PLUNGER LIFT SYSTEMS - National Oilwell Varco

PLUNGER LIFT SYSTEMS - National Oilwell Varco

PLUNGER LIFT SYSTEMS - National Oilwell Varco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

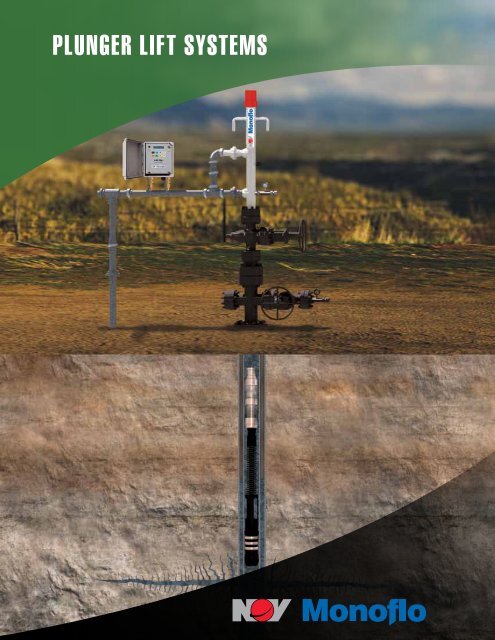

<strong>PLUNGER</strong> <strong>LIFT</strong> <strong>SYSTEMS</strong>

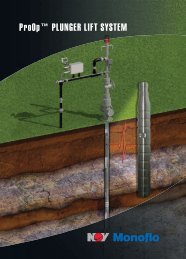

<strong>PLUNGER</strong> <strong>LIFT</strong> SYSTEM<br />

One Company, Unlimited Solutions<br />

Since 1841, <strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong> has been dedicated to ensuring customers receive the highest quality oilfield<br />

products and services. <strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong> is a worldwide leader in the design, manufacture and sale of equipment<br />

and components used in oil and gas drilling and production operations, the provision of oilfield services, and supply<br />

chain integration services to the upstream oil and gas industry. NOV also provides supply chain services through its<br />

network of more than 200 distribution service centers located near major drilling and production activity worldwide.<br />

We continue to build upon our unlimited, customer-focused solutions and are proud to deliver our Artificial Lift Systems<br />

through the NOV Monoflo division.<br />

NOV Monoflo<br />

Artificial Lift Systems<br />

Coverage<br />

The NOV Monoflo division is a true partner and worldwide source for complete Artificial Lift equipment and packaged<br />

solutions. Our Artificial Lift professionals collaborate with you to properly evaluate well conditions and provide customized<br />

artificial lift solutions that will optimize your production.<br />

• Professional Well Evaluation<br />

• Surface and Subsurface Equipment<br />

• Controllers and Production Automation<br />

• All Production Accessories and Expendables<br />

• Global Supply Chain and Service Solutions<br />

LLOYDMINSTER, CANADA HOUSTON, TEXAS

Understanding the Production Challenge<br />

Plunger Lift technology is a cost effective and efficient technique to deliquify and optimize oil and gas production in<br />

wells which have nominal flow trends. By optimizing production and reducing operating costs, each well becomes<br />

more profitable. When wells first begin producing, gas and fluids flow to the surface naturally. However, consistent,<br />

natural flow usually won’t last long. Liquid begins to collect against the walls of the tubing and starts to fall back<br />

accumulating at the bottom of the well. Liquid fall back continues and slugs of fluid are produced. As fluid slugs travel<br />

to the surface, as much as 75% of the fluid may fall back and continue to accumulate downhole. This accumulation<br />

of fluid is known as “liquid loading” and can be detrimental to well production. Without assistance, the column of<br />

fluid will grow too heavy for gas to pass through…and the well stops producing.<br />

Delivering the Right Solution<br />

A Plunger Lift System is an ideal solution for these well conditions. The plunger system uses an interface seal<br />

between the accumulated fluid and the stored gas in the annulus. The well is shut-in to allow the plunger to travel to<br />

the bottom which creates a bottomhole seal and well pressure to build. After a period of shut-in time, the head gas<br />

is blown down creating differential pressure across the plunger which brings the plunger to surface. As the plunger<br />

travels up the tubing, it lifts the fluid column to surface and a turbulent seal is formed which practically eliminates<br />

liquid fall back. The fluid column is lifted up and out allowing the well to produce again.<br />

