MASSEY- HARRIS - Antique Farming

MASSEY- HARRIS - Antique Farming

MASSEY- HARRIS - Antique Farming

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

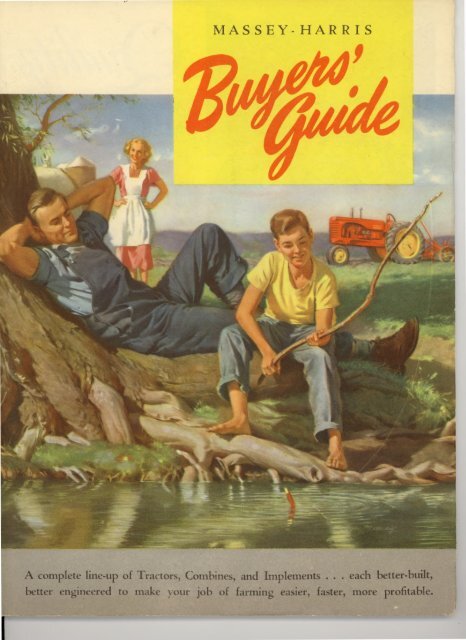

<strong>MASSEY</strong>- <strong>HARRIS</strong><br />

A complete line-up of Tractors, Combines, and Implements . . each better-built,<br />

better engineered to make your job of farming easier, faster, more profitable.

CONTENTS<br />

1-Plow Pony Page 4<br />

2-Plow 22 Page 5<br />

2-3 Plow 30 Page 6<br />

3-4 Plow 44 Page 7<br />

3-4 Plow 44 Diesel Page 8<br />

4-5 Plow 55 Page 9<br />

Tractor Engines Page 10<br />

Tractor Transmissions Page 10<br />

Depth-o-matic System Page 11<br />

Cultivators Pages 12, 13<br />

Listers Page 14<br />

Bedders Page 15<br />

Plows (moldboard and disc) Pages 16, 17<br />

Disc Harrows (tandem and single) Page 18<br />

Heavy-Duty Offset Harrows Page 19<br />

One Way Discs Page 20<br />

Grain Drills Page 21<br />

Low-Gallonage Sprayers<br />

(mounted and Trailer) Page 21<br />

Drill Corn Planters (2 & 4 row) Page 22<br />

15 and 17 Pull-Type Combines Page 23<br />

6 Ft. Clipper Combine Page 24<br />

7 Ft. Self-Propelled Clipper Page 25<br />

Super 26 and 27 Self-Propelled<br />

Combines Pages 26, 27, 28<br />

Swathers Page 28<br />

Self-Propelled Corn Picker Page 29<br />

Cream Separators Page 30<br />

Forage Clipper Page 31<br />

Mowers Page 32<br />

Hay Loaders and Rakes Page 33<br />

Manure Spreaders Page 34<br />

Tornado Hammermill Page 34<br />

Silo Blower Page 35<br />

Wagon Gear Page 35<br />

A WORKABLE CREED AT<br />

MASS;.<br />

TRACTOR PLANT • This is one of the three modern<br />

tractor assembly lines at Massey-Harris's Racine, Wisconsin<br />

plant. Scientifically arranged to speed flow of<br />

materials, sub-assemblies and parts are fed to the main<br />

line at timed intervals ready for orderly placement on<br />

the new tractor. The plant is exceptionally well lighted<br />

and completely equipped with the latest in modern<br />

machine tools and methods for turning out the most<br />

powerful, most economical tractors in Massey-Harris<br />

history.

go<br />

IV<br />

"Make it Better" . . . the basic watchword of<br />

Massey-Harris engineering was created more<br />

than 103 years ago when Daniel Massey<br />

founded the world-wide organization that now<br />

bears his name. Massey-Harris survived those<br />

humble beginnings—and expanded tremendously—because<br />

the desire to "make it better"<br />

resulted in new and more efficient farm machines—in<br />

quality products that can only be<br />

produced by better engineering and workman<br />

rirr;<br />

gis<br />

assure our farmer-customers of the finest<br />

.<br />

apg: ent, Massey-Harris aids engieering-knowledge<br />

and skilled workmanship<br />

with millions of dollars spent in research and<br />

development . . . in designing and testing to<br />

produce faster-operating, more economical<br />

IMPLEMENT DIVISION • Coming out of the implement<br />

assembly shop these mounted tools are ready for their<br />

brilliant coat of Massey-Harris red. Quality in<br />

Massey-Harris extends even to the lusty color of its<br />

products. Paint manufacturers are very much impressed<br />

by the specifications Massey-Harris insists are<br />

met before an order is issued. These high standards<br />

mean higher cost to Massey-Harris, of course, but no<br />

expense is spared in building a top-quality product<br />

for Massey-Harris customers.<br />

tractors, combines and implements.<br />

In the actual production of machines themselves,<br />

quality is positively controlled by a<br />

systematic check of parts while being processed.<br />

Exacting tolerances established by the<br />

engineering specifications assure accurate fitting<br />

of all parts. Should any deviation from<br />

these specifications occur, an immediate check<br />

of material, machine and operation is made.<br />

Such methods result in uniformity of parts,<br />

smoother operation, longer life to Massey-<br />

Harris products.<br />

Thanks to engineering leadership and quality<br />

control in manufacture, Massey-Harris<br />

customers receive an extra measure of value<br />

and performance in every Massey-Harris machine<br />

or implement they buy.<br />

31<br />

Combine Production • Massey-Harris Super 26<br />

and Super 27 Self-Propelled Combines are built<br />

up on this 526-foot automotive-type assembly<br />

line. At each of the stations various units are systematically<br />

channeled into the main line for fast,<br />

efficient assembly to the combine. The entire plant<br />

is designed for speed and accuracy . . . highly<br />

efficient methods of manufacture that result in<br />

lower production costs, rigid quality control .. .<br />

a better product for your farm.

<strong>MASSEY</strong>-<strong>HARRIS</strong> 1-PLOW PONY<br />

Ideal Power for faster farming on small acreage<br />

* You farm faster, easier . . . more<br />

economically with the Massey-<br />

Harris Pony. You bring real power<br />

performance to your farm . . .<br />

dollars and cents savings in time<br />

and cost of operation over horsedrawn<br />

or hand-operated tools. And<br />

it means greater freedom and independence<br />

for you in the bargain.<br />

There's lively, husky power in<br />

the Pony's 4-cylinder, 62-cubic-inch<br />

engine that lets you move right<br />

along at 2 3/4 or 3 3/4 m.p.h. with<br />

a 14-inch plow. A high of 7 miles<br />

per hour makes short work of hauling<br />

to and from fields.<br />

Clean styling gives plenty of<br />

vision for cultivating. Controls are<br />

handy for fast operation. Autotype<br />

dash has easy-to-read dials.<br />

Band-type brakes on the final drive<br />

are individually operated for easier<br />

turning at the row ends.<br />

You'll like the custom-designed,<br />

companion tools for the Pony. A<br />

complete line-up of equipment to<br />

breeze through plowing, discing,<br />

planting, cultivating, mowing. And<br />

all are built sturdy, flexible . . . easy<br />

to put on—easy to take off.<br />

More important, the Pony is a<br />

versatile performer. No matter<br />

where you put it to work—on small<br />

farms, big farms, golf courses,<br />

estates, parks, around factories,<br />

market gardens, airports—wherever<br />

1-plow power will do the job, you<br />

get the dependability of Massey-<br />

Harris construction . . . the moneysavings<br />

of Massey-Harris design.<br />

[4]<br />

ADJUSTABLE TREAD<br />

Front and rear treads on the Pony have<br />

ample adjustment to meet different row<br />

crop widths. Both can be adjusted in 4.<br />

inch steps from 41 inches to a maximum<br />

of 69 inches. The telescoping front axle is<br />

used with all of the Pony's mounted tools.<br />

Brakes can be locked together for road use.

<strong>MASSEY</strong>-<strong>HARRIS</strong> 2-PLOW "22"<br />

Full power, economy on every 2-plow job<br />

* Whether it's out on a tough<br />

plowing job . . . or a precision<br />

job of cultivating, you'll find the<br />

Massey-Harris "22" is the power and<br />

economy champion of the 2-plow<br />

class. You get husky, dependable<br />

power with the "22." That big 140cubic-inch,<br />

four-cylinder engine delivers<br />

lively, flexible power. It's a<br />

high-compression power plant for<br />

smooth, fast response. Built-in governor<br />

and automatic spark advance<br />

control power output . . . deliver<br />

just the power you need on every<br />

job. There's real money-saving advantages<br />

in the "22's" performance<br />

.. . less fuel consumption, faster,<br />

better work.<br />

Straight-line transmission reduces<br />

power loss . . . delivers full engine<br />

power to the drawbar. Husky con-<br />

struction in the gears, shafts, and<br />

case adds an extra bonus of quality,<br />

years of economical performance.<br />

The "22" is easy to handle—shockresistant<br />

steering, individually operated<br />

brakes and a short turning<br />

radius of "N feet, let you turn<br />

sharper, easier. Smart, streamlined<br />

styling gives you better vision .. .<br />

with the "22" you have a complete<br />

view of the field and your work.<br />

The "22" has a complete line-up of<br />

matched tools—raised and lowered<br />

by new Depth-o-matic System .. .<br />

a more accurate, hydraulic unit for<br />

fingertip control of mounted and<br />

semi-mounted implements.<br />

If yours is a family-size farm, get<br />

the proven power and economy<br />

leader of the 2-plow class . . . dollar<br />

for horsepower it's your best buy.<br />

[ 5 ]<br />

ROW CROP OR STANDARD<br />

The "22" is available in either Row Crop or conventional<br />

Standard tread design. The row crop models<br />

have a turning radius of 7 1/2 feet—the standards 10<br />

feet. Wheel base of the Row Crop is 82 3/4 inches—<br />

the Standard 74 3/4 inches. Row Crop has adjustable<br />

rear tread 48 to 88 inches—Standard tread is fixed<br />

at 48 inches.

