Air Force the Official Service Journal - Air Force Historical Studies ...

Air Force the Official Service Journal - Air Force Historical Studies ...

Air Force the Official Service Journal - Air Force Historical Studies ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

->",i"<br />

.""tJnil'et<br />

hj/'-<br />

By Col. Donald L. Putt<br />

Materiel Command<br />

FOR more than 25 vears, aeronautical engineers have experimented<br />

with pressurized cabins as <strong>the</strong> solution to<br />

problems of anoxia and bends encountered at high<br />

altitudes.<br />

The mechanical problem has been to build an airtight<br />

plane that can fly in <strong>the</strong> substratosphere where <strong>the</strong> air is<br />

thin and <strong>the</strong> pressure is low-an aircraft with a leak-proof<br />

cabin that would maintain low-altitude atmospheric pressure<br />

during high-altitude operations.<br />

Although <strong>the</strong> first tactical aircraft incorporating pressurization<br />

was <strong>the</strong> B-29, <strong>the</strong> AAF had launched its research<br />

program on pressurizing airplanes in 1919.<br />

There were two possible solutions to <strong>the</strong> problem. One<br />

was to force oxygen into <strong>the</strong> lungs through pressure masks<br />

worn at high altitudes; <strong>the</strong> o<strong>the</strong>r, to pressurize <strong>the</strong> cabin air.<br />

In 1919. Lt. Harold R. Harris, a test pilot, took off in an<br />

airplane with a sealed tank-like chamber covering <strong>the</strong> cockpit-<strong>the</strong><br />

first test flight of a pressure cabin. <strong>Air</strong> from a<br />

wind-driven blower mounted on <strong>the</strong> plane's wing was compressed<br />

in <strong>the</strong> cockpit. The test failed when <strong>the</strong> pressure<br />

control mechanism went havwirc. Instruments recorded a<br />

cabin temperature of I SO degrees and an altitude of 9,000<br />

feet below sea lcvcll<br />

Our cuzinccrs were faced with thc problem of designing<br />

<strong>the</strong> fuselage structure of airplanes to seal perfectly <strong>the</strong> joints,<br />

doors, windows and instruments. The project liad to wait<br />

because <strong>the</strong> proper planes wcrcu' t even on <strong>the</strong> drafting<br />

boards. Fifteen years had passed before <strong>the</strong> problem was<br />

tackled again. .<br />

In 19,4, \Vilev Post submitted a pressure snIt-a blown<br />

up pair of overalls made air tight \vith a rubberized .par~chute<br />

silk and an aluminum oxygen helmet-for expenmental<br />

test flights to high altitudes. The suit worked, but<br />

became of it: weight and bulk it greatly impaired movement<br />

of airmen.<br />

26<br />

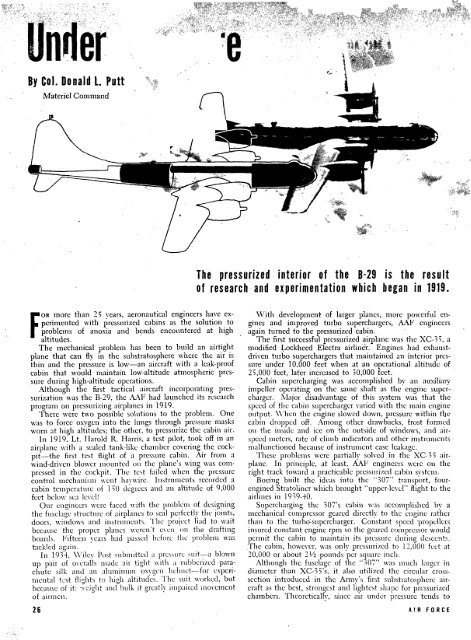

The pressurized interior of <strong>the</strong> 8.29 is <strong>the</strong> result<br />

of research and experimentation which began in 1919.<br />

With development of larger planes, more powerful engines<br />

and improved turbo superchargers, AAF engineers<br />

again turned to <strong>the</strong> pressurized cabin.<br />

The first successful pressurized airplane was <strong>the</strong> XC-)), a<br />

modified Lockheed Electra airliner. Engines had exhaustdriven<br />

turbo superchargers that maintained an interior pressure<br />

under 10,000 feet when at an operational altitude of<br />

25,000 feet, later increased to 30,000 feet.<br />

Cabin supercharging was accomplished by an auxiliary<br />

impeller operating on <strong>the</strong> same shaft as <strong>the</strong> engine supercharger.<br />

Major disadvantage of this system was that <strong>the</strong><br />

speed of <strong>the</strong> cabin supercharger varied with <strong>the</strong> main engine<br />

output. \\'hcn <strong>the</strong> engine slowed down, pressurc within <strong>the</strong><br />

cabin dropped off. Among o<strong>the</strong>r drawbacks, frost fanned<br />

on <strong>the</strong> inside and ice on thc outside of windows, and airspeed<br />

meters, rate of climb indicators and o<strong>the</strong>r instruments<br />

malfunctioned because of instrument case leakage.<br />

These problems were partially solved in <strong>the</strong> XC-,5 airplane.<br />

In principle, at least, AAF engineers were on <strong>the</strong><br />

right track toward a practicable pressurized cabin system.<br />

Boeing built <strong>the</strong> ideas into <strong>the</strong> ..30/" transport, fourengined<br />

Stratolincr which brought "upper-level" flight to <strong>the</strong><br />

airlines in 19~9-40.<br />

Supercharging <strong>the</strong> 307's cabin was accomplished hy a<br />

mechanical compressor geared directly to <strong>the</strong> engine ra<strong>the</strong>r<br />

than to <strong>the</strong> turbo-supercharger. Constant speed 'propellers<br />

insured constant engine rpm so <strong>the</strong> geared compressor would<br />

permit <strong>the</strong> cabin to maintain its pressurc during descents.<br />

Thc cabin, however, was only pressurized to 12,000 feet at<br />

20,000 or about 2V2 pounds per squarc inch.<br />

Although <strong>the</strong> fuselage of <strong>the</strong> "307" was much largcr in<br />

diameter than XC-3S's, it also utilized <strong>the</strong> circular crosssection<br />

introduced in <strong>the</strong> Army's first substratospherc aircraft<br />

as <strong>the</strong> best, strongest and lightcst shape for pressurized<br />

cham bers. Theoretically, since air under pressure tends to<br />

AIR FORCE