40 MW Wartsila 18V32 50 Hz - Powerplants

40 MW Wartsila 18V32 50 Hz - Powerplants

40 MW Wartsila 18V32 50 Hz - Powerplants

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

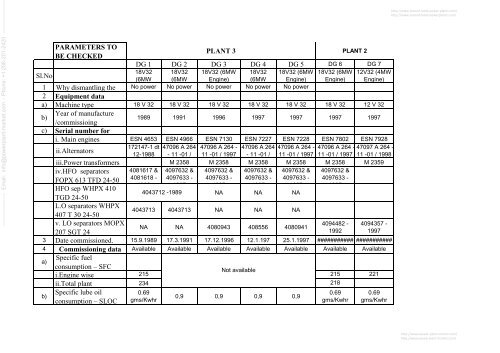

Sl.No<br />

PARAMETERS TO<br />

BE CHECKED<br />

DG 1 DG 2 DG 3 DG 4 DG 5 DG 6 DG 7<br />

<strong>18V32</strong> <strong>18V32</strong> <strong>18V32</strong> (6<strong>MW</strong> <strong>18V32</strong> <strong>18V32</strong> (6<strong>MW</strong> <strong>18V32</strong> (6<strong>MW</strong> 12V32 (4<strong>MW</strong><br />

(6<strong>MW</strong> (6<strong>MW</strong> Engine) (6<strong>MW</strong> Engine) Engine) Engine)<br />

1 Why dismantling the No power No power No power No power No power<br />

demand demand demand demand demand<br />

2 Equipment data<br />

a) Machine type 18 V 32 18 V 32 18 V 32 18 V 32 18 V 32 18 V 32 12 V 32<br />

b)<br />

Year of manufacture<br />

/commissioing<br />

c) Serial number for<br />

1989 1991 1996 1997 1997 1997 1997<br />

i. Main engines ESN 4653 ESN 4966 ESN 7130 ESN 7227 ESN 7228 ESN 7802 ESN 7928<br />

ii.Alternators<br />

172147-1 dt<br />

12-1988<br />

47096 A 264<br />

- 11 -01 /<br />

47096 A 264 -<br />

11 -01 / 1997<br />

47096 A 264<br />

- 11 -01 /<br />

47096 A 264 -<br />

11 -01 / 1997<br />

47096 A 264 -<br />

11 -01 / 1997<br />

47097 A 264 -<br />

11 -01 / 1998<br />

iii.Power transformers M 2358 M 2358 M 2358 M 2358 M 2358 M 2359<br />

iv.HFO separators<br />

FOPX 613 TFD 24-<strong>50</strong><br />

HFO sep WHPX 410<br />

TGD 24-<strong>50</strong><br />

L.O separators WHPX<br />

<strong>40</strong>7 T 30 24-<strong>50</strong><br />

v. LO separators MOPX<br />

207 SGT 24<br />

<strong>40</strong>81617 &<br />

<strong>40</strong>81618 -<br />

1996<br />

<strong>40</strong>97632 &<br />

<strong>40</strong>97633 -<br />

1997<br />

<strong>40</strong>97632 &<br />

<strong>40</strong>97633 -<br />

1997<br />

<strong>40</strong>97632 &<br />

<strong>40</strong>97633 -<br />

1997<br />

<strong>40</strong>97632 &<br />

<strong>40</strong>97633 -<br />

1997<br />

NA NA NA<br />

<strong>40</strong>43713 <strong>40</strong>43713 NA NA NA<br />

NA NA <strong>40</strong>80943 <strong>40</strong>8556 <strong>40</strong>80941<br />

<strong>40</strong>97632 &<br />

<strong>40</strong>97633 -<br />

1997<br />

<strong>40</strong>94482 -<br />

1992<br />

<strong>40</strong>94357 -<br />

1997<br />

3 Date commissioned. 15.9.1989 17.3.1991 17.12.1996 12.1.197 25.1.1997 ########### ###########<br />

4 Commissioning data Available Available Available Available Available Available Available<br />

a)<br />

b)<br />

Specific fuel<br />

consumption – SFC<br />

i.Engine wise<br />

215<br />

Not available<br />

215<br />

ii.Total plant gms/Kwhr 234 gms/Kwhr 218<br />

0.69<br />

gms/Kwhr<br />

0,9 0,9 0,9 0,9<br />

gms/Kwhr<br />

0.69<br />

gms/Kwhr<br />

Specific lube oil<br />

consumption – SLOC<br />

<strong>40</strong>43712 -1989<br />

PLANT 3<br />

PLANT 2<br />

221<br />

gms/Kwhr<br />

0.69<br />

gms/Kwhr<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

c) Operation data Available Available Available Available Available Available Available<br />

d) Vibration record Available Available Available Available Available Available Available<br />

e) Crankshaft alignment Available Available Available Available Available Available Available<br />

f) Hot deflection Available Available Available Available Available Available Available<br />

g) Spring pad height NA NA NA NA NA NA NA<br />

5 Past data records Available Available Available Available Available Available Available<br />

a) SFC<br />

i.<br />

ii.<br />

Engine wise<br />

Total plant<br />

224Gms/Kwhr<br />

228<br />

228<br />

b)<br />

6<br />

SLOC 0.80gms/Kw<br />

hr<br />

Present data - measured<br />

at our presence<br />

a) SFC<br />

0.80gms/Kw<br />

hr<br />

0.80gms/Kwhr 0.80gms/Kw<br />

hr<br />

0.80gms/Kwh<br />

r<br />

gms/Kwhr<br />

0.80gms/Kwh gms/Kwhr<br />

r<br />

228<br />

gms/Kwhr<br />

0.90gms/Kwh<br />

r<br />

i. Engine wise<br />

223 ~ 234<br />

gms/Kwhr<br />

223 ~ 234<br />

gms/Kwhr<br />

223 ~ 234<br />

gms/Kwhr<br />

223 ~ 234<br />

gms/Kwhr<br />

223 ~ 234<br />

gms/Kwhr<br />

223 ~ 234<br />

223 ~ 234 gms/Kwhr<br />

gms/Kwhr<br />

ii. Total plant<br />

223 ~ 234<br />

gms/Kwhr<br />

223 ~ 234<br />

gms/Kwhr<br />

223 ~ 234<br />

gms/Kwhr<br />

223 ~ 234<br />

gms/Kwhr<br />

223 ~ 234<br />

gms/Kwhr<br />

223 ~ 234<br />

gms/Kwhr<br />

b) SLOC 0.86 0.86 0.86 gms/Kwhr 0.86 0.86 0.86 1.2 gms/Kwhr<br />

7 Plant control system gms/Kwhr gms/Kwhr<br />

gms/Kwhr gms/Kwhr gms/Kwhr<br />

a)<br />

8<br />

PLC or not Allen<br />

bradely<br />

Allen bradely Allen bradely Allen bradely Allen bradely Allen bradely Allen bradely<br />

Manufacture’s test<br />

reports mainly for;<br />

a) Main engines Available Available Available Available Available Available Available<br />

b) Alternators Available Available<br />

Separate list enclosed Ref Plant 3 -Elect specification<br />

c) Power transformers Available Available<br />

9<br />

a)<br />

Last major overhaul<br />

reports for main engines<br />

including,<br />

Liner condition &<br />

replacement<br />

Hard copy<br />

available<br />

Hard copy<br />

available<br />

Hard copy<br />

available<br />

Hard copy<br />

available<br />

Maintenance data's available<br />

Hard copy<br />

available<br />

A 8 & A 1 Nil<br />

b) Head replacement - NIL Nil Nil Nil Nil Nil Nil Nil<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

c) Block machining data<br />

d) Sump cracks<br />

e) Vibration records<br />

A<br />

1,2,3,4,5,6,8<br />

,9,B1,2,3,4,<br />

Available<br />

Turbo Max<br />

20m2/sec in<br />

Turbo<br />

A3,A6<br />

Available<br />

Turbo<br />

Max20m2/se<br />

c in Turbo<br />

only lappling<br />

has been done<br />

Available<br />

Turbo Max<br />

20m2/sec in<br />

Turbo<br />

A4,6,8,9,B2,<br />

B8,B9<br />

Available<br />

Turbo Max<br />

20m2/sec in<br />

Turbo<br />

A4,5,6,8,B3,4,<br />

5,6<br />

Available<br />

Turbo Max<br />

20m2/sec in<br />

Turbo<br />

A<br />

1,3,4,5,6,8,9<br />

B 1,3,5,7,8,9<br />

Sump<br />

replaced at<br />

12847 Hrs on<br />

Available<br />

Turbo Max<br />

14m2/sec in<br />

Turbo<br />

A 3,4,5,6<br />

B 3,4,5,6<br />

Nil<br />

Available<br />

Turbo Max<br />

10m2/sec in<br />

Turbo<br />

f) Crankshaft alignment Available Available Available Available Available Available Available<br />