ROW CROP OR STANDARD<br />

The "30" is available in Standard or Row Crop tread.<br />

Both have the same shock-resistant steering, ease of<br />

handling. The Row Crop has a turning radius of 81/2<br />

Feet and a crop clearance of 251/2 inches. The Standard<br />

has a turning radius of 101/2 Feet—tread width is<br />

52 1/8 inches.<br />

<strong>MASSEY</strong>-<strong>HARRIS</strong> 2-3 PLOW "30"<br />

Smooth, dependable, productive power<br />

* Here's power that gets things<br />

done . . . quickly, easily, economically.<br />

You get smooth, flexible<br />

power from the "30" . . . pulling<br />

power that covers more acres on<br />

every tank of fuel. The "30" has a<br />

husky, heavy-duty, 4-cylinder engine<br />

. . . with high-compression for<br />

more pep, greater economy .. .<br />

dependable lugging power at the<br />

drawbar, smooth efficiency on the<br />

belt. Most important, you'll find the<br />

"30" has a reservoir of extra power,<br />

when a power bonus really counts.<br />

For faster field work, the "30"<br />

has 5 forward • speeds . . . each a<br />

practical speed to help you do a<br />

better job of farming. Transmission<br />

gears are precision-cut for a full<br />

rolling contact. Bearings, shafts,<br />

axles are tough, extra husky.<br />

1181111111111111M1111■MININ1111111.1."..-<br />

There's a wide range of fastworking<br />

tools available for the "30"<br />

. . . plows, planters, cultivators,<br />

bedders, listers . . . custom-designed<br />

for fast, clean work—less time in<br />

the field. And it's in the field where<br />

you will appreciate the streamlined<br />

styling of the "30" . . . the smooth,<br />

clean lines that give you a clear<br />

view of what you're doing. You<br />

work right up close to the rows,<br />

handle your combine or corn picker<br />

easier, faster . . . do an accurate job<br />

of plowing, discing, planting.<br />

But for the real test, get on the<br />

seat of the "30." Drive it. The easy<br />

way it handles, the convenience of<br />

controls, the solid feel of it, the<br />

comfort of its Velvet Ride Seat will<br />

help you decide that here's the kind<br />

of power you want for your farm.

<strong>MASSEY</strong>-<strong>HARRIS</strong> 3-4 PLOW "44"<br />

Tough, versatile 4-cylinder power<br />

* The first time you see the Massey-<br />

Harris "44" handle a tough field or<br />

belt job, you'll know that here's<br />

power that isn't stopped by packed<br />

soil, hilly land or an overloaded<br />

roughage mill. It's power that's<br />

husky, versatile .. . power with<br />

stamina to pull you through the<br />

stubborn spots on your farm.<br />

And right on your farm you get to<br />

know the comfort and convenience<br />

advantages of the "44" . . . self-starter,<br />

battery ignition, shock-resistant<br />

steering, easy handling, short turning,<br />

Velvet Ride Seat.<br />

The "44" engine is a big 260-cubicinch,<br />

4-cylinder power plant that<br />

delivers more lugging power, more<br />

dollars-and-cents savings in both<br />

operation and upkeep. And power<br />

with economy is a mighty important<br />

advantage in the "44" . . . it's the<br />

proven champion of its class.<br />

Five forward speeds in the "44"<br />

provide ideal speed range. Plowing<br />

or discing, cultivating or planting,<br />

you have a fuel-saving speed<br />

matched to your work. Moreover,<br />

the entire transmission is precisionbuilt.<br />

Accurate tolerances and husky<br />

construction result in greater efficiency<br />

and power-saving ability.<br />

From its smartly designed grille<br />

to its husky drawbar, the "44" is<br />

built for power performance, economical<br />

service, better farming.<br />

6-CYLINDER "44-6"<br />

If you prefer a 6-cylinder engine, you're sure<br />

to like the 3-plow "44-6." It has the same<br />

clean, clear vision styling, the same economical,<br />

efficient performance, the same 5-speed<br />

transmission as the "44." Individual porting<br />

in the "44-6" gives each cylinder an equal<br />

amount of fuel . . . you get constant power,<br />

smooth 3-plow power on every job.<br />

[ 7<br />

ROW CROP OR STANDARD<br />

The Standard Tread "44" and "44-6" have a turning<br />

radius of 11 Feet and tread width of 54 1/8 inches ...<br />

Row Crop models have a turning radius of 9 Feet<br />

with adjustable tread 52 to 88 inches. Crop clearance<br />

is 27 1/2 inches.

NEW <strong>MASSEY</strong>-<strong>HARRIS</strong> "44" DIESEL<br />

A world of power at low operating cost<br />

* Greater economy . . . new efficiency<br />

. . . more pulling at the drawbar,<br />

more money-saving field performance—yes,<br />

every advantage of<br />

Diesel farming is yours with the<br />

new Massey-Harris "44" Diesel.<br />

It's a different kind of Diesel design,<br />

yet no more intricate than a<br />

standard gasoline engine. The main<br />

chamber is designed for maximum<br />

turbulence giving a better-balanced<br />

fuel-air mixture. It's a smaller firing<br />

chamber — less compression heat<br />

escapes . . . complete combustion<br />

and greater economy result. A special<br />

energy cell—the Dyna-Cell—<br />

cushions the peak pressures of initial<br />

firing and reduces the main cylinder<br />

pressure to 750 pounds per square<br />

inch. It's cushioned power . . .<br />

smoother, more concentrated.<br />

Cushioned Power works like this :<br />

A simple injection nozzle shoots a<br />

coarse spray of fuel across the turbulence<br />

chamber. The spray fringes<br />

at the ends and ignites while the<br />

core enters the Dyna-Cell. This delays<br />

ignition in the main cylinder<br />

until the crankshaft begins its<br />

downward travel. Primary ignition<br />

occurs in the Dyna-Cell where the<br />

harshness of the explosion is confined.<br />

The burning fuel is metered<br />

into the main chamber setting up a<br />

cyclonic rotary turbulence. Burning<br />

fuel swirls the full length of the<br />

cylinder exerting equal pressure the<br />

length of the piston stroke.<br />

Fuel burns slower, delivers a<br />

pushing force . . . greater lugging<br />

power because there's a steady force<br />

the length of every stroke.<br />

[8]<br />

DYNA-CELL COMBUSTION<br />

Dyna-Cell distributes Fuel-air mixture uniformly<br />

in the main chamber. Combustion lasts<br />

longer, providing positive power throughout<br />

the cylinder stroke. Dyna-Cell softens the<br />

knock so common to ordinary Diesel engines<br />

...delivers more power From every gallon of<br />

Fuel ...develops greater power with less engine<br />

weight.<br />

13q<br />

m<br />

jo<br />

cc<br />

bt<br />

sp<br />

m<br />

ec<br />

ha<br />

to<br />

ve<br />

eq<br />

er,<br />

fo:<br />

co:<br />

op

<strong>MASSEY</strong>-<strong>HARRIS</strong> 4-5 PLOW "55"<br />

Controlled power to match heavy jobs<br />

* Big, husky, powerful . . . the<br />

Massey-Harris 4-5 plow "55" is<br />

packed with lugging ability that<br />

makes short work of your heaviest<br />

jobs. Here is brute strength with<br />

controlled power—the result of<br />

built-in governor and automatic<br />

spark control. You get economy unmatched<br />

in a tractor as big as the<br />

"55" . . . the correct power, the right<br />

economy for highest efficiency.<br />

Yet for all its bigness, the "55"<br />

handles easily . . . responds quickly<br />

to your touch. Comfort and convenience<br />

advantages are standard<br />

equipment with the "55"—self starter,<br />

battery ignition, full-width platform,<br />

Velvet Ride Seat, handy<br />

controls—all contribute to ease of<br />

operation . . . faster, better work.<br />

The "55" has a big 382-cubic-inch,<br />

4-cylinder engine with the kind of<br />

stamina you need for dependability<br />

under tough conditions. Pulling 4 or<br />

5 bottoms or on a heavy belt job, the<br />

"55" is master of its power output.<br />

Power is transferred in a straight<br />

line through the precision-built<br />

4-speed transmission to the drawbar.<br />

Gears mesh accurately even<br />

under shock loads. Oil-bath lubrication<br />

assures long life.<br />

It all results in more production<br />

on less fuel . . . more acres worked<br />

per day, efficiency unheard of in a<br />

tractor the size of the "55." For large<br />

wheat farms, the rugged conditions<br />

of the rice fields . . . wherever 4-5<br />

plow power is required, the "55"<br />

gives you more production and<br />

horsepower per dollar, more dollarsaving<br />

field performance.<br />

[9]<br />

On an all-day belt job, the "55" whisks through tough<br />

assignments convincingly demonstrating its rugged<br />

strength and brute power. Out in the field, the "55"<br />

is just as rugged ...and surprisingly easy to handle.<br />

It has a turning radius of 12 feet and tread of 57 inches.<br />

Gasoline or Distillate models are available.

