cpgp3.SmithVicente.QAY 1081..12

cpgp3.SmithVicente.QAY 1081..12

cpgp3.SmithVicente.QAY 1081..12

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

a17.8 Product Class 8:<br />

Porphyrins and Related Compounds<br />

K. M. Smith and M. G. H. Vicente<br />

General Introduction<br />

Previously published information regarding this product class can be found in Houben–<br />

Weyl, Vol. 4/1b, p 828 and Vol. E 9d, pp 577–833.<br />

Porphyrins and related compounds, such as chlorins, are tetrapyrrole systems which<br />

provide the basic chromophore for a host of biologically important natural products.<br />

Principal examples are the hemes (iron complexes found in hemoglobins, myoglobins,<br />

cytochromes, catalases, and peroxidases) and the chlorophylls and bacteriochlorophylls<br />

(dihydro- and tetrahydroporphyrin–magnesium complexes found in photosynthetic organisms).<br />

There also exist a number of nonnatural contracted and expanded porphyrin<br />

systems, which have been invented as vehicles for comparative investigation of the effects<br />

of ring size on the chemistry and spectroscopy of porphyrins. Examples of contracted<br />

systems are the corroles, which have one of the porphyrin interpyrrolic carbon atoms<br />

missing, and sapphyrins and pentaphyrins, both of which have no less than five pyrrole<br />

subunits within their chromophores.<br />

The field has been extensively reviewed in the very recent past; The Porphyrin Handbook<br />

(published in 2000) is a 10-volume, 3500-page, 61-chapter treatise dealing with all aspects<br />

of porphyrins and related compounds; [1] volumes 11 through 20 were published in<br />

2003. Prior to these, two versions of Porphyrins and Metalloporphyrins were published (in<br />

1975 [2] and 1964 [3] ) and a multivolume series, The Porphyrins, appeared between 1977 and<br />

1979. [4] From time to time, reviews of specific areas of the porphyrin research field have<br />

appeared, and four which are relevant to the present chapter can be found in Rodd s Chemistry<br />

of the Carbon Compounds, [5,6] and Total Syntheses of Natural Products. [7,8]<br />

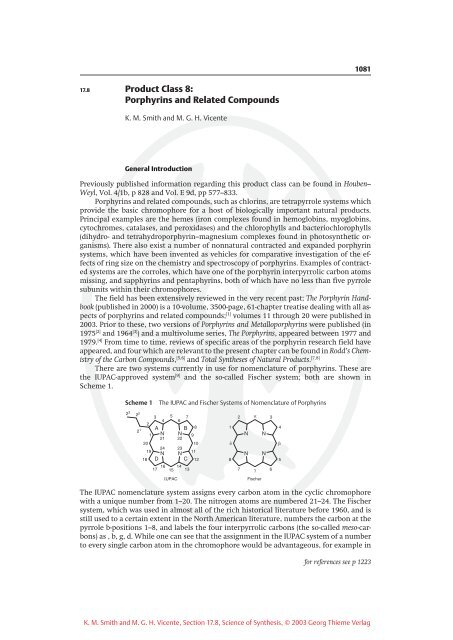

There are two systems currently in use for nomenclature of porphyrins. These are<br />

the IUPAC-approved system [9] and the so-called Fischer system; both are shown in<br />

Scheme 1.<br />

Scheme 1 The IUPAC and Fischer Systems of Nomenclature of Porphyrins<br />

23<br />

2 2<br />

2 1<br />

2<br />

3<br />

A<br />

4<br />

5<br />

6<br />

7<br />

B 8<br />

1 N<br />

21<br />

N<br />

22<br />

9<br />

20<br />

10<br />

19<br />

24<br />

N<br />

23<br />

N<br />

11<br />

18 D C 12<br />

17<br />

16<br />

15<br />

14<br />

13<br />

IUPAC<br />

N N<br />

N N<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

1<br />

δ<br />

2 α 3<br />

The IUPAC nomenclature system assigns every carbon atom in the cyclic chromophore<br />

with a unique number from 1–20. The nitrogen atoms are numbered 21–24. The Fischer<br />

system, which was used in almost all of the rich historical literature before 1960, and is<br />

still used to a certain extent in the North American literature, numbers the carbon at the<br />

pyrrole b-positions 1–8, and labels the four interpyrrolic carbons (the so-called meso-carbons)<br />

as , b, g, d. While one can see that the assignment in the IUPAC system of a number<br />

to every single carbon atom in the chromophore would be advantageous, for example in<br />

8<br />

7<br />

γ<br />

Fischer<br />

6<br />

4<br />

β<br />

5<br />

1081<br />

for references see p 1223

1082 Science of Synthesis 17.8 Porphyrins and Related Compounds<br />

abiosynthetic studies, the earlier Fischer system carried with it a very convenient subnomenclature<br />

of trivial names; whether or not the IUPAC system is being used by an investigator,<br />

these trivial names are still used in abundance! The examples protoheme IX<br />

(“heme”, 1), protoporphyrin IX (2), coproporphyrin III (3), uroporphyrin I (4), chlorophyll<br />

a (5, R 2 = Me), chlorophyll b (5, R 2 = CHO), chlorin e 6 (6, R 1 = Me), and rhodin g 7 (6,<br />

R 1 = CHO) are shown in Scheme 2.<br />

Scheme 2 Typical Natural Porphyrin Derivatives<br />

HO 2C<br />

HO 2C<br />

HO 2C<br />

5 R 1 =<br />

N N<br />

Fe<br />

N N<br />

1<br />

NH N<br />

N HN<br />

R 1 O 2C<br />

R 2 = Me, CHO<br />

3<br />

CO2H<br />

CO2H<br />

N N<br />

Mg<br />

N N<br />

13 2<br />

MeO 2C<br />

CO 2H<br />

R 2<br />

E 13 1<br />

O<br />

Et<br />

NH N<br />

N HN<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

HO2C<br />

HO 2C<br />

HO 2C<br />

HO 2C<br />

HO 2C<br />

HO2C<br />

2<br />

NH N<br />

N HN<br />

4<br />

CO 2H<br />

CO 2H<br />

NH N<br />

N HN<br />

CO 2H<br />

CO2H<br />

R 1<br />

CO 2H<br />

CO2H<br />

CO2H 6 R 1 = Me, CHO<br />

Though Scheme 2 might appear to indicate otherwise, there is in fact a system hidden<br />

within Fischer s trivial nomenclature. Porphyrins that have the same two different substituents<br />

on each pyrrole subunit, for example, methyl and ethyl, can have a maximum<br />

of four so-called “primary type-isomers” (structures 7–10) as indicated in Roman<br />

numerals in Scheme 3.<br />

Et

17.8.4 Isomeric, Contracted, and Expanded Porphyrin Systems 1083<br />

aScheme 3 The Four Primary Type-Isomers of the Etioporphyrins<br />

Et<br />

Et<br />

Et<br />

Et<br />

NH N<br />

I<br />

N HN<br />

7<br />

NH N<br />

III<br />

N HN<br />

9<br />

Et<br />

Et<br />

Et<br />

Et<br />

Et<br />

Et Et<br />

NH N<br />

N HN<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

Et<br />

II<br />

8<br />

Et Et<br />

NH N<br />

IV<br />

N HN<br />

When the substituents on each pyrrole subunit are methyl and ethyl, the series is called<br />

“etioporphyrin”. If instead, the substituents are methyl and propanoic acid the series is<br />

“coproporphyrin” or if they are acetic and propanoic acids they are “uroporphyrins”.<br />

These names are historically derived. For example, coproporphyrins are not very watersoluble<br />

and are therefore excreted in the feces, while uroporphyrins are extremely water-soluble<br />

and are excreted in the urine. The normal metabolites of heme are of the “primary<br />

type-isomer III” orientation, though “type I” is occasionally found in some disease<br />

states. If one has three (rather than two) types of substituent spread around the chromophore,<br />

with one identical substituent (usually methyl) common to each pyrrole subunit,<br />

there are 15 possible type-isomers. Protoporphyrin IX is the natural “secondary type-isomer”<br />

in heme metabolism and this can be seen to be related to “primary type-isomer III”<br />

by further modification of the non-methyl substituents of rings A and B in coproporphyrin<br />

III in the latter (Scheme 2). “Proto” simply refers to the importance of this molecule; its<br />

protiodevinylated analogue (3,8-di-H in place of 3,8-divinyl) is named “deuteroporphyrin<br />

IX” because it was regarded as the second most important porphyrin, and contrary to the<br />

assumption of many journal editors, deuteroporphyrin contains no deuterium! The trivial<br />

nomenclature employed for chlorophyll a and b derivatives, such as chlorin e 6 and rhodin<br />

g 7, is unfathomable, and is best left alone (though it is worth knowing that the subscript<br />

Arabic numeral refers to the number of oxygen atoms in the molecule).<br />

Scheme 4 Structures of Porphyrin, Chlorin, Bacteriochlorin, and Isobacteriochlorin<br />

R 1<br />

R 8<br />

R 2 R 3<br />

R 7<br />

NH N<br />

N HN<br />

11<br />

R 6<br />

R 4<br />

R 5<br />

R 2<br />

R 1<br />

R 10<br />

10<br />

R4 R3 R 9<br />

N HN<br />

NH N<br />

12<br />

Et<br />

R 5<br />

R 8<br />

Et<br />

R 6<br />

R 7<br />

for references see p 1223

1084 Science of Synthesis 17.8 Porphyrins and Related Compounds<br />

R 2<br />

aN<br />

R<br />

HN<br />

1<br />

R 12<br />

R4 R3 R 11<br />

NH N<br />

13<br />

R 5<br />

R 6<br />

R 7<br />

R10 R9 R8 N N<br />

NH HN<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

R 2<br />

R 1<br />

R 12<br />

R4 R3 R 11<br />

14<br />

R6 R5<br />

Porphyrins 11 are aromatic macrocycles containing a total of 22 conjugated p-electrons.<br />

At any one time only 18 p-electrons participate in the delocalization pathway, two other<br />

double bonds being cross conjugated. Porphyrins conform with Hückel s [4n+2] rule for<br />

aromaticity (n = 4). Therefore, one or two of the peripheral double bonds of porphyrins<br />

can undergo addition reactions to form chlorins 12, bacteriochlorins 13, or isobacteriochlorins<br />