10 Main engines<br />

a)<br />

Governor control and<br />

actuator types<br />

b) Fuel injections pump<br />

c)<br />

d)<br />

type<br />

Scheduled / forced<br />

maintenance records<br />

after last major overhaul<br />

Special maintenance<br />

before last overhaul<br />

Hydraulic<br />

Governor<br />

L Orange -<br />

PEO - G030<br />

Scheduled-<br />

Available &<br />

Froced - Nil<br />

Hydraulic<br />

Governor<br />

L Orange -<br />

PEO - G030<br />

Scheduled-<br />

Available &<br />

Froced - Nil<br />

Hydraulic<br />

Governor<br />

L Orange -<br />

PEO - G030 E<br />

Scheduled-<br />

Available &<br />

Froced - Nil<br />

Hydraulic<br />

Governor<br />

L Orange -<br />

PEO - G030<br />

Scheduled-<br />

Available &<br />

Froced - Nil<br />

Hydraulic<br />

Governor<br />

L Orange -<br />

PEO - G030<br />

Scheduled-<br />

Available &<br />

Froced - Nil<br />

nil nil nil nil nil<br />

721 721<br />

L Orange -<br />

PEO - G030<br />

Scheduled-<br />

Available &<br />

Froced - Nil<br />

L Orange -<br />

PEO - G030<br />

Scheduled-<br />

Available &<br />

Froced - Nil<br />

11 Alternator; AlstomAlstom- BHEL Make BHEL Make BHEL Make BHEL Make BHEL Make<br />

a) Rating plate data francefrance i. Voltage 11 KV 11 KV 11 KV 11 KV 11 KV 11 KV 11 KV<br />

ii. Current NA NA 394 Amps 394 Amps 394 Amps 394 Amps 262 Amps<br />

iii. Frequency <strong>50</strong> <strong>Hz</strong> <strong>50</strong> <strong>Hz</strong> <strong>50</strong> <strong>Hz</strong> <strong>50</strong> <strong>Hz</strong> <strong>50</strong> <strong>Hz</strong> <strong>50</strong> <strong>Hz</strong> <strong>50</strong> <strong>Hz</strong><br />

iv. Power factor 0.8 Lag 0.8 Lag 0.8 Lag 0.8 Lag 0.8 Lag 0.8 Lag 0.8 Lag<br />

v. VA rating 8125 7<strong>50</strong>0 KVA 7<strong>50</strong>0 KVA 7<strong>50</strong>0 KVA 7<strong>50</strong>0 KVA 7<strong>50</strong>0 KVA <strong>50</strong>00 KVA<br />

b) AVR type<br />

Controlled<br />

Thristor<br />

Controlled<br />

Thristor<br />

Controlled<br />

Thristor Bridge<br />

Controlled<br />

Thristor<br />

Controlled<br />

Thristor<br />

Controlled<br />

Thristor<br />

Controlled<br />

Thristor<br />

c)<br />

Whether there is<br />

parallel operation<br />

No<br />

Yes Yes Yes Yes Yes Yes Yes<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

d)<br />

Last major maintenance<br />

records including<br />

i. Winding insulation 2000<br />

ii. Air gap record for<br />

main rotor and exciter<br />

iii. No load excitation<br />

current at rated speed<br />

and voltage<br />

e) Other maintenance<br />

i. Special maintenance<br />

done after<br />

commissioning<br />

ii. All maintenances<br />

done after last major<br />

maintenance<br />

Power transformers /<br />

12<br />

Station transformers<br />

Regular<br />

AMC jobs<br />

Alternator<br />

Overahul<br />

done &<br />

DE/NDE<br />

Regular<br />

AMC jobs<br />

Regular AMC<br />

jobs<br />

Regular<br />

AMC jobs<br />

DE/NDE<br />

Bearings<br />

Replaced<br />

Regular AMC<br />

jobs<br />

2000<br />

12.4<br />

Megohm<br />

MM / 1.8<br />

Megohm<br />

11.1 MM / 2.2 MM<br />

MM<br />

Alternator<br />

Overahul<br />

done &<br />

DE/NDE<br />

Regular AMC<br />

jobs<br />

Current - 1.4<br />

Amps Volt-<br />

<strong>40</strong>V Speed<br />

7<strong>50</strong> RPM<br />

Alternator<br />

Overahul<br />

done & NDE<br />

Bearing<br />

Regular AMC<br />

jobs<br />

a) Maintenance records Available Available Available Available Available Available Available<br />

b) HV/LV voltages 11893 V 11893 V 11893 V 11893 V 11893 V 11893 V 11893 V<br />

c) Power ratings 8000 /11000 KVA V 8000 /11000 KVA V 8000 /11000 KVA V 8000 /11000 KVA V 8000 /11000 KVA V 8000 /11000 KVA V 5<strong>50</strong>0 /11000 KVA V<br />

13 Breaker condition for;<br />

a) Generator breakers<br />

b)<br />

c)<br />

d)<br />

Station transformer<br />

breakers<br />

Power transformer<br />

breakers<br />

Switchyard breakers<br />

(outdoor)<br />

Ref Plant 3 Electrical specific<br />

Breaker Details Plant 2 '!A1<br />

NA NA NA NA NA NA NA<br />

Should include NA NA NA NA NA NA NA<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

i. Number of<br />

operation cycles<br />

NA NA NA NA NA NA NA<br />

ii. Gas pressure NA NA NA NA NA NA NA<br />

iii. Operation<br />

(remote/local)<br />

NA NA NA NA NA NA NA<br />

14 HFO / LO separators<br />

Fuel oil separator WHPX<br />

410 - 1 No & Lub oil<br />

Fuel oil Separator FOPX 613 - 2 nos & Lub<br />

oil separator MOPX 207 - 3Nos<br />

FOPX 609 –<br />

MOPX 207 - 1 No<br />

2 Nos&<br />

a) Running hours 70 ,000 Hrs 70 ,000 Hrs 70 ,000 Hrs 70 ,000 Hrs 70 ,000 Hrs 70 ,000 Hrs 69 ,000 Hrs<br />

b) Controller type EPC <strong>40</strong>0 EPC <strong>40</strong>0<br />

DCU 41 for<br />

MOPX EPC<br />

<strong>40</strong>0 for FOPX<br />

DCU 41 for<br />

MOPX EPC<br />

<strong>40</strong>0 for<br />

DCU 41 for DCU 41 for<br />

MOPX EPC MOPX EPC<br />

<strong>40</strong>0 for FOPX <strong>40</strong>0 for FOPX<br />

DCU 41 for<br />

MOPX<br />

c)<br />

Heating electric or<br />

steam<br />

48 Kw-<br />

Electrical<br />

48 Kw-<br />

Electrical<br />

Electric<br />

Electric Heater -<br />

Heater - 60<br />

60 KW<br />

KW<br />

Electric<br />

Heater - 60<br />

KW<br />

Electric<br />

Heater - 60<br />

KW<br />

Electric<br />

Heater - 60<br />

KW<br />

for L.O seps<br />

For fuel oil seps<br />

d) Maintenance data Available Available Available Available Available Available Available<br />

15 Cooling system Water Water Water cooling Water Water cooling Water cooling Water cooling<br />

a) Radiators or cooling Cooling cooling Cooling cooling Cooling Cooling cooling Cooling Cooling Cooling<br />

Centralised Towers Central Towers Heat HTTowers & LT Heat HT Towers & LT HTTowers & LT Heat Central Towers Heat Central Towers Heat<br />

b)<br />

Intermediate heat<br />

exchangers?<br />

single heat<br />

exchanger<br />

for<br />

exchanger<br />

for Water - 1<br />

No &<br />

exchanger for<br />

Water each- 1<br />

No<br />

Heat<br />

exchanger<br />

for Water<br />

exchanger for exchanger for exchanger for<br />

Water each- 1 Water - 1 No Water - 1 No<br />

No Lub oil Heat Lub oil Heat<br />

LT/HT/L.O Lub oil Heat Lub oil Heat each- 1 No Lub oil Heat exchanger - exchanger -<br />

c)<br />

Charge air cooler<br />

(single stage or double)<br />

16 Turbo charger<br />

a) Type<br />

VTR 354 VTR 354<br />

Marine Filter Marine Filter<br />

b) No. of ports 3 Ports/ 3 Ports/<br />

17<br />

Bank Bank<br />

Charge air filters and<br />

silencers<br />

72 Kw - Electrical 90 KW - Electrical<br />

Double Double Double Double Double Double Double<br />

VTR 354 P 11<br />

VTR 354 P<br />

11<br />

3 Ports/ Bank 3 Ports/<br />

Bank<br />

VTR 354 P 11<br />

VTR 354 P<br />

11<br />

VTR 304 P<br />

11<br />

3 Ports/ Bank 3 Ports/ Bank 2 Ports/Bank<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

a)<br />

Condition to check the<br />

possibility of bringing<br />

down and reuse<br />

Yes Yes Yes Yes Yes Yes Yes<br />

18 Exhaust stack<br />

a) Stack height 34 Mts 34 Mts 55 Mts 55 Mts 55 Mts 55 Meters 55 Meters<br />

Silencer – condition to<br />

b) check the possibility of<br />

bringing down and<br />

19 Boiler<br />

Yes Yes Yes Yes Yes Yes Yes<br />

Thermax(W Thermax(W Thermax(Wate Thermax(W Thermax(Wat Thermax(Wat Thermax(Wat<br />