PONY-62 cubic in., 4 c Iders, L-Head<br />

21/4" Bore-3 1/2 Stroke<br />

"44"-260 cubic in., 4 cylinders, Overhead Valves<br />

3 7/s" Bore-51/2" Stroke<br />

"22"-140 cubic in., 4 cylinders, L-Head<br />

3 i h w Bore-4 3/8" Stroke<br />

"44"—Diesel 260 cu. in., 4 cylinders, Overhead Valves<br />

3 7/8" Bore-51/2" Stroke<br />

"30"-162 cubic in., 4 cylinders, L-Head<br />

Bore-4 3/8" Stroke<br />

•<br />

"55"-382 cubic in., 4 cylinders, Overhead Valves<br />

4 1/2" Bore-6" Stroke<br />

<strong>MASSEY</strong>-<strong>HARRIS</strong> TRACTOR ENGINES<br />

7.<br />

Deliver smooth, economical power<br />

Here's the heart of your Massey-Harris tractor .. .<br />

peppy, quick-responding engines that develop more<br />

power, more economy than any in its class. There's<br />

smooth, flexible power delivered by your Massey-<br />

Harris . . . L-head or Overhead design each measures<br />

up to the highest standards of engine efficiency. You<br />

have dependable power, constant power that turns<br />

that last furrow with time to spare.<br />

High compression in your Massey-Harris means a<br />

cooler-running engine . . . extra power for occasional<br />

STRAIGHT-LINE TRANSMISSION<br />

SAVES POWER<br />

* Massey-Harris transmissions are precision-built. Power<br />

moves in a straight line through the gears to the final drive.<br />

There's no lost motion . . . no power-consuming side<br />

tracking. Gears arc machined accurately for a full-rolling<br />

contact . . . case hardened for extra toughness, long-life.<br />

Heavy ribs in the transmission cases provide maximum<br />

strength with less weight. Shafts are short, husky . . . to<br />

eliminate flexing, take shock- loads easier. Heavy-duty<br />

bearings last longer . . . run smoother. Oil-bath lubrication<br />

positively protects gears, bearings and shafts.<br />

Speeds are determined after exhaustive tests under<br />

varying conditions and are job-matched to each tractor<br />

model. The Pony has 3 forward speeds; "22" - 4 forward;<br />

"30" - 5 forward; "44" - 5 forward; "44" Diesel - 5 forward;<br />

and "55" - 4 forward.<br />

[ 10 ]<br />

tough spots. Cylinder block and crankcase are cast in<br />

one piece . . . ribbed for more strength. Crankshaft is<br />

statically and dynamically balanced for true-running<br />

. . . smooth, vibrationless operation. Pistons are long<br />

lasting . . . fast lubricating. Built-in governor and automatic<br />

spark control give top economy on every job.<br />

Manifold is cast and machined in one piece for positive<br />

seal to engine. Valves, rods, bearings, crankshaft<br />

—all are husky, extra strong for years of plus-power.<br />

( "44," "44" Diesel, and "55" have removable sleeves. )<br />

WIDE,<br />

There's PIE<br />

Harris tray<br />

occasional<br />

off, too.<br />

As an attE<br />

advantage!<br />

clearance<br />

narrow rol

THESE ADVANTAGES MEAN<br />

ON-YrOUrfarM<br />

FASTER, EASIER WORK<br />

WIDE, ROOMY PLATFORM<br />

There's plenty of leg room on Massey-<br />

Harris tractors...room to enjoy that<br />

occasional stretch. Easier to get on and<br />

off, too.<br />

THROTTLE CONTROL<br />

It's easy to reach all controls. The throttle<br />

is right there before you for instant use.<br />

Quadrant is divided for field and belt use.<br />

WIDE-ARCH FRONT AXLE OR 'ANGLE FRONT WHEEL<br />

As an attachment For the row crop models, the wide-arch front axle gives you all the<br />

advantages of standard tread operation—plus a wide range of adjustment and extra<br />

clearance for work in tall row crops. Single front wheel is ideal for cultivation in extremely<br />

narrow rows. In both variations you get Massey-Harris safe, quick-responding steering.<br />

SELF-STARTER IS STANDARD<br />

You'll like the convenience and Fuel<br />

saving advantages of quick starts. When<br />

you stop it's no trouble to start again...<br />

you don't idle away fuel.<br />

GOVERNOR CONTROLLED<br />

Your Massey-Harris tractor delivers the<br />

right kind of power and economy for<br />

each job. You don't under-power heavy<br />

jobs nor over-power light jobs.<br />

AND NEW Depth-o-matic SYSTEM<br />

Depth-o-matic System is a small, compact double-action<br />

hydraulic cylinder with both fast and slow speed. It's cornpietely<br />

out of the way, leaving the tractor platform clear for an<br />

occasional stretch. It's safer too . . . no dangerous power lines<br />

or linkage to worry about.<br />

Depth-o-matic raises and lowers implements tinder power<br />

. . . there's no bouncing, banging, dropping of your implements.<br />

Once you set the depth adjustment for your conditions,<br />

it's automatic. A touch of the lever raises the implement; another<br />

touch lowers it to the original depth. A by-pass permits minor<br />

depth adjustments while you're working. Depth-o-matic System<br />

operates equally well with pull-behind and selective control<br />

rams. ( Available for "22," "30," "44" and "44-6" tractors. )<br />

SHOCK-RESISTANT VEERING<br />

Massey-Harris tractors are easy handling.<br />

Steering gears cushion shocks of<br />

rough fields and roads. Dodging in<br />

narrow rows is simple, safe.<br />

ADJUSTABLE TREAD<br />

Tread widths vary with the size or the<br />

tractor—the Pony is adjustable 41 to<br />

69 inches; "22"-48 to 88 inches;<br />

"30," "44," "44.6"-52 to 88 inches.

[ 12 II<br />

1C 4-row Beet and Bean Cultivator<br />

56C 2-row Spring Trip Cultivator<br />

57 2-row Spring Trip Cultivator<br />

41 1-row Spring Tooth Cultivator<br />

2C 6-row Beet and Bean Cultivator<br />

54C 2-row Disc Cultivator<br />

59 4-row Spring Trip Cultivator<br />

42 4-row Vegetable Cultivator<br />

22 2-row Spring Trip Cultivator<br />

53C 2-row Heavy Duty Cultivator<br />

74 Selective Control Cultivator<br />

40 Field Cultivator<br />

2.;

[12]<br />

1C 4-row Beet and Bean Cultivator 2C 6-row Beet and Bean Cultivator 22 2-row Spring Trip Cultivator<br />

56C 2-row Spring Trip Cultivator<br />

57 2-row Spring Trip Cultivator<br />

41 1-row Spring Tooth Cultivator<br />

54C 2-row Disc Cultivator<br />

59 4-row Spring Trip Cultivator<br />

42 4-row Vegetable Cultivator<br />

53C 2-row Heavy Duty Cultivator<br />

74 Selective Control Cultivator<br />

;<br />

I iller*<br />

L I I 11<br />

I I<br />

40 Field Cultivator

23 2-row Spring Tooth Cultivator<br />

55C 2-row Spring Tooth Cultivator<br />

41 1-row Spring Trip Cultivator<br />

/<br />

<strong>MASSEY</strong>•<strong>HARRIS</strong><br />

full-view cultivators<br />

1C Beet and Bean Cultivator 2C Beet and Bean Cultivator<br />

A 4-row cultivator for the "30" and "44" The 2C cultivates 6 rows at a time . • .<br />

tractors. Divided tool bar allows the IC to makes short work of cultivating large acreage.<br />

follow the lay of your land. Especially suited Tool bar is divided for floating action . . .<br />

to narrow row crops . . . spacing adjustable you do a better job . . . cultivate uniformly.<br />

for 18 to 28-inch rows. Standard set-up con- Usual set-up has 12 shovels and 7 sweeps<br />

sists of 8 shovels and 5 sweeps front-2 forward-2 sweeps (extra) rear. Adjustable<br />

