Customer magazine by Putzmeister Concrete Pumps GmbH 75 ...

Customer magazine by Putzmeister Concrete Pumps GmbH 75 ...

Customer magazine by Putzmeister Concrete Pumps GmbH 75 ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

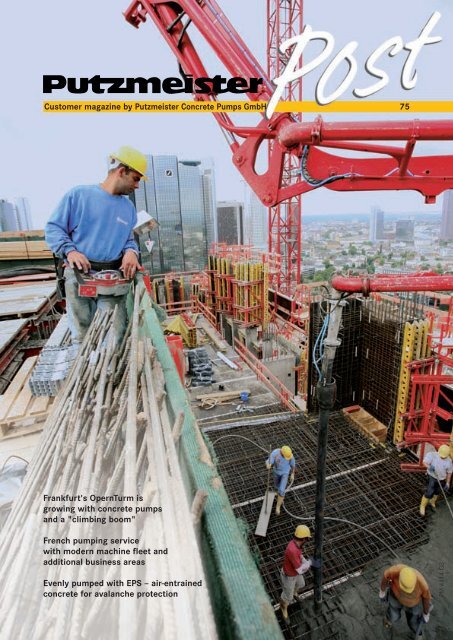

<strong>Customer</strong> <strong>magazine</strong> <strong>by</strong> <strong>Putzmeister</strong> <strong>Concrete</strong> <strong>Pumps</strong> <strong>GmbH</strong> <strong>75</strong><br />

Frankfurt's OpernTurm is<br />

growing with concrete pumps<br />

and a "climbing boom"<br />

French pumping service<br />

with modern machine fleet and<br />

additional business areas<br />

Evenly pumped with EPS – air-entrained<br />

concrete for avalanche protection PM<br />

4114 GB

Content<br />

Foreword<br />

Current economic crisis an opportunity<br />

Title story<br />

Frankfurt's OpernTurm is growing<br />

with concrete pumps and a "climbing boom"<br />

Background<br />

Not seasick in the slightest<br />

On site<br />

French pumping service with<br />

modern machine fleet and additional business areas<br />

<strong>Pumps</strong> used on historical soil<br />

Rotor pumps free-flowing cement screed –<br />

which can be walked on after 1 hour<br />

Evenly pumped with EPS –<br />

air-entrained concrete for avalanche protection<br />

BSA with crawler track for the pile foundation<br />

<strong>Concrete</strong> pumps on target<br />

Practical tip<br />

Too much pull?<br />

Training<br />

Intensive training on the "real" model<br />

2 PM 4114 GB<br />

3<br />

4<br />

10<br />

12<br />

15<br />

16<br />

18<br />

21<br />

22<br />

20<br />

24<br />

7<br />

12<br />

18<br />

23<br />

1<br />

2<br />

3<br />

4

Imprint<br />

■ Editor:<br />

<strong>Putzmeister</strong> <strong>Concrete</strong> <strong>Pumps</strong> <strong>GmbH</strong>,<br />

Max-Eyth-Straße 10,<br />

72631 Aichtal / Germany<br />

■ Editorial department:<br />

Jürgen Kronenberg,<br />

Layout and graphics:<br />

Friedrich Pippich,<br />

<strong>Putzmeister</strong> <strong>Concrete</strong> <strong>Pumps</strong> <strong>GmbH</strong>,<br />

Max-Eyth-Straße 10,<br />

72631 Aichtal / Germany<br />

■ Print: Druckerei Mack,<br />

Siemensstraße 15,<br />

71101 Schönaich / Germany<br />

Current<br />

economic crisis<br />

an opportunity<br />

For months now, the global financial crisis<br />

has been shaking the foundations of the<br />

international banking and financial system.<br />

The precarious situation that many credit<br />

institutions have found themselves in has<br />

led to a restrictive financing policy felt <strong>by</strong><br />

our clients as well as ourselves.<br />

The impact of the financial crisis has also<br />

affected the real economy. The construction<br />

industry is particularly affected, and has<br />

had to record weak downturns, in particular<br />

in the leading industrial nations. The recession<br />

in the USA and other important<br />

markets has not left our business untouched,<br />

and has led to significant adjustments<br />

in the organisation worldwide in line<br />

with market conditions.<br />

In addition to the negative economic development,<br />

2008 has been shaped <strong>by</strong> our<br />

Chinese competitors settling directly in<br />

Europe. This will enable us to excel at new<br />

technologies and prove our superiority in<br />

terms of technology and service in a direct<br />

comparison.<br />

With the realisation of the global region concept,<br />

<strong>Putzmeister</strong> is well positioned to take<br />

on the new challenges: <strong>by</strong> means of forced<br />

implementation of the global region concept<br />

for sales and service, we are achieving an<br />

even greater proximity to the global markets<br />

and our customers. The global production<br />

concept enables an optimised production<br />

process that is based on the requirements of<br />

the relevant market. The global logistics<br />

concept acts as the third pillar in coordinating<br />

the global production concept.<br />

Without doubt, the current situation requires<br />

even greater effort from all of us. We will<br />

only succeed in traversing new paths if<br />

together our employees, partners and customers<br />

all revise their thinking. To achieve<br />

this we have to move together even more<br />

closely than in the past; together we will<br />

master the new situation.<br />

Foreword<br />

All in all, we should not see the current economic<br />

crisis as a threat, but as an opportunity.<br />

Potential regarding new markets and<br />

technologies are frequently not used to the<br />

optimum in times of economic prosperity.<br />

We are now being offered the opportunity to<br />

direct greater attention to these areas in<br />

order to emerge stronger from the current<br />

crisis – even if this may take us some time.<br />

I wish all of you and your families a Merry<br />

Christmas and a Happy New Year.<br />

Felix Selinger, Dipl.-Ing.<br />

Managing Director of<br />

<strong>Putzmeister</strong> <strong>Concrete</strong> <strong>Pumps</strong> <strong>GmbH</strong><br />

PM 4114 GB 3<br />

5

Title story<br />

Frankfurt's OpernTurm is growing with<br />

concrete pumps and a "climbing boom"<br />

Ed. Züblin AG is currently erecting an imposing high-rise project, the OpernTurm, in the<br />

centre of Frankfurt am Main at a breathtaking speed. Including its base plate, around<br />