a) Manufacturer and type<br />

ater tube<br />

Boiler )-<br />

ater tube<br />

Boiler )-<br />

r tube Boiler )-<br />

Exhaust Gas<br />

ater tube<br />

Boiler )-<br />

er tube Boiler<br />

)- Exhaust<br />

er tube Boiler<br />

)- Exhaust<br />

er tube Boiler<br />

)- Exhaust<br />

Exhaust Exhaust Gas Recovery Exhaust Gas Gas Recovery Gas Gas<br />

b) Other rating data 34<strong>50</strong> kgs/hr 34<strong>50</strong> kgs/hr 2770 kgs/hr 2770 kgs/hr 2770 kgs/hr 2700 Kg/hr 1700 Kg/hr<br />

c)<br />

20<br />

21<br />

Auxiliary boiler – oil<br />

fired – available?<br />

Type and details of<br />

water treatment<br />

system for plant use<br />

Engine hall and other<br />

buildings<br />

NA NA NA NA NA NA NA<br />

HP Dosing -<br />

Tri Sodium<br />

Phospate<br />

LP Dosing<br />

HP Dosing -<br />

Tri Sodium<br />

Phospate LP<br />

Dosing<br />

HP Dosing - Tri<br />

Sodium<br />

Phospate LP<br />

Dosing<br />

HP Dosing -<br />

Tri Sodium<br />

Phospate LP<br />

Dosing<br />

HP Dosing -<br />

Tri Sodium<br />

Phospate LP<br />

Dosing<br />

HP Dosing -<br />

Tri Sodium<br />

Phospate LP<br />

Dosing<br />

HP Dosing -<br />

Tri Sodium<br />

Phospate LP<br />

Dosing<br />

a) Wall materials Concrete Concrete Concrete Concrete Concrete Concrete Concrete<br />

b)<br />

c)<br />

d)<br />

Buildings – possibility<br />

of bringing down and reassembling<br />

Roofing materials –<br />

reusable?<br />

Crane and crane beams<br />

– reusable?<br />

NO NO NO NO NO NO NO<br />

NO NO NO NO NO NO NO<br />

Yes Yes Yes Yes Yes Yes Yes<br />

22 Work shop NA NA NA NA NA NA NA<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

a)<br />

23<br />

Equipment we can bring<br />

down<br />

Other auxiliary units<br />

and equipment we can<br />

bring down<br />

a) Name the units<br />

b)<br />

c)<br />

Maintenance records of<br />

above<br />

Identified defects of<br />

above, those have to be<br />

repaired/corrected<br />

before re-<br />

NA NA NA NA NA NA NA<br />

Available Available Available Available Available Available Available<br />

NIL NIL NIL NIL NIL NIL NIL<br />

24 Test reports<br />

a) HFO Available Available Available Available Available Available Available<br />

b) LO Available Available Available Available Available Available Available<br />

c) Engine cooling water Available Available Available Available Available Available Available<br />

d) Boiler water Available Available Available Available Available Available Available<br />

e) Emission Available Available Available Available Available Available Available<br />

f)<br />

Sound levels with<br />

measuring points at site<br />

Available Available Available Available Available Available Available<br />

25 Usable spare parts Available Available Available Available Available Available Available<br />

a)<br />

26<br />

Please provide a list<br />

with part numbers<br />

and/or other details<br />

Dimensional plant<br />

layout and plan<br />

Fuel Feeder,Booster,<br />

Supply<br />

Units,MOPX,FOPX,Coolin<br />

g water system,Ventilation<br />

Fuel Feeder,Booster, Supply<br />

Units,MOPX,FOPX,Cooling water<br />

system,Ventilation Fan, Exhaust Fan,Luboil<br />

Charging,Drain Pumps<br />

Nil<br />

Fuel Feeder,Booster, Supply<br />

Units,MOPX,FOPX,Cooling<br />

water system,Ventilation<br />

Fan, Exhaust Fan,Luboil<br />

Available Available<br />

Available Available<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

HT & LT Breakers Details in Plant 2<br />

6<strong>MW</strong> INCOMER & URT 1 4<strong>MW</strong> INCOMER & URT 2 Auxilary Breaker & LT Braker<br />

Make ABB ABB ABB<br />

Sr.No S 7714 & S 7718 Year 1998 S 7717 & S 7720 Year 1998 S 7716 Year 1998<br />

Type Circuit Breaker HPA 12/20<strong>40</strong>C Circuit Breaker HPA 12/20<strong>40</strong>C Circuit Breaker HPA 12/20<strong>40</strong>C<br />

Standard IEC 56 IEC 56 IEC 56<br />

Rated Voltage 12 KV 12 KV 12 KV<br />

Insulation Level 28 / 75 KV 28 / 75 KV 28 / 75 KV<br />

Rated Frequency <strong>50</strong> <strong>Hz</strong> <strong>50</strong> <strong>Hz</strong> <strong>50</strong> <strong>Hz</strong><br />

Rated Current 2000 A 2000 A 2000 A<br />

Breaking Current <strong>40</strong> KA <strong>40</strong> KA <strong>40</strong> KA<br />

Making Capacity 100 KA 100 KA 100 KA<br />

Rated Shirt time Current 1/3 Sec <strong>40</strong> KA 1/3 Sec <strong>40</strong> KA 1/3 Sec <strong>40</strong> KA<br />

Mass Apprx<br />

Auxilary Voltage<br />

185 Kg 185 Kg 185 Kg<br />

Closing Coil 110 V DC 110 V DC 110 V DC<br />

Opening Coil 110 V DC 110 V DC 110 V DC<br />

Motor 2<strong>40</strong> V AC 2<strong>40</strong> V AC 2<strong>40</strong> V AC<br />

Indicator V V V<br />

SF 6 Pressure at 20°c 2-2.5 Bar ( 0.2 -0.25 Mpa) 2-2.5 Bar ( 0.2 -0.25 Mpa) 2-2.5 Bar ( 0.2 -0.25 Mpa)<br />

SF 6 Gas per Pole at 20°c 0.25 Kg 0.25 Kg 0.25 Kg<br />

Insulation Manual IN 5<strong>40</strong>9 0001 IN 5<strong>40</strong>9 0001 IN 5<strong>40</strong>9 0001<br />

Auxilary LT Breaker<br />

Auxilary LT Breaker<br />

L & T Larson& Tubro Ltd<br />

In 1600 A<br />

Ve 415 V <strong>50</strong>/60<strong>Hz</strong><br />

Icu-55 KA Ics 55 KA<br />

Icw 55 KA for 1 sec<br />

Utilization Catagery B<br />

Is 13947-2 IEC 947 -2 CN -CS<br />

1600 D<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

ALTERNATORS<br />

Description D.G # 1 D.G # 2 D.G # 3 D.G # 4 D.G # 5<br />

Make Alsthom Alsthom BHEL BHEL BHEL<br />

Type RP38A RP38AY-8P G851096 G851096 G851096<br />

Serial No 172147-1 157671-3 4<strong>50</strong>80A264-11-02 4<strong>50</strong>80A264-11-03 4<strong>50</strong>80A264-11-01<br />

IP 23 23 23 23 23<br />

KW 6<strong>50</strong>0 6000 6000 6000 6000<br />

p.f 0,8 0,8 0,8 0,8 0,8<br />

kVA 8125 7<strong>50</strong>0 7<strong>50</strong>0 7<strong>50</strong>0 7<strong>50</strong>0<br />

Star Voltage 11000 11000 11000 11000 11000<br />

Amps 426,3 393,6 394 394 394<br />

RPM 7<strong>50</strong> 7<strong>50</strong> 7<strong>50</strong> 7<strong>50</strong> 7<strong>50</strong><br />

Phase 3 3 3 3 3<br />

Frequency <strong>50</strong> <strong>50</strong> <strong>50</strong> <strong>50</strong> <strong>50</strong><br />

Insulation Class B F F F F<br />

Ambient Temp <strong>50</strong> Degree Celcius <strong>50</strong> Degree Celcius <strong>50</strong> Degree Celcius <strong>50</strong> Degree Celcius <strong>50</strong> Degree Celcius<br />

Duty S1 S1 S1 S1 S1<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

Exciter Make RBS RBS BHEL BHEL BHEL<br />

KW 79 79 79<br />

Exciter Voltage 225 V 225 V 225 V<br />

Exciter Amps 3<strong>50</strong> A 3<strong>50</strong> A 3<strong>50</strong> A<br />