sweeps rear (extra). 18 to 28-inch rows. "44" tractor equipment,<br />

22 Spring Trip Cultivator<br />

Excellent penetration and quick-attachable<br />

gangs are two big advantages you'll find in<br />

the 2-row 22 cultivator A simple latch locks<br />

the gang to the tool bar. Takes but a minute.<br />

Big 85-pound capacity fertilizer hoppers and<br />

runner-planter attachments available as extras.<br />

Shovel arrangement: 8 front, 11 front,<br />

8 front and 13 rear, or 11 front and 2 rear.<br />

Adjustable 28 to 42-inch rows.<br />

56C Spring Trip Cultivator<br />

The 56C has excellent clearance . . . gangs<br />

raise straight up-always to the same height.<br />

A variety of shovel combinations are available<br />

for the 56C-8 front, 3 rear, 11 front<br />

only, 8 front only, 11 front-2 rear. Adjustable<br />

28 to 42-inch rows. Spring pressure rods<br />

are adjustable to suit the 56C to your soil.<br />

'44" and "30" tractor equipment.<br />

53C Heavy-Duty Cultivator<br />

When hard, packed soil presents a problem,<br />

the 2-row 53C spring trip cultivator steps<br />

in to do a clean job of working your fields.<br />

Construction is husky, tough . . . yet simplicity<br />

and ease of attaching are maintained.<br />

11 shovels front-2 rear; adjustable 28 to 42inch<br />

rows. "44" tractor equipment.<br />

57 Spring Trip Cultivator<br />

Gangs on the 57 are full-floating for uniform<br />

penetration. Trigger Latch attaches gangs to<br />

tool bar quickly, easily-saves time even<br />

before you get into the field. Fertilizer<br />

attachment (extra) holds 170 lbs. Runner<br />

planter attachment also available. 8 shovels<br />

front, 3 rear. Adjustable 36 to 42-inch rows.<br />

"30" and "44" tractor equipment,<br />

74 Selective Control Cultivator<br />

The 74 Selective Control Cultivator is especially<br />

designed for working those specialized<br />

vegetable crops that are grown on one side<br />

of the bed. Two hydraulic rams-one to<br />

operate each side of the front tool barpermit<br />

selective use of the left, right or both<br />

sections. The rear tool bar has delayed lift<br />

action for a cleaner job at the row ends.<br />

Cast or rubber tired gauge wheels. "44"<br />

tractor equipment.<br />

41 Spring Tooth Cultivator<br />

Of simple, efficient design, the 41 singlerow<br />

Spring Tooth Cultivator has husky construction<br />

in the tool-bar, gangs and lift.<br />

Spring tooth shanks are extra strong-4 are<br />

mounted forward, 2 at the rear. Standard<br />

points are 2-inch reversible. 3-inch points<br />

and shield attachment available. Pony equipment.<br />

40 Field Cultivator<br />

25 and 26 Field Cultivators [13]<br />

The 40 spring tooth field cultivator is fully<br />

mounted. Simple, T-shaped frame design with<br />

3 full-floating gangs. Independent pressure<br />

springs on each gang mean you do a better<br />

job of cultivating in uneven land. Nine 1 1/2<br />

-inch reversible points are standard equipment.<br />

Sets of shovel points and weeder blades in<br />

4, 4 1/2 , 6, 7 and 12-inch sizes are special<br />

order. Pony Tractor equipment.<br />

23 Spring Trip Cultivator<br />

New trigger latch gangs save a lot of time<br />

with the 23 2-row cultivator . . . gangs go<br />

on quickly, easily-one man can do it alone.<br />

Fertilizer attachment (extra) holds a total of<br />

170 lbs. . . . you build up your soil as you<br />

cultivate. Adjustable 28 to 42-inch rows.<br />

22 tractor equipment.<br />

54C Disc Cultivator<br />

Specifically designed for rooty or vine-infested<br />

fields, the 54C has eight 16-inch discs forward,<br />

a 10-inch sweep behind each. Discs<br />

are electrically heat treated . . . cutting<br />

edges stay sharp longer. Bearings are tough,<br />

long lasting. The 54C is adjustable 38 to<br />

42-inch rows. Mechanical or Depth-o-matic<br />

control. "44" and "30" tractor equipment.<br />

55C Spring Tooth Cultivator<br />

A 2-row cultivator with 8 or 11 spring teeth<br />

in front and 2 or 3 rear. Adjustable 28 to<br />

42-inch rows. The multiple shovel arrangement,<br />

wide adjustment, and spring teeth make<br />

the 55C especially suited to light loam soil<br />

conditions. One-man hoeing attachment available.<br />

"30" and "44" tractor equipment.<br />

59 Spring Trip Cultivator<br />

You drive right into the 4-row 59 cultivator<br />

when hooking up to your tractor. Special<br />

legs hold the cultivator in exact position for<br />

easy lining up. In the field 59 has the flexibility<br />

you need for following up and down<br />

land variations . . . for clean cultivating on<br />

the contour. 18 front shanks, 3 rear. Adjustable<br />

28 to 42-inch rows. Cast or rubber tired<br />

gauge wheels. "30" and "44" tractor equipment.<br />

41 Spring Trip Cultivator<br />

The 1-row 41 cultivator is of single-row design<br />

with six stiff tooth spring trip shanks. Plenty<br />

of capacity for small-farm row crop work.<br />

Four shovels are mounted forward-two rear<br />

shovels take out wheel tracks. Easy on and<br />

easy off. Standard points are 2-inch reversible.<br />

Shield attachment; 3, 3 1/2 -inch and 51/2-inch<br />

shovels, 8, 10, 12 and 16-inch sweeps, available<br />

as ordered. Pony tractor equipment.<br />

42 Vegetable Cultivator<br />

The 42 vegetable cultivator has a full-floating<br />

one-piece frame, 84 inches long. It's of allwelded<br />

steel construction for strength and<br />

dependability. The full-floating advantage<br />

means you do a clean job on the high spots<br />

and in the low spots .. . handling four 16,<br />

18 or 20-inch rows at a time, (five 16-inch<br />

rows can be worked). Discs and sweeps are<br />

standard equipment-8 front and 2 rear, or<br />

8 discs front. Gauge wheels are cast. Pony<br />

equipment.<br />

Low-Wheel Cultivators<br />

Sturdily built, Massey-Harris low-wheel, cultivators<br />

are easy to handle, easy to adjust.<br />

Crank-operated depth control device, constantheight<br />

power lift, and Massey-Harris toptension<br />

drag bars with three-way clearance<br />

mean faster work under varying conditions.<br />

The low-wheel design makes for lighter<br />

draft, greater strength. Available in hand<br />

lift 11-tooth; power lift 9, 11, 13, 15 and<br />

19-tooth. Tractor hitch is standard on power<br />

lift models. Fore carriage is available on<br />

special order. Stiff-tooth Model 25; springtooth<br />

Model 26.