55,000 m 3 of concrete will be placed in the 170 m tower. The main players in the speedy<br />

construction progress are, among others, Europe's largest truck-mounted concrete<br />

pump M 63-5, a stationary high pressure concrete pump BSA 2109 as well as a stationary<br />

boom MX-32-4, on newly developed tubular columns with a climbing system.<br />

The new construction of tower building and<br />

podium in front is located precisely opposite<br />

Frankfurt's Alte Oper, which is steeped in<br />

tradition, and will, once completed, blend<br />

harmoniously into the surrounding architecture.<br />

In the three basement floors, the<br />

OpernTurm has 580 car parking spaces, and<br />

approximately 67,000 m 2 office and business<br />

space is rented over the 42 upper<br />

floors. The project developer is the American<br />

estate agency Tishman Speyer, which has<br />

already formed a striking image with the<br />

construction of the Frankfurt MesseTurm in<br />

the metropolis on the River Main. As the<br />

main contractor, Ed. Züblin AG is in charge<br />

of turnkey-ready construction work. Construction<br />

began in summer 2007 and is<br />

expected to be complete <strong>by</strong> the end of 2009.<br />

Massive base plate concreted with<br />

5,660 m 3 in 72 hours<br />

The order for concrete delivery, both for the<br />

base plate and for construction of the building<br />

itself, with 46 floors, was given to the<br />

concrete pumping service "Die Pumas".<br />

After extensive foundation work <strong>by</strong> Ed.<br />

Züblin Spezialtiefbau <strong>GmbH</strong> (in consortium),<br />

three truck-mounted concrete pumps from<br />

the pumping service situated in Lorsch with<br />

42, 52 and 63 metre booms took on the task<br />

of concrete delivery for the base plate with a<br />

thickness of 3.0 – 4.5 m in July 2007. Due to<br />

the highly restricted space available, setting<br />

up the large boom concrete pump was far<br />

After 72 hours, the three truck-mounted concrete pumps have finished concreting the huge base plate, which is up to 4.5 m thick<br />

4 PM 4114 GB

from easy: while there was space for the M<br />

42-5 and M 63-5 with one-side support on a<br />

makeshift ramp or on the very busy Bockenheimer<br />

Landstrasse, the third machine had<br />

to be set up on a specially-erected heavyload<br />

frame. Three consecutive days and<br />

nights were allocated for installing the<br />

5,660 m 3 concrete (strength class C 30/35).<br />

The <strong>Putzmeister</strong> M 63-5, the largest truckmounted<br />

concrete pump in Europe, alone<br />

delivered 2,000 m 3 of the total volume within<br />

24 hours without any problems. In consideration<br />

of performances at the neighbouring<br />

Alte Oper, a 20-hour break from<br />

concreting operations, which lasted several<br />

days, was accepted. It was thanks to finelybalanced<br />

concreting logistics that concrete<br />

was transported <strong>by</strong> truck mixers through<br />

the heavy inner-city traffic without any<br />

obstacles.<br />

6<br />

(Fig. Die Pumas)<br />

The M 63-5 works with one-side support from the roadside (Fig. Die Pumas)<br />

A small ramp is enough to set up the M 42-5 (Fig. Die Pumas)<br />

Title story<br />

PM 4114 GB 5<br />

7<br />

8

Titelstory Title story<br />

The concrete pumping service also has<br />

stationary booms and pumps for large<br />

projects<br />

In addition to a large fleet of truck-mounted<br />

concrete pumps (33 machines), the pumping<br />

service "Die Pumas" also has five stationary<br />

concrete pumps and seven stationary booms.<br />

This leaves the company in the best possible<br />

position to take on concrete delivery tasks<br />

for demanding high-rise projects. At Frankfurt's<br />

OpernTurm, "Die Pumas" are using<br />

for the first time the new <strong>Putzmeister</strong> tubular<br />

column system RS 850 with a simplified,<br />

automatic climbing system that carries the<br />

stationary boom with a reach of 32 metre.<br />

Central constructional elements of the<br />

OpernTurm are two building cores, which<br />

will, when the building is complete, accommodate<br />

the stair wells, lift shafts and supply<br />

lines. During the building phase, the two<br />

cores are always two to three stories ahead<br />

of the floors. Both the two cores and the<br />

floors are made of concrete of strenght class<br />

"Die Pumas" associate Ingo Melzer<br />

C50/60 with a maximum grain size of<br />

16 mm. The concrete batches, delivered<br />

from three mixing plants, are regularly<br />

monitored on the construction site <strong>by</strong> a<br />

laboratory.<br />

<strong>Concrete</strong> placing boom stands<br />

freely 16 m high on the tubular<br />

column without lateral guides<br />

During construction of the OpernTurm, the<br />

stationary boom climbs upwards, in line<br />

with construction progress, not inside one<br />

of the building shafts but between the two<br />

cores, through holes in the floor. A tubular<br />

column and boom were installed after the<br />

third floor was completed, i.e. at the height<br />

of level "0" (ground floor). Since then, the<br />

concrete placing boom has stood freely, without<br />

ballast, on a tubular column 16 m above<br />

the last floor guide. Due to its higher position,<br />

the boom not only reaches every point<br />

of the floors, each of which are 1,800 m 2 , but<br />

also the formworks of the building cores,<br />

which are three levels higher. The stationary<br />

boom is connected to the stationary concrete<br />

pump <strong>by</strong> means of an approximately<br />

80 m long ground line (DN 125). Later on, as<br />

the building height increased, the ground<br />

line was continued as a riser up to 170 m.<br />

Monitoring the concrete batches on the<br />

construction site<br />

Compact reinforcement (Fig. Tishman Speyer/Photographer: Klaus Helbig) The BSA 2109 H D is connected to the 170 m hi<br />

delivery line<br />

6 PM 4114 GB<br />

9<br />

10 11

The MX boom stands freely and without<br />

ballast on the tubular column, 16 m high<br />

13<br />

gh riser <strong>by</strong> means of an 80 m long horizontal<br />

12<br />

New tubular column system automates<br />

the climbing of concrete placing booms<br />

The boom tubular column is held <strong>by</strong> four<br />

lightweight floor corner brackets. Each<br />

weighing approximately 35 kg, these guides<br />

can comfortably be carried to the next but<br />

one floor after the climbing procedure –<br />

heavy floor frames are not an issue with this<br />

system. In the <strong>Putzmeister</strong> RS 850 tubular<br />

column system, the climbing cylinders and<br />

locating bolts that are otherwise customary<br />

are replaced <strong>by</strong> integrated extending feet<br />

and the climbing system that is secured to<br />

the tubular column and also rises. With the<br />

new tubular column system, the delivery<br />

line is also no longer guided sideways along<br />

the column but integrated in the tubular<br />

column. When the floor is broken through,<br />

therefore, only one square opening is required.<br />

Let the placing boom climb one storey,<br />

set up the formwork, position reinforcement,<br />

concrete and strip the formwork after<br />

12 hours – on average, one storey is completed<br />

every four days.<br />

Title story<br />

From a higher position, the PM stationary boom also distributes the concrete to<br />