The NOV Monoflo plunger lift system is the most economical and environmentally friendly form of artificial lift<br />

technology on the market today. The system is comprised of a well specific plunger, a bottom hole bumper spring,<br />

a specialized lubricator and catcher assembly, our electronic ControlOp controller, a motor valve and an arrival<br />

sensor. With the advanced controls and wide variety of optimization solutions, NOV Monoflo is able to offer a cost<br />

effective and environmentally friendly solution.<br />

Application Expertise<br />

The NOV Monoflo Plunger Lift System is the ideal solution for a wide range of applications and conditions including:<br />

• Dewatering liquid loading gas wells<br />

• Wells with high gas-to-oil ratio<br />

Controller<br />

Lubricator<br />

Arrival<br />

Sensor<br />

• Wells that are currently being soaped<br />

• Paraffin and hydrate control<br />

Dual Pad<br />

Plunger<br />

Bottom Hole<br />

Bumper Spring<br />

www.nov.com/ArtificialLift<br />

MonofloALS@nov.com

<strong>PLUNGER</strong> <strong>LIFT</strong> SYSTEM<br />

Plungers<br />

Our plungers are available in a variety of models and sizes, manufactured with the objective of improving production<br />

rates and operating in various well conditions. Contact us for information on sizes and availability.<br />

Pad Plungers<br />

Our pad plungers utilize a unique pad design to provide<br />

superior seal efficiency and rugged durability for clean<br />

well bore fluid conditions. Available in either a single or<br />

dual pad configuration.<br />

• The raised shoulder design on the fish neck gives<br />

additional durability and energy displacement<br />

• Interlocking pad design provides superior gas and fluid<br />

seal<br />

• Built rugged utilizing a dual support rail design<br />

• Stainless steel design applicable for both sweet and<br />

sour applications<br />

Bypass Plungers<br />

The bypass plunger is designed for faster fall time by<br />

allowing fluid to flow through the plunger rather than<br />

around it. Designed to be deployed while the well is<br />

producing.<br />

• The mechanical seal allows more gas bypass which<br />

results in a faster fall and less downtime<br />

• Removable plugs allow for customized fall rates<br />

• Contoured rings allow for a superior turbulent seal<br />

• The bypass functionality allows the plunger to fall<br />

against the production flow<br />

• Available in 4140 alloy steel for sweet service or stainless<br />

steel for sour service.<br />

Bar Stock Plungers<br />

Our bar stock plungers are low maintenance and ideal<br />

for wells that require paraffin and scale control.<br />

• The raised shoulder design on the fish neck gives<br />

additional durability and energy displacement<br />

• Built in wear grooves for easy service<br />

• Can be easily modified for a variety of tubing<br />

conditions<br />

• The rifled top and bottom create a helical rotation that<br />

produces a superior turbulent seal (Rifled Plunger Only)<br />

• Available in 4140 alloy steel for sweet service or stainless<br />

steel for sour service.<br />

Brush Plungers<br />

Our brush plungers are designed for maximum sealing<br />

efficiency sandy conditions.<br />

• The raised shoulder design on the fish neck gives<br />

additional durability and energy displacement<br />

• Excellent sealing efficiency<br />

• Ideal for use in wells that require sand removal both<br />

produced and Frac<br />

• Durable 6.6 Nylon Brush design for harsh conditions<br />

• Designed with a replaceable brush for superior<br />

economics<br />

• Available in 4140 alloy steel for sweet service or stainless<br />

steel for sour service.