23 2-row Spring Tooth Cultivator<br />

55C 2-row Spring Tooth Cultivator<br />

41 1-row Spring Trip Cultivator<br />

25 and 26 Field Cultivators<br />

<strong>MASSEY</strong>-<strong>HARRIS</strong><br />

full-view cultivators<br />

1C Beet and Bean Cultivator<br />

A 4-row cultivator for the "30" and "44"<br />

tractors. Divided tool bar allows the 1C to<br />

follow the lay of your land. Especially suited<br />

to narrow row crops . . . spacing adjustable<br />

for 18 to 28-inch rows. Standard set-up consists<br />

of 8 shovels and 5 sweeps front-2<br />

sweeps rear (extra).<br />

22 Spring Trip Cultivator<br />

Excellent penetration and quick-attachable<br />

gangs are two big advantages you'll find in<br />

the 2-row 22 cultivator A simple latch locks<br />

the gang to the tool bar. Takes but a minute.<br />

Big 85-pound capacity fertilizer hoppers and<br />

runner-planter attachments available as extras.<br />

Shovel arrangement: 8 front, 11 front,<br />

8 front and 13 rear, or 11 front and 2 rear.<br />

Adjustable 28 to 42-inch rows.<br />

56C Spring Trip Cultivator<br />

The 56C has excellent clearance . . . gangs<br />

raise straight up—always to the same height.<br />

A variety of shovel combinations are available<br />

for the 56C-8 front, 3 rear, 11 front<br />

only, 8 front only, 11 front-2 rear. Adjustable<br />

28 to 42-inch rows. Spring pressure rods<br />

are adjustable to suit the 56C to your soil.<br />

'44" and "30" tractor equipment.<br />

53C Heavy-Duty Cultivator<br />

When hard, packed soil presents a problem,<br />

the 2-row 53C spring trip cultivator steps<br />

in to do a clean job of working your fields.<br />

Construction is husky, tough . . . yet simplicity<br />

and ease of attaching are maintained.<br />

11 shovels front-2 rear; adjustable 28 to 42inch<br />

rows. "44" tractor equipment.<br />

57 Spring Trip Cultivator<br />

Gangs on the 57 are full-floating for uniform<br />

penetration. Trigger Latch attaches gangs to<br />

tool bar quickly, easily—saves time even<br />

before you get into the field. Fertilizer<br />

attachment (extra) holds 170 lbs. Runner<br />

planter attachment also available. 8 shovels<br />

front, 3 rear. Adjustable 36 to 42-inch rows.<br />

"30" and "44" tractor equipment.<br />

74 Selective Control Cultivator<br />

The 74 Selective Control Cultivator is especiolly<br />

designed for working those specialized<br />

vegetable crops that are grown on one side<br />

of the bed. Two hydraulic rams—one to<br />

operate each side of the front tool bar—<br />

permit selective use of the left, right or both<br />

sections. The rear tool bar has delayed lift<br />

action for a cleaner job at the row ends.<br />

Cast or rubber tired gauge wheels. "44"<br />

tractor equipment.<br />

41 Spring Tooth Cultivator<br />

Of simple, efficient design, the 41 singlerow<br />

Spring Tooth Cultivator has husky construction<br />

in the tool-bar, gangs and lift.<br />

Spring tooth shanks are extra strong-4 are<br />

mounted forward, 2 at the rear. Standard<br />

points are 2-inch reversible. 3-inch points<br />

and shield attachment available. Pony equipment.<br />

40 Field Cultivator<br />

The 40 spring tooth field cultivator is fully<br />

mounted. Simple, T-shaped frame design with<br />

3 full-floating gangs. Independent pressure<br />

springs on each gang mean you do a better<br />

job of cultivating in uneven land. Nine 1 t/2<br />

-inch reversible points are standard equipmedt.<br />

Sets of shovel points and weeder blades in<br />

4, 4 t/2 , 6, 7 and 12-inch sizes are special<br />

order. Pony Tractor equipment.<br />

[13]<br />

2C Beet and Bean Cultivator<br />

The 2C cultivates 6 rows at a time . . .<br />

makes short work of cultivating large acreage.<br />

Tool bar is divided for floating action . . .<br />

you do a better job . . . cultivate uniformly.<br />

Usual set-up has 12 shovels and 7 sweeps<br />

forward-2 sweeps (extra) rear. Adjustable<br />

18 to 28-inch rows. "44" tractor equipment.<br />

23 Spring Trip Cultivator<br />

New trigger latch gangs save a lot of time<br />

with the 23 2-row cultivator . . . gangs go<br />

on quickly, easily—one man can do it alone.<br />

fertilizer attachment (extra) holds a total of<br />

170 lbs. . . . you build up your soil as you<br />

cultivate. Adjustable 28 to 42-inch rows.<br />

22 tractor equipment.<br />

54C Disc Cultivator<br />

Specifically designed for rooty or vine-infested<br />

fields, the 54C has eight 16-inch discs forward,<br />

a 10-inch sweep behind each. Discs<br />

are electrically heat treated . . . cutting<br />

edges stay sharp longer. Bearings are tough,<br />

long lasting. The 54C is adjustable 38 to<br />

42-inch rows. Mechanical or Depth-o-matic<br />

control. "44" and "30" tractor equipment.<br />

55C Spring Tooth Cultivator<br />

A 2-row cultivator with 8 or 11 spring teeth<br />

in front and 2 or 3 rear. Adjustable 28 to<br />

42-inch rows. The multiple shovel arrange•<br />

ment, wide adjustment, and spring teeth make<br />

the 55C especially suited to light loam soil<br />

conditions. One-man hoeing attachment available.<br />

"30" and "44" tractor equipment.<br />

59 Spring Trip Cultivator<br />

You drive right into the 4-row 59 cultivator<br />

when hooking up to your tractor. Special<br />

legs hold the cultivator in exact position for<br />

easy lining up. In the field 59 hos the flexibility<br />

you need for following up and down<br />

land variations . . . for clean cultivating on<br />

the contour. 18 front shanks, 3 rear. Adjustable<br />

28 to 42-inch rows. Cast or rubber tired<br />

gauge wheels. "30" and "44" tractor equipment.<br />

41 Spring Trip Cultivator<br />

The 1-row 41 cultivator is of single-row design<br />

with six stiff tooth spring trip shanks. Plenty<br />

of capacity for small-farm row crop work.<br />

Four shovels are mounted forward—two rear<br />

shovels take out wheel tracks. Easy on and<br />

easy off. Standard points are 2-inch reversible.<br />

Shield attachment; 3, 3 1/2 -inch and 51/2-inch<br />

shovels, 8, 10, 12 and 16-inch sweeps, available<br />

as ordered. Pony tractor equipment.<br />

42 Vegetable Cultivator<br />

The 42 vegetable cultivator has a full-floating<br />

one-piece frame, 84 inches long. It's of allwelded<br />

steel construction for strength and<br />

dependability. The full-floating advantage<br />

means you do a clean job on the high spots<br />

and in the low spots . . . handling four 16,<br />

18 or 20-inch rows at a time, (five 16-inch<br />

rows can be worked). Discs and sweeps are<br />

standard equipment-8 front and 2 rear, or<br />

8 discs front. Gauge wheels are cast. Pony<br />

equipment.<br />

Low-Wheel Cultivators<br />

Sturdily built, Massey-Harris low-wheel, cultivators<br />

are easy to handle, easy to adjust.<br />

Crank-operated depth control device, constantheight<br />

power lift, and Massey-Harris toptension<br />

drag bars with three-way clearance<br />

mean faster work under varying conditions.<br />

The low-wheel design makes for lighter<br />

draft, greater strength. Available in hand<br />

lift 11-tooth; power lift 9, 11, 13, 15 and<br />

19-tooth. Tractor hitch is standard on power<br />

lift models. Fore carriage is available on<br />

special order. Stiff-tooth Model 25; springtooth<br />

Model 26.

2 4 2-Row Lister for "22" Tractor<br />

Husky, all-steel construction gives the 24 lister<br />

plenty of strength For tough conditions. Single-point<br />

hitch for uniform work. Planting and Fertilizer attachments<br />

(extra). Adjustable 36 to 42-inch rows.<br />

4<br />

1 1 4C 4-Row Lister for "44" Tractors<br />

The 114C matches the Flexibility of a pull-behind<br />

tool . . . lists and plants uniformly . . . starts your<br />

crop toward bigger yields. Planting and Fertilizer<br />

attachments available—adjustable 36, 38, 40, 42inch<br />

rows.<br />

1 1 2C 3-Row Lister for "30" Tractors<br />

You'll do good, clean work with the 112C . . . on<br />

Rat land or on the contour. As on all Massey-Harris<br />

listers, bottoms have special kick-back when an<br />

obstruction is hit. Planting and fertilizer attachments<br />

are special order equipment. Adjustable 36, 38,<br />

40, 42-inch rows.<br />

<strong>MASSEY</strong>-<strong>HARRIS</strong><br />

Accurate, high-speed lister planters<br />

Modern design improvements in Massey-Harris listers result<br />

in greater flexibility . . . increased efficiency at fast tractor<br />

speeds. You do more and better work . . . at lower cost, in<br />

less time.<br />

Massey-Harris listers cut uniform furrows that help hold<br />

moisture through the winter. You can use them to relist in<br />

the spring, to sweep or knife beds . . . to do all the ground<br />

preparation work wherever lack of moisture is a problem.<br />

Massey-Harris listers have a single point hitch that<br />

extends well forward on the tractor frame for easy accessibility.<br />

You hook-up or remove the Massey-Harris listers as<br />

easily as a pull-behind tool. Single point hitch makes it<br />

easy . . . gives the entire lister a full-floating action . . . it<br />

follows the lay of your land . . . your fields are worked uniformly<br />

on the slopes and in the low spots.<br />

When you operate the Depth-o-matic lift, bottoms rise<br />

[ 14 ]<br />

evenly, quickly. A touch of the hydraulic lift lever and<br />

they're lowered under power to the original depth.<br />

By adding the planting attachment, your lister becomes<br />

an accurate, dependable planter. Massey-Harris cell-drop<br />

planting mechanism fills each hole carefully, quickly . . . as<br />

though by hand. Seed mechanism stops automaticallywhen<br />

bottoms are raised. You save seed at the rows ends . . .plant<br />

faster.<br />

Whether your operations require a 2, 3, or 4-row model,<br />

you'll find the Massey-Harris listers are simple in design,<br />

rugged in construction, easy to adjust. Moreover, they're<br />

easy to pull . require less power, less fuel . . . reduce your<br />

operating costs.<br />

Attachments include: Fertilizer attachment, Planting<br />

attachment, Disc marker, Press wheels, Cotton and corn or<br />

Corn hoppers, Hitch Adjusting Lever for 112 and 24.

