Copper Tubes & Rods Copper Tubes for Plumbing and Heating ...

Copper Tubes & Rods Copper Tubes for Plumbing and Heating ...

Copper Tubes & Rods Copper Tubes for Plumbing and Heating ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Copper</strong> <strong>Tubes</strong> & <strong>Rods</strong><br />

<strong>Copper</strong> <strong>Tubes</strong> <strong>for</strong> <strong>Plumbing</strong> <strong>and</strong> <strong>Heating</strong> Systems<br />

This product is supplied in 3 or 6 meter straight length in the half hard condition, an ideal temper <strong>for</strong> cold bending <strong>and</strong> <strong>for</strong>ming max can be easily<br />

bent on an appropriate bending machine or <strong>for</strong> 6 to 22 mm o.d. sizes, with a bending spring.its ease of manipulating <strong>and</strong> relatively light weight,<br />

combine with its ability to withst<strong>and</strong> high internal pressure makes the ideal products <strong>for</strong> Hot <strong>and</strong> Cold water, central heating, gas services, hot <strong>and</strong><br />

installation. These are the general purpose copper tube <strong>for</strong> above ground services. Ideal <strong>for</strong> drinking water, central heating, gas services <strong>and</strong> cold<br />

water, gas various engineering . Also as per BS EN 1057-R220 (Previous Designation BS 2871; Part 1 : Table Y) supplied as either 6m long half or<br />

annealed 25M or 23m long coils. With wall thickness aproximately 1.5 times thicker than Max, it is the ideal product <strong>for</strong> underground application.<br />

The extra wall thickness also allows its use on certain pressurized stem installations with maximum working temperature of 205C. These copper<br />

tubes are recommended <strong>for</strong> use on underground services <strong>and</strong> also suitable <strong>for</strong> Drinking water, Central <strong>Heating</strong>, Sanitation Gas <strong>and</strong> various<br />

engineering application.<br />

<strong>Copper</strong> <strong>Tubes</strong> on Straight Length<br />

Manufacturing Range - Outer Diameter - 6mm to 250mm wall thickness - 0.5mm to any thickness.<br />

Material<br />

Electrolytic Tough Pitch High Conductivity<br />

<strong>Copper</strong> (E.T.P.) - C 1001<br />

Nominal Composition Cu - Min - 99.9%<br />

Fire refined, Tough Pitch High<br />

Conductivity <strong>Copper</strong> (FHRC) - C 102<br />

Cu- Min 99.9%<br />

P- 0.004 Max<br />

As - 0.012 Max.<br />

Deoxidized <strong>Copper</strong> Low<br />

Phosphorous<br />

Cu - 99.85%<br />

P-0.01 - 0.015%<br />

92 to 96<br />

Condition O TA M O TA M O TA M<br />

Tensile Strength (kg.mm2)<br />

20.4 27.5 28.6<br />

25.5 Min Min<br />

Elongation (5.65 SO Min)<br />

40 30 -<br />

60 75- 100<br />

Hardness HV<br />

MAX 100 MIN<br />

Material<br />

20.4 25.5 28.6<br />

25.5 Min Min<br />

40 30 -<br />

60 75- 100<br />

20.4 25.5 28.6<br />

25.5 Min Min<br />

40 30 -<br />

60 75- 100<br />

MAX 100 MIN MAX 100 MIN<br />

Phpophorous Deoxidized<br />

Non - Arsenical <strong>Copper</strong><br />

(DHP) - C 106<br />

Phosporous Deoxidized<br />

Arsenical <strong>Copper</strong> (DPA)<br />

C 107<br />

Electrolytic Tough<br />

Pitch High Conductivity<br />

<strong>Copper</strong> with Silver ETP -<br />

C 101 Ag.