Bottom Hole Bumper Springs<br />

NOV Monoflo bottomhole bumper spring<br />

assemblies are designed to absorb the impact of<br />

the plunger when it reaches the bottom of the well.<br />

Various seating assemblies can be used (e.g.: hold<br />

down, seal stop, tubing stop, collar stop) depending<br />

on the application. We offer bumper springs in<br />

various sizes and materials suitable for use in sweet<br />

and sour service environments. All of our bumper<br />

springs are designed for maximum flow area without<br />

compromising strength. A ball and seat can also be<br />

used to retain liquids in the tubing string.<br />

• Easy to set and retrieve<br />

• Large flow area<br />

• The raised shoulder design on the fish<br />

neck gives additional durability and energy<br />

displacement<br />

• Stainless steel material<br />

• Spring material available in Inconel X750, and<br />

MP35<br />

Lubricators<br />

NOV Monoflo lubricators are spring-loaded receivers<br />

designed to cushion the arrival of the plunger at<br />

the surface. The lubricator has a catcher designed<br />

to catch the plunger upon arrival which allows the<br />

operator to retrieve and inspect it. Available in a<br />

variety of sizes and in special materials built rugged<br />

for the harshest environments.<br />

• Built to API 6A specifications<br />

• Field serviceable<br />

• Suitable for high pressure applications<br />

• Sweet and Sour service available<br />

• Cold temperature material good to -50°C<br />

• Threaded and Flanged available<br />

• Single and Dual Port available<br />

• Threaded and Bowen Union available<br />

• Extensive testing, pressure, hydro, and X-ray<br />

www.nov.com/ArtificialLift<br />

MonofloALS@nov.com

<strong>PLUNGER</strong> <strong>LIFT</strong> SYSTEM<br />

Controllers<br />

NOV Monoflo provides a complete range of electronic self-optimizing controllers for plunger lift systems that can<br />

help optimize plunger cycles and increase production. Many of the benefits of using controllers are:<br />