Fast-operating<br />

precision plantin<br />

bedders<br />

Model 25, 2-Row Bedder for "22" Tractor<br />

Of all-welded steel construction the 25 is built extra<br />

strong to stand heavy work in tough soils. And with frontmounted<br />

design you have a good, clear view of the work<br />

you are doing . . . you do a better job faster, easier. Bottoms<br />

have a floating action . . . work at uniform depth anywhere<br />

in the field. And . . . because they raise parallel to the<br />

ground, with plenty of clearance, you never disturb the<br />

depth setting. It all adds up to better work . . . top field<br />

performance that gets the job done ahead of schedule.<br />

Adjustable 34 to 42-inch rows. Extra equipment includes<br />

Planting, Hill Drop and Fertilizer Attachments, Rolling<br />

Coulters.<br />

220C 2-Row Bedder for "30" Tractor<br />

The 220C is modern in every detail, rigidly constructed,<br />

yet quickly and easily adjusted to your individual field conditions.<br />

You'll like the large gauge wheels, positive drive,<br />

handy, easy-to-reach levers. Because the 220C is frontmounted,<br />

you can use your tractor for in-between jobs<br />

without removing the bedder. The high parallel lift raises<br />

gangs quickly and easily, with plenty of clearance. Adjustable<br />

from 36 to 40-inch rows. The 220C may be ordered<br />

with 14 or 22-inch heavy shares—bottoms are 12-inch<br />

J.B.H. Extra equipment includes Seeding, Fertilizer, and<br />

Hill Drop Attachments.<br />

121 C 2-Row Bedder for "44" Tractor<br />

Front-mounted design means clear vision, better-worked<br />

rows with 121C. For rush drawbar jobs, you can leave the<br />

bedder on the tractor. Parallel lift raises bottoms to a high<br />

level with plenty of clearance. Long braces hold the 121C<br />

to its work even at fast speeds; handy adjustments provide<br />

easy setting for depth and pitch of bottoms. 12-inch J.B. or<br />

J.B.H. bottoms-14 or 22-inch shares. Seeding, and Third<br />

Beam attachments extra.<br />

120C 4-Row Bedder for "44" Tractors<br />

If your work is sufficiently heavy to use a 4-row Planter<br />

or 3-row Bedder, you'll find the 120C will make short<br />

work of your heavy-duty planting or bedding operations.<br />

The 120C takes "top honors" for fast dependable work.<br />

And you do a more thorough job because front-mounted<br />

design lets you see just how the bottoms are working your<br />

land. Except for its wider design ( two additional gangs )<br />

the 120C is identical in construction to the 2-row 121C.<br />

[ 15 ]<br />

..1110.0910.,<br />

220C 2-Row Redder For "30" Tractor<br />

Model 25, 1-Row Bedder For "22" Tractor<br />

121C 2-Row Bedder for "44" Tractor<br />

120C 4-Row Bedder for "44" Tractors

Fast-operating<br />

precision plantin<br />

bedders<br />

Model 25, 2-Row Bedder for "22" Tractor<br />

Of all-welded steel construction the 25 is built extra<br />

strong to stand heavy work in tough soils. And with frontmounted<br />

design you have a good, clear view of the work<br />

you are doing ... you do a better job faster, easier. Bottoms<br />

have a floating action ... work at uniform depth anywhere<br />

in the field. And . . . because they raise parallel to the<br />

ground, with plenty of clearance, you never disturb the<br />

depth setting. It all adds up to better work . . . top field<br />

performance that gets the job done ahead of schedule.<br />

Adjustable 34 to 42-inch rows. Extra equipment includes<br />

Planting, Hill Drop and Fertilizer Attachments, Rolling<br />

Coulters.<br />

220C 2-Row Bedder for "30" Tractor<br />

The 220C is modern in every detail, rigidly constructed,<br />

yet quickly and easily adjusted to your individual field conditions.<br />

You'll like the large gauge wheels, positive drive,<br />

handy, easy-to-reach levers. Because the 220C is frontmounted,<br />

you can use your tractor for in-between jobs<br />

without removing the bedder. The high parallel lift raises<br />

gangs quickly and easily, with plenty of clearance. Adjustable<br />

from 36 to 40-inch rows. The 220C may be ordered<br />

with 14 or 22-inch heavy shares—bottoms are 12-inch<br />

J.B.H. Extra equipment includes Seeding, Fertilizer, and<br />

Hill Drop Attachments.<br />

121 C 2-Row Bedder for "44" Tractor<br />

Front-mounted design means clear vision, better-worked<br />

rows with 121C. For rush drawbar jobs, you can leave the<br />

bedder on the tractor. Parallel lift raises bottoms to a high<br />

level with plenty of clearance. Long braces hold the 121C<br />

to its work even at fast speeds; handy adjustments provide<br />

easy setting for depth and pitch of bottoms. 12-inch J.B. or<br />

J.B.H. bottoms-14 or 22-inch shares. Seeding, and Third<br />

Beam attachments extra.<br />

120C 4-Row Bedder for "44" Tractors<br />

If your work is sufficiently heavy to use a 4-row Planter<br />

or 3-row Bedder, you'll find the 120C will make short<br />

work of your heavy-duty planting or bedding operations.<br />

The 120C takes "top honors" for fast dependable work.<br />

And you do a more thorough job because front-mounted<br />

design lets you see just how the bottoms are working your<br />

land. Except for its wider design ( two additional gangs )<br />

the 120C is identical in construction to the 2-row 121C.<br />

[ 15 ]<br />

220C 2-Row Bedder for "30" Tractor<br />

Model 25, 1-Row Bedder for "22" Tractor<br />

121 C 2-Row Bedder for "44" Tractor<br />

1 20C 4-Row Bedder for "44" Tractors

as ullin clean scouring<br />

EQUIR LE S P 1 WER . . L I<br />

No. 28 PLOW 2, 3, 4, or 5 BOTTOMS<br />

The No. 28—with its 3 exclusive features—gives you a fast,<br />

clean-scouring plow that does a better job of preparing your<br />

soil. Constant clearance lift raises bottoms to -N inches no<br />

matter how deep you may be plowing. X Frame— heavier,<br />

husky braces . . . forged to fit the beams. Adjustable Cone-<br />

Type Wheel Bearings—chilled for extra hardness, true running,<br />

snug fitting. Rear furrow wheel locks while plowing . . .<br />

unlocks to full castering position when lift is tripped. Levers<br />

are adjustable to suit your particular reach. 12, 14 or 16-inch<br />

bottoms. Rubber tires extra.<br />

No. 27 2-BOTTOM<br />

Here's an easy handling, light draft 2-bottom plow with rugged<br />

construction in every brace, nut and bolt. It's a real husky, built for<br />

fast, economical plowing over more years. The frame of the No. 27<br />

has patented X bracing . . . braces are forged to fit the channel of<br />

the heavy beams for rigid alignment. Simple, quick-acting power lift<br />

raises bottoms to high clearance in only 2 feet of travel. Levers are<br />

short . . . easy to reach and adjust. Bottoms are available to suit<br />

varying plowing conditions.<br />

No. 32 TWO-BOTTOM MOUNTED PLOW<br />

You get good, firm traction with the 32 because its mounted<br />

to your tractor . . . close coupled for easier mounting, easier<br />

handling in small or odd-shaped fields. You make shorter turns,<br />

work right up to the corners. High lift gives the 32 exceptional<br />

clearance. Depth-o-matic System controls depth of plowing<br />

hydraulically . . . accurately, positively. Handy adjustments<br />

are easy to set. Frame is Massey-Harris X design for true<br />

alignment. 10, 12 and 14-inch bottoms. "22" tractor equipment.<br />

No. 33 Two-Bottom Roll-Over Plow<br />

The No. 33 is a compact, husky 2-bottom, 2-way mounted<br />

plow that pulls directly behind your tractor for lighter draft.<br />

The hitch extends well forward on the tractor .. . a single<br />

pulling point that results in more flexibility . . . uniform plowing,<br />

easier handling anywhere in your field.<br />

The 33 is simple in operation. At the furrow end, you simply<br />

raise the bottoms, spin them over, and you're ready for the<br />

return trip . . . turning all the furrows one way. Bottoms<br />

automatically lock in position when turned . . . unlock with<br />

convenient turning lever. Frame is husky, high-carbon steel<br />

.. well braced for rigidity and strength. Bottoms are 12, 14 and<br />

16-inch. Single point hitch. Mechanical or Depth-o-matic<br />

Hydraulic lift. "30" and "44" tractor equipment.

<strong>MASSEY</strong>-<strong>HARRIS</strong> PLOWS<br />

ORE RS AT LESS COST<br />

<strong>MASSEY</strong>-<strong>HARRIS</strong> DISC PLOWS<br />

Stony, rooty or hard-to-scour land is no problem for the<br />

Massey-Harris 400 and 600 Series Disc Plows. You'll like<br />

the way they turn over the trash of a combined field .. .<br />

ride right over rocks and heavy roots. Overhead frame<br />

design and high, constant-clearance lift reduce clogging<br />

. . . you move right along, covering more acres, in less<br />

time.<br />

The 400 and 600 are essentially the same in design and<br />

construction. The 600 series have a heavier frame to meet<br />

extremely difficult conditions. Frames are twin-beam<br />

design. Hangers are clamped— not bolted—to the frame<br />

. . . the original strength of the steel is retained. Discs are<br />

heavy, durable . . . mounted on Timken tapered roller<br />

bearings for smooth-running, light draft. Hitch has wide<br />

range of adjustment. Wheels have chilled cone-type bearings<br />

for longer life.<br />

400 Series available in 2, 3, and 4-furrow sizes-600<br />

Series in 5 and 6-furrow sizes.<br />

[ 17 ]<br />

No. 801 MOUNTED PLOW<br />

The No. 801 Mounted Plow is a full-floating singlefurrow<br />

mounted plow available in 10, 12, or 14inch<br />

bottoms. Exceptional flexibility permits the<br />

801 to maintain uniform plowing depth regardless<br />

of up or down variations in your land. Depth is<br />

controlled by a convenient lever linked to front end<br />

of the hitch . . . crank adjustment makes leveling<br />

easy. You raise and lower the 801 without disturbing<br />

depth setting. Pony tractor equipment.<br />

No. 41 Two-Way MOUNTED PLOW<br />

Especially designed for irrigated land, the No. 41<br />

2-way Mounted plow does a good, clean job in<br />

tough soil conditions. The No. 41 turns all of your<br />

land one way eliminating dead furrows. Beams<br />

extend well forward under the tractor frame for<br />

straight line of draft . . . easier pulling. Bottoms<br />

penetrate quickly . . . maintain constant depth<br />

setting. Width of cut is easily adjusted. Available<br />

in 12 and 14-inch bottoms. Pony tractor equipment.