14 (shown in Scheme 4), without interfering with the delocalization pathway<br />

or introducing any major loss of aromatic character. Chlorins and bacteriochlorins are,<br />

however, progressively less aromatic than porphyrins qualitatively because fewer resonance<br />

structures can be drawn for the more reduced chromophores. The positions<br />

around the porphyrin periphery available, for example for electrophilic aromatic substitution,<br />

are the unsubstituted b-pyrrolic positions (at 2, 3, 7, 8, 12, 13, 17, and 18 in 11),<br />

and the four meso positions at 5, 10, 15, and 20. X-ray studies [10,11] indicate that the numerous<br />

C—C and the C—N bonds in 1 are almost equivalent. NMR spectroscopic, [12] X-ray, and<br />

theoretical studies [13,14] show that the thermodynamically most-favored tautomers for<br />

symmetrically substituted porphyrins are the degenerate trans-NH-tautomers depicted<br />

in 15 and 17 (Scheme 5). The mechanism for N–H migration between porphyrin trans-tautomers<br />

appears to proceed in a stepwise manner, via the less-favored cis-tautomers, such<br />

as 16. [15]<br />

The favored pathways for delocalization of the p-electrons in free-base porphyrins, in<br />

metal porphyrinates, and in porphyrin dications are also shown in Scheme 5. The peripheral<br />

b-positions of metal porphyrinates and porphyrin dications display similar reactivities,<br />

whereas the two opposite b–b¢ double bonds in free-base porphyrins experience<br />

more double-bond character. In the case of free-base chlorins, the most stable trans-tautomers<br />

(e.g., 18) appear to be those in which the imine-type nitrogens are on the reduced<br />

pyrrole subunit D and its opposite ring B. Though both forms of chlorin trans-tautomers<br />

18 and 19 have been observed experimentally, X-ray studies [10,11] and ab initio calculations<br />

[16] indicate that 18 is the major tautomer. The predominant p-electron delocalization<br />

pathway for free-base chlorins 18 causes the double bond of ring B to be the preferred<br />

site for electrophilic aromatic substitutions and addition reactions. In metal chlorinates,<br />

based on experimental observations, the preferred b-pyrrolic reaction sites are<br />

those in rings A and C, either side of the reduced pyrrole subunit. In metal porphyrinates,<br />

consideration of the various resonance structures leads to structure 20 as the resonance<br />

hybrid.<br />

Scheme 5 Tautomeric and Resonance Forms of Porphyrin, Metal Complex, Dication, and<br />

Chlorin<br />

NH N<br />

N HN<br />

15<br />

NH HN<br />

N N<br />

16<br />

R 10<br />

R 7<br />

R 8<br />

R 9<br />

N HN<br />

NH N<br />

17

A B<br />

aNH N<br />

17.8.1 Porphyrins 1085<br />

R 1<br />

R 2<br />

R 3 R 4<br />

N HN<br />

D C<br />

N N<br />

M<br />

N N<br />

N N<br />

M<br />

N N<br />

R 1<br />

R 2<br />

N N<br />

M<br />

N N<br />

N N<br />

M<br />

N N<br />

R 3 R 4<br />

NH N<br />

N HN<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

18<br />

N N<br />

M<br />

N N<br />

N N<br />

M<br />

N N<br />

R 1<br />

R 2<br />

R 3 R 4<br />

N HN<br />

NH N<br />

19<br />

N N<br />

M<br />

N N<br />

20 M = metal, 2H +<br />

Although they have been shown to be more electron-rich than the b-positions, the meso<br />

positions of the porphyrin system 11 are often sterically hindered, especially when two of<br />

the abutting b-positions are occupied by substituents. The b-pyrrolic positions, therefore,<br />

are sterically favored and tend to undergo electrophilic substitution and addition reactions.<br />

In metal-free porphyrins, the central nitrogen atoms readily react with electrophilic<br />

reagents and are easily protonated and metalated. In metal porphyrinates the central<br />

nitrogen atoms play an important role (both chemically and biologically) in the transmission<br />

of electronic information from the metal ion and its axial ligands to the porphyrin psystem,<br />

and vice versa. In chlorins, the meso positions adjacent to the reduced (nonaromatic)<br />

pyrrole unit are more electron rich and are correspondingly more reactive toward<br />

electrophilic reagents. [17]<br />

17.8.1 Product Subclass 1:<br />

Porphyrins<br />

There are many methods available for the synthesis of porphyrins, and these have been<br />

reviewed in the recent past. [18–21] The synthetic route to be used should depend upon the<br />

symmetry and the complexity of the various peripheral substituents on the target porphyrin.<br />

For example, it would be wasteful in time and resources to attempt the synthesis<br />

of 2,3,7,8,12,13,17,18-octaethylporphyrin (OEP, 21; Scheme 6) by way of a laborious multistep<br />

fabrication of an open-chain tetrapyrrolic intermediate, followed by cyclization to<br />

produce the porphyrin macrocycle; symmetrically substituted compounds such as 21 are<br />

most efficiently synthesized by polymerization of a suitable monopyrrole. On the other<br />

hand, without help from enzymes which participate in the biosynthesis of heme and<br />

chlorophylls, there is no possibility that protoporphyrin IX (2) could be synthesized by a<br />

monopyrrole self-condensation route; with such complex asymmetric target molecules,<br />

highly sophisticated multistep chemical approaches are the only way that this can be accomplished.<br />

for references see p 1223

1086 Science of Synthesis 17.8 Porphyrins and Related Compounds<br />

aScheme 6 Structures of Octaethylporphyrin and meso-Tetraphenylporphyrin<br />

Et<br />

Et<br />

Et Et<br />

Et<br />

NH N<br />

N HN<br />

21<br />

Et<br />

Et<br />

Et<br />

Ph<br />

NH N<br />

N HN<br />

The porphyrin field has a very rich history, which has produced numerous Nobel laureates.<br />

Hans Fischer [22–24] was unquestionably the major personality in porphyrin synthesis<br />

and chemistry in the 20th century. Fischer s group in Munich was responsible for<br />

much of the fundamental porphyrin synthetic chemistry that has been used since. New<br />

principles of contemporary organic chemistry and new reagents have been developed<br />

(benzyl esters, tert-butyl esters, diborane, catalytic hydrogenation, etc.), but Fischer must<br />

be credited with the basic philosophy that we all still employ. For porphyrin synthesis,<br />

Fischer s choice of intermediates were dipyrromethenes (see Section 17.8.1.1.1.1), and in<br />

the 1920s and 1930s the Munich school developed many approaches based on these dipyrrolic<br />

intermediates. However, methodologies for differential protection of reactive functional<br />

groups had not yet been developed, so syntheses of unique porphyrins without<br />

contamination by other isomers and congeners were usually not possible in Fischer s<br />

time. The problems of symmetry inherent when two dipyrromethenes are used to construct<br />

a porphyrin were fully understood; when syntheses were ambiguous and mixtures<br />

of porphyrins resulted, methods were developed to enable the separation of these mixtures.<br />

Ingenious use of substituent polarity differences usually allowed the mixtures to<br />

be separated. Moreover, in Fischer s time it was a straightforward matter to synthesize<br />

porphyrins (and mixtures of porphyrins) on the gram scale, thereby permitting development<br />

of separation methodology such as countercurrent distribution, solvent extraction,<br />

based on Willstätter s acid numbers, crystallization, and later, chromatography.<br />

Modern practitioners of the art of porphyrin synthesis have preferred to design their<br />

routes so that one unique porphyrin is the product; the scale of a research reaction also<br />

rarely exceeds 100 milligrams of product porphyrin. Separation of synthetic porphyrin<br />

mixtures, these days, is regarded as inelegant, even though chromatographic methods<br />

for separation (including high-performance liquid chromatography) have improved dramatically.<br />

Hence, very complex porphyrins with diverse substituents have, in the recent<br />

past, been approached via routes involving characterizable open-chain tetrapyrrolic intermediates.<br />

The task then reduces to a search for conditions, which will allow relatively<br />

labile side chains to be carried through reaction sequences intact, and will not scramble<br />

the often acid-labile pyrrole rings in oligopyrrole intermediates.<br />

Scheme 7 depicts the various bond-forming strategies of syntheses of porphyrins. Approaches<br />

A and B involve the tetramerization of monopyrroles. Case A utilizes a pyrrole<br />

(which must have identical substituents on its 3- and 4-positions to avoid production of<br />

mixtures) and an interpyrrolic one-carbon unit; the classic example here is the reaction<br />

of pyrrole with benzaldehyde to give 5,10,15,20-tetraphenylporphyrin (TPP, 22; Scheme<br />

6). In Scheme 7, case B, the interpyrrolic carbon is already affixed to the 2-position of the<br />

pyrrole; strangely enough, because of acid-catalyzed pyrrole ring redistribution reactions,<br />

the 3- and 4-positions must also usually possess identical substituents, and such an approach<br />

is the method of choice for synthesis of 2,3,7,8,12,13,17,18-octaethylporphyrin<br />

(OEP, 21). Mode C represents a new development in which two different pyrroles (one<br />

with two interpyrrolic carbons, and one with none) are condensed together to give one<br />

porphyrin only. Methods D–F in Scheme 7 employ dipyrrolic precursors. In case D, a sin-<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

Ph<br />

Ph<br />

22<br />

Ph

17.8.1 Porphyrins 1087<br />

agle dipyrromethane is treated with a reagent carrying a one-carbon linker (e.g., a formaldehyde<br />

equivalent, or benzaldehyde); in this case the dipyrromethane self-condenses, so<br />

use of two dipyrromethanes will yield a mixture of three porphyrins. Example E involves<br />

reaction of two different dipyrromethanes or dipyrromethenes with each other; in this<br />

case the two required interpyrrolic carbons are attached to one or other of the dipyrromethanes,<br />

and for synthesis of a unique porphyrin product, one or other of the dipyrromethanes<br />

must be symmetrically substituted about the dipyrromethane 5-(meso)-carbon.<br />

When dipyrromethanes are used in case E, the approach is one of the variations of the socalled<br />

MacDonald [2+2] route; use of dipyrromethenes in this approach was pioneered by<br />