• Well head sensing and control<br />

• Flexible application programming<br />

• Field proven reliability<br />

• Wireless sensor networking<br />

• Remote access and control<br />

• Compatible with online services<br />

• Intrinsic Safety certification<br />

Lift Op TM<br />

Well Head<br />

Production<br />

Control<br />

Time Op TM<br />

Well Head<br />

Controller<br />

Trip Op TM<br />

Arrival<br />

Sensor<br />

Features Applications<br />

• Simple to Use - intuitive keypad layout<br />

• LCD Display Manager - customized LCD displays<br />

• Rugged and Durable - NEMA 4X rated enclosure<br />

• Wireless Networking - add sensors and controls<br />

• Simple Sensor Hook-Up - Removable terminal blocks<br />

• SCADA Ready - Modbus RTU protocol<br />

• Multi-Valve Operation - single or dual valve control<br />

• Sensor Measurement - pressure, flow and plunger<br />

• Easy to Use Control Panel - simplifies setup and operation<br />

• Sealed Control Panel - for ultimate protection<br />

• Lifetime Sealed Battery - never needs changing<br />

• Built-In Solar Charger - self-starting and maintaining<br />

• Rugged, Durable Enclosure - shatterproof solar panel<br />

• Industry Standard For Reliability<br />

• Minimum 1 Second Pulse<br />

• Robust, Electronic Output Switch<br />

• 2-Wire or 3-Wire Hook-up<br />

• Multiple Hook-up Configurations<br />

• I.S. Class 1, Division 1 Certified<br />

• Weatherproof Design<br />

• Well Intermitting<br />

• Plunger / Gas Lift<br />

• De-Watering<br />

• Compressor Control<br />

• Automated Soaping<br />

• Chemical Injection<br />

• Flow Measurement<br />

• Flow Rate Control<br />

• Remote Access<br />

• Data Logging<br />

• Stripper Well Timer<br />

• Pressure Switch Control<br />

• Plunger Lift Controller<br />

• Compressor Controller<br />

• Tank Battery Control<br />

• Pipeline Maintenance<br />

• Plunger Arrival Sensing

Control Op TM<br />

Sensors<br />

Control Op TM<br />

Valve<br />

Controller<br />

Control Op TM<br />

3X Pulse<br />

Counter<br />

Control Op TM<br />

Data Router<br />

Control Op TM<br />

Uplink<br />

Manager<br />

Features Applications<br />

• Static Pressure Sensors - 0-2000 psi, non-ratiometric<br />

• DP Transmitter - 0-138 InW flowing differential<br />

• Two Switch Inputs - Dry contact or 0-30Vdc logic<br />

• Two Switch Outputs - low side, 20 V @ 2 A drive<br />

• Digital Gauge Set Points - low, window, high<br />

• Data logging - selectable sample rate<br />

• Network Ready - Bluetooth 802.15.4 wireless<br />

• Modbus RTU Slave - R/W coils and data registers<br />

• One or Two Solenoid Valves - pneumatic dual-port valves<br />

• Individual Valve Control - separate timers and controls<br />

• Versatile Cycle Control - day-of-week and time-of-day<br />

• Two Switch Inputs - dry contact or 0-30Vdc logic<br />

• Two Switch Outputs - low side, 20 V @ 2 A drive<br />

• Data logging - selectable sample rate<br />

• Network Ready - Bluetooth 802.15.4 wireless<br />

• Modbus RTU Slave - R/W coils and data registers<br />

• Three Pulse Counters - 4-byte binary counters<br />

• High Count Rate - up to 32 kHz count rate<br />

• +10 Vdc Sensor Power - logic On/Off power control<br />

• Data Logging - automatic count data logs<br />

• Rechargable Batteries - high capacity NiMh AA cells<br />

• Six Event Tags - High and Low counts<br />

• Network Ready - Bluetooth 802.15.4 wireless<br />

• Modbus RTU Slave - R/W coils and data registers<br />

• Analog Voltage Outputs - settable zero, span and units<br />

• Flexible Unit Conversions - English and metric scales<br />

• Floating Point Calculations - high resolution and precision<br />

• Two Switch Outputs - low side, 20 V @ 2 A drive<br />

• Two Switch Inputs - Dry contact or 0-30Vdc logic<br />

• Digital Gauge Set Points - low, window, high<br />

• Network Ready - Bluetooth 802.15.4 wireless<br />

• Modbus RTU Slave - R/W coils and data registers<br />

• RS-232/485 Serial Port - 9600, 19.2k and 38.4k baud<br />

• Network Uplink - centralized data collection<br />

• Two Switch Outputs - low side, 20 V @ 2 A drive<br />

• Two Switch Inputs - Dry contact or 0-30Vdc logic<br />

• Network Coordinator - links sensors and controls<br />

• Data Logging - network data repository<br />

• Network Ready - Bluetooth 802.15.4 wireless<br />

• Modbus RTU Slave - R/W coils and data registers<br />

• Pressure Monitoring<br />

• Flow Measurement<br />

• Digital Switch Gauge<br />

• Check Flow Meter<br />

• Automation Sensors<br />

• Well Head Control<br />

• Gas Allocation Meter<br />

• Compressor Control<br />

• Pneumatic Control<br />

• Intermitter/Timer<br />

• Plunger/Gas Lift<br />

• Chemical Injection<br />

• Pipeline Maintenance<br />

• Compressor Control<br />

• Distributed Controls<br />

• Mass Flow Sensors<br />

• RPM Monitoring<br />

• Stroke Counters<br />

• Event Counting<br />

• Distributed Controls<br />

• Gas Flow Sensors<br />

• Frequency Meter<br />

• Frequency Converter<br />

• Switch Translation<br />

• Digital Signal Router<br />

• Analog Voltage Translation<br />

• Switch Event Logger<br />

• Analog Data Router<br />

• Plunger / Gas Lift<br />

• Compressor Control<br />

• Well Head Control<br />

• Remote System Control<br />

• SCADA Interface<br />

• Multiple Well Control<br />

• Digital Signal Router<br />

• Oil and Gas Production<br />

• Waste Management<br />

• Water Management<br />

• Limit Monitoring<br />

www.nov.com/ArtificialLift<br />

MonofloALS@nov.com

Corporate<br />

Headquarters<br />

7909 Parkwood Circle Drive<br />

Houston, Texas 77036<br />

United States<br />

Phone: 713 375 3700<br />

Fax: 713 346 7687<br />

Sales<br />

8708 West Little York Road<br />

Suite 100<br />

Houston, Texas 77040<br />

United States<br />

Phone: 281 854 0300<br />

Fax: 281 854 0301<br />

<strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong> has produced this brochure for general information only, and it is not<br />

intended for design purposes. Although every effort has been made to maintain the accuracy and<br />

reliability of its contents, <strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong> in no way assumes responsibility for liability for any<br />

loss, damage or injury resulting from the use of information and data herein. All applications for the<br />

material described are at the user’s risk and are the user’s responsibility.<br />

One Company . . . Unlimited Solutions<br />

Downhole Solutions<br />

Drilling Solutions<br />

Engineering and Project Management Solutions<br />

Industrial Solutions<br />

Lifting and Handling Solutions<br />

Production Solutions<br />

Supply Chain Solutions<br />

Tubular and Corrosion Control Solutions<br />

Well Service and Completion Solutions<br />

MonofloALS@nov.com www.nov.com<br />

© 2013 <strong>National</strong> <strong>Oilwell</strong> <strong>Varco</strong><br />

All Rights Reserved<br />

D392002611-MKT-001 Rev. 04