Nominal Cu-Min. 99.85%<br />

Cu-Min 99.20%<br />

P - 0.015 - 0.05%<br />

Cu - 99.9%<br />

Composition P - 0.013 - 0.05% AS - 0.030 - 0.050% AG - 0.01 Min<br />

COPPER TUBES FOR AIR CONDITIONING & REFRIGERATION<br />

Manufacturing Range - IN 10 mtrs, 15mtrs, 25mtrs, & 30mtrs, As per ASTM B - 68/80 <strong>and</strong> 280/80 (BS C 106)<br />

CHEMICAL REQUIREMENT<br />

<strong>Copper</strong> 99.95% MIN<br />

Phosphorous 0.015 TO 0.40%<br />

PHYSICAL REQUIREMENT<br />

Temper<br />

Anneale<br />

d<br />

Tensile<br />

Strength<br />

% Elongation on<br />

2" 0r 50mm<br />

22 40<br />

Flattening, double over test, pneumatics, Hydrogen Embrittlement, cleanliness<br />

<strong>and</strong> micro structure test as per specification.<br />

USES - Refrigeration <strong>and</strong> air conditioning.

1) PHOSPHOROUS DEOXIDIZED NON ARSENICAL COPPER (C 106)<br />

CHEMICAL REQUIREMENT<br />

<strong>Copper</strong> (inc silver) 99.85% Min<br />

Phosphorous 0.013 to 0.05%<br />

Total Impurities 0.060% Max<br />

PHYSICAL REQUIREMENT<br />

Temper<br />

Tensile<br />

strength kg/<br />

mm2 Min<br />

% Elongation<br />

on 5.65 A Min<br />

Annealed 21.5 33<br />

As Manufactured 23.5 13<br />

USES - House hold general purpose.<br />

2) CADMIUM COPPER RODS (C 108)<br />

CHEMICAL REQUIREMENT<br />

<strong>Copper</strong> (inc silver) 98. 5%<br />

Cadmium 0.5 to 1.2%<br />

PHYSICAL REQUIREMENT<br />

Tensile strength 35 kg/mm2 Min<br />

Elongation 4 D 8% Min<br />

Electrical 80 Min % I.A.C.S<br />

Conductivity at 20 C<br />

COPPER RODS FOR GENERAL ENGINEERING PURPOSES

USES - Electrical holder <strong>for</strong> resistance welding machines arc - Furnaces, Electrodes <strong>for</strong> spot<br />

seam welding of aluminium alloys, commutatobras, spring, contact, switch gear<br />

components & other equipments requiring high conductivity with strength <strong>and</strong> resistance to<br />

wear.<br />

Manufacturing Range - BS 2847 : 1969 Mfg Range 6mm to 120 mm<br />

1) ETP COPPER RODS (C101)<br />

CHEMICAL REQUIREMENT<br />

<strong>Copper</strong> (inc<br />

silver)<br />

Total Impurities<br />

(Excl. Silver &<br />

Oxygen)<br />

99.9% Min Size mm<br />

PHYSICAL PROPERTIES - (1/2 HARD)<br />

HIGH CONDUCTIVITY COPPER RODS<br />

Tensile strength<br />

kg/mm2<br />

%Elongation on<br />

5.65 A Min<br />

0.03% Max 10 = 12 26.5 12<br />

12 = 15 26.5 18<br />

Over 25 23.5 22<br />

Electrical<br />

Conductivity at<br />

20 C<br />

99.25 % I.A.C.S<br />

USES - Electrical Conductors, Switches, Terminals, Gaskets, Radiators, Cotters Pins, Nails, Rivets etc. Requiring high electrical <strong>and</strong> thermal conductivity.

2) ARSENICAL COPPER (C 107)<br />

CHEMICAL REQUIREMENT<br />

<strong>Copper</strong> (inc silver) 99.20%<br />

Arsenic 0.2 to 0.5%<br />

PHYSICAL REQUIREMENT - (1/2 HARD)<br />

BS 2870 : 1980<br />

Specification As per ISS,ASTM,BSS,JISH<br />

COPPER STRIPS, PLATES, BUS BARS & FLATS<br />

Material ETP Grade copper & DHP Grade copper<br />

Type As extruded & drawn<br />

Form<br />

In coils & Straight Length (also Tinned<br />

coated)<br />

Edges Sharp & radius<br />

Width Maximum 300mm - Minimum 10mm<br />

Thickness Maximum 50mm - minimum 1.5mm<br />

<strong>Copper</strong> plates are also available in the size<br />

of 1ft. X 1ft. - 2mtr.x2mtrx 8" x 4"