hard-to-reach parts of the ceiling formwork<br />

Easy-to-move floor guides keep the<br />

boom tubular column laterally fixed<br />

PM 4114 GB 7<br />

14<br />

15

Title story<br />

The RS 850 system –<br />

well thought out right down<br />

to the last detail<br />

New tubular column<br />

The RS 850 tubular column system comes<br />

with 3 m, 6 m or 9 m columns as standard,<br />

with standard pipeline lengths. Different<br />

tubular columns for setting up the boom<br />

pedestal and arm assembly are not required.<br />

The double M tubular column profile<br />

requires only one simple, square cut-out<br />

(1 m x 1 m) in the floors. When an adapter<br />

is used, existing booms can continue to be<br />

used with the RS 850 tubular column.<br />

Automatic climbing procedure<br />

The climbing system integrated in the tubular<br />

column profile allows automatic climbing<br />

in the building. Once the climbing procedure<br />

is complete, the climbing cylinder is drawn<br />

upwards along the climbing bar, using a<br />

cable winch.<br />

Simple column connection<br />

Instead of the procedure common up until<br />

now, in which the tubular columns had to be<br />

laboriously screwed together, re-usable pins<br />

are now used in the RS 850 system. They<br />

can be simply inserted <strong>by</strong> hand and secured.<br />

16<br />

17<br />

18 20<br />

19 21<br />

8 PM 4114 GB

In order to place the average of 100 – 120 m 3<br />

concrete in the ceiling formworks, the concrete<br />

workers need around three hours. To<br />

concrete a core (30 – 50 m 3 ), one and a half<br />

hours. The stationary concrete pump at the<br />

base of the OpernTurm is operated <strong>by</strong><br />

Matheo Placido, one of the most experienced<br />

"PUMA" machine operators. On top of the<br />

formwork, a specially-trained construction<br />

site employee controls the MX stationary<br />

boom <strong>by</strong> radio remote control. The two<br />

machine operators stay in contact <strong>by</strong> walkietalkies<br />

so that the output can be adjusted<br />

immediately. The boom and tubular column<br />

climbing process, which is largely automated,<br />

is also controlled <strong>by</strong> site workers. The<br />

climbing procedure from one storey to<br />

another, including placing the corner brackets,<br />

takes approximately 1.5 hours.<br />

<strong>Concrete</strong> is delivered right up to the top<br />

level <strong>by</strong> a ZX pipeline that is around 250 m<br />

long in total. This version is permitted for<br />

use with pressures up to 130 bar. In fact, the<br />

<strong>Putzmeister</strong> BSA 2109 H D in rod side operation<br />

at the Frankfurt OpernTurm "only"<br />

requires around 90 bar concrete pressure at<br />

delivery rates of 35 – 40 m 3 /h.<br />

Title story<br />

When the floors are concreted, approximately 100 –120 m3 concrete is placed<br />

within three hours, high above Frankfurt<br />

23<br />

Machine operator Matheo Placido stays in contact with the boom operator up on the<br />

floor <strong>by</strong> means of a two-way radio<br />

Technical data of the BSA 2109 H D<br />

Motor: 6-cylinder Deutz<br />

Drive performance: 200 kW<br />

Stroke: 2,100 mm<br />

Diameter of delivery cylinder: 200 mm<br />

Max. delivery pressure<br />

(piston side): 91 bar<br />

Max. delivery output<br />

(piston side): 95 m3 /h<br />

Transmission ratio<br />

(piston side): i = 2.3<br />

Max. delivery pressure<br />

(rod side): 152 bar<br />

Max. delivery output<br />

(rod side): 57 m3 /h<br />

Transmission ratio<br />

(rod side): i = 3.8<br />

PM 4114 GB 9<br />

22

Background<br />

Not seasick<br />

in the slightest<br />

Since 22nd August 2008, the first M 70-5 large boom concrete pump has been on the<br />

American continent. This was preceded <strong>by</strong> careful planning and routine processing <strong>by</strong><br />

PM dispatch, transfer to Bremerhaven on its own axis and a 3-week sea crossing.<br />

Meanwhile, the second M 70-5 will soon be ready for delivery from <strong>Putzmeister</strong> in<br />

