- Page 2 and 3:

Journal of Science & Technology Jou

- Page 4 and 5:

International Advisory Board Adarsh

- Page 6 and 7:

ut bovine milk allergy by far is th

- Page 8 and 9:

Selected Articles from UPM-Malaysia

- Page 11 and 12:

ISSN: 0128-7680 © 2013 Universiti

- Page 13 and 14:

Aspect of Fatigue Analysis of Compo

- Page 15 and 16:

Aspect of Fatigue Analysis of Compo

- Page 17 and 18:

Aspect of Fatigue Analysis of Compo

- Page 19 and 20:

Aspect of Fatigue Analysis of Compo

- Page 21 and 22:

Aspect of Fatigue Analysis of Compo

- Page 23 and 24:

Aspect of Fatigue Analysis of Compo

- Page 25 and 26:

ISSN: 0128-7680 © 2013 Universiti

- Page 27 and 28:

Application of Anthropometric Dimen

- Page 29 and 30:

Application of Anthropometric Dimen

- Page 31 and 32:

Application of Anthropometric Dimen

- Page 33 and 34:

Application of Anthropometric Dimen

- Page 35 and 36:

Application of Anthropometric Dimen

- Page 37 and 38:

Application of Anthropometric Dimen

- Page 39 and 40:

ISSN: 0128-7680 © 2013 Universiti

- Page 41 and 42:

Different Media Formulation on Bioc

- Page 43 and 44:

Different Media Formulation on Bioc

- Page 45:

Different Media Formulation on Bioc

- Page 48 and 49:

Heng, S. C., Ibrahim, Z. B., Suleim

- Page 50 and 51:

Heng, S. C., Ibrahim, Z. B., Suleim

- Page 52 and 53:

Heng, S. C., Ibrahim, Z. B., Suleim

- Page 54 and 55:

CONCLUSION Heng, S. C., Ibrahim, Z.

- Page 56 and 57:

Y. Yusuf, J. M. Juoi, Z. M. Rosli,

- Page 58 and 59:

Y. Yusuf, J. M. Juoi, Z. M. Rosli,

- Page 60 and 61:

Y. Yusuf, J. M. Juoi, Z. M. Rosli,

- Page 62 and 63:

Surface Roughness Y. Yusuf, J. M. J

- Page 64 and 65:

DISCUSSION Y. Yusuf, J. M. Juoi, Z.

- Page 66 and 67:

Y. Yusuf, J. M. Juoi, Z. M. Rosli,

- Page 69 and 70:

ISSN: 0128-7680 © 2013 Universiti

- Page 71 and 72:

Modelling of Motion Resistance Rati

- Page 73 and 74:

The Empirical Method Modelling of M

- Page 75 and 76:

Modelling of Motion Resistance Rati

- Page 77 and 78:

Modelling of Motion Resistance Rati

- Page 79 and 80:

Modelling of Motion Resistance Rati

- Page 81 and 82:

Modelling of Motion Resistance Rati

- Page 83 and 84:

Modelling of Motion Resistance Rati

- Page 85 and 86:

ISSN: 0128-7680 © 2013 Universiti

- Page 87 and 88:

Assessment of Heavy Metal Pollution

- Page 89 and 90:

TABLE 1: Size of mussels in average

- Page 91 and 92:

Assessment of Heavy Metal Pollution

- Page 93 and 94:

TABLE 5: Heavy metal concentrations

- Page 95 and 96:

Assessment of Heavy Metal Pollution

- Page 97 and 98:

Assessment of Heavy Metal Pollution

- Page 99 and 100:

Assessment of Heavy Metal Pollution

- Page 101 and 102:

Assessment of Heavy Metal Pollution

- Page 103 and 104:

Assessment of Heavy Metal Pollution

- Page 105 and 106:

Assessment of Heavy Metal Pollution

- Page 107 and 108: ISSN: 0128-7680 © 2013 Universiti

- Page 109 and 110: Physico-Chemical and Electrical Pro

- Page 111 and 112: Physico-Chemical and Electrical Pro

- Page 113 and 114: Physico-Chemical and Electrical Pro

- Page 115 and 116: TABLE 1: (continued) Physico-Chemic

- Page 117 and 118: Physico-Chemical and Electrical Pro

- Page 119: Physico-Chemical and Electrical Pro

- Page 122 and 123: Norhashila Hashim et al. effectiven

- Page 124 and 125: Statistical Analysis Norhashila Has

- Page 126 and 127: Norhashila Hashim et al. Post-hoc a

- Page 128 and 129: Norhashila Hashim et al. Cubero, S.

- Page 130 and 131: S. Ismail and K. A. Mohd Atan 4 4 p

- Page 132 and 133: S. Ismail and K. A. Mohd Atan The f

- Page 134 and 135: Lemma 1.1 The equation S. Ismail an

- Page 136 and 137: CONCLUSION S. Ismail and K. A. Mohd

- Page 138 and 139: INTRODUCTION Tajau, R. et al. A hig

- Page 140 and 141: Tajau, R. et al. the acrylate’s c

- Page 142 and 143: Tajau, R. et al. double bond) and C

- Page 144 and 145: Tajau, R. et al. Ulanski, P., & Ros

- Page 146 and 147: Aji, I. S., Zinudin, E. S., Khairul

- Page 148 and 149: Aji, I. S., Zinudin, E. S., Khairul

- Page 150 and 151: CONCLUSION Aji, I. S., Zinudin, E.