Extation Voltage 86 V 84 V 155 V 155 V 155 V<br />

Amps 8A 8A 4.5 A 4.5 A 4.5 A<br />

Regulator 6156 6116<br />

Weight 30000 Kg 27000Kg 33<strong>50</strong>0 Kg 33<strong>50</strong>0 Kg 33<strong>50</strong>0 Kg<br />

Year Dez 88 Jan 90 1996 1996 1996<br />

URT # 1 URT # 2 URT # 3 URT # 4 URT # 5<br />

KVA 8000 8000 8000 8000 8000<br />

Rated Voltage No Load<br />

UNIT RATIO TRANSFORMERS<br />

Primary 11000 11000 11000 11000 11000<br />

Secondary 11893 11893 11893 11893 11893<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

Rated Current<br />

Primary 420 420 419,9 419,9 419,9<br />

Secondary 388,87 388,87 388,4 388,4 388,4<br />

Phases<br />

Primary 3 3 3 3 3<br />

Secondary 3 3 3 3 3<br />

Make Voltas Voltas Bharat Bijilee Bharat Bijilee Bharat Bijilee<br />

Makers serial No RY- 3552 RY- 3645/1 4183/1 4183/2 4183/3<br />

Type of cooling ONAN ONAN ONAN ONAN ONAN<br />

Frequency <strong>50</strong> <strong>50</strong> <strong>50</strong> <strong>50</strong> <strong>50</strong><br />

Impendance Volts 13,10% 12,10%<br />

Vector group Dyn11 Dyn11 Dyn11 Dyn11 Dyn11<br />

Core & Winding 8200 Kg 8200 Kg<br />

Weight of oil 3900 Kg 3900 Kg 4558 kg 4558 kg 4558 kg<br />

Total Weight 18800 Kg 18800 Kg 18700 kg 18700 kg 18700 kg<br />

Oil Litre 4<strong>50</strong>0 4<strong>50</strong>0 5300 5300 5300<br />

Ambient Temprature 45 Degree Celcius 45 Degree Celcius<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

Max.Temp. Rise in Oil <strong>50</strong> Degree Celcius <strong>50</strong> Degree Celcius<br />

Max.Temp. Rise in Winding 55 Degree Celcius 55 Degree Celcius<br />

Tap Changer<br />

CIRCUIT BREAKER<br />

D.G # 1 D.G # 2 D.G # 3 D.G # 4 D.G # 5<br />

Type Vaccum Vaccum SF6 SF6 SF6<br />

Make Siemens Siemens ABB ABB ABB<br />

Type 3AF-1752-4-S 3AF-1752-4-S IEC56 IEC56 IEC56<br />

Serual No 1926 2578 S5953 S5952 S8396<br />

Rated votage 11000 11000 11000 11000 11000<br />

Rated current 12<strong>50</strong> 12<strong>50</strong> 12<strong>50</strong> 12<strong>50</strong> 12<strong>50</strong><br />

Insulation level 28 / 75 KV 28 / 75 KV 28 / 75 KV<br />

Making capacity 100 KA 100 KA 100 KA<br />

Frequency <strong>50</strong> <strong>50</strong> <strong>50</strong> <strong>50</strong> <strong>50</strong><br />

Rated short time current 31.5KA/3S 31.5KA/3S <strong>40</strong>KA/ 1S <strong>40</strong>KA/ 1S <strong>40</strong>KA/ 1S<br />

Rated output duty 0.3S-CO-3min-CO 0.3S-CO-3min-CO<br />

Provided for all the five URT's.<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

Mass 108kg 108kg 185kg 185kg 185kg<br />

Year 1989 1990 1996 1996 1996<br />

Closing coil 110V DC 110V DC 110V DC 110V DC 110V DC<br />

Opening coil 110V DC 110V DC 110V DC 110V DC 110V DC<br />

Motor supply 230V AC 230V AC 230V AC 230V AC 230V AC<br />

Gas pressure 2 - 2.5 Bar 2 - 2.5 Bar 2 - 2.5 Bar<br />

Gas per pole 0.25 kg 0.25 kg 0.25 kg<br />

All the five D.G Circuit Breakers cannot be taken out of line.<br />

ONLOAD ISOLATOR<br />

DG # 1 DG # 2 DG # 3 DG # 4 DG # 5<br />

Make Driescher Panicker Driescher Panicker Driescher Panicker Driescher Panicker Driescher Panicker<br />

Type ZLDT 10/630/EA ZLDT 10/630/EA ZLDT 10/630/EA ZLDT 10/630/EA ZLDT 10/630/EA<br />

Serial no B1368 C1573 B2827 B2828 B2829<br />

Ur / Un 11000 11000 11000 11000 11000<br />

In 630 A 630 A 630 A 630 A 630 A<br />

Jn 5468 5595 6164 6164 6164<br />

All the five Onload Isolatord are not in good condition.<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

NEUTRAL GROUNDING RESISTOR / NEUTRAL GROUNDING TRANSFORMER<br />

DG # 1 DG # 2 DG # 3 DG # 4 DG # 5<br />

Make Driescher Panicker Driescher Panicker National switchgear National switchgear National switchgear<br />

System volts 11000 V 11000 V 11000 V 11000 V 11000 V<br />

Frequency <strong>50</strong> <strong>Hz</strong> <strong>50</strong> <strong>Hz</strong> <strong>50</strong> <strong>50</strong> <strong>50</strong><br />

Fault current 53 A 53 A 53 A<br />

Duration 60 s 60 s 60 s<br />

Total resistance( +10 % ) 2.42 OHMS 2.42 OHMS 2.42 OHMS<br />

Material of element Stainless Steel Stainless Steel Stainless Steel<br />

Type LOTP/Z 10 / 630 F LOTP/Z 10 / 630 F Coil wound Coil wound Coil wound<br />

Serial No C 1666 0/187 0/188 0/189<br />

Year 1996 1996 1996<br />

Ref. Drg No 4-1459R1 4-1459R1 4-1459R1<br />

AUTOMATIC VOLTAGE REGULATOR<br />

DG # 1 DG # 2 DG # 3 DG # 4 DG # 5<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

Make ACEO ACEO BHEL BHEL BHEL<br />

Serial No 7<strong>50</strong>8516 7<strong>50</strong>8518 7<strong>50</strong>8517<br />

OUTPUT RATING<br />

No load 1.4 A, 65 V DC 1.4 A, 65 V DC 1.4 A, 65 V DC<br />

Rated load 8A,86 V DC 8A,84 V DC 4.5 A, 155 V DC 4.5 A, 155 V DC 4.5 A, 155 V DC<br />

VOLTAGE REGULATOR<br />

Sensing supply 110VAC,10VA,3ph 110VAC,10VA,3ph 110VAC,10VA,3ph<br />

CT supply 1A,2VA,1ph,<strong>50</strong><strong>Hz</strong> 1A,2VA,1ph,<strong>50</strong><strong>Hz</strong> 1A,2VA,1ph,<strong>50</strong><strong>Hz</strong><br />

Auto control range 90-110%En(NL-FL) 90-110%En(NL-FL) 90-110%En(NL-FL)<br />

Manual control range 70-110%En(NL-FL) 70-110%En(NL-FL) 70-110%En(NL-FL)<br />

Regulation accuracy 1.0 % (NL-FL) 1.0 % (NL-FL) 1.0 % (NL-FL)<br />

Compounding 0-10 % En 0-10 % En 0-10 % En<br />

Compounding supply 110V, 3ph, <strong>50</strong><strong>Hz</strong> 110V, 3ph, <strong>50</strong><strong>Hz</strong> 110V, 3ph, <strong>50</strong><strong>Hz</strong><br />

Compounding CT 5A / 1A 5A / 1A 5A / 1A<br />

Note:<br />

* All the materials can be given only as it is condition.<br />

* A.M.C Details available for Maintenance Records<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

ESN : 7802 TYPE :18 V 32<br />

Date 17.08.07 Running Hours 72943<br />

Engine Load Engine Speed Turbo charger Speed<br />

4800 KW 80% of Load 748 R.P.M 20149 20277<br />

Charge Air Temperature / Pressure<br />

BAR<br />

Location<br />

of<br />

meas.p<br />

oints<br />

o C<br />

Vertical<br />

Direction<br />

Vel.mm/s<br />

Transverse<br />

Direction<br />

Vel.mm/s<br />

VIBRATION MEASUREMENT DATA RECORD<br />

Turbo chargers make & type HT NO - A - bank HT NO - B -bank<br />

ABB VTR 354 P - 11 419158 419159<br />

Longitudinal<br />

Direction<br />

Vel.mm/s<br />

Instrument -make & type Serial no<br />

Bruel &Kajer<br />

Location<br />

points<br />

Vertical<br />

Direction<br />

Vel.mm/s<br />

Transvers Longitudinal<br />

e Direction Direction<br />

Vel mm/s Vel. mm/s<br />

Acclereati<br />

Direction<br />

Vel.m/s²<br />

A 1 - a 7,0 9,0 5,0 <strong>40</strong> - a # # 10,0 4,0<br />

A 3 - a 8,0 7,0 7,0 41 - a # 14,0 # 10,0<br />

A 4 - a 10,0 12,0 9,0 42 - a 20,0 # # 8,0<br />

A 5 - a 44 - a # # 10,0 10,0<br />

B 2 - a # # 45 - a # 12,0 # 7,0<br />

C 1 - a 10,0 13,0 9,0 46 - a 13,0 # # 6,0<br />

C 3 - a 10,0 13,0 7,0<br />

C 4 - a 10,0 12,0 8,0 <strong>40</strong> - b # # 10,0 8,0<br />

C 5 - a 41 - b # 16,0 # 4,0<br />

D 2 - a 2,20 1,60 2,20 42 - b 12,0 # # 7,0<br />

D 4 - a 44 - b # # 10,0 7,0<br />

E 2 - a 1,00 1,00 2,00 45 - b # 18,0 # 7,0<br />

E 4 - a 46 - b 16,0 # # 6,0<br />

A 1 - b #<br />

A 3 - b 7,0 7,0 7,0 Installation data Purpose of measurement<br />

Short Base frame Base line measurement<br />

B 2 - b # # Rubber Pads Periodic check up<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

