The Electrical experimenter

The Electrical experimenter

The Electrical experimenter

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

40 THE ELECTRICAL EXPERIMENTER May, 1917<br />

THE<br />

A Simple Electric Motor Attachment<br />

for Phonographs<br />

phonograph is without doubt one<br />

of the greatest of all pleasure giving<br />

instruments. This fact is amply<br />

demonstrated by the large numljer of these<br />

machines in<br />

is, however,<br />

use<br />

like<br />

at tlie present time.<br />

many other articles,<br />

It<br />

appreciated<br />

most wlien new, and is little used<br />

By R. U. CLARK, 3rd<br />

at a constant speed by the governor with<br />

which the talking machine is fitted, may<br />

appear rather inappropriate, but. altho<br />

some heating does take place in this motor<br />

it is not sufficient to cause e.xcessive wear<br />

or shorten its life materially.<br />

<strong>The</strong> actual method of driving the talk-<br />

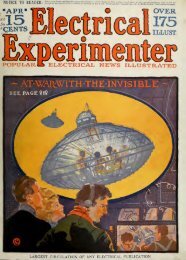

Illustrating How the Author Devised a Simple and Effective Electric Motor Drive for a<br />

Disc Style Talking Machine. <strong>The</strong> Old Governor Mechanism Is Retained and the Motor Drives<br />