No. 32 Tandem Disc Harrow<br />

Big, tough, heavy-duty tandem disc For unusually difficult soils.<br />

7-inch blade spacing. Screw or rope control to angle gangs. 20, 24,<br />

28, 32, 36 or 40 blades 18 or 20-inch blades. Adjustable bearings.<br />

No. 40 Disc Harrow for Pony Tractor<br />

The No. 40 is a 10-blade, 5-foot cut disc with heavy<br />

angle overhead frame. Gangs are mounted on heavy-duty<br />

bearings. Small, compact, ideal for working close to fences<br />

or in corners on small acreage. Hand lift with special<br />

helper springs for easy lifting. Center tooth attachment<br />

available.<br />

No. 20 Wide Disc Harrow<br />

Here's big capacity PLUS the advantage of quickly reduced width for clearing<br />

gates and easy storage. End gangs fold back . . . takes but a minute.<br />

Gangs are independently mounted for greater flexibility . . . uniform work.<br />

Blades are spaced 7 inches apart. Bearings are adjustable. Four sizes 22, 28,<br />

34 and 38 blades-16 or 18-inch sizes. Center tooth attachment available.<br />

<strong>MASSEY</strong>-<strong>HARRIS</strong><br />

No. 26 Wide Level Disc Harrow<br />

Especially adapted to shallow cultivation. Ideal For soil conservation—helps<br />

check wind erosion. 5 independently mounted gangs of six blades each.<br />

Raised and lowered by Roto-Lift . . . gangs clear ground in just 24 inches<br />

of travel. Bearings are adjustable to 8 positions. Turns right or left. Cutting<br />

width 15 feet. Transport width 8 feet. Grain box available.<br />

No. 31 Tandem Disc Harrow<br />

Built for general farming conditions . . . husky, dependable,<br />

with the low-maintenanre advantage of adjustable<br />

bearings. Rope control angles gangs From tractor seat.<br />

20. 24, 28, 32, 36 or 40 blades-16 or 18 inch.<br />

deep-penetrating, clean-cutting discs<br />

You do a thorough job of mixing trash and soil<br />

with Massey-Harris Disc Harrows. Combined fields or<br />

tough hybrid corn roots offer little resistance to the<br />

sharp cutting blades. And you move right along with a<br />

Massey-Harris Disc . . . covering more. acres faster,<br />

easier because they're built for high-speed tractor operation.<br />

Husky, rigid frame construction results in more dependability<br />

season after season. Sturdy, steel frames<br />

with heavy angle iron braces mean extra rigidity and<br />

strength . . . true cutting over the entire width of the<br />

harrow.<br />

Correct blade spacing gives deep, even penetration<br />

. . . thoroughly worked land, a better start for your<br />

crops. Disc blades are specially heat-treated to retain<br />

their sharp cutting edges in the toughest soil.<br />

[18]<br />

Bearings in the Massey-Harris Harrows are adjustable<br />

to 8 positions, assuring uniform distribution of<br />

wear. They're reversible and interchangeable, fullchilled<br />

to offset end thrust. Two chilled rings take the<br />

end thrust while the surfaces take the rolling friction<br />

and the pull from the drawbar. Felt seals protect the<br />

bearings from dust and grit.<br />

Controls are easily reached for quick, convenient<br />

operation. Straightening or angling gangs takes but a<br />

second. Simple hitches are easy to attach to your tractor<br />

drawbar.<br />

You have all the advantages of modern han-ow design<br />

in Massey-Harris Discs . . . deep-penetrating,<br />

clean-cutting . . . husky, rigid construction . . . correct<br />

spacing, high-speed operation—plus years of dependable<br />

performance and service.

<strong>MASSEY</strong>-<strong>HARRIS</strong><br />

Heavy-Duty<br />

GOBLE OFFSET DISC HARROWS<br />

MAKE BETTER SEED BEDS . . .<br />

* Stubborn fields are left in a smooth, even condition<br />

when you work them with a Goble Offset<br />

Disc. Discing-in cover crops, breaking up heavy<br />

corn stubble, cultivating orchards and vineyards<br />

. in some conditions even to prepare your ground<br />

for small grains, the Goble does a clean job on<br />

them all ... with no center ridges or dead furrows.<br />

The husky, rugged look of the Goble means dependability<br />

season after season. Tough, all-welded<br />

frames easily resist the twists and strains of<br />

hard work. Yet in a Goble you have the flexibility<br />

you need for uniform discing on hilly, uneven land<br />

or on the contour. Hitch can be adjusted to offset<br />

harrow either to the right or left of the tractor.<br />

For all its weight and huskiness the Goble is an<br />

easy-pulling offset disc . . . the result of patented<br />

oil-bath bearings with center thrust. Each section<br />

runs in constant bath of oil, fully protected, fully<br />

lubricated . . . reducing power requirements 1 to<br />

5 horsepower. Lighter draft and less power mean<br />

lower fuel consumption, lower costs. Locating the<br />

thrust bearing in the center gives it positive protection<br />

and relieves the radial bearings of any<br />

thrust load . . . adds strength and support to the<br />

axles. A hardened steel washer eliminates wear<br />

in the thrust bearing assembly. The radial load is<br />

carried by two 6-inch bearings held snugly in<br />

place by axle collars.<br />

Modern construction . . . stronger, tougher .. .<br />

eliminates flexing and distortion under heavy<br />

loads . . . gives the Massey-Harris Goble Discs<br />

longer life, better, smoother field performance.<br />

Standard machine turns left. Fits all popular<br />

makes of tractors. Right hand turning attachment<br />

available as an extra.<br />

Ie"<br />

r Squadron Disc for large acreage and crawler type tractors.<br />

Nine models-10'6' to 24-foot sixes. Turns right or left.<br />

Special "Washington-type" disc—a right-hand machine with<br />

leFt-hand turn attachment available.<br />

[19]<br />

Regular Offset Disc available in 15 widths ranging<br />

From 3'9' to 18-foot sizes. Patented Oil bath bearings.<br />

Right-hand turn attachment extra.<br />

Roadside Disc designed For road maintenance, cutting<br />

fire strips, destroying weeds. 5'3' cut-7 or<br />

9-inch spacing.<br />

Bedder Disc prepares seed bed ridges and irrigation<br />

dikes. Singles of 6 or 8 blades; tandems If 12 or<br />

16. 22 or 24-inch blades.<br />

Border Disc for setting up ridges in light loam<br />

or sandy soil. One size only . . . four 24-inch<br />

blades.<br />

Pick-up Disc for operation behind hydraulic<br />

lift equipped tractors. One size: 41/2-foot cut,<br />

twelve 24-inch blades.