- Page 152 and 153: D. Bachtiar, S. M. Sapuan, E. S. Za

- Page 154 and 155: D. Bachtiar, S. M. Sapuan, E. S. Za

- Page 156 and 157: TABLE 1: (continue) 4 D. Bachtiar,

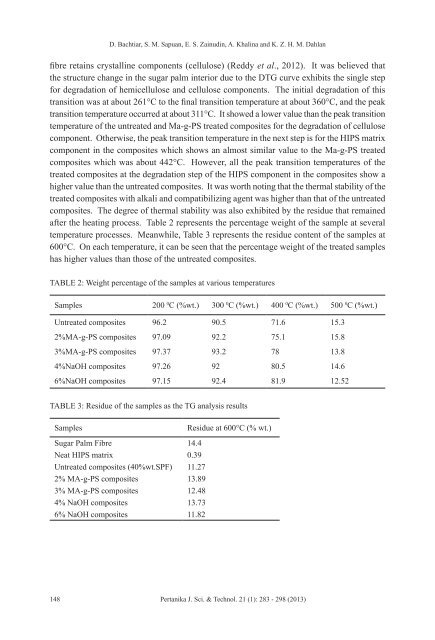

- Page 160 and 161: D. Bachtiar, S. M. Sapuan, E. S. Za

- Page 162 and 163: N. Maizatul, I. Norazowa, W. M. Z.

- Page 164 and 165: N. Maizatul, I. Norazowa, W. M. Z.

- Page 166 and 167: N. Maizatul, I. Norazowa, W. M. Z.

- Page 168 and 169: REFERENCES N. Maizatul, I. Norazowa

- Page 171 and 172: ISSN: 0128-7680 © 2013 Universiti

- Page 173 and 174: CBIR Using Colour and Shape Fused F

- Page 175 and 176: CBIR Using Colour and Shape Fused F

- Page 177 and 178: CBIR Using Colour and Shape Fused F

- Page 179 and 180: ISSN: 0128-7680 © 2013 Universiti

- Page 181 and 182: Toward Automatic Semantic Annotatin

- Page 183 and 184: Toward Automatic Semantic Annotatin

- Page 185 and 186: Toward Automatic Semantic Annotatin

- Page 187 and 188: Toward Automatic Semantic Annotatin

- Page 189 and 190: Toward Automatic Semantic Annotatin

- Page 191 and 192: Toward Automatic Semantic Annotatin

- Page 193 and 194: ISSN: 0128-7680 © 2013 Universiti

- Page 195 and 196: Issues on Trust Management in Wirel

- Page 197 and 198: Issues on Trust Management in Wirel

- Page 199 and 200: Trust Value MF-ID 1 0.8 0.6 0.4 0.2

- Page 201 and 202: Issues on Trust Management in Wirel

- Page 203 and 204: ISSN: 0128-7680 © 2013 Universiti

- Page 205 and 206: A Negation Query Engine for Complex

- Page 207 and 208: A Negation Query Engine for Complex

- Page 209 and 210:

A Negation Query Engine for Complex

- Page 211 and 212:

A Negation Query Engine for Complex

- Page 213 and 214:

REFERENCES A Negation Query Engine

- Page 215 and 216:

ISSN: 0128-7680 © 2013 Universiti

- Page 217 and 218:

The Problem Association Rule Mining

- Page 219 and 220:

Association Rule Mining threshold t

- Page 221 and 222:

Association Rule Mining must be sor

- Page 223 and 224:

Association Rule Mining On the othe

- Page 225:

Association Rule Mining Quinlan, J.

- Page 228 and 229:

Che Mustapha Yusuf, J., Mohd Su’u

- Page 230 and 231:

Che Mustapha Yusuf, J., Mohd Su’u

- Page 232 and 233:

Che Mustapha Yusuf, J., Mohd Su’u

- Page 234 and 235:

Che Mustapha Yusuf, J., Mohd Su’u

- Page 236 and 237:

Che Mustapha Yusuf, J., Mohd Su’u

- Page 238 and 239:

Az Azrinudin Alidin and Fabio Crest

- Page 240 and 241:

Az Azrinudin Alidin and Fabio Crest

- Page 242 and 243:

Az Azrinudin Alidin and Fabio Crest

- Page 244 and 245:

Az Azrinudin Alidin and Fabio Crest

- Page 246 and 247:

Az Azrinudin Alidin and Fabio Crest

- Page 248 and 249:

Az Azrinudin Alidin and Fabio Crest

- Page 250 and 251:

Yogan Jaya Kumar, Naomie Salim, Ahm

- Page 252 and 253:

Yogan Jaya Kumar, Naomie Salim, Ahm

- Page 254 and 255:

Yogan Jaya Kumar, Naomie Salim, Ahm

- Page 256 and 257:

REFERENCES Yogan Jaya Kumar, Naomie

- Page 258 and 259:

Hasiah Mohamed@Omar, Azizah Jaafar

- Page 260 and 261:

Hasiah Mohamed@Omar, Azizah Jaafar

- Page 262 and 263:

Hasiah Mohamed@Omar, Azizah Jaafar

- Page 264 and 265:

Hasiah Mohamed@Omar, Azizah Jaafar

- Page 266 and 267:

Hasiah Mohamed@Omar, Azizah Jaafar

- Page 268 and 269:

Hasiah Mohamed@Omar, Azizah Jaafar

- Page 271 and 272:

ISSN: 0128-7680 © 2013 Universiti

- Page 273 and 274:

The Role of Similarity Measurement

- Page 275 and 276:

The Role of Similarity Measurement

- Page 277 and 278:

The Role of Similarity Measurement

- Page 279 and 280:

The Role of Similarity Measurement

- Page 281 and 282:

TABLE 5: Winners MRS The Role of Si

- Page 283:

REFEREES FOR THE PERTANIKA JOURNAL

- Page 286 and 287:

Guidelines for Authors Publication

- Page 288 and 289:

table should be prepared on a separ

- Page 290 and 291:

The Journal’s review process What

- Page 293 and 294:

Usability of Educational Computer G