Aichtal. It is also headed for an American concrete pumping service.<br />

<strong>Putzmeister</strong> processes almost all transfers<br />

of truck-mounted concrete pumps to customers<br />

abroad with the support of two or three<br />

renowned shipping companies. These transportation<br />

companies have the best contacts<br />

at the customs offices, liaison offices in the<br />

countries of destination and, with their<br />

experienced personnel, guarantee a reliable<br />

transfer of machinery. For the M 70-5 transfer,<br />

for instance, PM dispatch commissioned<br />

the shipping company Alfons Köster & Co.<br />

<strong>GmbH</strong> (headquarters in Hamburg). For noneveryday<br />

shipping tasks, the large logistics<br />

companies occasionally work together with<br />

specialised partners.<br />

This was also the case with the transfer of<br />

the M 70-5 from the Aichtal <strong>Putzmeister</strong><br />

works to the roll-on / roll-off terminal (RoRo)<br />

at Bremerhaven. This part of the journey was<br />

overseen <strong>by</strong> the shipping company Gerber<br />

Transfer und Logistik <strong>GmbH</strong> (Munich).<br />

Some of their drivers are specially trained in<br />

transporting heavy loads on roads. For one<br />

thing was clear: a truck-mounted concrete<br />

pump with 52-metre boom and a gross<br />

weight of 48 t drives (and brakes) somewhat<br />

differently to a machine weighing almost 80 t<br />

with a 70-metre boom. Driver Hans Ott took<br />

it all in his stride, however: with decades of<br />

professional experience in heavy goods<br />

vehicle traffic and gross vehicle weights of<br />

over 300 t, he had done this more than<br />

enough times in the past.<br />

Different driving and braking behaviour<br />

Since the M 70-5 was designed for the<br />

American market, the machine required an<br />

official certificate of exemption for the transfer<br />

journey, on account of the special axle<br />

configuration. This certificate specified not<br />

only the course of the journey, but also offperiods<br />

in which the journey had to be interrupted<br />

(6.00 – 8.30 am and 3.30 – 6.00 pm).<br />

An accompanying vehicle followed the 10axle<br />

semi-trailer concrete pump at a distance<br />

of 50 m. A police escort was not required.<br />

The route took the vehicle directly north. The<br />

only time that the semi-trailer truck had to<br />

use non-motorway roads was when a motor-<br />

way bridge section between Würzburg and<br />

Fulda, prohibited for heavy goods vehicles<br />

over 44 t, had to be avoided. Travelling via<br />

Kassel and Hanover, the M 70-5 long-reach<br />

boom pump reached the pier in Bremerhaven<br />

after 816 km and 14 hours of travel time.<br />

A 16,000 km sea journey<br />

We asked the driver Hans Ott whether the<br />

Kenworth C500B (10 x 6/4), which with<br />

370 kW was not exactly "over motored", was<br />

not too slow for a tractor unit. "No", was the<br />

answer. "Even in the mountains around<br />

Kassel, with their steep, drawn-out climbs,<br />

we were still able to travel at at least 30 – 40<br />

km/h." The experienced driver probably had<br />

to adapt on the downward gradients: while<br />

European manufacturers usually equip their<br />

trucks in this weight class with eddycurrent<br />

brakes or retarders as permanent<br />

brakes as standard, the Kenworth still has<br />

the traditional engine brake for stopping the<br />

Specialist in unusual transportation:<br />

driver Hans Ott<br />

speed on longer downward gradients<br />

("throttle valve" principle).<br />

For shipping on the "Cepheus Leader", a<br />

vehicle transporter 200 m in length, 32 m in<br />

width and with a capacity of 62,600 GRT,<br />

the concrete pump drove on board backwards<br />

over a loading ramp. This showed<br />

once more that the combination of tractor<br />

truck and air-sprung semi-trailer is completely<br />

manoeuvrable, even when the traffic<br />

area is on different levels.<br />

On the subsequent three-week sea voyage<br />

on the "Cepheus Leader", the M 70-5 longreach<br />

boom pump was left alone. Sailing<br />

southwest, the huge transport ship crossed<br />

the Atlantic and headed first for the east coast<br />

of America and Florida's Jacksonville harbour.<br />

The civilian section of the Jacksonville<br />

harbour facility is the most important port<br />

of transshipment for vehicles in the USA.<br />

After a brief stopover, the journey continued<br />

through the Caribbean, and in mid-August<br />

the M 70-5, on board the transport ship,<br />

passed through the almost 82 km long<br />

Panama Canal, with its three lock installations.<br />

After a total of 8,635 nautical miles<br />

(approximately 16,000 km), on 22nd August<br />

the largest truck-mounted concrete pump in<br />

the world rolled off the ship in San Diego<br />

harbour (California) on its own axis in a<br />

wholly unspectacular manner – and without<br />

any sign of sea sickness: Welcome to<br />

America!<br />

24 25<br />

On the loading ramp, the semi-trailer<br />

concrete pump adapts to the different<br />

levels (Fig. Köster)<br />

26<br />

View of the Kenworth driver's cab<br />

10 PM 4114 GB

The M 70-5 travels at speed even on rural roads<br />

(Fig: L. Franke / Köster)<br />

After a 16,000 km sea voyage, first arrival at San Diego harbour<br />

Background<br />

PM 4114 GB 11<br />

27<br />

28

On site<br />

French pumping service<br />

with modern machine fleet<br />

and additional business areas<br />

In the small, northern French town of Hazebrouck, approximately 40 km south of Dunkirk, the construction company Eifrage TP<br />

Nord (Wattignies/Lille) is currently building a rainwater storage basin with a capacity of 10,000 m 3 . Their customer is the municipality<br />

of the township numbering 21,000 inhabitants. The basin, sunk 12 m deep, has a diameter of approximately 35 m and will<br />

relieve the strain on the town's sewage system after heavy rainfall. It is only worthwhile to use truck-mounted concrete pumps<br />

with a large working range and flexible boom technology here.<br />

The order for pumping approximately 1,100<br />

m 3 concrete for the basin wall, base plate<br />

and eight columns that will later carry the<br />

reservoir cover went to the concrete pump<br />

operator Transports Samyn from Arques, 20<br />

km away. The company's first <strong>Putzmeister</strong><br />

truck-mounted concrete pump M 47-5, only<br />

a few months old, provides the best preconditions<br />

for civil engineering, namely sufficient<br />

reach and highly-flexible boom kinematics<br />

in the 5-arm boom.<br />

M 47-5 in civil engineering with<br />

EBC boom damping<br />

The machine stands, correctly supported,<br />

directly in front of the concrete circle that<br />

contains the rainwater storage basin, and<br />

today will concrete the connection between<br />

the base plate and the basin wall (52 m 3 ). To<br />

do this, the machine operator, Bernard<br />

Battel, has to drive the boom tip in an arc of<br />

35 m diameter at a depth of 12 m. During<br />

this process, the end hose is either within<br />

the reinforcement or constantly approximately<br />

20 cm above it. Since the M 47-5 is<br />

equipped with EBC boom control, Mr. Battel<br />

can switch on additional damping for the<br />

placing boom using the radio remote control.<br />

Machine operator Bernard Battel<br />

29<br />

Wide, deep and across columns – the M 47 "Quintuplet" adjusts flexibly to<br />

construction site conditions, even in this rainwater storage basin<br />

12 PM 4114 GB

The M 47-5's flatbed offers ample space<br />

for additional delivery pipes<br />

31<br />

100 m delivery line on board – concrete<br />

pressure can be limited with EPS<br />

But the machine is also at home on construction<br />

sites of very different scales. This<br />

is clear from some specifications given <strong>by</strong><br />

customers. For instance, in France, the 35 t<br />

4-axle vehicle (DB 4144) was loaded to 41 t<br />

permissible gross weight and fitted with<br />

additional brackets as well as support cradles<br />

for further delivery pipes. It total,<br />

Transports Samyn's M 47-5 can now carry<br />

up to 100 m pipelines (DN 100) on board.<br />

The computer-aided electronic pump control<br />

stands the machine operator in good stead<br />

On site<br />

when ensuring that concrete pressure in the<br />

delivery line installed on the ground does<br />

not increase too much during pumping operations.<br />

For the EPS system not only offers a<br />

considerably quieter pumping process with<br />

correspondingly lower fuel consumption in<br />

comparison to conventional control systems,<br />

it also allows concrete pressure to be limited.<br />

To do this, the rotary selector on the<br />

radio remote control can be used to specify<br />

the maximum pressure required. This value<br />

is also shown in the display and can be<br />

changed at any time.<br />

PM 4114 GB 13<br />

30

On site<br />

Supplying concrete and other building<br />

material for 25 years<br />

The company Transports-Samyn has been in<br />

existence for 25 years. It was founded <strong>by</strong><br />

Patrick Samyn, who quickly earned a good<br />

reputation as a transportation company for<br />

concrete and other building materials in<br />

northern France, shortly afterwards setting<br />

up his own concrete pumping service. In<br />

2001, Damien Cousin took over the company,<br />

including all employees. Meanwhile,<br />

the workforce has grown to 47 persons,<br />

including Cousin's wife Aurelie.<br />

The vehicle fleet has almost doubled in the<br />

past seven years. Alongside other trucks,<br />

Samyn now has 15 truck mixers, 12 PUMI ®<br />

truck mixer concrete pumps and 13 truckmounted<br />

concrete pumps. The company is<br />

distinguished <strong>by</strong> one special feature: some<br />

of the Samyn truck mixers, both PUMI ® and<br />

truck-mounted concrete pumps, can be rented<br />

without machine operators, instead being<br />

driven <strong>by</strong> internal personnel.<br />

Mr. Cousin considers the main area of operation<br />

for Transports Samyn to fall within a<br />

radius of a roughly two-hour car journey<br />

around the company headquarters in<br />

Arques. For this reason, drivers frequently<br />

do not return to company premises in the<br />

evening, instead taking the concrete pumps<br />

home with them. This saves both time and<br />

fuel. The machines are then cleaned on the<br />

premises of one of the concrete plants that<br />

work with Transports Samyn.<br />

Quick parts delivery<br />

Damien Cousin has routine maintenance<br />

work and repairs performed in his own,<br />

well-equipped workshop. If wear parts are<br />

required for the <strong>Putzmeister</strong> concrete<br />

pumps that are not in stock in his own warehouse,<br />

these can be supplied quickly. "Parts<br />

transport from <strong>Putzmeister</strong> France's central<br />

warehouse in southern Paris to us takes<br />

only around three hours – I can live with<br />

that", says Mr. Cousin in an interview. In<br />

addition to the rapid-response customer<br />

service, Mr. Cousin rates the constantly<br />

expanding <strong>Putzmeister</strong> range of technical<br />

innovations above all as positive, currently,<br />

for instance, the "Follow Me" boom control<br />

<strong>by</strong> movement of the end hose.<br />

Damien Cousin, the "patron" of<br />

Transports-Samyn<br />

Safety taken seriously<br />

The degree of seriousness with which the<br />

issues of safety and employee training are<br />

taken at Transports Samyn is exemplary.<br />

For instance, before a new concrete pump<br />

operator can take over his machine, an experienced<br />

colleague accompanies him on<br />

the construction site over a period of several<br />

weeks. Thus, it is taught not just in principle<br />

but also in practice how the PUMI ® or truckmounted<br />

concrete pump is safely supported<br />

or the required distance from power lines is<br />

kept. Naturally, cleaning the delivery line<br />

and pump is also taught "on the object".<br />

Moreover, in Francois Gruwe, Transport<br />

Samyn has an employee who, in addition to<br />

his everyday work in the office and warehouse,<br />

takes charge of complying with<br />

safety-relevant aspects in the company, on<br />

the vehicles and construction sites.<br />

Mr. Cousin operates smaller construction sites with his truck mixer concrete pumps,<br />