Application - Electrical <strong>and</strong> General Engineering Industries.<br />

Manufacturing Range<br />

1. Circumscribing circle diameter<br />

A) <strong>for</strong> extruded product - 4,125" Max<br />

B) <strong>for</strong> drawn product - 4" max Cross<br />

Sectional - 1/2 S2 Inch minimum.<br />

2. Element thickness<br />

A) Extruded - 4mm Min.<br />

B) drawn - 3mm Min.<br />

3. Length<br />

A) Extruded: 50ft.Max weight limit up to 55<br />

kgs.<br />

B) Drawn: 10ft. Max. Weight limit upto 55<br />

kgs.<br />

4. Tolerance<br />

A) Extruded : +0.30" Min. on any dimension.<br />

B) Drawn : +0.005 min. on any dimension.<br />

5. Temper<br />

any st<strong>and</strong>ard desire temper.<br />

6. Material<br />

We can supply section in the following copper<br />

<strong>and</strong> copper based alloys.<br />

* <strong>Copper</strong> : Electrolytic <strong>Copper</strong> - DHP <strong>Copper</strong>,<br />

DPA <strong>Copper</strong>, DLP.<br />

* <strong>Copper</strong> based alloy : Brass 63/37, Brass<br />

70/30<br />

COPPER SECTIONS AND PROFILES

7. Shapes<br />

Profiled <strong>Tubes</strong> <strong>and</strong> <strong>Rods</strong> in Reeded, Oval,<br />

Rectangle, Polygon, Square <strong>and</strong> twisted<br />

shape.<br />

COPPER TUBES<br />

Half Hard Nitrogenized Seamless <strong>Copper</strong> <strong>Tubes</strong> <strong>for</strong> Gas Application SVMC copper tube is manufactured from phosphorous deoxidized (non-arsenical copper) to BS<br />

6017 Cu-DHP. These copper tubes are sealed with patented plugs, which maintain the st<strong>and</strong>ard of cleanliness from to the job site. SVMC <strong>Copper</strong> tubes are<br />

pressurized with nitrogen to provide maximum protection against the <strong>for</strong>mation of harmful oxides. H<strong>and</strong> or machine can bend the st<strong>and</strong>ard SVMC TUBES, <strong>for</strong><br />

plumbing <strong>and</strong> straight lengths. These are available in a range of diameters from 6mm to 159mm.

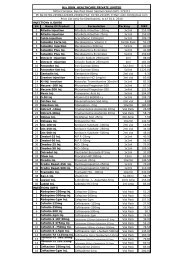

WEIGHT OF COPPER TUBES IN VARIOUS SIZE & GAUGES - EXTERNAL DIAMETER<br />

WALL THICKNESS<br />

I.S.W.G 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 30 I.S<br />

Millimeter 4.877 4.470 4.064 3.658 3.251 2.946 2.642 2.337 2.032 1.829 1.626 1.422 1.219 1.016 0.914 0.813 0.711 0.610 0.559 0.508 0.457 0.4166 0.3759 0.315<br />

Inches 0.192 0.176 0.160 0.144 0.128 0.116 0.104 0.092 0.080 0.072 0.064 0.056 0.048 0.040 0.036 0.032 0.028 0.024 0.022 0.820 0.018 0.01640 0.0148 0.0124 In<br />