Fischer. Scheme 7, case F also depicts the MacDonald route [25] when a dipyrromethane is<br />

used, or a variation of the Fischer method when a dipyrromethene is used. In this case, a<br />

single dipyrromethane or dipyrromethene bearing one interpyrrolic carbon is self-condensed<br />

to give a centrosymmetric porphyrin; use of two dipyrromethanes or dipyrromethenes<br />

will afford a mixture of three porphyrin products.<br />

Scheme 7 Common Bond Formations in Porphyrin Syntheses<br />

N N<br />

N N<br />

A<br />

N N<br />

N N<br />

D<br />

N N<br />

N N<br />

G<br />

N N<br />

N N<br />

B<br />

N N<br />

N N<br />

E<br />

N N<br />

N N<br />

H<br />

N N<br />

N N<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

C<br />

N N<br />

N N<br />

F<br />

N N<br />

N N<br />

Mode G in Scheme 7 depicts the so-called [3+1] route to porphyrins, and methods H and I<br />

illustrate two examples of the open-chain tetrapyrrole route (using bilenes or a,c-biladienes,<br />

see Sections 17.8.1.1.3.2 and 17.8.1.1.3.3). Case H shows the approach when the<br />

final interpyrrolic carbon is added separately (as a formaldehyde or orthoformate equivalent,<br />

or simply as benzaldehyde), and in mode I the interpyrrolic carbon is pre-attached to<br />

the open-chain tetrapyrrole (seco-porphyrin).<br />

17.8.1.1 Syntheses of Intermediates Used in Porphyrin Syntheses<br />

No matter how simple or complex the target may be, porphyrin syntheses require the<br />

ready availability of functionalized monopyrrole building blocks. Syntheses and functionalization<br />

of such monopyrroles are outside the scope of this chapter, but these issues have<br />

been reviewed comprehensively by Black in Section 9.13, Science of Synthesis, Vol. 9 (Fully<br />

I<br />

for references see p 1223

1088 Science of Synthesis 17.8 Porphyrins and Related Compounds<br />

aUnsaturated Small-Ring Heterocycles and Monocyclic Five-Membered Hetarenes with<br />

One Heteroatom). The functionalization reactions of monopyrroles are also of key importance<br />

because approaches to porphyrins via oligopyrroles require that monopyrroles be<br />

selectively linked to other pyrroles in a rational and unambiguous way.<br />

17.8.1.1.1 Dipyrroles<br />

Previously published information regarding this product subclass can be found in Houben–Weyl,<br />

Vol. E 9b, pp 585–588.<br />

There are four types of dipyrrole unit that have been used extensively in syntheses of<br />

porphyrins and their ring-contracted and -expanded derivatives. These are dipyrromethenes<br />

(usually handled as the highly crystalline hydrobromide salts 23), dipyrromethanes<br />

24, dipyrroketones 25, and bipyrroles 26 (Scheme 8). An added level of complexity<br />

is related to whether or not the dipyrroles are symmetrically substituted about<br />

some central point in the molecule (e.g., the 5-position in 23–25). For the purposes of generality<br />

in the syntheses of porphyrins, the unsymmetrically functionalized dipyrroles are<br />

clearly the most useful; it also follows that they are the most difficult to prepare. Unsymmetrical<br />

dipyrromethenes and dipyrromethanes are invariably approached using methodology<br />

that employs differential protection of substituents on the two constituent pyrrole<br />

rings. Symmetrical examples, on the other hand, can often be obtained by some kind<br />

of self-condensation of a monopyrrole, or by treatment of two moles of a monopyrrole<br />

with a one-carbon reagent which will provide the 5-carbon. Both types of approach will<br />

be discussed here. In the case of bipyrroles 26, which are not actually synthetic precursors<br />

of normal porphyrin systems, only symmetrical routes have been developed to date.<br />

Scheme 8 Common Dipyrrolic Intermediates<br />

R 2<br />

R 2<br />

R 3 R 4<br />

R<br />

NH HN<br />

5<br />

R1 R6 +<br />

Br −<br />

R 3 R 4<br />

NH HN<br />

R 1 R 6<br />

24<br />

17.8.1.1.1.1 Method 1:<br />

Dipyrromethenes<br />

R 5<br />

R 2<br />

23<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

R 2<br />

R3 R4 O<br />

NH HN<br />

R 1 R 6<br />

25<br />

R 3 R 4<br />

R<br />

NH HN<br />

5<br />

R1 R6 +<br />

Br −<br />

For historical reasons, dipyrromethene synthesis will be dealt with first, though they are<br />

little used in contemporary porphyrin synthesis.<br />

17.8.1.1.1.1.1 Variation 1:<br />

Condensation of 2-Formyl-1H-pyrroles with 2-Unsubstituted 1H-Pyrroles<br />

The best and most commonly used method for the preparation of unsymmetrically substituted<br />

dipyrromethenes (e.g., 29) is the condensation of a 2-formyl-1H-pyrrole 27 with a<br />

2-unsubstituted 1H-pyrrole 28 in the presence of acid; the product is often obtained in virtually<br />

quantitative yield, provided it is isolated as the salt 29 (Scheme 9). [26] Because of<br />

R 5<br />

R2 4<br />

R 1<br />

5<br />

R3 3<br />

N<br />

H<br />

2 2'<br />

26<br />

R 4<br />

3'<br />

N<br />

H<br />

5'<br />

R5 4'<br />

R 6

17.8.1 Porphyrins 1089<br />

atheir acid–base chemistry, dipyrromethenes tend to spread widely on chromatography<br />

columns, so crystallization is usually the best method for isolation, and recrystallization<br />

for purification.<br />

Scheme 9 Condensation of 2-Formyl-1H-pyrroles with 2-Unsubstituted 1H-Pyrroles [26,27]<br />

HO2C<br />

N<br />

H<br />

27<br />

Et<br />

CHO<br />

+<br />

N<br />

H<br />

28<br />

NH HN<br />

+<br />

Br −<br />

29<br />

3-Ethyl-2,8,9-trimethyldipyrromethene-1-carbocylic Acid Hydrobromide (29); Typical<br />

Procedure: [27]<br />

4-Ethyl-5-formyl-3-methyl-1H-pyrrole-2-carboxylic acid (27; 2.4 g, 13.25 mmol) and 2,3-dimethyl-1H-pyrrole<br />

(28; 1.2 g, 12.61 mmol) were suspended in AcOH (6 mL) and treated, after<br />

cooling, with 48% HBr (2 mL). Scratching the container with a glass rod caused the dipyrromethene<br />

hydrobromide to crystallize from soln. After 1 h the solid was collected by<br />

filtration and washed with AcOH/Et 2O. The dipyrromethene salt 29 was obtained by recrystallization<br />

(AcOH); yield: 3.3 g (77%); mp 1708C.<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

HBr<br />

77%<br />

Et<br />

HO 2C<br />

17.8.1.1.1.1.2 Variation 2:<br />

Reaction of 2-(Bromomethyl)-1H-pyrroles with 2-Bromo-1H-pyrroles<br />

Heating of 2-(bromomethyl)-1H-pyrroles, e.g. 31 (obtained in situ by bromination of the<br />

corresponding 2-methyl-1H-pyrrole 30), with the same 2-bromo-1H-pyrrole 30 (synthesized<br />

by bromination of 2-unsubstituted 1H-pyrrole 32) and bromine affords good yields<br />

of dipyrromethene hydrobromides 33 (Scheme 10). [28]<br />

Scheme 10 Reaction of 2-(Bromomethyl)-1H-pyrroles with 2-Bromo-1H-pyrroles [28]<br />

Br<br />

Br<br />

N<br />

H<br />

30<br />

N<br />

H<br />

31<br />

Br 2<br />

CO2Et<br />

CO2Et<br />

Br<br />

+<br />

Br<br />

N<br />

H<br />

32<br />

N<br />

H<br />

30<br />

Br 2<br />

CO2Et<br />

CO2Et<br />

Br 2, AcOH<br />

37%<br />

EtO2C<br />

Br<br />

NH HN<br />

+<br />

Br −<br />

33<br />

CO 2Et<br />

Diethyl 1-Bromo-2,7,9-trimethyldipyrromethene-3,8-dicarboxylate Hydrobromide (33);<br />

Typical Procedure: [28]<br />

Ethyl 5-bromo-2,4-dimethyl-1H-pyrrole-3-carboxylate (30; 1.2 g, 4.88 mmol) was dissolved<br />

in AcOH and treated with Br 2 (0.8 g, 5.00 mmol). The soln turned red and HBr gas was given<br />

off. The solid product was collected by filtration and washed with EtOH then Et 2O. Recrystallization<br />

(acetone/H 2O) gave 33; yield: 0.66 g (37%); mp >2608C.<br />

for references see p 1223

1090 Science of Synthesis 17.8 Porphyrins and Related Compounds<br />

a17.8.1.1.1.1.3 Variation 3:<br />

Self-Condensation of Monopyrroles<br />

Very useful dipyrromethenes, the so-called “brominated kryptodipyrromethenes” 35 and<br />

36, can be obtained by treatment of kryptopyrrole 34 with bromine in hot acetic acid<br />

(Scheme 11). [29] If the 2-tert-butyl ester 1H-pyrrole 37 is used, [30] dipyrromethene 36 can<br />

be obtained pure. These dipyrromethene salts can be separated by crystallization (based<br />

upon the relative insolubility of the perbromide salt 35), or used as a mixture in formic<br />

acid for the synthesis of etioporphyrin I (see Section 17.8.1.2).<br />

Dipyrromethenes (e.g., 39) which are symmetrically substituted about the 5-(meso)carbon<br />

are prepared by self-condensation of 2-unsubstituted 1H-pyrroles 38 (R 1 =H) or<br />

1H-pyrrole-2-carboxylic acids 38 (R 1 =CO 2H) in boiling formic acid containing hydrobromic<br />

acid. [31]<br />

Scheme 11 Self-Condensation of Monopyrroles [29–33]<br />

Et<br />

Et<br />

Et<br />

N<br />

H<br />

34<br />

N<br />

H<br />

37<br />

N<br />

H<br />

CO2Bu t<br />

R 1<br />

38 R 1 = H, CO2H<br />

Br 2, AcOH, heat<br />

Br 2, Et 2O<br />

56−70%<br />

1. HCO2H, heat<br />

2. HBr<br />

R1 = H 37%<br />

Et<br />

NH HN<br />

+<br />

Br −<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

Et<br />

Br<br />

35<br />

Et<br />

Br<br />

NH HN<br />

+<br />

Br −<br />

36<br />

Et<br />

Br<br />

Et Et<br />

NH HN<br />

+<br />

Br −<br />

39<br />

+<br />

Et<br />

Br<br />

NH HN<br />

+<br />

Br −<br />

1-Bromo-9-(bromomethyl)-3,8-diethyl-2,7-dimethyldipyrromethene Hydrobromide (36);<br />

