical with those in the NC style. Drill collars with 8-1/4 and 9-1/2 inches<br />

outside diameters are shown with 6-5/8 and 7-5/8 Regular connections, since there are no NC con-<br />

nections in the recommended bending strength ratio range.<br />

† lnsufficient metal to accommodate stress relief grooves.<br />

F<br />

+0 / –1/8"<br />

45°<br />

1/4" R<br />

1-1/2"<br />

±1/8<br />

13/64<br />

+1/64 –0<br />

30°<br />

5

6<br />

recommenDeD proceDUre for maKing Up<br />

DriLL coLLarS With neW jointS<br />

Connector Sub or Drill Collar<br />

Suggested Marking<br />

1. Thoroughly clean with distillate, pin and box threads and shoulder. After cleaning, the joint must<br />

be dried before lubricant is applied.<br />

2. Coat all areas of the pin and box threads and shoulders with a thin even coat of a good grade<br />

lubricant from a covered or newly opened can. A molydisulfide lubricant is recommended.<br />

3. Extreme care should be used when stabbing the joints to avoid stabbing wounds. If drill collar<br />

connecting subs are used, it is preferred that the subs be applied by hand rather than with lifting<br />

equipment.<br />

4. Make up joints manually with chain tongs as far as possible and then use cathead to the full<br />

recommended torque as shown on attached chart.<br />

5. Scribe vertical chalk line across joint make-up line of box and pin faces.<br />

6. Break joint, clean and dry threads. Inspect the threads and joint faces carefully for evidence<br />

of galling or “hair like” slivers of steel. Stone or file all rough spots and remove slivers. Be careful<br />

not to remove chalk line across joint face.<br />

7. Again make up joints manually with chain tongs as far as possible and then with cathead using<br />

full recommended torque. The joint must make up to the chalk mark or father. If the joint does not<br />

make up to this line, again break the joint, dry and clean. Inspect the threads and joint faces care-<br />

fully and in general proceed as under 6 above.<br />

8. If the joints make up to the chalk line or farther, a center punch mark shall be made on both the<br />

box and pin halves, adjacent to the shoulder, as permanent inspection mark. After each run, these<br />

match making spots should be inspected and as long as there is no creep between the two marks,<br />

the joints should be left unbroken if possible (nonworking joints). As the drill collars wear, it is<br />

recommended that the center punch marks be deepened so that they will always be in evidence.<br />

When it is noted that creep has occurred on the nonworking joints, they should be broken apart,<br />

inspected and if necessary recut.

DriLL coLLar torQUe recommenDationS (ft-LBS) *<br />

Weak<br />

Member<br />

Drill Drill Collar Bore (in)<br />

Connection Collar<br />

Size type o.D - / - / - / - / - / - / 6<br />

3 2,500 - 2,750 2,500 - 2,750 2,500 - 2,750 Box<br />

API NC 23 3-1/8 3,300 - 3,630 3,300 - 3,630 2,600 - 2,860 Pin<br />

3-1/4 4,000 - 4,400 3,400 - 3,740 2,600 - 2,860 Pin<br />

3 3,800 - 4,180 3,800 - 4,180 2,900 - 3,190 Pin<br />

2-7/8 PAC 3-1/8 4,900 - 5,390 4,200 - 4,620 2,900 - 3,190 Pin<br />

3-1/4 5,200 - 5,720 4,200 - 4,620 2,900 - 3,190 Pin<br />

2-3/8 API IF 3-1/2 4,600 - 5,060 4,600 - 5,060 3,700 - 4,070 Pin<br />

API NC 26 3-3/4 5,500 - 6,050 4,700 - 5,170 3,700 - 4,070 Pin<br />

2-7/8 Slim Hole<br />

2-7/8 Xtra Hole 3-3/4 4,100 - 4,510 4,100 - 4,510 4,100 - 4,510 Box<br />

3-1/2 Dbl. Streamline 3-7/8 5,300 - 5,830 5,300 - 5,830 5,300 - 5,830 Box<br />

2-7/8 Mod. Open 4-1/8 8,000 - 8,800 8,000 - 8,800 7,400 - 8,140 Pin<br />

2-7/8 API IF 3-7/8 4,600 - 5,060 4,600 - 5,060 4,600 - 5,060 4,600 - 5,060 Box<br />

API NC 31 4-1/8 7,300 - 8,030 7,300 - 8,030 7,300 - 8,030 6,800 - 7,480 Pin<br />

3-1/2 Slim Hole 4-1/4 8,800 - 9,680 8,800 - 9,680 8,100 - 8,910 6,800 - 7,480 Pin<br />