C 1 - b 12,0 10,0 4,0<br />

C 3 - b<br />

61<br />

65<br />

Remarks :<br />

Pipe module Pre - overhaul / Repair check<br />

Post -overhaul / Repair check<br />

Machine trouble shooting<br />

Note : All measurements are in RMS values<br />

Name & Signature<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

ESN : 7928 TYPE :12 V 32<br />

Date 17.08.07<br />

Running Hours 70599<br />

Engine Load Engine Speed Turbo Charger Speed<br />

3<strong>50</strong>0 KW 87.5 % of Load 737 R.P.M 24802 24751<br />

Charge Air Temperature / Pressure<br />

o<br />

C BAR<br />

Location<br />

of meas.<br />

points<br />

Vertical<br />

Direction<br />

Vel.mm/s<br />

Transverse<br />

Direction<br />

Vel.mm/s<br />

VIBRATION MEASUREMENT DATA RECORD<br />

Turbo chargers make & type HT NO - A -bank HT NO - B bank<br />

ABB VTR 304 P - 11 420618 420617<br />

Longitudinal<br />

Direction<br />

Vel.mm/s<br />

Instrument -make & type Serial no<br />

Bruel & Kajer<br />

Location<br />

of meas.<br />

points<br />

Vertical<br />

Direction<br />

Vel.mm/s<br />

Transvers<br />

e Direction<br />

Vel mm/s<br />

Longitudina<br />

Direction<br />

Vel. mm/s<br />

Acclereati<br />

Direction<br />

Vel.m/s²<br />

A 1 - a 7,0 4,5 2,4 <strong>40</strong> - a # # 14,0 8,0<br />

A 3 - a 5,0 5,0 3,0 41 - a # 8,0 # 3,5<br />

A 4 - a 7,0 10,0 4,0 42 - a 14,0 # # 8,0<br />

A 5 - a 44 - a # # 13,0 6,0<br />

B 2 - a # # 45 - a # 10,0 # 5,0<br />

C 1 - a 7,0 7,0 3,5 46 - a 17,0 # # 5,0<br />

C 3 - a 6,5 5,5 4,0<br />

C 4 - a 5,5 6,5 4,0 <strong>40</strong> - b # # 18,0 9,0<br />

C 5 - a 41 - b # 12,0 # 5,0<br />

D 2 - a 2,00 3,00 1,00 42 - b 14,0 # # 9,0<br />

D 4 - a 44 - b # # 14,0 8,0<br />

E 2 - a 2,00 3,00 1,20 45 - b # 14,0 # 7,0<br />

E 4 - a 46 - b 18,0 # # 7,0<br />

A 1 - b #<br />

A 3 - b 4,5 4,5 4,0 Installation data Purpose of measurement<br />

Short Base frame Base line measurement<br />

B 2 - b # # Rubber Pads Periodic check up<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

C 1 - b 7,0 7,0 3,5<br />

C 3 - b<br />

61<br />

65<br />

Remarks :<br />

Pipe module Pre - overhaul / Repair check<br />

Post -overhaul / Repair check<br />

Machine trouble shooting<br />

Note : All measurements are in RMS values<br />

Name & Signature<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

ESN : 7802 TYPE : 18 V 32 Date 09.08.07 Operating Hours 72756<br />

Engine load Speed Frequency in HZ P . F<br />

Load,% of nominal<br />

<strong>50</strong>00 KW 747 RPM 49,57<br />

0,85 83%<br />

Alternator Voltage / Current KV / A<br />

11.1/ 296 Load Indicator Position<br />

OPERATION DATA RECORD<br />

"A" BANK CYLINDER "B" BANK CYLINDER Main bearings<br />

Cyl.no<br />

Peak Pr.<br />

in Bar<br />

Rack in<br />

mm<br />

Exh.Tem<br />

perature<br />

Peak Pr.<br />

Cyl.no<br />

In Bar<br />

Rack in<br />

mm<br />

Exh.Te<br />

mperatu<br />

Temperature<br />

Thrust 91<br />

A 1 120 43,0 430 B 1 119 <strong>40</strong>,0 383 1 91<br />

A 2 118 <strong>40</strong>,0 <strong>40</strong>8 B 2 120 42,0 411 2 95<br />

A 3 118 43,0 427 B 3 120 <strong>40</strong>,0 410 3 96<br />

A 4 116 41,0 419 B 4 120 45,0 445 4 96<br />

A 5 115 41,0 383 B 5 120 <strong>40</strong>,5 419 5 95<br />

A 6 118 41,0 416 B 6 122 42,5 431 6 96<br />

A 7 118 <strong>40</strong>,5 384 B 7 118 42,5 393 7 98<br />

A 8 120 39,5 <strong>40</strong>3 B 8 120 43,5 398 8 96<br />

A 9 118 39,0 396 B 9 118 42,0 <strong>40</strong>1 9 96<br />

Avg. Rack Pos/Temp. 41 <strong>40</strong>7 Avg. Rack Pos/Temp. 42 410 10 91<br />

Exhaust.Temp.After T/C 308 Exhaust .Temp.After T/C 343<br />

Turbo speed -"A" 20411 RPM Turbo speed -B 20661 RPM DE 75<br />

PLATE HEAT EXCHANGER READINGS<br />

NDE 74<br />

LT Water<br />

LUB Oil<br />

HT Water<br />

RAW Water<br />

7,0<br />

Room Temp<br />

Pressure in Bar Temperatures in Diff. U 76/78<br />

IN OUT IN OUT Temp. V 77/75<br />

2,9 0,9 W 79/75<br />

6,1 6,2<br />

0,8 1,3<br />

3,4 1,7<br />

o C<br />

ENGINE READINGS<br />

Pressure in Bar Temperatures in o C<br />

Charge Air . 2,35 58<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

A Bank CAC B Bank CAC<br />

LT Water 3,0<br />

IN OUT IN OUT<br />

49 56 49 56<br />

HT Water 3,4<br />

Before & After Engine<br />

82 90<br />

After T/C A & B Bank<br />

Lub.Oil 5,7 68 82 ####<br />

Nozzle Coolant<br />

bf engine af engine<br />

3,6 3,1<br />

87 94 ####<br />

Fuel oil 7,3 132 Viscosity Cst<br />

CAC Differential Pressure A / B bank mm H 2 O<br />

Crankcase Pressure mm H 2 O<br />

ExhaustBack pressure mm H 2 O<br />

Charge air Filter Diff.Pressure A/B bank mm H 2 O<br />

17/22<br />

320 365<br />

14<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

ESN : 7928 TYPE : 12 V 32 Date 17.08.07 Operating Hours 70599<br />

Engine load Speed Frequency in HZ P . F<br />

Load,% of nominal<br />

3<strong>50</strong>0 KW 737 RPM 49,15<br />

0,99 88%<br />

Alternator Voltage / Current KV / A<br />

11/190<br />

Load Indicator Position<br />

OPERATION DATA RECORD<br />

"A" BANK CYLINDER "B" BANK CYLINDER Main bearings<br />

Cyl.no<br />

Peak Pr.<br />

in Bar<br />

Rack in<br />

mm<br />

Exh.Tem<br />

perature<br />

Peak Pr.<br />

Cyl.no<br />

In Bar<br />

Rack in<br />

mm<br />

Exh.Te<br />

mperatu<br />

Temperature<br />

Thrust 88<br />

A 1 129 <strong>40</strong>,0 393 B 1 129 41,5 <strong>40</strong>5 1 90<br />

A 2 131 41,0 419 B 2 132 <strong>40</strong>,0 417 2 94<br />

A 3 130 <strong>40</strong>,0 411 B 3 128 <strong>40</strong>,0 <strong>40</strong>0 3 95<br />