Typical Procedure: [30]<br />

A rapidly stirred soln of tert-butyl 4-ethyl-3,5-dimethyl-1H-pyrrole-2-carboxylate (37; 20g,<br />

89.6 mmol) in Et 2O (600 mL) was treated with Br 2 (4.8 mL, 93.4 mmol) in Et 2O (400 mL),<br />

adding the Br 2 soln over a period of 2 or 3 min. The soln was stirred for a further 30 min<br />

and then added dropwise over a period of 1 h to a stirred soln of Br 2 (9.6 mL, 187.1 mmol)<br />

in Et 2O (800 mL). After 30 min the mixture was placed in a refrigerator and left overnight.<br />

The product was collected by filtration, washed with ice-cold Et 2O, and then dried in vacuo<br />

to give 36; yield: 12–15 g (56–70%); mp >300 8C.<br />

2,8-Diethyl-3,7-dimethyldipyrromethene Hydrobromide (39); Typical Procedure: [32,33]<br />

3-Ethyl-4-methyl-1H-pyrrole (38, R 1 = H; 3 g, 27.5 mmol) was treated with dry HCO 2H<br />

(30 mL) and heated for 5 min on a boiling water bath. After cooling, the mixture was treated<br />

with aq HBr (6 mL) and left to stand for 12 h. The product 39 was collected by filtration;<br />

yield: 1.57 g (37%); mp 1708C<br />

36<br />

Et<br />

Br

17.8.1 Porphyrins 1091<br />

a17.8.1.1.1.1.4 Variation 4:<br />

Oxidation of Dipyrromethanes<br />

Controlled oxidation of dipyrromethanes 40, for example with iron(III) chloride or bromine,<br />

[26,34] also provides a convenient route to dipyrromethenes 41 (Scheme 12). The bromine-promoted<br />

oxidation method has also been widely used for the identification of dipyrromethanes<br />

on analytical thin-layer chromatography plates; exposure of a developed<br />

plate to bromine vapor causes colorless dipyrromethanes to turn red-pink (dipyrromethene<br />

salt) thereby enabling their identification in mixtures of products.<br />

Scheme 12 Oxidation of Dipyrromethanes [26,34]<br />

R 2<br />

R 3<br />

NH HN<br />

40<br />

R 4<br />

R 1 R 6<br />

17.8.1.1.1.2 Method 2:<br />

Dipyrromethanes<br />

R 5<br />

FeCl3 or Br2<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

R 2<br />

R 3<br />

R<br />

NH HN<br />

5<br />

+<br />

X −<br />

R1 R6 17.8.1.1.1.2.1 Variation 1:<br />

Unsymmetrically Substituted Dipyrromethanes by Reaction of 2-Substituted<br />

1H-Pyrroles with 2-Unsubstituted 1H-Pyrroles<br />

Unsymmetrically substituted dipyrromethanes, e.g. 44, can be prepared by condensation<br />

of 2-(acetoxymethyl)-1H-pyrroles 42 with 2-unsubstituted 1H-pyrroles 43 in methanol or<br />

acetic acid containing a catalytic amount (

1092 Science of Synthesis 17.8 Porphyrins and Related Compounds<br />

aScheme 13 Unsymmetrically Substituted Dipyrromethanes by Reaction of 2-Substituted<br />

1H-Pyrroles with 2-Unsubstituted 1H-Pyrroles [35,38–43]<br />

BnO 2C<br />

BnO2C<br />

R 1<br />

R 1<br />

R 1<br />

R 2<br />

R 2<br />

R 2<br />

Et<br />

N<br />

H<br />

47<br />

N<br />

H<br />

50<br />

N<br />

H<br />

42<br />

N<br />

Me<br />

45<br />

R 3<br />

R 3<br />

CO 2Me<br />

Et<br />

SePh<br />

Br<br />

OAc<br />

OAc<br />

+<br />

+<br />

+<br />

Et<br />

Et<br />

N<br />

H<br />

43<br />

N<br />

H<br />

43<br />

R 4 R 5<br />

N<br />

H<br />

48<br />

R 6<br />

CO 2Bn<br />

CO2Bn<br />

R 4 R 5<br />

A B<br />

HO2C A<br />

N<br />

H<br />

51<br />

py<br />

R 3<br />

+<br />

N<br />

Br −<br />

+<br />

LiO 2C<br />

N<br />

H<br />

52<br />

R 4 R 5<br />

B<br />

N<br />

H<br />

53<br />

LiOMe<br />

MeOH<br />

TsOH, MeOH<br />

MeO 2C<br />

BnO2C<br />

NH HN<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

93%<br />

K-10 clay<br />

CH2Cl2 90%<br />

A: CuOTf•benzene<br />

CH2Cl2, −78 oC B: benzene, heat<br />

R 6<br />

R 6<br />

heat<br />

Et<br />

BnO 2C<br />

R 2<br />

R 2<br />

R 1<br />

R 1<br />

Et<br />

R 3<br />

R 3<br />

44<br />

NMe HN<br />

46<br />

NH HN<br />

49<br />

A B<br />

NH HN<br />

54<br />

Et<br />

Et<br />

R 4<br />

R 4<br />

CO2Bn<br />

CO 2Bn<br />

Dibenzyl 7-Ethyl-3-[2-(methoxycarbonyl)ethyl]-2,8-dimethyldipyrromethane-1,9-dicarboxylate<br />

(44); Typical Procedure: [35]<br />

A suspension of benzyl 5-(acetoxymethyl)-4-[2-(methoxycarbonyl)ethyl]-3-methyl-1H-pyrrole-2-carboxylate<br />

(42; 373 mg, 1.0 mmol) and benzyl 4-ethyl-3-methyl-1H-pyrrole-2-carboxylate<br />

(43; 243 mg, 0.95 mmol) in MeOH (5 mL) was treated with TsOH (10 mg) and heated<br />

at 408C under N 2 with stirring for 5 h. The soln was diluted with H 2O (0.5 mL) and the<br />

dipyrromethane was collected by filtration. Recrystallization (CH 2Cl 2/hexanes) gave 44;<br />

yield: 520 mg (93%); mp 89–90 8C.<br />

Dibenzyl 2,3,7-Triethyl-N A,8-dimethyldipyrromethane-1,9-dicarboxylate (46); Typical<br />

Procedure: [43]<br />

Benzyl 5-(acetoxymethyl)-3,4-diethyl-1-methyl-1H-pyrrole-2-carboxylate (45; 1.70 g,<br />

4.95 mmol) was added to a well-stirred soln of benzyl 4-ethyl-3-methyl-1H-pyrrole-2-carboxylate<br />

(43; 1.20 g, 4.93 mmol) in CH 2Cl 2 (100 mL) containing a suspension of montmorillonite<br />

K-10 clay (20 g). After being stirred for 30 min the mixture was filtered free from<br />

R 6<br />

R 6<br />

R 5<br />

R 5

17.8.1 Porphyrins 1093<br />

athe clay and concentrated to dryness to afford the dipyrromethane 46 as a viscous oil;<br />

yield: 2.34 g (90%).<br />

Dipyrromethanes from 2-[(Phenylselenyl)methyl]-1H-pyrroles and 2-Unsubstituted 1H-<br />

Pyrroles; General Procedures: [40]<br />

Using Copper(I) Triflate: To a soln of 2-[(phenylselenyl)methyl]-1H-pyrrole (47; 0.2 mmol)<br />

and 2-unsubstituted 1H-pyrrole (48; 0.21 mmol) in dry degassed CH 2Cl 2 (5 mL) containing<br />

powdered CaCO 3 (0.24 mmol) at –78 8C under argon was added the benzene complex of<br />

copper(I) trifluoromethanesulfonate (0.12 mmol) in dry degassed benzene (0.5 mL) (CAU-<br />

TION: carcinogen). The mixture was stirred for 1–2 min at –788C, then poured into H 2O<br />

(20 mL), and extracted with CH 2Cl 2 (4 ” 10 mL). The combined organic extracts were washed<br />

with H 2O (20 mL). The solvent was removed and the product 49 was purified by preparative<br />

TLC (silica gel, hexanes/Et 2O 1:9).<br />

Thermal Method: The 2-[(phenylselenyl)methyl]-1H-pyrrole (47; 0.2 mmol) and 2-unsubstituted<br />

1H-pyrrole (48; 0.21 mmol) were heated in dry degassed benzene (10 mL)<br />

(CAUTION: carcinogen) under argon for 5 h. The workup was then as above for the copper(I)<br />

trifluoromethanesulfonate method.<br />

Dipyrromethanes from Pyrrole Pyridinium Salts and Lithium Carboxylate; General Procedure:<br />

[42]<br />

A soln of the 1H-pyrrole-2-carboxylic acid (52; 0.01 mol) and LiOMe (0.38 g, 0.01 mol) in<br />

warm aq MeOH (100 mL, 50%) was added to the 2-(bromomethyl)-1H-pyrrole (50;<br />

0.01 mol) in pyridine (3.2 mL, 0.04 mol). The mixture was refluxed on a steam bath for several<br />

hours under N 2. On cooling to rt the dipyrromethane crystallized and was collected<br />

by filtration, washed with H 2O, and dried. When ethylene glycol or HCONH 2 was used as<br />

solvent, the mixture was worked up by dilution with H 2O (ca. 1 L) and extracted with Et 2O<br />

(4 ” 150 mL). The Et 2O was dried (MgSO 4), concentrated to dryness, and the residue was<br />

chromatographed [alumina, petroleum ether (bp 60–80 8C)/toluene] to give 54.<br />

17.8.1.1.1.2.2 Variation 2:<br />

Unsymmetrically Substituted Dipyrromethanes by Reduction of<br />

Dipyrromethenes<br />

Reduction of dipyrromethenes, e.g. 55, with sodium borohydride also furnishes dipyrromethanes<br />