4-1/2 10,000 - 11,000 9,300 - 10,230 8,100 - 8,910 6,800 - 7,480 Pin<br />

4-1/2 8,900 - 9,790 8,900 - 9,790 8,900 - 9,790 7,400 - 8,140 Pin<br />

API NC 35 4-3/4 12,100 - 13,310 10,800 - 11,880 9,200 - 10,120 7,400 - 8,140 Pin<br />

5 12,100 - 13,310 10,800 - 11,880 9,200 - 10,120 7,400 - 8,140 Pin<br />

4-1/4 5,100 - 5,610 5,100 - 5,610 5,100 - 5,610 5,100 - 5,610 Box<br />

3-1/2 Xtra Hole 4-1/2 8,400 - 9,240 8,400 - 9,240 8,400 - 9,240 8,200 - 9,020 Pin<br />

4 Slim Hole 4-3/4 11,900 - 13,090 11,700 - 12,870 10,000 - 11,000 8,200 - 9,020 Pin<br />

3-1/2 Mod. Open 5 13,200 - 14,520 11,700 - 12,870 10,000 - 11,000 8,200 - 9,020 Pin<br />

5-1/4 13,200 - 14,520 11,700 - 12,870 10,000 - 11,000 8,200 - 9,020 Pin<br />

3-1/2 API IF 4-3/4 9,900 - 10,890 9,900 - 10,890 9,900 - 10,890 9,900 - 10,890 8,300 - 9,130 Pin<br />

API NC 38 5 13,800 - 15,180 13,800 - 15,180 12,800 - 14,080 10,900 - 11,990 8,300 - 9,130 Pin<br />

4-1/2 Slim Hole 5-1/4 16,000 - 17,600 14,600 - 16,060 12,800 - 14,080 10,900 - 11,990 8,300 - 9,130 Pin<br />

5-1/2 16,000 - 17,600 14,600 - 16,060 12,800 - 14,080 10,900 - 11,990 8,300 - 9,130 Pin<br />

* Adapted from API RP7G<br />

7

8<br />

DriLL coLLar torQUe recommenDationS (ft-LBS) *<br />

Drill Drill Collar Bore (in)<br />

Connection Collar<br />

Size type o.D. - / - / - / - / 6<br />

4-3/4 8,700 - 9,570 8,700 - 9,570 8,700 - 9,570 8,700 - 9,570 8,700 - 9,570 Box<br />

3-1/2 H-90 5 12,700 - 13,970 12,700 - 13,970 12,700 - 13,970 12,700 - 13,970 19,400 - 11,440 Pin<br />

5-1/4 16,900 - 18,590 16,700 - 18,370 15,000 - 16,500 13,100 - 14,410 10,400 - 11 440 Pin<br />

5-1/2 18,500 - 20,350 16,700 - 18,370 15,000 - 16,500 13,100 - 14,410 10,400 - 11,440 Pin<br />

4 API Full Hole 5 10,800 - 11,880 10,800 - 11,880 10,800 - 11,880 10,800 - 11,880 10,800 - 11,880 Box<br />

API NC 40 5-1/4 15,100 - 16,610 15,100 - 16,610 15,100 - 16,610 14,800 - 16,280 12,100 - 13,310 Pin<br />

5-1/2 19,700 - 21,670 18,600 - 20,460 16,900 - 18,590 14,800 - 16,280 12,100 - 13,310 Pin<br />

4 Mod. Open 5-3/4 20,400 - 22,440 18,600 - 20,460 16,900 - 18,590 14,800 - 16,280 12,100 -13,310 Pin<br />

4-1/2 Dbl. Streamline 6 20,400 - 22,440 18,600 - 20,460 16,900 - 18,590 14,800 - 16,280 12,100 - 13,310 Pin<br />

5-1/4 12,500 - 13,750 12,500 - 13,750 12,500 - 13,750 12,500 - 13,750 Box<br />

5-1/2 17,300 - 19,030 17,300 - 19,030 17,300 - 19,030 16,500 - 18,150 Pin<br />

5-3/4 22,300 - 24,530 21,500 - 23,650 19,400 - 21,340 16,500 - 18,150 Pin<br />

4 H-90 6 23,500 - 25,850 21,500 - 23,650 19,400 - 21,340 16,500 - 18,150 Pin<br />

6-1/4 23,500 - 25,850 21 500 - 23,650 19,400 - 21,340 16,500 - 18,150 Pin<br />

5-1/2 15,400 - 16,940 15,400 - 16,940 15,400 - 16,940 15,400 - 16,940 Box<br />

4-1/2 API Regular 5-3/4 20,300 - 22,330 20,300 - 22,330 19,400 - 21,340 16,200 - 17,820 Pin<br />

