Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1.1.4 Nickel–Alkene Complexes 65<br />

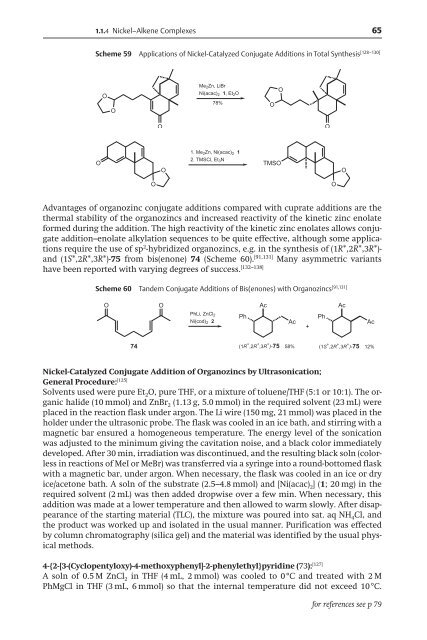

Scheme 59 Applications of Nickel-Catalyzed Conjugate Additions in Total Synthesis [128–130]<br />

O<br />

O<br />

O<br />

O<br />

O<br />

O<br />

Me 2Zn, LiBr<br />

Ni(acac) 2 1, Et2O<br />

78%<br />

1. Me2Zn, Ni(acac)2 1<br />

2. TMSCl, Et 3N<br />

O<br />

O<br />

TMSO<br />

Advantages of organozinc conjugate additions compared with cuprate additions are the<br />

thermal stability of the organozincs and increased reactivity of the kinetic zinc enolate<br />

formed during the addition. The high reactivity of the kinetic zinc enolates allows conjugate<br />

addition–enolate alkylation sequences to be quite effective, although some applications<br />

require the use of sp 2 -hybridized organozincs, e.g. in the synthesis of (1R*,2R*,3R*)and<br />

(1S*,2R*,3R*)-75 from bis(enone) 74 (Scheme 60). [91,131] Many asymmetric variants<br />

have been reported with varying degrees of success. [132–138]<br />

Scheme 60 Tandem Conjugate Additions of Bis(enones) with Organozincs [91,131]<br />

O O<br />

74<br />

PhLi, ZnCl2<br />

Ni(cod)2 2<br />

Ph<br />

Ac<br />

Ac<br />

(1R ∗ ,2R ∗ ,3R ∗ )-75 58%<br />

+<br />

Ph<br />

O<br />

O<br />

O<br />

Ac<br />

Ac<br />

(1S ∗ ,2R ∗ ,3R ∗ )-75 12%<br />

Nickel-Catalyzed Conjugate Addition of Organozincs by Ultrasonication;<br />

General Procedure: [125]<br />

Solvents used were pure Et 2O, pure THF, or a mixture of toluene/THF (5:1 or 10:1). The organic<br />

halide (10 mmol) and ZnBr 2 (1.13 g, 5.0 mmol) in the required solvent (23 mL) were<br />

placed in the reaction flask under argon. The Li wire (150 mg, 21 mmol) was placed in the<br />

holder under the ultrasonic probe. The flask was cooled in an ice bath, and stirring with a<br />

magnetic bar ensured a homogeneous temperature. The energy level of the sonication<br />

was adjusted to the minimum giving the cavitation noise, and a black color immediately<br />

developed. After 30 min, irradiation was discontinued, and the resulting black soln (colorless<br />

in reactions of MeI or MeBr) was transferred via a syringe into a round-bottomed flask<br />

with a magnetic bar, under argon. When necessary, the flask was cooled in an ice or dry<br />

ice/acetone bath. A soln of the substrate (2.5–4.8mmol) and [Ni(acac) 2](1; 20 mg) in the<br />

required solvent (2 mL) was then added dropwise over a few min. When necessary, this<br />

addition was made at a lower temperature and then allowed to warm slowly. After disappearance<br />

of the starting material (TLC), the mixture was poured into sat. aq NH 4Cl, and<br />

the product was worked up and isolated in the usual manner. Purification was effected<br />

by column chromatography (silica gel) and the material was identified by the usual physical<br />

methods.<br />

4-{2-[3-(Cyclopentyloxy)-4-methoxyphenyl]-2-phenylethyl}pyridine (73): [127]<br />

A soln of 0.5 M ZnCl 2 in THF (4 mL, 2 mmol) was cooled to 08C and treated with 2 M<br />

PhMgCl in THF (3 mL, 6 mmol) so that the internal temperature did not exceed 108C.<br />

for references see p 79