the Record Table by Means of a String or Cord Belt. (Fig. 1.)<br />

after its novelty wears ofT, owing to the<br />

constant attention required to operate it.<br />

Winding up the spring to keep the motor<br />

going is the one thing which detracts most<br />

from the pleasure which should be derived<br />

from any good talking machine.<br />

By means of a simple electric motor attachment<br />

it is at once possible to do away<br />

with practically all the bother incident to<br />

the operation of the talking machine, with<br />

the exception of changing the records.<br />

Most of the standard machines on the<br />

market today lend themselves very readily<br />

to the attachment of an auxiliary motor<br />

device, so that, by the employment of a<br />

little care and ingenuity, it is a simple<br />

matter to remodel a phonograph so as to<br />

run it by electric motive power.<br />

<strong>The</strong> actual amount of power required<br />

to drive the turntable of most any phonograph<br />

at the proper speed is very small,<br />

although it may not appear so to the person<br />

who has to be continually winding up<br />

the ordinary spring motor. Just how little<br />

power will suffice depends more or less on<br />

the machine to be driven, but for most<br />

machines a universal electric motor of 1/40<br />

H.P. will be found quite sufficient. <strong>The</strong>se<br />

motors can be purchased new in most cases<br />

for as little as $4 complete, and can be<br />

attached by a flexible wire direct to the<br />

ordinary lamp socket, without using any<br />

extra resistance. <strong>The</strong> motor used by the<br />

author with considerable success was<br />

bought originally as a fan motor for $4;<br />

the fan, guard, and base which came with<br />

the motor were removed.<br />

<strong>The</strong> motor mentioned above was designed<br />

to drive a six-inch fan at about<br />

3,000 r.p.m. Under this load the makers<br />

claim it can be run at a cost of about 1<br />

cent per 6 hours, the rate per K.W. being<br />

10 cents. This motor is equipped with<br />

special patented bearings which require no<br />

oiling; for about 2 months, during which<br />

time the author's machine has been run a<br />

great deal, no oil has been placed on the<br />

bearings.<br />

<strong>The</strong> use of such a small motor, as mentioned<br />

above, for such exacting work as<br />

running a large turntable, which is held<br />

ing machine turntable on which the records<br />

rest, as described in this article, is by direct<br />

belt connection, which method requires<br />

perhaps the least accuracy in construction.<br />

<strong>The</strong> author after considerable experimenting<br />

with a simple friction drive, direct<br />

from the electric motor shaft, which was<br />

fitted up with various rubber and composition<br />

friction wheels, was forced to<br />

give up this method in the favor of belt<br />

drive. Friction drive applied to such a<br />

mechanism as the phonograph requires<br />

very accurate construction, and even then<br />

direct friction drive on most machines<br />

would prove noisy and imsatisfactory, due<br />

motor, but does not effect the speed governing<br />

mechanism, which is left in place,<br />

for use with the electric inotor, to control<br />

the speed in the usual manner.<br />

.-\fter disconnecting the spring motor<br />

from the turntable shaft, the table should<br />

be removed and a small groove from 1/32<br />

to 1/16 of an inch deep, the actual depth<br />

depending<br />

table rim,<br />

on the thickness of the turn-<br />

should be made for the belt to<br />

run in around the outside of the rim. This<br />

groove should be about Jg of an inch wide,<br />

and should<br />

of the rim.<br />

not be too near the top edge<br />

On certain machines there is<br />

a narrow shoulder located under the rim.<br />

which in<br />

As the<br />

some cases will hold the belt.<br />

phonograph is to be driven by a<br />

belt a small grooved pulley wheel for the<br />

motor is necessary. This wheel is best<br />

made of metal with a small groove about<br />

Yi inch wide, either V or semi-circular in<br />

cross-section, and about 1/16 inch deep.<br />

<strong>The</strong> greatest diameter of the pulley should<br />

be about 1 inch or under. <strong>The</strong> author<br />

has used e.\perimentally several sizes from<br />

5,^ inch up to 1 inch, all with considerable<br />

success, but when a 1 inch wheel is used,<br />

the motor which then turns at about 800<br />

r.p.m. seems to run the quietest, and with<br />

practically no belt slippage. Within the<br />

sizes mentioned the diameter of the pulley<br />

will have little effect upon the speed of<br />

the turntable, which<br />

its own governor as<br />

is still controlled by<br />

mentioned above, but<br />

of course the motor pulley-belt speed will<br />

be decreased by the use of a small pulley<br />

and increased when a large pulley is employed.<br />

.\ 10 cent pulley from a mechanical<br />

toy set is satisfactory.<br />

<strong>The</strong> metl.od to be used in mounting the<br />

motor will necessarily depend somewhat<br />

upon the type of talking machine used.<br />

<strong>The</strong>re are two simple ways of attaching<br />

the motor, one of which should be applicable<br />

to nearly any machine made. Wherever<br />

the construction of the talking machine<br />

permits, the motor can be hung out<br />

of sight, from the top-board of the body<br />

of the phonograph, with the shaft extending<br />

so that<br />

thru this<br />

the pulley<br />

board<br />

wheel<br />

about<br />

can be<br />

16 inch.<br />

mounted<br />

with ease from the top side of the board<br />

on which the motor is hung, as shown in<br />

Fig. 1. This mode of mounting is possible<br />

to the notoriously imperfect, peripheral only with a certain class of phonographs,<br />

arc described by most talking machine mostly the larger sizes. For use with<br />

turntables.<br />

small machines, where the motor cannot be<br />

<strong>The</strong> first step in the preparation of the<br />

talking machine for the addition of an<br />

electric motor is to run the machine until<br />

hung out of sight, it can be inverted and<br />

fastened to the top board, in such a manner<br />

that the pulley groove, which comes<br />

the spring is completely imwound. This next in position to the motor bearing,<br />

requires about fifteen minutes time. <strong>The</strong> with the hub near the outside end of the<br />

spring motor and top board is then re- shaft, comes in line with the grooved pormoved<br />

temporarily from the phonograph,<br />

if possible, by removing the crank handle.<br />

tion of the turntable. (See Fig 2.)<br />

To use the method of attachment first<br />

In some machines it<br />

is possible to get at<br />

the motor from the<br />

bottom, .^s soon as<br />

access to the motor<br />

is obtained, the gears<br />

and shaft, which<br />

form the connecting<br />

link between the<br />

turntable shaft and<br />

the spring motor<br />

gears are removed.<br />

<strong>The</strong> unit<br />

moved is<br />

to be<br />

clearly<br />

reindicated<br />

in Fig. 1, .\<br />

A. <strong>The</strong> heavy center<br />

line A—.\ which<br />

passes thru the lower<br />

Where it is Not Possible to Conceal the Motor in the Cabinet, as<br />

(n >Small Machines, the Motor Can Be Readily Mounted Above the<br />

Cabinet Shelf as Shown. (Fig. 2.)<br />

part of the spring<br />

motor casing indicates the position of the<br />

unit to be tr.ken out. Removing thi? piece,<br />

by letting up on the set screws, which hold<br />

the pivot bearings, on which the shaft<br />

mentioned above runs, simply disconnects<br />

the turntable and its shaft from the spring<br />

described it is necessary to drill three holes<br />

in the top board spaced about 2 inches<br />

from the edge of the turntable. <strong>The</strong><br />

center hole is made to accommodate the<br />

main bearing and shaft of the motor. <strong>The</strong><br />

(Continued on page 76)