509-9-inch spacing. 4, 6 and 81/2-foot<br />

sizes-24-inch blades. Cast or rubber tires.<br />

Seed box available for 6 and 81/2-foot.<br />

510-10-inch spacing. 6, 8 1/2 and 10-foot sizes-<br />

26-inch blades. Cast or rubber tires. Crawler-type<br />

hitch available in place of regular hitch on 81/2 and<br />

10-foot models.<br />

<strong>MASSEY</strong>-<strong>HARRIS</strong><br />

one-way discs with ift,*<br />

Here's a fast operating, easy to handle One-Way that does<br />

a better job of after-harvest cultivation . . . builds up your<br />

soil with surface cultivation of summer fallow . . . works<br />

your land and seeds at the same time, saving a lot of time<br />

and moisture.<br />

The Massey-Harris One-Ways are Roto-Lift controlled<br />

. . . the revolutionary lift that rolls blades in and out of the<br />

ground in only 24 inches . . . less than the diameter of a<br />

single blade. Lifting is complete<br />

in only 40 inches of<br />

travel. Blades are rolled in<br />

and out of the ground under<br />

power . . . requires less<br />

power, cutting edges stay<br />

sharp longer. Fewer working<br />

parts mean less mainte-<br />

[ 20 ]<br />

VM Snight .<br />

ngs in the land<br />

nance. Roto-Lift actually has only 2 lubricated joints.<br />

Simple hand wheels regulate depth and leveling. 509<br />

has depth regulator for instant depth changes accessible<br />

from tractor seat. 510 has crank adjustment. Flexible hitch<br />

lets you turn right or left or back up. The front and rear<br />

furrow wheels are connected by a radius rod . . . wheels<br />

don't wobble when turning, rigidly follow each other. And<br />

Roto-Lift works equally well when backing up.<br />

Bearings are heavy-duty with 2 full-chilled rings to take<br />

the end thrust . . . easy, inexpensive to replace. There are<br />

more high quality bearings on the Massey-Harris One-Way.<br />

Timken tapered roller bearings carry the load on the land<br />

wheel.<br />

It all adds up to more One-Way Disc for your money than<br />

ever before . . . more speed, flexibility . . . more years of<br />

dependable, low-cost operation.<br />

21<br />

17(<br />

so<br />

or<br />

fe<br />

8(<br />

g(<br />

di<br />

D<br />

Sr<br />

31<br />

H<br />

jo<br />

D<br />

qi<br />

st<br />

n(<br />

L,<br />

b(<br />

w<br />

se<br />

g(<br />

bi<br />

dc

Accurate Seed-<br />

Saving Drills<br />

20-A COMBINATION GRAIN & FERTILIZER DRILL<br />

Your grain gets the full benefit of fertilizer when you<br />

sow them together. With the Massey-Harris 20A you<br />

have the advantage of sowing seed and fertilizing in<br />

one trip across your field. A simple feeder drops the<br />

fertilizer with the seed. Quantities range from 50 to<br />

800 lbs. per acre. Grain runs are driven by a multiple<br />

gear with 8 speeds to meet a variety of seeding conditions.<br />

Wheels have 4-inch face for good traction.<br />

Drill sizes: 11, 12, 13, 15 and 20 runs—all with 7-inch<br />

spacing.<br />

300 SERIES GRAIN DRILLS<br />

Here's accurate dependability for that all-important<br />

job of seeding . . . the Massey-Harris 306, 307, 308<br />

Drills with 6, 7, or 8-inch spacing to meet your requirements.<br />

Large, free-flowing seed box is built of<br />

steel with inside corners smoothly rounded. There's<br />

no warping or sagging . . . each run seeds evenly.<br />

Lever indicator regulates amount of seed to be sown.<br />

Main frame is constructed of heavy angle steel members.<br />

Double feed runs handle coarse or fine grains<br />

with equal accuracy. Center seed delivery deposits<br />

seed at uniform depth where moisture is available for<br />

germination. Big capacity . . . accurate . . . dependable—you<br />

know when you're through that the job is<br />

done right.<br />

NO. 2 FRONT-MOUNTED - NO. 3 TRAILER<br />

Massey-Harris low gallonage Weed Sprayers cover a wide 20 or 30-foot swath.<br />

Booms are corrosion-resistant . . . fold back for easy transporting and clearing<br />

gates. Non-corroding nozzles are spaced 20 inches apart .. . produce a fanshaped<br />

spray for thorough coverage. Location of pressure gauge on the boom<br />

side indicates the pressure at the nozzle. Ample filtering capacity in the nozzles<br />

and hose keeps chemical flowing evenly. Pump is all bronze to resist rust and<br />

corrosion . . . with five-second shut off toprevent overdosage at row ends.<br />

Two Models—No. 2 front-mounted with 20-foot boom. Illustrated with row<br />

crop attachment above for application against both insects and weeds. No. 3<br />

Trailer-type with 30-foot boom. Booms are adjustable for height.<br />

<strong>MASSEY</strong>-<strong>HARRIS</strong> WEED SPRAYERS<br />

[ 21 ]<br />

for cleaner<br />

fields...<br />

Bigger yields

75<br />

ACRES<br />

A<br />

DAY<br />

* You move right along when you drill your corn . . . * More time saved—no check wire to bother with. Massey.<br />

planting accurately at speeds of 5 and 6 m.p.h.—a fast, low- Harris Drill planters are more flexible . . . ideal for planting<br />

cost, time-saving job. on the contour.<br />

* Faster, more thorough cul ivation. And easier, too,<br />

because you're not bumping over cross ridges. Faster cultivation<br />

means less fuel . . . added economy.<br />

<strong>MASSEY</strong>-<strong>HARRIS</strong> DRILL CORN PLANTERS<br />

for fast, easy planting on level land or contours<br />

* From the standpoint of yields, convenience, speed,<br />

harvesting . . . the advantages are all in your favor when<br />

you drill your corn. Traveling along at a good clip, you<br />

plant as much as 75 acres a day with the Massey-Harris<br />

4-row models— 40 acres with the 2-row models. It's accurate<br />

planting—no skips or bunching. What's more there are no<br />

check wires or stakes to slow production. The entire operation<br />

of growing corn moves right along . . . cultivating is<br />

simpler, faster, harvesting is smoother, easier, takes less<br />

time.<br />

You hook-up the Massey-Harris Drill Planters in less<br />

than a minute. Single-point-hitch makes it a fast, completely<br />

safe job. Operation of the planter itself is simplified.<br />

Check-heads, valves, and clutches are eliminated. Frames<br />

2 -row 233<br />

* The saving extends right into harvesting. Your corn picker<br />

doesn't take a beating with slug after slug as in checked corn.<br />

Operating efficiency is higher.<br />

are welded for strength and rigidity. Lifting is either<br />

mechanical or by Depth-o-matic System. 4 models. 2-row<br />

233 for "30" tractor; 2-row 235 for "22" tractor; 1-row 41<br />

for Pony tractor; 4-row 433 for "44" tractors. Disc furrowers<br />

and cowpea attachments available.<br />

BIG FERTILIZER HOPPERS<br />

Fertilizer attachment (extra equipment)<br />

places fertilizer in two bands<br />

on each side of the seed at the same<br />

depth as the seed. Gives your corn<br />

an early boost. Big 85-lb. hoppers<br />

mean less stops for refills.<br />

4-row 433

<strong>MASSEY</strong>-<strong>HARRIS</strong> 1 5 AND 17 COMBINES<br />

big capacity harvesting for medium-size farms<br />

No. 15-8-foot cut<br />

* Fast . . . big capacity . . . easy handling . . . economical<br />

operation—all mighty important advantages you have with<br />

the 15 and 17 combines bringing in your grain.<br />

There are years of experience behind the 15 and 17 .. .<br />

experience that has proved the practical construction of<br />

the tripod-type frame, simple chain and belt drive, vertical<br />

elevator, and rasp-bar cylinder. Tripod design in the frame<br />

provides better distribution of weight. Heavy channel<br />

beams make up the back bone of the frame. Braces and<br />

beams are welded for extra strength. True alignment results<br />

. . . extra support and stability are built into the<br />

15 and 17. Sagging just can't occur . . . means true running,<br />

easy handling. Better weight distribution reduces excessive<br />

or "dead" weight . . . your tractor has an easier job, more<br />

reserve for the tough spots.<br />

alb/ III 11/1<br />

kl%<br />

No. 17-10-foot cut<br />

Simple belt and chain drive lowers maintenance . . .<br />

makes servicing easy. Massey-Harris vertical elevator delivers<br />

grain and straw in a smooth, uniform flow to the cylinder<br />

for a better job of separating . . . reduces slugging and<br />

bunching. The rasp-bar cylinder gets more of your grain.<br />

Four steel walkers pitch and toss the straw shaking out the<br />

grain. It's straight-thru separation . . . with no turns to<br />

clog the combine, clean separation that means more and<br />

cleaner grain in the bin.<br />

No. 15 is an 8-foot machine with 25-bushel tank. No. 17<br />

has 10-foot cut and 35-bushel grain tank. Models available<br />

either as P.T.O. or Engine-Driven units. 60-inch diameter<br />

fully adjustable reel. Rubber tires. Extra equipment: straw<br />

spreader, rotary screen for tank, table transport, pick-up<br />

attachment.<br />

\\%\\ \\\<br />

//0<br />

Massey-Harris vertical eleva- Threshing body of the 15 and Massey-Harris rasp-bar cylintor<br />

feeds an even flow of grain 17 combines is 32 inches wide der and adjustable concave<br />

and straw to the cylinder . . . for extra capacity. Sieves are rub the grain out gently . . .<br />

no slugs or bunching. full width. in heavy or light crop.<br />

[23 1<br />

Four steel walkers pitch and<br />

toss the straw getting more of<br />

your grain. They're wide,<br />

roomy, big capacity.

Your Harvest Is ore Profitable With a<br />

P.T.O. CLIPPER<br />

ENGINE DRIVEN<br />

If you need an engine-driven<br />

combine, the Clipper may be<br />

ordered with a dependable<br />

Wisconsin air-cooled engine.<br />

In a heavy or light crop, you<br />

get constant threshing speed<br />

. . . clean, thorough separation.<br />

And in soybean or coldweather<br />

harvesting, you'll<br />

appreciate the air-cooled feature<br />

which eliminates draining<br />

each night or the addition<br />

of an antifreeze.<br />

* The minute you decide to give the Clipper<br />

a place on your farm, you're in for a new<br />

kind of harvesting experience . . . more efficient<br />

because of the Clipper's ability to<br />

handle any combinable crop in almost any<br />

condition . . . faster because the Clipper has<br />

the capacity of a much larger machine. And<br />

faster, more efficient harvesting means you<br />

save all of your crop. Your time is more productive<br />

.. . you spend fewer hours in the<br />

field, and . . . there's cleaner grain and more<br />

of it in the bin ... more profit from the entire<br />

operation.<br />

The P.T.O. Clipper takes a full 6-foot cut<br />

. . . a big advantage when you're working<br />

against time. It's a load any good 2-plow<br />

tractor can easily handle because the Clipper's<br />

a light draft, free-running unit.<br />

Grain is rubbed out the natural, easy way<br />

with the Clipper's big 5-foot rasp bar cylinder.<br />

It's a gentle action . . . more complete<br />

separation takes place right here. Because of<br />

its extra width, the Clipper cylinder eliminates<br />

bunching . . . takes an even flow of<br />

straw for easier, better separation. Fully<br />

adjustable concave provides maximum cylinder<br />

efficiency.<br />

When the straw leaves the cylinder it goes<br />

directly to the full-width, straight-thru separating<br />

rack—in the same thin, even flow. The<br />

loose straw is pitched and tossed thoroughly,<br />

shaking out all of your grain. There are no<br />