A 4 128 41,0 412 B 4 126 42,0 414 4 96<br />

A 5 126 42,0 <strong>40</strong>3 B 5 127 41,0 391 5 94<br />

A 6 129 42,0 425 B 6 128 <strong>40</strong>,5 416 6 96<br />

7 92<br />

Avg. Rack Pos/Temp. 41 411 Avg. Rack Pos/Temp. 41 <strong>40</strong>7<br />

Exhaust.Temp.After T/C 328 Exhaust .Temp.After T/C 322<br />

Turbo speed -"A" 24802 RPM Turbo speed -B 24751 RPM DE 76<br />

PLATE HEAT EXCHANGER READINGS<br />

NDE 75<br />

6,8<br />

Room Temp<br />

Pressure in Bar Temperatures in Diff. U 65 / 65<br />

IN OUT IN OUT Temp. V 65 / 64<br />

LT Water 3,0 2,2 47 49 W 67 / 67<br />

LUB Oil 6,5 6,2 76 58<br />

1,8 42<br />

2,4 1,2 46<br />

o C<br />

HT Water 54<br />

RAW Water 36<br />

ENGINE READINGS<br />

Pressure in Bar Temperatures in o C<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

Charge Air .<br />

2,0 58<br />

A Bank CAC B Bank CAC<br />

LT Water 3,4<br />

IN OUT IN OUT<br />

<strong>40</strong> 46 <strong>40</strong> 46<br />

HT Water 3,5<br />

Before & After Engine<br />

83 90<br />

After T/C A & B Bank<br />

83/92 83/92<br />

Lub.Oil 5,8 68 80 ####<br />

Nozzle Coolant<br />

bf engine af engine<br />

3,5 2,5<br />

98 100 ####<br />

Fuel oil<br />

6,5 Viscosity Cst<br />

CAC Differential Pressure A / B bank mm H 2 O<br />

Crankcase Pressure mm H 2 O<br />

ExhaustBack pressure mm H 2 O<br />

Charge air Filter Diff.Pressure A/B bank mm H 2 O<br />

320 3<strong>50</strong><br />

9<br />

Note:<br />

* All the materials can be given only as it is condition.<br />

* A.M.C Details available for Maintenance Records<br />

6 x 6 <strong>MW</strong> each, <strong>Wartsila</strong> make <strong>18V32</strong> Generators & 1 x 4 <strong>MW</strong> each,<br />

<strong>Wartsila</strong> make 12V32 Generators all operating at 11 kV, year of make ranging from 1990 – 1998.<br />

Price: ask - info@powerplant-market.com - Phone: +1 206-201-2420<br />

All offers subject to prior sale<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

INSPECTION REPORT<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

Date : 11-08-2010<br />

Ordered : 08-08-2010<br />

Done : 10-08-2010<br />

Reported : 11-02-2010<br />

Cust. No. : GEN<br />

_______________________________________________________________________________________<br />

REPORT SUBJECT : Inspection of Power Plant for shifting, revamping and overhauling the engines<br />

_______________________________________________________________________________________________<br />

_________________________________________________________________________________________________<br />

_________________________________________________________________________________________________<br />

_________________________________________________________________________________________________<br />

Total Working hours/days :<br />

Total Travelling hours/days :<br />

Total Reporting hours/days :<br />

ESN TYPE USE RPM FUEL RUN. DATE<br />

HOURS<br />

7802 <strong>18V32</strong> DG SET 7<strong>50</strong> LSHS 91,234 10.08.2010<br />

7928 12V32 DG SET 7<strong>50</strong> LSHS 81,112 10.08.2010<br />

4966 <strong>18V32</strong> DG SET 7<strong>50</strong> LSHS 11,4862 10.08.2010<br />

4653 <strong>18V32</strong> DG SET 7<strong>50</strong> LSHS 111,244 10.08.2010<br />

7130 <strong>18V32</strong> DG SET 7<strong>50</strong> LSHS 85,258 10.08.2010<br />

7227 <strong>18V32</strong> DG SET 7<strong>50</strong> LSHS 93,878 10.08.2010<br />

7228 <strong>18V32</strong> DG SET 7<strong>50</strong> LSHS 94,807 10.08.2010<br />

Page 2 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

Details of Worked Performed<br />

Inspection of all the engines, alternator, control system and plant Auxiliary carried out on 9 th and 10 th of August<br />

2010.<br />

Plant II<br />

Plant II has following DG sets:<br />

1 x <strong>18V32</strong><br />

1 x 12V32<br />

DG #1(<strong>18V32</strong>)<br />

ESN-7802<br />

Year of installation:-1998<br />

Place of manufacturing: Khopoli, India<br />

R/H of last major maintenance: 86264, dated 08-05-2009<br />

Present R/H - 91234<br />

Page 3 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

DG #2(12V32)<br />

ESN-7928<br />

KW- 4160 KW<br />

Year of installation:-1998<br />

Place of manufacturing: Khopoli, India<br />

Present R/H-81,112<br />

CYLINDER HEADS<br />

DG#1 DG#2<br />

Visual Inspection<br />

1. The visual appearance of cylinder heads was clean. No deposits observed on rocker arm, springs,<br />

push rods and rotocaps.<br />

2. No leakage observed from exhaust clamp of cylinder head.<br />

3. Both 10 mm and 8 mm rotocaps (old Type)observed. Inlet valves are also with Springs and rotocaps No<br />

water leakage observed from most of the cylinder head skirts.<br />

Observation from Last maintenance report<br />

<strong>18V32</strong><br />

1. 18 number exhaust valve seat are 1 mm oversize<br />

2. 15 number exhaust valves were renewed which shows high wear rate.<br />

3. 8 number inlet valve seats also renewed (30 Deg). All seats will need replacement with new 20 deg<br />

seats.<br />

4. Rotocaps are 10 mm and 8 mm old type of design. We can use the 10 mm Rotocaps in inlet valves and<br />

all exhaust valve seats should be fitted with new design of rotocaps.<br />

5. No oversize valve guides are used.<br />

6. Exhaust valves are Stellite. These will have to be replaced by hard nimonic valves.<br />

Page 4 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

Recommendations<br />

A. All inlet seats and valves to be replaced with 20 Deg seats and valves.<br />

B. 10 mm Rotocaps can be used in inlet valves and all exhaust valve seats should be fitted with new<br />

design of rotocaps.<br />

C. Oversizing of exhaust seat pocket is max 1 mm only in <strong>18V32</strong>. The max recommended size is 3mm.<br />

PISTON<br />

Observation from Last maintenance report & Recommendations<br />

1. Customer has never replaced piston skirts, gudgeon pins and most of the crowns.<br />

2. Piston of both Mahle and KS were used.<br />

3. 9 crowns in <strong>18V32</strong> were renewed that can be inspected and based on measurement values can be for<br />

reused in standby DG set.<br />

4. Piston have 3 compression and 1 oil scrapper ring.<br />

5. All piston will need replacement for LN stage II conversion.<br />

CYLINDER LINER<br />

Observation from Last maintenance report & Recommendations<br />

1. All the liners were equipped with APR(Anti Polishing rings).<br />

2. 9-10 liners were close to wear limits of <strong>18V32</strong> at the time of overhaul.<br />

3. 5 new liners in <strong>18V32</strong> were fitted during the overhaul that can be reused in the standby engine.<br />

4. No water in engine water passages increases the risk of corrosion. As the engine was operated till<br />

January 2010<br />

CONNECTING ROD<br />

Observation from Last maintenance report & Recommendations<br />

1. All the connecting Rod are H profile.<br />

2. <strong>18V32</strong> - Maximum Deviation/ovality recorded in last overhaul is 0.020 mm. The limit for rejection is<br />

0.10 mm. This shows the connecting rods are in very good shape.<br />

3. <strong>18V32</strong> - All small end bushes are also in ok condition.<br />

GEAR TRAIN<br />

Observation from Last maintenance report & Recommendations<br />

1. The gear train is hydraulically tightened screw type.<br />

2. <strong>18V32</strong> - The gear train bush was inspected and found ok. Customer stated that the gear train bush<br />

were replaced at every 24K overhaul.<br />

3. <strong>18V32</strong> - General observation comments, backlash and journal diameter measurement indicates good<br />

condition of components.<br />

GOVERNOR<br />

Observation from Last maintenance report & Recommendations<br />

1. Engine is controlled with an electronic Woodward governor with 721 controller and hydraulic<br />

actuator.<br />

2. <strong>18V32</strong> - Drive shaft, clamping ring, gear and bush were renewed in last overhaul. Same drive shaft<br />

can be reused.<br />

Page 5 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

GEAR PUMPS(HT, LT & Lube Oil), THERMOSTAT, PHE & PIPING<br />

Observation from Last maintenance report & Recommendations<br />

1. General condition of the parts was o.k.<br />

2. <strong>18V32</strong> - One drive gear of HT pump was renewed.<br />

3. Sealing sets used were not from <strong>Wartsila</strong>.<br />

4. Cavitation was observed in Lube Oil pump. Same can be inspected and casing might need<br />

replacement.<br />

5. PHE are of Alfa Laval make with clip on gaskets and can be reused after inspection.<br />

6. Housings are in good condition, elements will be changed based on condition.<br />

7. The engine is with Pipe module. The modules can be shifted along with all equipments.<br />

VALVE MECHANISM<br />

Observation from Last maintenance report & Recommendations<br />

1. <strong>18V32</strong> - All valve Guide blocks were overhauled in last overhaul.<br />