6 23,400 - 25,740 21,600 - 23,760 19,400 - 21,340 16,200 - 17,820 Pin<br />

6-1/4 23,400 - 25,740 21,600 - 23-760 19,400 - 21,340 16,200 - 17,820 Pin<br />

5-3/4 20,600 - 22,660 20,600 - 22,660 29,600 - 22,660 18,000 - 19,800 Pin<br />

6 25,000 - 27,500 23,300 - 25,630 21,200 - 23,320 18,900 - 19,800 Pln<br />

API NC 44 6-1/4 25,000 - 27,500 23,300 - 25,630 21,200 - 23,320 18,000 - 19,800 Pin<br />

6-1/2 25,000 - 27,500 23,300 - 25,630 21,200 - 23,320 18,000 - 19,800 Pin<br />

5- 1/2 12,900 - 14,190 12,900 - 14,190 12,900 - 14,190 12,900 - 14,190 12,900 - 14,190 Box<br />

5-3/4 17,900 - 19,690 17,900 - 19,690 17,900 - 19,690 17,900 - 19,690 17,700 - 19,470 Pin<br />

4-1/2 API Full Hole 6 23,300 - 25,630 23,300 - 25,630 22 800 - 25,080 19,800 - 21,780 17,700 - 19,470 Pin<br />

6-1/4 27,000 - 29,700 25,000 - 27,500 22,800 - 25,080 19,800 - 21,780 17,700 - 19,470 Pin<br />

6 -1/2 27,000 - 29,700 25,000 - 27,500 22,800 - 25,080 19,800 - 21,780 17,700 - 19,470 Pin<br />

Weak<br />

Member<br />

* Adapted from API RP7G

DriLL coLLar torQUe recommenDationS (ft-LBS) *<br />

Drill Drill Collar Bore (in)<br />

Connection Collar<br />

Size type o.D. - / - / - / 6 - /<br />

4-1/2 Xtra Hole 5-3/4 17,600 - 19,360 17,600 - 19,360 17,600 - 19,360 17,600 - 19,360 … Box<br />

API NC 46 6 23,200 - 25,520 23,200 - 25,520 22,200 - 24,420 20,200 - 22,220 … Pin<br />

4 API IF 6-1/4 28,000 - 30,800 25,500 - 28,050 22,200 - 24,420 20,200 - 22,220 … Pin<br />

4-1/2 Semi IF 6-1/2 28,000 - 30,800 25,500 - 28,050 22,200 - 24,420 20,200 - 22,220 … Pin<br />

5 DbI.Streamllne 6-3/4 28,000 - 30,800 25,500 - 28,050 22,200 - 24,420 20,200 - 22,220 … Pin<br />

4-1/2 Mod.Open … … … … … … …<br />

5-3/4 17,600 - 19,360 17,600 - 19,360 17,600 - 19,360 17,600 - 19,360 … Box<br />

6 23,400 - 25,740 23,400 - 25,740 23,000 - 25,300 21,000 - 23,100 … Pin<br />

4-1/2 H-90 6-1/4 28,500 - 31,350 26,000 - 28,600 23,000 - 25,300 21,000 - 23,100 … Pin<br />

6-1/2 28,500 - 31,350 26,000 - 28,600 23,000 - 25,300 21,000 - 23,100 … Pin<br />

6-3/4 28,500 - 31,350 26,000 - 28,600 23,000 - 25,300 21 000 - 23,100 … Pin<br />

6-1/4 25 000 - 27,500 25,000 - 27,500 25 000 - 27,500 25 000 - 27,500 … Box<br />

5 H-90 6-1/2 31,500 - 34,640 31,500 - 34,640 29,500 - 32,450 27,000 - 29,700 … Pin<br />

6-3/4 35,000 - 38,500 33,000 - 36,300 29,500 - 32 450 27,000 - 29,700 … Pin<br />

7 35,000 - 38,500 33,000 - 36,300 29 500 - 32,450 27,000 - 29,700 … Pin<br />

4-1/2 API IF 6-1/4 22,800 - 25,080 22,800 - 25,080 22,000 - 25,080 22,800 - 25,080 22,800 - 25,080 Box<br />

API NC 50 6-1/2 29,500 - 32,450 29 500 - 32 450 29 500 - 32 450 29 500 - 32 450 26,500 - 29,150 Pin<br />