External<br />

Diameter<br />

WEIGHT IN KILOGRAMS PER METRE<br />

In MM In<br />

1/4<br />

5/16<br />

3/8<br />

7/16<br />

%<br />

9/16<br />

5/8<br />

11/16<br />

3/4<br />

13/16<br />

7/8<br />

15/16<br />

1<br />

1-1/8<br />

1-1/4<br />

1-3/8<br />

1-1/2<br />

1-5/8<br />

1-3/4<br />

1-7/8<br />

2<br />

2-1/8<br />

2-1/4<br />

2-3/8<br />

2-1/2<br />

6.350<br />

7.938<br />

9.524<br />

11.112<br />

12.700<br />

14.288<br />

15.875<br />

17.462<br />

19.050<br />

20.638<br />

22.225<br />

23.812<br />

25.400<br />

28.575<br />

31.750<br />

34.925<br />

38.100<br />

41.275<br />

44.450<br />

47.625<br />

50.800<br />

53.975<br />

57.150<br />

60.325<br />

63.500<br />

-<br />

-<br />

-<br />

-<br />

1.065<br />

1.281<br />

1.497<br />

1.713<br />

1.929<br />

2.145<br />

2.361<br />

2.577<br />

2.793<br />

3.225<br />

3.657<br />

4.090<br />

4.522<br />

4.954<br />

5.386<br />

5.818<br />

6.250<br />

6.682<br />

7.114<br />

7.547<br />

7.979<br />

-<br />

-<br />

0.631<br />

0.829<br />

1.027<br />

1.225<br />

1.423<br />

1.621<br />

1.819<br />

2.017<br />

2.215<br />

2.413<br />

2.611<br />

3.007<br />

3.403<br />

3.799<br />

4.195<br />

4.592<br />

4.988<br />

5.384<br />

5.780<br />

6.176<br />

6.572<br />

6.986<br />

7.364<br />

-<br />

-<br />

0.619<br />

0.799<br />

0.979<br />

1.160<br />

1.340<br />

1.520<br />

1.700<br />

1.880<br />

2.060<br />

2.240<br />

2.420<br />

2.780<br />

3.140<br />

3.500<br />

3.860<br />

4.220<br />

4.580<br />

4.941<br />

5.301<br />

5.661<br />

6.021<br />

6.381<br />

6.741<br />

-<br />

-<br />

0.599<br />

0.761<br />

0.923<br />

1.085<br />

1.247<br />

1.409<br />

1.571<br />

1.733<br />

1.895<br />

2.057<br />

2.219<br />

2.543<br />

2.868<br />

3.192<br />

3.516<br />

3.840<br />

4.164<br />

4.488<br />

4.812<br />

5.136<br />

5.460<br />

5.784<br />

6.108<br />

-<br />

-<br />

0.569<br />

0.713<br />

0.857<br />

1.001<br />

1.145<br />

1.289<br />

1.434<br />

1.578<br />

1.722<br />

1.866<br />

2.010<br />

2.298<br />

2.586<br />

2.874<br />

3.162<br />

3.450<br />

3.738<br />

4.026<br />

4.314<br />

4.602<br />

4.890<br />

5.179<br />

5.467<br />

-<br />

-<br />

0.541<br />

0.671<br />

0.802<br />

0.933<br />

1.063<br />

1.194<br />

1.324<br />

1.455<br />

1.585<br />

1.716<br />