like the rotor PUMI ® 24.67 Q shown here<br />

14 PM 4114 GB<br />

32<br />

33

<strong>Pumps</strong> used on historical soil<br />

The plan is to open the extensive plot, with<br />

its modern, landscaped swimming area <strong>by</strong><br />

the turn of 2008/2009. During the winter<br />

months, the Bretton Woods area is primarily<br />

visited <strong>by</strong> cross-country and downhill<br />

skiers. At warmer times of the year, the<br />

Mount Washington Hotel, above all the<br />

rambling and well-manicured golf course, is<br />

a focus for guests.<br />

While the name Carroll, a small town in the<br />

US state of New Hampshire that is home to<br />

around 700 inhabitants, is hardly well<br />

known, much has been written around the<br />

world about the southeastern district of<br />

Bretton Woods with its Mount Washington<br />

Hotel, for some time. This is because the<br />

imposing hotel, built in 1902, was the venue<br />

for the Bretton Woods conference (1st –<br />

23rd July 1944). The decisions made here<br />

led a little later to the formation of the World<br />

Bank and the International Monetary Fund<br />

– institutions that, on the one hand, even<br />

today play an important role in the international<br />

economic system but on the other,<br />

also face criticism from opponents of globalisation.<br />

On site<br />

The Mount Washington Hotel, which became known in 1944 as the Bretton Woods conference venue, is currently being expanded<br />

into a wellness area. During the construction work concrete is delivered into the individual formwork sections <strong>by</strong> a <strong>Putzmeister</strong><br />

BSF 36.16 H.<br />

M 36-4 carrying out concreting work in Bretton Woods (Fig. Brinkmann)<br />

PM 4114 GB 15<br />

35<br />

34<br />

36

On site<br />

Rotor pumps pourable cement screed –<br />

which can be walked on after one hour<br />

Many pump operators are presumably aware that rotor pumps can deliver not only concrete but also liquid screed. Liquid anhydritebased<br />

screed (i.e. containing gypsum) is widespread, particularly in France, due to its easy workability for constructing floors in<br />

residential and industrial construction. In the meantime, the cement screed suitable for external and damp areas has also been –<br />

mark you: in pourable form – delivered <strong>by</strong> truck-mounted concrete pumps with rotor systems.<br />

A typical construction site situation for this<br />

is displayed <strong>by</strong> these photographs from a<br />

Paris suburb. Here, the concrete pumping<br />

service Inter Service Pompe (ISP) which<br />

operates across the country is using a<br />

<strong>Putzmeister</strong> pourable concrete pump BQF<br />

28-4.80 from its fleet to cast the shared terrace<br />

in the inner courtyard of a semidetached<br />

house with pourable cement screed.<br />

With its 4-arm, 28-metre boom, the dimensions<br />

of the machine are more than sufficient<br />

for this kind of job. A total of 16 m 3 material<br />

is required for the outer area, which is<br />

approximately 90 m 3 . The substructure consists<br />

of a concrete ceiling of an underground<br />

car park.<br />

Once the 8 m 3 batch from the first truck<br />

mixer has been pumped quickly into the<br />

inner courtyard at the semidetached house<br />

construction site, operations stall. The<br />

second truck mixer is clearly in a traffic jam<br />

and does not appear for another half an<br />

hour. In the meantime, the concrete pump<br />

operator has swung back the boom and<br />

begun pumping the pourable cement screed<br />

in a circle, with the end hose over his own<br />

hopper. This is because he knows the mixture<br />

breakdown, which, among other elements,<br />

contains a maximum grain size of 8 mm,<br />

300 kg/ m 3 cement and a setting accelerator:<br />

although the material is nothing special<br />

to look at (consistency of pea soup), it has<br />

to be processed very quickly, as the screed<br />

will set after only an hour, allowing the<br />

ground to be walked on.<br />

The <strong>Putzmeister</strong> BQF 28-4.80 is equipped<br />

with a rotor pump. The delivery system is<br />

largely the same as the rotor, as is known<br />

from the rotor PUMI ® . With a delivery output<br />

of 80 m 3 /h (max./theor.), the rotor unit<br />

in the truck-mounted concrete pump is,<br />

however, significantly more powerful than<br />

that on the PUMI ® .<br />

Looking over the new 2-storey building from the street – with the 28-metre boom,<br />

the BQF rotor concrete pump has a considerable working range<br />

16 PM 4114 GB<br />

37

If a truck mixer does not come and the concrete threatens to set,<br />

only one thing helps: pumping in a circle (i.e. into your own hopper)<br />

The machine does, however, have all the<br />

benefits that characterise a rotor pump<br />

■ very quiet in operation<br />

■ continuous, interruption-free delivery<br />

■ even the smallest concrete volumes can<br />

be pumped<br />

■ pump system and concrete hopper can<br />

be emptied almost completely after use<br />

– meaning that there is no concrete<br />

residue to dispose of<br />

■ easy to clean<br />

Overview of screed types<br />

On site<br />

A basic distinction is drawn between<br />

screeds based on cement and those<br />

based on anhydrite, both of which are<br />

available in different quality grades.<br />

While traditional screed (bonded <strong>by</strong><br />

cement or gypsum [anhydrite]) does<br />

not pump due to its stiff, thin consistency<br />

but can only be delivered using<br />

compressed air (<strong>Putzmeister</strong> Mixokret<br />

system), liquid screed based on anhydrite<br />

and cement is well pumpable and<br />

easy to process. Due to its particularly<br />

even pumping characteristics, screw<br />

conveyor pumps, as well as rotor<br />

pumps, are mainly used to deliver this<br />

material.<br />

But anhydrite liquid screed with gypsum<br />

as a binding agent does not have<br />

only benefits. For instance, this material<br />

is not suitable for outside structural<br />

elements (balconies, terraces, garages),<br />

or rooms with high air humidity (bathrooms,<br />

shower rooms, swimming pool<br />

areas). Due to the relatively high water<br />

content, floors made of anhydrite liquid<br />

screed cannot be walked on or bear<br />

load until considerably later than floors<br />

constructed from traditional cement<br />

screed.<br />

Cement-bonded liquid screed is, therefore,<br />

an alternative for floor construction<br />

in outside or wet areas. It contains<br />

Portland cement as the binding agent<br />

and is laid floating or sliding, as with<br />

synthetic resin cement screed (binding<br />

agent: resin coated special cements).<br />

PM 4114 GB 17<br />

38<br />

39

On site<br />

Evenly pumped with EPS – air-entrained<br />

concrete for avalanche protection<br />

Klosters is erecting an avalanche protection gallery at a height of 1,800 m in the<br />