2. All worn out spares were replaced<br />

3. Rocker arm bushes needs replacement.<br />

FIP & INJECTION VALVE<br />

Observation from Last maintenance report & Recommendations<br />

Make - L`Orange<br />

Type - POGO 30E<br />

1. All Fuel pumps were overhauled and worn out parts replaced.<br />

Page 6 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

2. All pumps will need replacement for LN Stage II conversion.<br />

3. All FIV are of L’Orange Make will need replacement for LN stage II conversion.<br />

CAMSHAFT<br />

Observation from Last maintenance report & Recommendations<br />

1. Camshaft numbers are<br />

a. 18 V32, 1V14K0144/145<br />

b. 12V32, 1V14K0129/130<br />

2. Camshaft bushes were changed in past can be reused after inspection.<br />

3. Camshaft pieces needs replacement for LN stage II conversion<br />

CRANKSHAFT & FLEXIBLE COUPLING<br />

Observation from Last maintenance report & Recommendations<br />

1. All the pins are of standard size. All big end and main bearing are of standard dimensions.<br />

Coupling pads needs replacement as recommended in the overhauling report of <strong>18V32</strong>.<br />

TURBOCHARGERS<br />

Observation from Last maintenance report & Recommendations<br />

Make ABB<br />

<strong>18V32</strong> model - 354-11<br />

12V32 model - 304 P11<br />

1. Customer has never changed the shaft (recommended interval 100.000 hrs), compressor wheel<br />

(48,000 hrs), nozzle ring, gas inlet and outlet casings.<br />

2. Turbochargers needs replacement of shaft, compressor wheel and other components while conversion<br />

to LN stage II.<br />

ENGINE BLOCK & BASE FRAME<br />

Page 7 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

Observation from Last maintenance report & Recommendations<br />

1. The engine is installed on fixing rail with steel chocks and rubber pads are provided between fixing<br />

rail and foundation.<br />

2. The alternator is installed on steel chocks.<br />

3. No damage observed in engine block.<br />

4. Inside of engine block found clean.<br />

5. Water leakage marks observed at few places from liner seating surface. Block machining has been<br />

done in past at various cylinders.<br />

AUXILIARIES<br />

FUEL BOOSTER(Comman)<br />

Observation & Recommendations<br />

1. The fuel booster unit was manufactured at Khopoli, India and is in bad shape.<br />

2. The additional small panels above original panel indicates malfunctioning in original panel.<br />

3. The booster unit is without automatic filter.<br />

4. A new steam heater was installed recently by customer for reducing electrical auxiliary power.<br />

5. Complete booster needs replacement.<br />

Page 8 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

LUBE OIL SEPARATOR (individual)<br />

Observation & Recommendations<br />

Make - Alfa Laval<br />

Type - MOPX 207.<br />

1. The separator can be fully refurbished and reused after inspection at our Separator Works.<br />

LOCAL CONTROL PANEL(individual)<br />

Observation & Recommendations<br />

1. The local control panel is in bad shape. A panel on top of local panel of 4 <strong>MW</strong> genset indicates<br />

defective old panel.<br />

MAINTENANCE WATER TANK (common)<br />

Observation & Recommendations<br />

Found in ok condition, can be reused.<br />

Page 9 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

AIR COMPRESSOR UNIT (common) & AIR RECEIVER<br />

Observation & Recommendations<br />

Make IR<br />

1. The hour counter was removed.<br />

2. Air compressor unit visually is in ok condition and can be reused after refurbishing.<br />

3. Air receiver are in good condition and can be used after changing necessary gauges and automation.<br />

Page 10 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

CHARGE AIR FILTER& INTAKE AIR SILENCER<br />

Observation & Recommendations<br />

1. The filter and silencer are in ok condition and can be reused after repair.<br />

EXHUAST GAS SYSTEM & CHIMNEY<br />

Observation & Recommendations<br />

1. The exhaust gas bellows were removed and kept inside the plant. Condition of pipes can be checked<br />

only after removing the insulation. Exhaust stack is self supported type and can’t be<br />

shifted/transported.<br />

REAMINING COMPONENTS<br />

Observation & Recommendations<br />

1. Charge air cooler are never renewed. Air cooler must be replaced at the time of overhaul.<br />

2. Pipe module can be shifted but the fuel oil, raw water, DM water piping should be replaced. Only a<br />

little leakages were observed in hot box and at exhaust. Same can be inspected, recorded during<br />

running trials.<br />

3. DM/RO water hydrofore unit will be required additionally.<br />

4. Only volumetric flow meters were observed in bad condition. Which shows the SFC data was not<br />

calculated actually. Mass Flow meter should be installed at new installation.<br />

5. High Load turbine washing machine was also observed.<br />

6. Most of the gauges were missing/defective. Temperature sensors and pressure switches were also<br />

missing/faulty.<br />

7. Unloading unit, fuel storage tank, chimney and other auxiliaries were not inspected.<br />

8. Details of electrical components is in trailing electrical report for both the plants.<br />

Page 11 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

Plant III<br />

Plant II has following DG sets:<br />

3 x <strong>18V32</strong><br />

2 x <strong>18V32</strong><br />

DG #1(<strong>18V32</strong> D)<br />

ESN-4966<br />

Year of installation:- 1989<br />

Place of manufacturing-Vassa, Finland<br />

R/H of last major maintenance: 105635, dated 19-02-2007<br />

Present R/H-114,862<br />

DG #2(<strong>18V32</strong> D)<br />

ESN-4653<br />

Year of installation:- 1991<br />

Place of manufacturing-Vassa, Finland<br />

R/H of last major maintenance: 106668, dated 24-10-2005<br />

Present R/H-111,244<br />

DG #3(<strong>18V32</strong>E)<br />

ESN-7130<br />

Year of installation:- 1997<br />

Place of manufacturing-Khopoli, India<br />

R/H of last major maintenance: 80,675, dated 17-12-2008<br />

Present R/H-85,258<br />

DG #4(<strong>18V32</strong>E)<br />

ESN-7227<br />

Year of installation:- 1997<br />

Place of manufacturing-Khopoli, India<br />

R/H of last major maintenance: 81,970, dated 28-09-2007<br />

Present R/H-93,878<br />

DG #4(<strong>18V32</strong>E)<br />

ESN-7228<br />

Year of installation:- 1997<br />

Place of manufacturing-Khopoli, India<br />

R/H of last major maintenance: 89,838, dated 15-04-2009<br />

Present R/H-94,807<br />

Page 12 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

CYLINDER HEADS<br />

Visual Inspection<br />

1. The visual appearance of cylinder heads was clean. No deposits observed on rocker arm, springs,<br />

push rods and rotocaps.<br />

2. No leakage observed from exhaust clamp of cylinder heads. It appears that the exhaust manifold was<br />

repaired by customer.<br />

3. Both 10 mm and 8 mm rotocaps (old Type)observed. Inlet valves are also with Springs and rotocaps<br />

4. No water leakage observed from most of the cylinder head skirts.<br />

Observation from Last maintenance report<br />

DG #1<br />

1. All inlet seats & valves are of old design, needs replacement.<br />

2. No record of oversize seats.<br />

3. 13 number exhaust valves were renewed out of 22 rejected valves, which shows high wear rate.<br />

4. Rotocaps are 10 mm and 8 mm old type of design. We can use the 10 mm Rotocaps in inlet valves<br />

and all exhaust valve seats should be fitted with new design of rotocaps.<br />

5. No oversize valve guides are used. 21 guides replaced.<br />

6. Exhaust valves used are mix of Stellite, soft nimonic and hard nimonic.<br />

7. All the collars were machined at site to remove pits/avoid water leakage and assembled with one<br />

additional gasket. Same to be replaced.<br />

DG #2<br />

1. All inlet seats & valves replaced with new 20 deg versions. All parts used were not supplied by<br />

<strong>Wartsila</strong>.<br />

2. No record of oversize seats.<br />

3. 21 number exhaust valves were renewed which shows high wear rate.<br />

4. Rotocaps are 10 mm and 8 mm old type of design. We can use the 10 mm Rotocaps in inlet valves<br />

and all exhaust valve seats should be fitted with new design of rotocaps.<br />

5. No oversize valve guides are used.<br />

6. Exhaust valves used are mix of Stellite, soft nimonic and hard nimonic.<br />

DG #3<br />

1. All inlet seats & valves are of old design.<br />

2. No record of oversize seats.<br />

3. 15 number exhaust valves were renewed out of 17 rejected valves, which shows high wear rate.<br />