1.846<br />

2.107<br />

2.368<br />

2.63<br />

2.891<br />

3.152<br />

3.413<br />

3.674<br />

3.935<br />

4.196<br />

4.457<br />

4.718<br />

4.979<br />

0.273<br />

0.390<br />

0.507<br />

0.624<br />

0.742<br />

0.859<br />

0.976<br />

1.093<br />

1.210<br />

1.327<br />

1.444<br />

1.561<br />

1.678<br />

1.912<br />

2.146<br />

2.380<br />

2.614<br />

2.848<br />

3.082<br />

3.316<br />

3.550<br />

3.784<br />

4.018<br />

4.252<br />

4.487<br />

0.262<br />

0.365<br />

0.469<br />

0.572<br />

0.676<br />

0.779<br />

0.883<br />

0.986<br />

1.090<br />

1.193<br />

1.297<br />

1.401<br />

1.504<br />

1.711<br />

1.918<br />

2.125<br />

2.332<br />

2.539<br />

2.746<br />

2.953<br />

3.161<br />

3.368<br />

3.575<br />

3.782<br />

3.989<br />

0.245<br />

0.335<br />

0.425<br />

0.515<br />

0.605<br />

0.695<br />

0.785<br />

0.875<br />

0.965<br />

1.055<br />

1.145<br />

1.235<br />

1.325<br />

1.505<br />

1.685<br />

1.865<br />

2.045<br />

2.225<br />

2.405<br />

2.586<br />

2.766<br />

2.946<br />

3.126<br />

3.306<br />

3.486<br />

0.231<br />

0.312<br />

0.393<br />

0.474<br />

0.555<br />

0.636<br />

0.717<br />

0.789<br />

0.879<br />

0.960<br />

1.041<br />

1.122<br />

1.203<br />

1.365<br />

1.527<br />

1.689<br />

1.851<br />

2.013<br />

2.175<br />

2.337<br />

2.499<br />

2.661<br />

2.823<br />

2.986<br />

3.148<br />

0.214<br />

0.286<br />

0.358<br />

0.430<br />

0.501<br />

0.574<br />

0.646<br />

0.718<br />

0.790<br />

0.863<br />

0.935<br />

1.007<br />

1.079<br />

1.223<br />

1.367<br />

1.511<br />

1.655<br />

1.799<br />

1.943<br />

2.087<br />

2.231<br />

2.375<br />

2.519<br />

2.663<br />

2.807<br />

0.196<br />

0.259<br />

0.322<br />

0.385<br />

0.448<br />

0.511<br />

0.574<br />

0.637<br />

0.700<br />

0.763<br />

0.826<br />

0.889<br />

0.952<br />

1.078<br />

1.204<br />

1.330<br />

1.456<br />

1.582<br />

1.708<br />

1.834<br />

1.960<br />

2.086<br />

2.212<br />

2.338<br />

2.464<br />

1.327 1.116 0.922 0.747 0.590 0.485 0.389 0.305 0.230 0.187 0.148 0.113 0.083 0.057 0.047 0.037 0.028 0.021 0.017 0.015 0.012 0.010 0.008 0.006<br />

TO CALCULATE THE WEIGHT WHEN INTERNAL DIAMETER IS GIVEN, ADD FIGURE AT THE BOTTOM OF COLUMN TO THE CORRESPONDING FIGURE FOR THE WEIGHT OF EXTENAL DIAMETER OF SIZE REQUIRED.<br />