56 (Scheme 14). [44] Both symmetrical and unsymmetrical dipyrromethenes are<br />

available; this method is applicable to both.<br />

Scheme 14 Unsymmetrically Substituted Dipyrromethanes by Reduction of<br />

Dipyrromethenes [44]<br />

+<br />

H3N CO2Me<br />

NH HN<br />

+<br />

2Br −<br />

55<br />

NaBH4, H2O<br />

H2N CO2Me<br />

NH HN<br />

56<br />

for references see p 1223<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag

1094 Science of Synthesis 17.8 Porphyrins and Related Compounds<br />

a2-(2-Aminoethyl)-8-[2-(methoxycarbonyl)ethyl]-3,7-dimethyldipyrromethane (56); Typical<br />

Procedure: [44]<br />

2-(2-Aminoethyl)-8-[2-(methoxycarbonyl)ethyl]-3,7-dimethyldipyrromethene dihydrobromide<br />

(55; 1.0 g, 2.08 mmol) in deoxygenated distilled H 2O (60 mL) was treated with<br />

NaBH 4 (1.7 g, 44.9 mmol) in H 2O (30 mL) while a stream of N 2 was being passed through<br />

the soln. Effervescence took place and the red dipyrromethene color was immediately discharged.<br />

CH 2Cl 2 (100 mL) and 10% aq NaHCO 3 (30 mL) were added rapidly and, after separation,<br />

the organic phase was dried (Na 2SO 4), concentrated to dryness, and used immediately<br />

in the next reaction (to form the porphyrin in Woodward s chlorophyll a synthesis).<br />

17.8.1.1.1.2.3 Variation 3:<br />

Symmetrically Substituted Dipyrromethanes by Self-Condensation of<br />

2-Substituted 1H-Pyrroles<br />

Dipyrromethanes 59 which are symmetrically substituted about the 5-carbon are obtained<br />

in good yield by self-condensation of 2-(bromomethyl)-1H-pyrroles 58 (obtained<br />

from the corresponding 2-methyl-1H-pyrrole 57 by bromination in diethyl ether) in hot<br />

methanol, [45] or by heating 2-(acetoxymethyl)-1H-pyrroles 42 [obtained by treatment of<br />

the corresponding 2-methyl-1H-pyrrole 60 with lead(IV) acetate in acetic acid] in methanol/hydrochloric<br />

acid to give, for example, 61 [46] (Scheme 15); the mechanism for formation<br />

of 59 and 61 involves loss of one 2-CH 2X group.<br />

Scheme 15 Symmetrically Substituted Dipyrromethanes by Self-Condensation of<br />

2-Substituted 1H-Pyrroles [45–48]<br />

N<br />

H<br />

57<br />

CO 2Bn<br />

Br 2, Et 2O<br />

Br<br />

MeOH<br />

heat<br />

BnO 2C<br />

NH HN<br />

59 56%<br />

CO 2Bn<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

N<br />

H<br />

58<br />

CO 2Bn<br />

MeO2C MeO2C<br />

N<br />

H<br />

60<br />

CO2Bn<br />

Pb(OAc) 4<br />

AcOH<br />

AcO<br />

N<br />

H<br />

42<br />

CO2Bn<br />

BnO 2C<br />

MeOH, HCl, heat<br />

88%<br />

MeO 2C CO2Me<br />

NH HN<br />

61<br />

CO2Bn<br />

Dibenzyl 2,3,7,8-Tetramethyldipyrromethane-1,9-dicarboxylate (59); Typical<br />

Procedure: [47]<br />

Benzyl 3,4,5-trimethyl-1H-pyrrole-2-carboxylate (57; 2.0 g, 8.22 mmol) in rapidly stirred<br />

anhyd Et 2O (45 mL) was treated with Br 2 (0.5 mL, 9.73 mmol) in Et 2O (10 mL). The 2-(bromomethyl)-1H-pyrrole<br />

58 immediately precipitated from the soln, but the mixture was stirred<br />

for an additional 1.5 h before evaporation of the Et 2O(CAUTION: HBr gas) to give an<br />

orange residue of benzyl 5-(bromomethyl)-3,4-dimethyl-1H-pyrrole-2-carboxylate (58).

17.8.1 Porphyrins 1095<br />

aThe solid was dissolved in MeOH (25 mL) and refluxed for 4 h, then set aside at rt overnight.<br />

The product 59 was collected by filtration and recrystallized (CH 2Cl 2/petroleum<br />

ether); yield: 1.1 g (56%); mp 178–1798C.<br />

Dibenzyl 3,7-Bis[2-(methoxycarbonyl)ethyl]-2,8-dimethyldipyrromethane-1,9-dicarboxylate<br />

(61); Typical Procedure: [48]<br />

Benzyl 5-(acetoxymethyl)-4-[2-(methoxycarbonyl)ethyl]-3-methyl-1H-pyrrole-2-carboxylate<br />

(42; 320 mg, 0.857 mmol) in MeOH (5 mL) and HCl (d 1.18; 0.3 mL) was heated on a<br />

water bath for 4 h. After cooling the dipyrromethane 61 was collected by filtration; yield:<br />

230 mg (88%); mp 99–1008C.<br />

17.8.1.1.1.2.4 Variation 4:<br />

Symmetrically Substituted Dipyrromethanes from 2-Unsubstituted<br />

1H-Pyrroles<br />

2-Unsubstituted 1H-pyrroles such as 62, when treated with formaldehyde, give dipyrromethanes,<br />

e.g. 63. [49,50] A general method for 5-alkyldipyrromethane synthesis is available;<br />

[51] high yields of dipyrromethanes 64 and 65 can be obtained by using a 2-unsubstituted<br />

monopyrrole (e.g., 43 or 62, respectively) with dimethylacetals of aliphatic aldehydes<br />

and an acid catalyst (Scheme 16). 5-Substituted dipyrromethanes (usually 5-aryl derivatives,<br />

e.g. 66) can also be synthesized by treatment of an aldehyde (e.g., benzaldehyde)<br />

with an excess of 2-unsubstituted 1H-pyrrole (e.g., pyrrole) and an acid catalyst. [52]<br />

Scheme 16 Symmetrically Substituted Dipyrromethanes from 2-Unsubstituted 1H-<br />

Pyrroles [39,49–52]<br />

Et Et<br />

Et<br />

N<br />

H<br />

62<br />

N<br />

H<br />

43<br />

Et Et<br />

N<br />

H<br />

N<br />

H<br />

62<br />

CO 2Et<br />

CO2Bn<br />

CO2Et<br />

HCHO<br />

MeO<br />

PhCHO, TFA (cat.)<br />

49%<br />

OMe<br />

77%<br />

Et<br />

CO 2Me<br />

TsOH, toluene, heat<br />

OMe<br />

MeO CO 2Me<br />

EtO 2C<br />

NH HN<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

Et<br />

TsOH, K-10 clay, 1,4-dioxane, 70 o C<br />

66%<br />

Ph<br />

NH HN<br />

66<br />

63<br />

BnO 2C<br />

Et<br />

Et<br />

Et<br />

CO 2Et<br />

NH HN<br />

Et<br />

64<br />

EtO 2C<br />

CO2Me<br />

Et<br />

Et<br />

CO 2Bn<br />

CO2Me<br />

Et<br />

NH HN<br />

65<br />

Et<br />

CO 2Et<br />

for references see p 1223

1096 Science of Synthesis 17.8 Porphyrins and Related Compounds<br />

aDibenzyl 3,7-Diethyl-5-[(methoxycarbonyl)methyl]-2,8-dimethyldipyrromethane-1,9-dicarboxylate<br />

(64); Typical Procedure: [51]<br />

Benzyl 4-ethyl-3-methyl-1H-pyrrole-2-carboxylate (43; 3.31g, 13.6 mmol) in toluene<br />

(50 mL) was treated with TsOH (326 mg) and methyl 3,3-dimethoxypropanoate (1.0 mL,<br />

7.05 mmol). The mixture was heated at 120 8C for 5 h then CH 2Cl 2 was added and the organic<br />

layer washed with H 2O, brine, and then dried (Na 2SO 4). The solvent was removed<br />

under reduced pressure and the residue was flash chromatographed (silica gel, EtOAc/cyclohexane<br />

first 1:9, increasing to 1:5) to give 64 as a yellow foam; yield 2.98 g (77%).<br />

Diethyl 5-(Methoxycarbonyl)-2,3,7,8-tetraethyldipyrromethane-1,9-dicarboxylate (65);<br />

Typical Procedure: [39]<br />

Ethyl 3,4-diethyl-1H-pyrrole-2-carboxylate (62; 632 mg, 3.24 mmol) in 1,4-dioxane (7 mL)<br />

was treated with methyl dimethoxyacetate (0.15 mL, 3.24 mmol) and TsOH/K-10 clay (see<br />

below; 3 g). The mixture was stirred at 708C for 5 h before filtering off the clay. Evaporation<br />

of the filtrate gave a residue which was dissolved in CH 2Cl 2 and washed with aq NaH-<br />

CO 3 and then with brine. After drying (Na 2SO 4) the solvent was removed to give an oil<br />

which was then chromatographed (silica gel, CH 2Cl 2 then increasing amounts of THF).<br />

The appropriate eluates were collected and concentrated to give the product, which was<br />

crystallized (CHCl 3) to give 65; yield: 493 mg (66%); mp (slowly melts) 169–2118C.<br />

TsOH/K-10 clay: Dioxane (1 L) was saturated with TsOH. Montmorillonite K-10 clay<br />

was added until the mixture almost became too stiff to stir with a stirrer bar. The mixture<br />

was stirred overnight and then concentrated to dryness. The residual mixture was suspended<br />

in CH 2Cl 2 and then filtered and rinsed with THF and 1,4-dioxane to remove the<br />

excess of non-adsorbed TsOH from the clay. The clay was dried overnight in a vacuum<br />

oven at 528C.<br />

5-Phenyldipyrromethane (66); Typical Procedure: [52]<br />

A soln of benzaldehyde (0.1 mL, 1 mmol) and 1H-pyrrole (2.8 mL, 40 mmol) was degassed<br />

by bubbling argon through it for 10 min and then treated with TFA (0.008 mL, 0.1 mmol).<br />

The soln was stirred for 15 min at rt (TLC monitoring), before being diluted with CH 2Cl 2<br />