Swiss Canton of Graubünden. The standard EPS equipment for the stationary concrete<br />

pump BSA 1003 D stands the machine operator in good stead when air-entrained concrete<br />

is to be delivered, as this equipment can limit the maximum delivery pressure<br />

precisely. Despite frequent concreting operations, the firm manages to avoid any disruption<br />

to railway services on the Klosters-Davos route.<br />

By creating a gallery on another section of<br />

track, the Rhaetian Railway is eliminating a<br />

possible source of danger that can, in some<br />

Alpine regions, lead to repeated accidents<br />

due to landslides and avalanches after heavy<br />

precipitation. The construction site for protecting<br />

the railway track is located only a<br />

few kilometres north of the popular holiday<br />

resorts of Davos and Klosters. The construction<br />

costs are estimated at CHF 2.7 m.<br />

(approx. EUR 1.8 m.).<br />

In order to construct the 90 m long Seehorn<br />

avalanche gallery (7 m wide, 8 m high) all<br />

components will be concreted using a concrete<br />

pump, and even the 61 double-sided<br />

slanted concrete supports will be manufactured<br />

on site. The gallery has a longitudinal<br />

gradient of 2.5 % and, due to the small curve<br />

radius, a transverse gradient of 6.4 %. Due to<br />

the limited space available and the trains<br />

running at 20-minute intervals, particular<br />

care has to be taken with the logistics of the<br />

construction site.<br />

Air-entrained concrete prepared<br />

homogeneously in the mixing trough<br />

The construction site equipment directly<br />

next to the railway track includes a small<br />

concrete mixing and pump installation. The<br />

pre-mixed gravel components (0 – 32 mm)<br />

are delivered <strong>by</strong> truck and transferred to a<br />

compulsory mixer with a tipping trough.<br />

The exact quantities of cement, plasticising<br />

admixture and air-entraining agent are<br />

added in this mixer. With the air-entraining<br />

agent, the construction site reaches a pore<br />

volume of approximately 4.3 % in the concrete.<br />

The tiny air voids are required in<br />

order to create numerous small air chambers<br />

in the cement paste, which provide space<br />

into which the freezing water can expand at<br />

winter temperatures. This increases the<br />

A glimpse of how the construction site is set up: The tipping trough (right) in its vertical position transfers the gravel additives into a<br />

compulsory mixer (covered with a sheet here), in which the aggregate is prepared with water, cement, plasticising admixture and airentraining<br />

agent to form concrete. Underneath that is a double-shaft additional mixer, which transfers the concrete batches to the<br />

hopper of the BSA 1003 D.<br />

18 PM 4114 GB<br />

40

component's frost resistance. After being<br />

mixed for 90 seconds in the compulsory<br />

mixer, the concrete and its additives are<br />

intensively homogenised once again in a<br />

double-shaft pre-mixing trough with a 3 m 3<br />

volume, which transfers the concrete in<br />

equal doses to the hopper of the BSA 1003 D.<br />

<strong>Concrete</strong> pressure always under control<br />

While delivering air-entrained concrete<br />

using a rotor pump may be problem-free (a<br />

maximum pressure of 25 bar may apply, depending<br />

on the system), caution is necessary<br />

when a piston pump such as the BSA<br />

1003 D is used: for instance, at higher concrete<br />

pressures (up to 80 bar is possible<br />

with this pump type) the air voids in the<br />

concrete are compressed and thus destroyed.<br />

In consequence, the concrete would no<br />

longer be frost resistant and the component<br />

would have to be torn down again.<br />

<strong>Putzmeister</strong> stationary concrete pumps have<br />

clear advantages here, due to Ergonic ®<br />

pump control (EPS): with EPS the maximum<br />

pressure required can be set precisely. This<br />

is practical not only for pumping concrete<br />

with air voids, but also if the pipeline's wall<br />

thickness (i.e. its compressive strength) is<br />

unknown.<br />

Over the course of the 62 concreting operations<br />

between July and October 2008, the<br />

BSA 1003 D delivered concrete outputs of<br />

15 m 3 /h at pressures between 19 and 24<br />

The work does not interfere with rail<br />

traffic<br />

41<br />

bar. It manufactured foundations, guide<br />

walls, back walls, supports and floors for the<br />

gallery, concreting sections of 15 to 150 m 3 .<br />

During this time, the length of the delivery<br />

line (DN 125) reached up to 130 m. At two<br />

points, the pipeline had to pass under the<br />

railway embankment, in consideration of<br />

the client's strict special requirements. In<br />

total, the BSA 1003 D delivered 1,900 m 3<br />

air-entrained concrete (C25/30, exposition<br />

class: XF4) for the Seehorn avalanche gallery,<br />

with 36-40 cm spread and a relatively<br />

low W/C eq value of 0.42.<br />

Information on the Rhaetian Railway<br />

The Rhaetian Railway (RhB) is a narrowgauge<br />

railway company in the Swiss<br />

Canton Graubünden, founded in the year<br />

43<br />

On site<br />

Gallery construction has the same longitudinal and transverse incline as the 61 concrete<br />

columns on the valley side<br />

Measuring device to determine the air<br />

void contents<br />

1888. The RhB has a rail network of total<br />

384 km in length, with a track width of<br />

1,000 mm, made up of eight regular<br />

stretches of track and one motorail connection.<br />

Every year, the Rhaetian Railway<br />

transports 9.7 million passengers.<br />

The RhB's rolling equipment includes 80<br />

locomotives, 391 passenger carriages<br />

and 743 goods wagons. With 1,270<br />

employees, the company generates revenue<br />

of approximately CHF 296 m.<br />

(approx. EUR 197 m. (all figures from<br />

2007). A significant part of the business<br />

profit is spent on ensuring the safety and<br />

on renovating routes, including the 582<br />

bridges and 114 tunnels, as well as on<br />

modernising the machine fleet. In summer<br />

2008, the technically and scenically<br />

spectacular RhB rail route between<br />

Thusis and Tirano (Albula/Bernina) was<br />

designated a UNESCO World Heritage<br />

Site.<br />

PM 4114 GB 19<br />

42<br />

44

Practical tip<br />

Too much<br />

pull?<br />

Pipe brackets on placing booms play a<br />

"bearing role", since, on stationary<br />

booms and truck-mounted concrete<br />

pumps, they connect the delivery line to<br />

the outrigger. But it is important to make<br />

sure that pipe bracket clamping strips<br />

are not fastened too tightly!<br />

At <strong>Putzmeister</strong>, a pipe bracket design in<br />

which delivery pipes are usually clasped<br />

and held <strong>by</strong> a pipe clamp before and after<br />

the coupling has been proving its worth for<br />

years now. The bracket is made of a flexible<br />

steel clamping strip and a steel pipe rest as<br />

a counterpart. With this design, the actual<br />

holding powers are deflected to the boom <strong>by</strong><br />

Stress distribution in the area of the<br />

pipe bracket when the clamping strip is<br />

very tight<br />

means of a pipe holding pipe welded securely<br />

to the pipe rest.<br />

The trend seen in recent years towards<br />

greater boom lengths, reduced material<br />

thickness (in the interests of saving weight)<br />

and, on average, ever greater concrete pressures<br />

requires increased attention to be paid<br />

A reduced tightening torque on the clamping strip relieves clamping strips, delivery<br />