4. Rotocaps are 10 mm and 8 mm old type of design. We can use the 10 mm Rotocaps in inlet valves<br />

and all exhaust valve seats should be fitted with new design of rotocaps.<br />

5. No oversize valve guides are used.<br />

6. Exhaust valves used are mix of Stellite, soft nimonic and hard nimonic.<br />

DG #4<br />

1. All inlet seats & valves are of old design.<br />

2. No record of oversize seats.<br />

3. 12 number exhaust valves were replaced which shows high wear rate.<br />

4. Rotocaps are 10 mm and 8 mm old type of design. We can use the 10 mm Rotocaps in inlet valves<br />

and all exhaust valve seats should be fitted with new design of rotocaps.<br />

5. No oversize valve guides are used.<br />

6. Exhaust valves used are mix of Stellite, soft nimonic and hard nimonic.<br />

DG #5<br />

1. All inlet seats & valves are of old design.<br />

Page 13 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

2. 5 pockets oversize by 1-2mm.<br />

3. 15 number exhaust valves were renewed out of 20 rejected valves, which shows high wear rate.<br />

4. Rotocaps are 10 mm and 8 mm old type of design. We can use the 10 mm Rotocaps in inlet valves<br />

and all exhaust valve seats should be fitted with new design of rotocaps.<br />

5. No oversize valve guides are used.<br />

6. Exhaust valves used are mix of Stellite, soft nimonic and hard nimonic.<br />

Recommendations<br />

A. All inlet seats and valves of older version to be replaced with 20 Deg seats and valves.<br />

B. 10 mm Rotocaps can be used in inlet valves and all exhaust valve seats should be fitted with new<br />

design of rotocaps.<br />

C. Over sizing of exhaust seat pocket is 1mm, 2 mm and 3 mm for 4 cylinder heads . The max<br />

recommended size is 3mm.<br />

PISTON<br />

Observation from Last maintenance report & Recommendations<br />

1. Customer has never replaced gudgeon pins and some of the skirts as indicated in work reports.<br />

2. New crowns in these engines can be inspected and based on measurement values can be for reused in<br />

standby DG set.<br />

3. Piston have 3 compression and 1 oil scrapper ring.<br />

4. Mix of Mahle and KS piston is indicated in the records.<br />

5. All piston will need replacement for LN stage II conversion.<br />

CYLINDER LINER<br />

Observation from Last maintenance report & Recommendations<br />

1. All the liners were equipped with APR(Anti Polishing rings).<br />

2. Most of the liners are close to wear limits.<br />

3. New liners fitted during the overhaul can be reused in the standby engine.<br />

4. No water in engine water passages increases the risk of corrosion.<br />

5. Most of the liner are with strong back ring design. Same needs to be changed with new design.<br />

6. Water leakage from liner seating surface observed in most of the engines. All the liner seating surface<br />

needs machining. For example 16 out of 18 cylinder liner of DG #2 were machined in last overhaul<br />

and shims were added.<br />

Page 14 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

CONNECTING ROD<br />

Observation from Last maintenance report & Recommendations<br />

1. All the connecting Rod are H profile.<br />

2. <strong>18V32</strong> - Maximum Deviation/ovality recorded in last overhaul is 0.04 mm. The limit for rejection<br />

is 0.10 mm. This shows the connecting rods are in very good shape.<br />

3. Most of small end bushes are close to or have crossed the limits for rejection. For example all the<br />

bushes of DG #3 were above rejection limit in last overhaul and only one was replaced.<br />

4. Some of the connecting rods of DG #1 were used in DG #3. This indicates DG #3 requires some<br />

additional connecting rods.<br />

GEAR TRAIN<br />

Observation from Last maintenance report & Recommendations<br />

1. The gear train in all engines is hydraulically tightened screw type.<br />

2. The gear train bush were inspected and not replaced in most of the engines. Customer stated that the<br />

gear train bush were replaced at every 24K overhaul.<br />

GOVERNOR<br />

Observation from Last maintenance report & Recommendations<br />

1. Engine is equipped with Woodward hydraulic governor. All governor needs calibration and<br />

overhaul.<br />

2. Back lash of all drive shafts is within limits. Same drive shafts can be reused.<br />

Page 15 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

GEAR PUMPS(HT, LT & Lube Oil), THERMOSTAT, PHE & PIPING<br />

Observation from Last maintenance report & Recommendations<br />

1. Sealing sets used were not from <strong>Wartsila</strong>.<br />

2. Water pump shaft and impeller of DG #2 needs replacement.<br />

3. Cavitation was observed in Lube oil pump of DG #3 and same was recommended for replacement.<br />

Casing of LO pump of DG #2 was replaced in last overhaul.<br />

4. Lube oil pump of DG #1 was used in DG#4.<br />

5. PHE are of Alfa Laval and some local make with clip on as well as stick on gaskets. PHE with clip<br />

on gasket can be reused after inspection.<br />

6. Thermostat housings are in good condition, elements will be changed based on condition.<br />

VALVE MECHANISM<br />

Observation from Last maintenance report & Recommendations<br />

1. All valve Guide blocks were overhauled and worn parts were not replaced.<br />

Page 16 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

2. Rocker arm bushes needs replacement.<br />

FIP & INJECTION VALVE<br />

Observation from Last maintenance report & Recommendations<br />

Make - L`Orange<br />

Type - POGO 30<br />

1. All Fuel pumps were overhauled and worn out parts were not replaced in the last overhauls.<br />

2. All pumps will need replacement for LN Stage II conversion.<br />

CAMSHAFT<br />

Observation from Last maintenance report & Recommendations<br />

4. Camshaft numbers are<br />

a. 3 x 18 V32E, 1V14K0144/145<br />

b. 1 x <strong>18V32</strong>, 1V14K022/27<br />

c. 1 x <strong>18V32</strong>, 1V14K092/93<br />

5. Camshaft bushes were not changed in past needs replacement.<br />

6. Camshaft pieces needs replacement for LN stage II conversion<br />

CRANKSHAFT & FLEXIBLE COUPLING<br />

Observation from Last maintenance report & Recommendations<br />

1. All the pins are of standard size. All big end and main bearing are of standard dimensions.<br />

Page 17 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

2. Coupling pads of all the engine needs replacement.<br />

TURBOCHARGERS<br />

Observation from Last maintenance report & Recommendations<br />

Make ABB/BBC<br />

2 x <strong>18V32</strong> model - 354 - 11(BBC)<br />

3 x <strong>18V32</strong> model - 354 P-11<br />

1. Customer has never changed the shaft (recommended interval 100.000 hrs), compressor wheel<br />

(48,000 hrs), nozzle ring, Gas inlet and outlet casings.<br />

2. Turbochargers needs replacement of shaft, compressor wheel and other components while<br />

conversion to LN stage II.<br />

ENGINE BLOCK & BASE FRAME<br />

Observation from Last maintenance report & Recommendations<br />

1. 3 x <strong>18V32</strong> - The engine is installed on fixing rail with steel chocks and rubber pads are provided<br />

between fixing rail and foundation.<br />

2. 2 x <strong>18V32</strong> - The engine is installed on rubber pads.<br />

3. 3 x <strong>18V32</strong> - The alternator is installed on steel chocks.<br />

4. No damage observed in engine block.<br />

5. Inside of engine block found clean.<br />

6. Water leakage marks observed at few places from liner seating surface. Block machining has been<br />

done in past at various cylinders.<br />

Page 18 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

AUXILIARIES<br />

FUEL BOOSTER(One for 3 x <strong>18V32</strong>E and one for 2 x <strong>18V32</strong>D ) Observation &<br />

Recommendations<br />

1. The fuel booster unit for 3 x <strong>18V32</strong>E was manufactured at Khopoli, India and is in bad shape.<br />

2. The fuel booster unit for 23 x <strong>18V32</strong>D was supplied by <strong>Wartsila</strong> Finland and is not in a condition for<br />

further use.<br />

3. The booster units are without automatic filter.<br />

4. Complete booster units needs replacement.<br />

LUBE OIL SEPARATOR (individual)<br />

Observation & Recommendations<br />

Page 19 of 21<br />

http://www.second-hand-power-plants.com/<br />

http://www.second-hand-powerplants.com/<br />

http://www.power-plant-market.com/<br />

http://www.powerplant-market.com/

------------------- Email: info@powerplant-market.com - Phone: +1 206-201-2420 -------------------<br />

Make - Alfa Laval<br />

Type - MOPX 207.<br />

1. The separator can be fully refurbished and reused after inspection at our Separator Works.<br />

AIR COMPRESSOR UNIT (common) & AIR RECEIVER<br />

Observation & Recommendations<br />

The compressor unit needs replacement.<br />

CHARGE AIR FILTER& INTAKE AIR SILENCER<br />

Observation & Recommendations<br />

1. The oil bath filter and silencer of 3 x <strong>18V32</strong> are in are in ok condition and can be reused after repair.<br />

2. 2 x <strong>18V32</strong> has marine type air filter.<br />

EXHUAST GAS SYSTEM & CHIMNEY<br />

Observation & Recommendations<br />