(50 mL), washed with 0.1 M aq NaOH and H 2O, and then dried (Na 2SO 4). The solvent was<br />

removed under reduced pressure, and unreacted 1H-pyrrole was removed by vacuum distillation<br />

at rt. The resulting yellow amorphous solid was dissolved in a small amount of<br />

the eluent and then purified by flash chromatography [silica gel (230–400 mesh), cyclohexane/EtOAc/Et<br />

3N 80:20:1). The dipyrromethane-containing fractions were collected<br />

and evaporated to give 66; yield: 110 mg (49%); mp 100–1018C.<br />

17.8.1.1.1.3 Method 3:<br />

Dipyrroketones<br />

The most efficient method for the synthesis of unsymmetrical dipyrroketones (e.g., 68,<br />

R 1 = O) involves a modification of the Vilsmeier–Haack reaction. Condensation of the<br />

phosphoryl chloride complex of a pyrrole N,N-dimethylcarboxamide 67 with a nucleophilic<br />

2-unsubstituted 1H-pyrrole (e.g., 34) followed by hydrolysis of the intermediate<br />

imine salt 68 (R 1 =NMe 2 + Cl – ) gives the dipyrroketone 68 (R 1 = O) in very good yield<br />

(Scheme 17). [53] Alternatively, treatment of a pyrrole acid chloride 69 with a pyrrole Grignard<br />

derivative 70 (or with the 2-unsubstituted 1H-pyrrole in the presence of a Friedel–<br />

Crafts catalyst) gives dipyrroketones 71 [53,54] (Scheme 17).<br />

Symmetrically substituted dipyrroketones (e.g., 73) are generally obtained by treatment<br />

of pyrrole Grignard reagents 72 with phosgene, [55] or, for example in the preparation<br />

of 76, by oxidative hydrolysis of dipyrrothiones 75, which can in turn be obtained<br />

directly from 2-unsubstituted 1H-pyrroles 74 by treatment with thiophosgene (Scheme<br />

17). [56]<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag

17.8.1 Porphyrins 1097<br />

aOxidation of dipyrromethanes (e.g., 77) with lead(IV) oxide, lead(IV) acetate, [57] sulfuryl<br />

chloride, or bromine/sulfuryl chloride [58] also gives good yields of dipyrroketones 78.<br />

Reduction of dipyrroketones 78 with sodium amalgam [57] or diborane yields the corresponding<br />

dipyrromethanes 77.<br />

Scheme 17 Dipyrroketone Syntheses [53–57]<br />

Et<br />

BnO2C CONMe2<br />

N<br />

H<br />

67<br />

EtO2C<br />

N<br />

COCl<br />

H<br />

Et<br />

N<br />

H<br />

74<br />

N<br />

H<br />

72<br />

69<br />

Et<br />

MgX<br />

S<br />

Cl Cl<br />

benzene<br />

EtOH<br />

64%<br />

+<br />

O<br />

XMg<br />

Cl Cl<br />

EtO2C CO 2Et<br />

EtO2C CO 2Et<br />

NH HN<br />

EtO 2C CO2Et<br />

77<br />

1. POCl3<br />

Et<br />

2.<br />

, CH2Cl2<br />

N<br />

H<br />

34<br />

N<br />

H<br />

70<br />

80%<br />

BnO2C<br />

NH HN<br />

68 R 1 = O, NMe 2 + Cl −<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

Et<br />

O<br />

Et<br />

EtO 2C<br />

Et Et<br />

NH HN<br />

S<br />

NH HN<br />

75<br />

Pb(OAc) 4, PbO 2<br />

62%<br />

Zn/Hg or B 2H 6<br />

Zn/Hg: 20%<br />

73<br />

KOH, H 2O 2<br />

EtOH<br />

71%<br />

Et<br />

R 1<br />

NH HN<br />

78<br />

O<br />

NH HN<br />

71<br />

EtO2C CO2Et<br />

O<br />

Et<br />

NH HN<br />

76<br />

EtO2C CO 2Et<br />

O<br />

EtO2C CO2Et Benzyl 3,8-Diethyl-2,7,9-trimethyl-5-dipyrroketone-1-carboxylate (68,R 1 = O); Typical Procedure:<br />

[53]<br />

Benzyl 5-[(dimethylamino)carbonyl]-4-ethyl-3-methyl-1H-pyrrole-2-carboxylate (67; 10g,<br />

31.81 mmol) was dissolved in POCl 3 (15 mL) and stirred until the absorption at 374 nm<br />

was maximized (e 15,000). The excess of POCl 3 was removed by concentration under reduced<br />

pressure, then 1,2-dibromoethane (10 mL) was added and the soln concentrated to<br />

Et<br />

for references see p 1223

1098 Science of Synthesis 17.8 Porphyrins and Related Compounds<br />

aremove the last traces of POCl 3. The oily product was dissolved in CH 2Cl 2 (15 mL) and 3ethyl-2,4-dimethyl-1H-pyrrole<br />

(34; 4.35 g, 35.31 mmol) in CH 2Cl 2 (15 mL) was added. After<br />

stirring until the absorption at 402 nm was maximized (e 7900), NaOAc (60 g) in H 2O<br />

(100 mL) was added and the mixture was refluxed with vigorous stirring for 2 h. The mixture<br />

was cooled, the organic layer was separated, and the aqueous layer was extracted<br />

with CHCl 3. The combined organic phases were washed with aq Na 2CO 3 (10%) and H 2O,<br />

dried (MgSO 4), and concentrated to dryness. The dark oil crystallized when triturated<br />

with MeOH, and the product was recrystallized (CHCl 3/petroleum ether) to give the product;<br />

yield: 9.7 g (80%); mp 1828C.<br />

1,2,3,7,8,9-Hexamethyl-5-dipyrroketone (76); Typical Procedure: [56]<br />

CAUTION: Thiophosgene is a severe respiratory irritant and very toxic by inhalation.<br />

A stirred soln of 2,3,4-trimethyl-1H-pyrrole (74; 5.0 g, 45.8 mmol) in Et 2O (100 mL) was<br />

treated dropwise at 0 8C with a soln of thiophosgene (1.78 mL) in benzene (20 mL) (CAU-<br />

TION: carcinogen). The mixture was stirred for 10 min before addition of aq EtOH (90%,<br />

100 mL) and stirring for another 30 min at rt. The mixture was concentrated to give a crystalline<br />

residue, which was recrystallized (aq EtOH) to give the dipyrrothione 75; yield:<br />

3.8 g (64%); mp 205–2078C. The thione 75 (50 mg, 0.19 mmol) in EtOH (95%, 10 mL) containing<br />

KOH (0.1 g) was treated with aq H 2O 2 (5%, 1 mL) and then heated on a steam bath<br />

for 5 min. H 2O (30 mL) was added and the mixture was extracted with CHCl 3 (3 ” 5 mL).<br />

Evaporation of the solvent gave a residue, which was purified by sublimation (2008C/<br />

1 Torr) to give the dipyrroketone 76; yield: 33 mg (71%); mp 219–2218C.<br />

Diethyl 3,7-Bis[2-(ethoxycarbonyl)ethyl]-2,8-bis[(ethoxycarbonyl)methyl]-5-dipyrroketone-1,9-dicarboxylate<br />

(78); Typical Procedure: [57]<br />

A soln of diethyl 3,7-bis[2-(ethoxycarbonyl)ethyl]-2,8-bis[(ethoxycarbonyl)methyl]dipyrromethane-1,9-dicarboxylate<br />

(77; 2.0 g, 3.02 mmol) in AcOH (75 mL) was treated with<br />

Pb(OAc) 4 (2.9 g, 6.54 mmol) and stirred at rt for 4 d. PbO 2 (90%, 2.3 g, 8.65 mmol) was then<br />

added and stirring was continued for another 2 d. The mixture was centrifuged and the<br />

supernatant was poured into ice water (500 mL). The colorless precipitate was separated,<br />

washed with H 2O, dissolved in Et 2O, and then washed successively with H 2O, 5% aq NaH-<br />

CO 3, and H 2O, and then dried (Na 2SO 4). After concentration, crystals separated; these were<br />

then recrystallized (Et 2O) to give 78; yield: 1.27 g (62%); mp 152.5–153.5 8C.<br />

Diethyl 3,7-Bis[2-(ethoxycarbonyl)ethyl]-2,8-bis(ethoxycarbonylmethyl)dipyrromethane-<br />

1,9-dicarboxylate (77); Typical Procedure: [57]<br />

Diethyl 3,7-bis[2-(ethoxycarbonyl)ethyl]-2,8-bis(ethoxycarbonylmethyl)-5-dipyrroketone-<br />

1,9-dicarboxylate (78; 668 mg, 0.99 mmol) in EtOH (5 mL) was added to H 2O (1 mL) and<br />

concd HCl (1 mL) and Zn amalgam (780 mg). The mixture was refluxed for 3 h, cooled,<br />

and then filtered. The soln was concentrated and then refrigerated to give crystals of the<br />

dipyrromethane 77; yield: 146 mg (20%), mp 948C.<br />

17.8.1.1.1.4 Method 4:<br />

Bipyrroles<br />

Bipyrroles 26 are not used in porphyrin syntheses because they contain a direct pyrrole–<br />

pyrrole link. However, this direct link is present in corroles, which will be discussed later<br />

in the chapter. Bipyrroles are prepared using a variation [59–61] of the Ullmann reaction, in<br />

which treatment of iodopyrrole 79 with copper affords the symmetrical bipyrrole 80 in<br />

ca. 60% yield (Scheme 18). The yields in this Ullmann approach have been improved [62] by<br />

the use of iodopyrroles (e.g., 81), which are functionalized with electron-withdrawing<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag

17.8.1 Porphyrins 1099<br />

agroups on the ring nitrogen (to give 82). Thus, treatment of 82 with copper powder in dimethylformamide<br />

at 1108C affords bipyrroles 83, which then can be pyrolyzed to give a<br />

good overall yield of bipyrroles 84.<br />

Scheme 18 Bipyrrole Synthesis [59–62]<br />

EtO 2C<br />

EtO 2C<br />

N<br />

H<br />

79<br />

R 1 R 2<br />

N<br />

H<br />

81<br />

CO2Et<br />

I<br />

I<br />

Cu powder, DMF, 110 o C<br />

Cu bronze, DMF, rt, 17 h<br />

63%<br />

DMAP, CH 2Cl 2, (t-BuO 2C) 2O<br />

EtO 2C<br />

EtO2C<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

R 1<br />

R 2<br />

EtO 2C<br />

R 2<br />

N<br />

H<br />

N<br />

CO2Et<br />

N<br />

H<br />

80<br />

R 1 R 2<br />

R 1<br />

82<br />

R 1<br />

EtO 2C<br />

CO 2Bu t<br />

EtO<br />

N N<br />

2C<br />

CO2Et Bu<br />

83<br />

tO2C CO2But I<br />

N<br />

H<br />

R 2<br />

CO 2Et<br />

heat<br />

R 2<br />

N<br />

H<br />

84 65−83%<br />

R 1<br />

CO 2Et<br />

Tetraethyl 4,4¢-Dimethyl-2,2¢-bipyrrole-3,3¢,5,5¢-tetracarboxylate (80); Typical Procedure:<br />

[59]<br />

Diethyl 5-iodo-3-methyl-1H-pyrrole-2,4-dicarboxylate (79; 10.0 g, 28.48 mmol) in DMF<br />

(50 mL) was treated with powdered Cu bronze (10 g) and stirred at rt for 17 h. The Cu<br />

bronze was separated off and washed with hot CHCl 3 (4 ” 50 mL). The filtrate and washings<br />

were then washed with aq 1 M HCl (2 ” 100 mL), and H 2O (2 ” 100 mL), then dried.<br />

The solvent was removed under reduced pressure and the crude product was triturated<br />

with petroleum ether (bp 60–80 8C; 30 mL). The product was collected by filtration, washed<br />

with petroleum ether (bp 60–80 8C; 2 ” 15 mL), and then dried at 80 8C, to give 80; yield:<br />

4.04 g (63%); mp 178–1808C.<br />

Bipyrrole Synthesis Using the Modified Ullmann Reaction; General Procedure: [62]<br />

The 2-iodo-1H-pyrrole (81; 0.01 mol) and DMAP (0.10 equiv) were mixed with di-tert-butyl<br />

dicarbonate (1.2 equiv) in dry CH 2Cl 2 (50 mL). The mixture was then passed through a<br />

short plug of silica gel, eluting with CH 2Cl 2. After evaporation, the residual oil 82 was dissolved<br />

in DMF (20 mL) under N 2 and then treated with Cu powder (4.7 equiv); after heating<br />

at 110 8C in an oil bath until iodopyrrole could no longer be detected (TLC monitoring),<br />

the mixture was cooled to rt, and filtered through Celite (to remove Cu residues). The Celite<br />

was washed with hot CHCl 3 until eluates were clear, and the combined organic phases<br />

were washed with 10% aq HCl (” 3), 10% aq Na 2S 2O 3 (” 3), sat. aq NaHCO 3, and then with<br />

sat. aq NaCl. The organic phase was dried (Na 2SO 4) and concentrated to give the bipyrrole<br />

for references see p 1223

1100 Science of Synthesis 17.8 Porphyrins and Related Compounds<br />

a83. This solid was heated under an inert atmosphere at 1808C until gas evolution ceased.<br />

The cooled solidified glass was recrystallized (hot EtOH or hexanes) to give 84; yield: 65–<br />

83%.<br />

17.8.1.1.2 Tripyrroles<br />

Previously published information regarding this product subclass can be found in Houben–Weyl,<br />

Vol. E 9d, pp 588–590.<br />

The tripyrroles most often used in porphyrin syntheses are the so-called tripyrranes<br />

86, which possess three pyrrole rings joined by two methylene groups (Scheme 19); tripyrrenes<br />

85 are non-nucleophilic on the dipyrromethene side. Tripyrranes have been obtained<br />

from tripyrrenes by reduction.<br />

Scheme 19 Unsymmetrical Tripyrranes<br />

R 5<br />

R 6<br />

R 4 R 3<br />

R 7<br />

NH HN<br />

X −<br />

+<br />

NH<br />

R 8<br />

85<br />

R 1<br />

R 2<br />

reduction<br />

17.8.1.1.2.1 Method 1:<br />

The [2+1] Approach to Tripyrranes<br />

NH HN<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

R 5<br />

R 6<br />

R 4 R 3<br />

Tripyrrane 88 is obtained in 35% yield by treatment of a dipyrromethane 87 (R 1 = H) with a<br />

2-(acetoxymethyl)-1H-pyrrole 42 (Scheme 20). [35,63] The tripyrrene 91 was employed as an<br />

intermediate in the synthesis of tripyrrane 92; this was subsequently used in the synthesis<br />

of a pentapyrrolic sapphyrin. [64] Treatment of the dipyrromethane 89 [35] with the 2formyl-1H-pyrrole<br />

90 afforded the tripyrrene dibenzyl diester 91 in excellent yield. Catalytic<br />

hydrogenation to tripyrrane caused debenzylation of the esters as well as reduction<br />

of the dipyrromethene link. The unstable tripyrrane 92, however, was not characterized<br />

(Scheme 20). [64] Reduction of the methene link has also been achieved by MacDonald and<br />

co-workers using sodium borohydride. [37] The route used to prepare tripyrrane 88 is also<br />

capable of yielding tripyrranes with an unsymmetrical array of substituents, as is the approach<br />

to 92.<br />

R 7<br />

NH<br />

R 8<br />

86<br />

R 1<br />

R 2

17.8.1 Porphyrins 1101<br />

aScheme 20 Unsymmetrical Tripyrranes by the [2 +1] Approach [35,63,64]<br />

MeO 2C<br />

MeO2C<br />

NH<br />

NH<br />

87 R 1 = H, CO 2t-Bu<br />

NH<br />

NH<br />

89<br />

CO2Bn<br />

+<br />

R 1<br />

CO 2Bn<br />

OHC<br />

+<br />

N<br />

H<br />

90<br />

MeO 2C<br />

AcO<br />

CO2Bn<br />

MeOH, TsOH (cat.)<br />

NH HN<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

N<br />

H<br />

42<br />

CO 2Bn<br />

MeO2C<br />

MeO2C<br />

HCl<br />

H 2, Pd/C<br />

35%<br />

NH<br />

88<br />

CO2Bn<br />

NH HN<br />

Cl − +<br />

NH<br />

CO2Bn<br />

91<br />

NH HN<br />

NH<br />

CO 2H<br />

92<br />

CO 2Me<br />

CO 2Bn<br />

CO 2Bn<br />

Dibenzyl 3,7,12-Tris[2-(methoxycarbonyl)ethyl]-2,8,13-trimethyltripyrrane-1,14-dicarboxylate<br />

(88); Typical Procedure: [35]<br />

Benzyl 9-tert-(butoxycarbonyl)-3,7-bis[2-(methoxycarbonyl)ethyl]-2,8-dimethyldipyrromethane-1-carboxylate<br />

(87, R 1 =CO 2t-Bu; 290 mg, 0.498 mmol) was dissolved in TFA<br />

(4 mL) and the soln was set aside at rt for 30 min while a stream of N 2 was passed through<br />

it. The solvent was removed under reduced pressure and the residual oil was dissolved in<br />

CH 2Cl 2, washed with sat. aq NaHCO 3, and dried (Na 2SO 4). The solvent was removed under<br />

reduced pressure to leave 87 (R 1 = H) as an oil. This was treated with benzyl 5-(acetoxymethyl)-4-[2-(methoxycarbonyl)ethyl]-3-methyl-1H-pyrrole-2-carboxylate<br />

(42; 186 mg,<br />

0.498 mmol) and TsOH (9 mg) in MeOH (4 mL). This mixture was warmed at 358C with stirring<br />

for 5 h before being cooled to rt and then neutralized with a few crystals of<br />

CO2H<br />

for references see p 1223

1102 Science of Synthesis 17.8 Porphyrins and Related Compounds<br />

aNaOAc•3H 2O. The tripyrrane was collected by filtration and recrystallized (Et 2O/hexanes)<br />

to give 88; yield: 140 mg (35%); mp 97–99 8C.<br />

17.8.1.1.2.2 Method 2:<br />

The [1]+[1] 2 Approach to Symmetrical Tripyrranes<br />

The classical route to tripyrranes is that discovered by Sessler and co-workers. [65,66] In its<br />

present state of development it only yields symmetrically substituted tripyrranes, but the<br />

ease with which tripyrranes can be synthesized using this method far outweighs the apparent<br />

symmetry limitation. In a typical example, treatment of electron-rich 3,4-diethyl-<br />

1H-pyrrole with 2 equivalents of a 2-(acetoxymethyl)-1H-pyrrole 93 affords tripyrrane 94<br />

in excellent yield, presumably via an intermediate dipyrromethane (Scheme 21). Catalytic<br />

debenzylation then affords the tripyrrane-1,14-dicarboxylic acid 95 (R 1 =CO 2H), which is<br />

chemically equivalent to the corresponding 1,14-di-unsubstituted derivative 95 (R 1 =H).<br />

Scheme 21 Unsymmetrical Tripyrranes by the [1]+[1] 2 Approach [65,66]<br />

Et Et<br />

N<br />

H<br />

93<br />

82%<br />

+<br />

AcO<br />

Et<br />

Et<br />

Et<br />

N<br />

H<br />

93<br />

NH HN<br />

NH<br />

CO 2Bn<br />

Et Et<br />

CO 2Bn<br />

94<br />

CO2Bn<br />

TsOH, EtOH<br />

60 oC, 8 h<br />

H 2, Pd/C, THF<br />

R 1 = CO2H 100%<br />

NH HN<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

Et<br />

Et<br />

Et<br />

Et Et<br />

NH HN<br />

NH<br />

CO 2Bn<br />

Et Et<br />

R 1<br />

95 R 1 = H, CO 2H<br />

Dibenzyl 3,7,8,12-Tetraethyl-2,13-dimethyltripyrrane-1,14-dicarboxylate (94); Typical<br />

Procedure: [65]<br />

3,4-Diethyl-1H-pyrrole (0.6 g, 4.9 mmol), benzyl 5-(acetoxymethyl)-4-ethyl-3-methyl-1Hpyrrole-2-carboxylate<br />