pipes and pipe brackets<br />

to the way in which delivery pipes are secured.<br />

This is because the clamping strip pivots<br />

react highly sensitively if tightening torques<br />

are too great. In extreme cases, this could<br />

even cause strips to crack. This is added to<br />

<strong>by</strong> the dynamic loads of the placing boom,<br />

which lead to additional forces on the clamping<br />

strips.<br />

However, if the screw tightening torque is<br />

too great, this will also have detrimental<br />

effects on the wear and weight optimised<br />

twin pipes. These double-walled delivery<br />

pipes are now part of the original equipment<br />

for most <strong>Putzmeister</strong> truck-mounted<br />

concrete pumps and repeatedly baffle concrete<br />

pump operators due to their longevity.<br />

However wear-resistant twin pipes may be,<br />

if the clamping strip is tightened too much,<br />

cracks may appear in the inner pipe. Cracks<br />

in twin pipes are usually harmless, however.<br />

But if the inner pipe becomes so distorted<br />

that gaps appear, the cracks will be eroded<br />

at this point and increased wear will occur.<br />

For this reason, <strong>Putzmeister</strong> recommends<br />

reducing the screw tightening torque on<br />

clamping strips in order to relieve the strain<br />

on pipe brackets and delivery pipes. If the<br />

tightening torque is reduced on the clamping<br />

strip, the pipe is fixed significantly more<br />

flexibly in its bracket than it was previously,<br />

since minimal pipe movements in the bracket<br />

can be made without any great resistance.<br />

This prevents secondary bending and relieves<br />

clamping strips, delivery pipes and pipe<br />

brackets.<br />

In practice, this means that tightening<br />

torques can be lowered to 15 Nm when new<br />

pipework is initially assembled (including<br />

new clamping strips). If a torque wrench is<br />

not available, the following procedure is<br />

recommended:<br />

1. Without increasing your effort, tighten<br />

the clamping strip screws until the clamping<br />

strip is resting against the pipe and you<br />

feel increased resistance when you turn the<br />

wrench.<br />

2. To reach the required screw tightening<br />

torque of approximately 15 Nm, turn the nut<br />

on a free-moving thread one full turn<br />

(360°). If the thread is stiff, 1.5 turns (540°)<br />

are advisable.<br />

20 PM 4114 GB<br />

45<br />

46

BSA with crawler track<br />

for the pile foundation<br />

In September, considerably earlier than planned, the Spezialtiefbau consortium (Ed.<br />

Züblin AG and Bilfinger Berger AG) completed the contracted foundation work for the<br />

future Rhine Gallery in Ludwigshafen. A significant amount of this rapid construction<br />

progress was due to a <strong>Putzmeister</strong> concrete pump on a crawler track, which manufactured<br />

hundreds of drilled piles using the screw conveyor in-situ concrete procedure<br />

(SOB).<br />

47<br />

Both on crawler trucks, the heavy augured pile device and the concrete pump<br />

can also be used to their full extent "off road". A hose line creates the connection<br />

between the two machines<br />

The new shopping centre, which later will<br />

have 120 retail outlets, is being built on a 10<br />

hectare plot in Ludwigshafen, on the former<br />

Winterhafen site, which was filled in in 1957.<br />

To ensure that the planned Rhine Gallery<br />

will stand on firm ground, its 400 m x 80 m<br />

base plate is being erected on numerous<br />

reinforced concrete pillars, which are placed<br />

in a precise grid.<br />

Before the 15.5 to 21 m deep holes are sunk,<br />

any existing obstacles in the building<br />

ground were eliminated <strong>by</strong> means of fragmentation<br />

drilling. To manufacture the SOB<br />

pillars, a heavy piling device was used to<br />

screw a hollow stem auger in the prepared<br />

building ground. Once the target depth was<br />

reached, concrete was delivered under<br />

pressure using the bore of the endless auger<br />

in the hole. In this process, the drilling<br />

apparatus pulled the auger upwards without<br />

rotating it. Once the auger and the drilled<br />

material accumulated on the surface had<br />

been removed, a reinforcement cage was<br />

shaken onto the freshly-concreted pillar.<br />

The holes were filled with concrete <strong>by</strong> a<br />

<strong>Putzmeister</strong> BSA 1412 D RF pump on a<br />

crawler track. The machine is equipped with<br />

an off-road chassis so that it can follow the<br />

Practical tip<br />

chain-driven, heavy piling device even on<br />

unsecured terrain. The two machines were<br />

connected <strong>by</strong> means of an approximately<br />

22 m long hose line that was connected to<br />

the auger on a pipeline with flexible<br />

connection hoses (DN 125). Drive commands,<br />

steering and operation of the concrete<br />

pumps were performed via radio remote<br />

control. The relatively high pump output<br />

(max. 120 m 3 /h) was not required in continuous<br />

operation when the drilled piles were<br />

concreted, but was frequently beneficial<br />

during the first phase of hole filling when<br />

relatively large volumes of concrete had to<br />

be installed quickly.<br />

Meanwhile, many civil engineers prefer to<br />

use self-driving construction site concrete<br />

pumps to fill the drilled piles, and for good<br />

reason. This is because, in contrast to truckmounted<br />

concrete pumps, a crawler track<br />

BSA does not have to be supported, and can<br />

begin work on the next hole within a very<br />

short period of time. In addition, when constructing<br />

pile foundations, concreting with<br />

this machine is much safer as it does not<br />

require such precise coordination of movements<br />

between the two machines: the danger<br />

of the drilling apparatus suddenly pulling<br />

on the end hose, and therefore on the placing<br />

boom, is also excluded (result: the truckmounted<br />

concrete pump tips over). And, in<br />

comparison to concreting with a delivery<br />

pipe, the placing output with a concrete<br />

pump is considerably higher.<br />

Of the 580 concrete piles, the Spezialtiefbau<br />

consortium manufactured 510 (between 90<br />

and 120 cm in diameter) out of screw conveyor<br />

in situ concrete. The average daily output<br />

was between 12 and 13 SOB pillars. The<br />

remaining 70 piles are concreted in the<br />

usual way with a delivery pipe. In total,<br />

approximately 9,000 m 3 concrete (C25/30)<br />

was required for the pillar foundations of<br />

the Rhine Gallery.<br />

The machine operator controls the selfdriving<br />

concrete pump<br />

PM 4114 GB 21<br />

48

On site<br />

<strong>Concrete</strong> pumps on target<br />

Since January 2008, an extensive building complex has been under construction<br />

directly on the start and home stretches of the Nürburgring. During concreting operations,<br />

it is good to observe the ever-changing <strong>Putzmeister</strong> truck-mounted concrete<br />

pumps such as the popular models M 24-4 and M 36-4, the compact M 46-5 and M 52-5<br />

or the imposing M 58-5 and M 62-6. With their 5 and 6-arm booms, the long-reach<br />

boom pumps, which extend over walls, can reach even inconveniently-situated formwork<br />

sections.<br />

From the set-up site beyond the 350 m long wall, the PM long-reach boom pump M 62-6 can comfortably reach the formwork<br />