0.175<br />

0.229<br />

0.283<br />

0.337<br />

0.391<br />

0.445<br />

0.499<br />

0.553<br />

0.607<br />

0.661<br />

0.715<br />

0.769<br />

0.823<br />

0.931<br />

1.039<br />

1.147<br />

1.255<br />

1.363<br />

1.471<br />

1.579<br />

1.687<br />

1.795<br />

1.903<br />

2.011<br />

2.119<br />

0.151<br />

0.196<br />

0.241<br />

0.286<br />

0.331<br />

0.376<br />

0.421<br />

0.466<br />

0.511<br />

0.556<br />

0.601<br />

0.646<br />

0.691<br />

0.781<br />

0.871<br />

0.961<br />

1.051<br />

1.142<br />

1.232<br />

1.322<br />

1.412<br />

1.502<br />

1.592<br />

1.682<br />

1.772<br />

0.139<br />

0.179<br />

0.220<br />

0.260<br />

0.301<br />

0.341<br />

0.382<br />

0.422<br />

0.463<br />

0.503<br />

0.544<br />

0.584<br />

0.625<br />

0.706<br />

0.787<br />

0.868<br />

0.949<br />

1.030<br />

1.111<br />

1.192<br />

1.273<br />

1.354<br />

1.435<br />

1.516<br />

1.597<br />

0.126<br />

0.162<br />

0.198<br />

0.234<br />

0.270<br />

0.306<br />

0.342<br />

0.378<br />

0.414<br />

0.450<br />

0.486<br />

0.522<br />

0.558<br />

0.630<br />

0.702<br />

0.774<br />

0.846<br />

0.918<br />

0.990<br />

1.062<br />

1.134<br />

1.206<br />

1.278<br />

1.350<br />

1.422<br />

0.112<br />

0.143<br />

0.175<br />

0.206<br />

0.238<br />

0.269<br />

0.301<br />

0.332<br />

0.364<br />

0.395<br />

0.427<br />

0.459<br />

0.490<br />

0.553<br />

0.616<br />

0.679<br />

0.742<br />

0.805<br />

0.868<br />

0.931<br />

0.994<br />

1.057<br />

1.120<br />

1.183<br />

1.246<br />

0.098<br />

0.125<br />

0.152<br />

0.179<br />

0.206<br />

0.233<br />

0.260<br />

0.287<br />

0.314<br />

0.341<br />

0.368<br />

0.395<br />

0.422<br />

0.476<br />

0.53<br />

0.584<br />

0.638<br />

0.692<br />

0.746<br />

0.800<br />

0.854<br />

0.908<br />

0.962<br />

1.016<br />

1.070<br />

0.090<br />

0.115<br />

0.140<br />

0.165<br />

0.189<br />

0.214<br />

0.239<br />

0.264<br />

0.288<br />

0.313<br />

0.338<br />

0.363<br />

0.387<br />

0.437<br />

0.486<br />

0.536<br />

0.585<br />

0.635<br />

0.684<br />

0.734<br />

0.784<br />

0.833<br />

0.883<br />

0.932<br />

0.982<br />

0.083<br />

0.106<br />

0.128<br />

0.151<br />

0.173<br />

0.196<br />

0.219<br />

0.242<br />

0.264<br />

0.287<br />

0.310<br />

0.332<br />

0.355<br />

0.400<br />

0.445<br />

0.490<br />

0.536<br />

0.581<br />

0.626<br />

0.671<br />

0.717<br />

0.762<br />

0.807<br />

0.852<br />

0.898<br />

0.076<br />

0.096<br />

0.116<br />

0.137<br />

0.157<br />

0.177<br />

0.198<br />

0.218<br />

0.238<br />

0.259<br />

0.279<br />

0.299<br />

0.320<br />

0.361<br />

0.401<br />

0.442<br />

0.483<br />

0.525<br />

0.564<br />

0.605<br />

0.646<br />

0.687<br />

0.727<br />

0.768<br />

0.809<br />

0.069<br />

0.088<br />

0.106<br />

0.125<br />

0.144<br />

0.162<br />

0.181<br />

0.199<br />

0.218<br />

0.236<br />

0.255<br />

0.273<br />

0.292<br />

0.329<br />

0.366<br />

0.403<br />

0.440<br />

0.477<br />

0.515<br />

0.552<br />

0.589<br />

0.626<br />

0.663<br />

0.700<br />

0.737<br />

0.063<br />

0.080<br />

0.096<br />

0.113<br />

0.130<br />

0.147<br />

0.163<br />

0.180<br />

0.197<br />

0.214<br />

0.230<br />

0.247<br />

0.264<br />

0.297<br />

0.331<br />

0.364<br />

0.398<br />

0.431<br />

0.465<br />

0.498<br />

0.532<br />

0.565<br />

0.599<br />

0.632<br />

0.666<br />

0.053<br />

0.067<br />

0.081<br />

0.095<br />

0.109<br />

0.123<br />

0.138<br />

0.152<br />

0.160<br />

0.180<br />

0.194<br />

0.208<br />

0.222<br />

0.250<br />

0.278<br />

0.306<br />

0.334<br />

0.362<br />

0.390<br />

0.418<br />

0.446<br />

0.474<br />

0.502<br />

0.530<br />

0.558<br />

Mill<br />

Exte<br />

Diam<br />

1/4<br />

5/16<br />

3/8<br />

7/16<br />

1/2<br />

9/16<br />

5/8<br />

11/16<br />

3/4<br />

13/16<br />

7/8<br />

15/16<br />

1<br />

1-1/8<br />

1-1/4<br />

1-3/8<br />

1-1/2<br />

1-5/8<br />

1-3/4<br />

1-7/8<br />

2<br />

2-1/8<br />

2-1/4<br />

3-3/8<br />

2-1/2