(93; 2.5 g, 7.9 mmol), and TsOH (0.15 g) were dissolved in abs EtOH<br />

(60 mL) and heated at 608C for 8 h under N 2. The resulting suspension was reduced in volume<br />

to 30 mL and then placed in a freezer for several hours. The product was collected by<br />

filtration, washed with a small amount of cold EtOH, and recrystallized (CH 2Cl 2/EtOH) to<br />

give 94 as a white powder; yield: 2.07 g (82%); mp 211 8C.<br />

3,7,8,12-Tetraethyl-2,13-dimethyltripyrrane-1,14-dicarboxylic Acid (95,R 1 =CO 2H); Typical<br />

Procedure: [65]<br />

Dibenzyl 3,7,8,12-tetraethyl-2,13-dimethyltripyrrane-1,14-dicarboxylate (94; 4.5g,<br />

7.1 mmol) in THF (500 mL) containing Et 3N (1 drop) was hydrogenated over 5% Pd/C<br />

(250 mg) at 1 atm of H 2 until TLC indicated completion of the reaction. The catalyst was<br />

separated by filtration and the filtrate was concentrated to dryness on a rotary evaporator.<br />

The residue was crystallized (CH 2Cl 2/hexanes) to give 95 (R 1 =CO 2H) as an unstable<br />

white powder; yield: 3.2 g (100%); mp 111–1158C.<br />

R 1

17.8.1 Porphyrins 1103<br />

a17.8.1.1.3 Open-Chain Tetrapyrrolic Intermediates<br />

Previously published information regarding this product subclass can be found in Houben–Weyl,<br />

Vol. E 9d, pp 590–596.<br />

Open-chain tetrapyrrole intermediates for use in porphyrin syntheses can potentially<br />

exist in a variety of different forms; these are bilanes 96, a-bilenes 97 and b-bilenes 98,<br />

a,b-biladienes 99 and a,c-biladienes 100, and a,b,c-bilatrienes 101 (Scheme 22). However,<br />

not all open-chain tetrapyrroles can be employed effectively. Among the bilane group,<br />

only the a-oxo- and b-oxobilanes (102 and 103, respectively) are useful. The only types of<br />

bilene to be used for syntheses of pure porphyrins are the b-bilenes 98; a,c-biladienes 100<br />

have been shown to be the only useful biladienes (and in fact have been the most useful of<br />

all open-chain tetrapyrroles). a,b,c-Bilatrienes 101, though proposed to be intermediates<br />

in the syntheses of porphyrins via b-bilenes and a,c-biladienes, have not been used routinely<br />

as intermediates in porphyrin synthesis.<br />

Scheme 22 Open-Chain Tetrapyrroles<br />

R 2<br />

R 3<br />

R 2<br />

R 3<br />

R 2<br />

O<br />

R 3<br />

R 1 R 8<br />

R 4<br />

NH HN<br />

a c<br />

NH HN<br />

b<br />

96<br />

R 5<br />

R 1 R 8<br />

R 4<br />

N HN<br />

NH N<br />

99<br />

R 5<br />

R 1 R 8<br />

R 4<br />

NH HN<br />

NH HN<br />

102<br />

R 5<br />

R 7<br />

R 6<br />

R 7<br />

R 6<br />

R 7<br />

R 6<br />

R 2<br />

R 3<br />

R 2<br />

R 3<br />

R 2<br />

R 3<br />

R 1 R 8<br />

R 4<br />

NH HN<br />

N HN<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

97<br />

N HN<br />

NH N<br />

R 5<br />

R 1 R 8<br />

R 4<br />

100<br />

R 5<br />

R 1 R 8<br />

R 4<br />

NH HN<br />

NH HN<br />

O<br />

103<br />

R 5<br />

R 7<br />

R 2<br />

R 1 R 8<br />

NH HN<br />

R 7<br />

N HN<br />

R3 R6 R6 R 7<br />

R 2<br />

R 4<br />

98<br />

NH N<br />

R 5<br />

R 1 R 8<br />

R 7<br />

N N<br />

R3 R6 R6 R 7<br />

R 6<br />

R 4<br />

101<br />

R 5<br />

for references see p 1223

1104 Science of Synthesis 17.8 Porphyrins and Related Compounds<br />

a17.8.1.1.3.1 Method 1:<br />

Oxobilanes<br />

17.8.1.1.3.1.1 Variation 1:<br />

a-Oxobilanes<br />

Making use of one of the dipyrromethane syntheses mentioned earlier (Section<br />

17.8.1.1.1.2.1), reaction between the pyridinium salt 104 of a 1-(chloromethyl)dipyrroketone<br />

and the lithium salt 105 of a dipyrromethane-5-carboxylic acid gives a good yield of<br />

a-oxobilane-1,19-dibenzyl ester 106 (Scheme 23). [67,68] These compounds are easily isolated,<br />

crystallized, and characterized.<br />

Scheme 23 Synthesis of a-Oxobilanes [67,68]<br />

MeO 2C<br />

N + Cl −<br />

O<br />

NH HN<br />

104<br />

CO 2Me<br />

CO2Bn<br />

MeO 2C<br />

NH HN<br />

HCONH2, py, heat CO2Bn 35%<br />

CO2Bn NH HN<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

+<br />

−<br />

O2C CO2Bn Li NH HN<br />

+<br />

MeO 2C CO 2Me<br />

105<br />

O<br />

106<br />

CO 2Me<br />

MeO2C CO2Me<br />

Dibenzyl 3,8,13,17-Tetrakis[2-(methoxycarbonyl)ethyl]-2,7,12,18-tetramethyl-b-oxobilane-1,19-dicarboxylate<br />

(106); Typical Procedure: [68]<br />

Benzyl 9-(chloromethyl)-3,8-bis[2-(methoxycarbonyl)ethyl]-2,7-dimethyl-5-dipyrroketone-<br />

1-carboxylate (6.4 g, 11.79 mmol) was dissolved in pyridine (12 mL) with gentle warming<br />

on a water bath to give 104. 9-(Benzyloxycarbonyl)-3,7-bis[2-(methoxycarbonyl)ethyl]-2,8dimethyldipyrromethane-2-carboxylic<br />

acid (6.92 g, 13.19 mmol) was suspended in<br />

HCONH 2 (200 mL), LiOMe (502 mg, 13.21 mmol) was added, and the suspension was shaken<br />

until the solid had dissolved to give 105. The reactants were combined and the resulting<br />

clear amber soln was heated at 50 8C under N 2 for 18 h. An oil slowly deposited during<br />

heating to form a viscous lower layer. After a further 17 h at rt under N 2, the oil had partially<br />

solidified and the supernatant liquid was decanted. The gummy deposit was washed<br />

with H 2O and dissolved in CH 2Cl 2. The soln was washed with H 2O, dried (MgSO 4), and concentrated<br />

in vacuo. Reconcentration of the residue with Et 2O (50 mL) under reduced pressure<br />

yielded a brown foam, which was redissolved in Et 2O (100 mL) and set aside overnight<br />

under N 2. The crystallized material was collected by filtration, and washed with a<br />

little ice-cold Et 2O to give 106; yield: 4.07 g (35%); mp 123–1248C.

a17.8.1.1.3.1.2 Variation 2:<br />

b-Oxobilanes<br />

17.8.1 Porphyrins 1105<br />

b-Oxobilanes can be readily synthesized from dipyrromethane precursors using the Vilsmeier–Haack<br />

procedure, as was described earlier for the synthesis of simple dipyrroketones<br />

(Section 17.8.1.2.1). Thus, the phosphoryl chloride complex of a 1-[(dimethylamino)carbonyl]dipyrromethane<br />

107 reacts with a 1-unsubstituted dipyrromethane 87 (R 1 =H)<br />

to give a good yield of tetrapyrrolic imine salt 108; column chromatography at this stage<br />

enables the polar imine salt to be obtained in fairly pure form. Hydrolysis then gives the<br />

b-oxobilane-1,19-dibenzyl ester 109 (Scheme 24). [69] Catalytic debenzylation of 109 then<br />

gives a quantitative yield of the corresponding 1,19-dicarboxylic acid 110.<br />

Scheme 24 Synthesis of b-Oxobilanes [69]<br />

Et<br />

Me2N<br />

POCl 3<br />

CH 2Cl 2<br />

O<br />

NH HN<br />

107<br />

Et<br />

Me2N +<br />

Cl −<br />

Et<br />

CO2Bn<br />

+<br />

NH HN<br />

NH HN<br />

108<br />

NH HN<br />

MeO 2C CO 2Me<br />

Et<br />

CO 2Bn<br />

CO 2Bn<br />

MeO2C CO 2Me<br />

87 R 1 = H<br />

aq Na 2CO 3<br />

H2, Pd/C<br />

CO 2Bn<br />

NH HN<br />

NH HN<br />

K. M. Smith and M. G. H. Vicente, Section 17.8, Science of Synthesis, 2003 Georg Thieme Verlag<br />

CH 2Cl 2<br />

86%<br />

Et<br />

O<br />

Et<br />

O<br />

NH HN<br />

NH HN<br />

109 45%<br />

110<br />

Et<br />

MeO 2C CO 2Me<br />

Et<br />

CO 2Bn<br />

CO 2Bn<br />

CO 2H<br />

CO 2H<br />

MeO2C CO2Me<br />

Dibenzyl 3,8-Diethyl-13,17-bis[2-(methoxycarbonyl)ethyl]-2,7,12,18-tetramethyl-b-oxobilane-1,19-dicarboxylate<br />

(109); Typical Procedure: [69]<br />

Benzyl 3,8-diethyl-9-[(dimethylamino)carbonyl]-2,7-dimethyldipyrromethane-1-carboxylate<br />

(107; 4.35 g, 9.99 mmol) was dissolved in POCl 3 (40 mL) and kept at 50 8C for 15 min.<br />

The excess of POCl 3 was removed by distillation under reduced pressure and dry 1,2-dibromoethane<br />

(10 mL) was added and distilled off to remove the POCl 3. The residual orange-brown<br />

oil was dissolved in CH 2Cl 2 and mixed with a soln of benzyl 3,7-bis[2-(meth-<br />

for references see p 1223

1106 Science of Synthesis 17.8 Porphyrins and Related Compounds<br />

aoxycarbonyl)ethyl]-2,8-dimethyldipyrromethane-1-carboxylate [87, R 1 = H (obtained by<br />

decarboxylation of the corresponding 1-carboxylic acid); 5.5 g, 11.44 mmol]. The mixture<br />

was refluxed and a slow stream of N 2 gas was bubbled through it until spectrophotometry<br />