sections for the new "world of adventure" at the Nürburgring<br />

For around € 25.5 million, the carcass of a<br />

"world of adventure" is being erected opposite<br />

the grandstand on the legendary race<br />

track in the Hocheifel region. Among other<br />

elements, the project includes an underground<br />

car park (700 parking spaces), a<br />

"boulevard", on which automobile manufacturers<br />

and accessory suppliers will give presentations,<br />

an arena for 3,500 guests, an<br />

"event hall" with capacity for 1,800 people<br />

and the "Welcome Centre". The leisure time<br />

facilities will be rounded off with a gocarting<br />

track and a roller coaster. In addition,<br />

a new, modern grandstand is to be built<br />

with 5,000 covered seats as well as a "business<br />

lounge" for 600 guests. The order for<br />

the 350 m-long building complex has been<br />

assigned to the Nürburgring consortium<br />

(Ed. Züblin AG, Max Bögl Bauunternehmen<br />

<strong>GmbH</strong> & Co.KG and Fritz Meyer <strong>GmbH</strong>).<br />

Around 60,000 m 3 of ready-mixed concrete<br />

will be delivered <strong>by</strong> the mixing plants of<br />

KANN Beton <strong>GmbH</strong> & Co. KG, Beton Union<br />

Rhein-Ahr <strong>GmbH</strong> & Co. KG as well as<br />

CityMix <strong>GmbH</strong> for this major project. With<br />

the truck-mounted concrete pumps used,<br />

the supply association is able to rely on its<br />

own fleet, to a certain extent. Thus, Beton<br />

Union is once providing its 21-metre PUMI ®<br />

and truck-mounted concrete pumps with 27,<br />

28 and 34 metre booms, and KANN Beton a<br />

24-metre PUMI ® , a M 24-4 and a M 36-4. In<br />

addition, CityMix is ordering its M 36-4 as<br />

well as the new M 46-5 to the Nürburgring.<br />

If, however, greater horizontal reach and<br />

boom flexibility is required, the long-reach<br />

boom pumps M 52-5, M 58-5 and M 62-6<br />

owned <strong>by</strong> BEKA Betonpumpen-Service<br />

<strong>GmbH</strong> will be ordered to the construction<br />

site.<br />

Practically all of the machines are also consistently<br />

in use for the construction of the<br />

neighbouring "Congress & Motorsporthotel<br />

Nürburgring". An additional 20,000 m 3 of<br />

concrete will be delivered here. Work on the<br />

new 4-star hotel began at almost the same<br />

time as the laying of the foundation stone for<br />

the "adventure world" along the start/home<br />

stretches. On completion, the classy 160room<br />

lodgings will also have a helipad and<br />

direct access to the grandstand.<br />

22 PM 4114 GB<br />

49<br />

50

This M 36-4 is concreting the base plate of the neighbouring<br />

"Congress & Motorsporthotel Nürburgring"<br />

Training for the 5th run of the long-distance championship at the Nürburgring<br />

51 53<br />

PM 4114 GB 23<br />

52<br />

Attractive world<br />

of motor racing<br />

On site<br />

Completed in 1927, the Nürburgring<br />

with its 89 left and 85 right-hand<br />

bends, inclines up to 27 % and a<br />

length of almost 23 km was, until<br />

1977, a regular venue for the Formula<br />

1 Race – "Grand Prix of Germany".<br />

After several serious accidents, however,<br />

the track was made off-limits for<br />

the Grand Prix sport. After its first<br />

reconstruction (1983), with provision<br />

for extensive safety measures, the<br />

ring, surrounded <strong>by</strong> beautiful countryside,<br />

has been used for motor<br />

racing once more since 1984.<br />

In the meantime, the legend of the<br />

Nürburgring has become a brandname<br />

product. More than 300 races,<br />

leisure time, incentive and music<br />

events are held here professionally<br />

every year. The circuit includes both a<br />

Nürburgring racing driver school and<br />

a course in driver safety training.<br />

Approximately two million people<br />

attend the numerous events every<br />

year, or take advantage of the leisure<br />

facilities all around the famous race<br />

track. Due to growing interest, the<br />

offer has now been extended from the<br />

coming year, for that is when the<br />

"Leisure and business centre<br />

Nürburgring 2009" project, costing a<br />

total of € 215 million, is to be started<br />

up.

Training<br />

Intensive training<br />

on the "real" model<br />

With an attractive range of programs on<br />

offer, the <strong>Putzmeister</strong> Academy has started<br />

its training season 2008/2009. The<br />

many courses available have different<br />

areas of focus and are directed towards,<br />

among others, concrete pump operators<br />

with little practical work experience and<br />

experienced machine operators who want<br />

to refresh or enhance their knowledge, as<br />

well as operations managers, fleet scedulers<br />

and workshop managers.<br />

Since the <strong>Putzmeister</strong> trainers not only<br />

impart theory but also want to undertake<br />

practical work with seminar participants<br />

"on the real thing", <strong>Putzmeister</strong> has installed<br />

two complete training pumps in the<br />

training rooms. These are "real" truckmounted<br />

concrete pumps without the truck<br />

chassis, and are driven <strong>by</strong> an electric motor.<br />

This kind of practical work on fully-functioning<br />

models allows participants to carry out<br />

all necessary set-up work, for instance, and<br />

receive direct training in troubleshooting.<br />

The two training concrete pumps are also<br />

equipped with additional sensors. These<br />

record all of the important data for concrete<br />

pumping operations, such as main pump<br />

high pressure, low pressure, charge pressure,<br />

control pressure, accumulator pressure and<br />

volumetric flow rate, as well as the pump<br />

control system's electric control current.<br />

This data is transmitted to a PC <strong>by</strong> means of<br />

a CAN bus system. The computer visualises<br />

the measured values obtained and presents<br />

the information accurately in the form of<br />

virtual pressure gauge displays. These displays<br />

are shown to all seminar participants<br />

in enlarged format as projected images. By<br />

preparing the visualisation in a didactical<br />

manner, the seminar leaders can illustrate<br />

complex processes and dependencies in the<br />

hydraulic systems of <strong>Putzmeister</strong> concrete<br />

pumps.<br />

In the meantime, practical modules both on<br />

the training pumps and on the "right" truckmounted<br />

concrete pumps have become an<br />

integral part of any course for machine operators<br />

and mechanics at the <strong>Putzmeister</strong><br />

Academy. For more information, call<br />

+49 (0) 7127 599-586.<br />

<strong>Putzmeister</strong> <strong>Concrete</strong> <strong>Pumps</strong> <strong>GmbH</strong>, Max-Eyth-Str. 10, 72631 Aichtal<br />

PSdg, Deutsche Post AG, Entgelt bezahlt, E 60458<br />

One of the "real" concrete pumps with an image projection of all important parameters<br />

– an example of practice-oriented training at the <strong>Putzmeister</strong> Academy<br />

All rights and technical details subject to alteration · The illustrations show special mechanical equipment and snapshots in practice on construction sites, which do not always<br />

correspond to the regulations of the Industrial Employers’ Liability Insurance Association · © 2008 <strong>by</strong> <strong>Putzmeister</strong> <strong>Concrete</strong> <strong>Pumps</strong> <strong>GmbH</strong> · Printed in Germany (40812Ma)<br />

24 PM 4114 GB<br />

54<br />

55