Instructions for Use 3 mm - Varicor

Instructions for Use 3 mm - Varicor

Instructions for Use 3 mm - Varicor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3. GENERAL PROCESSING GUIDELINES<br />

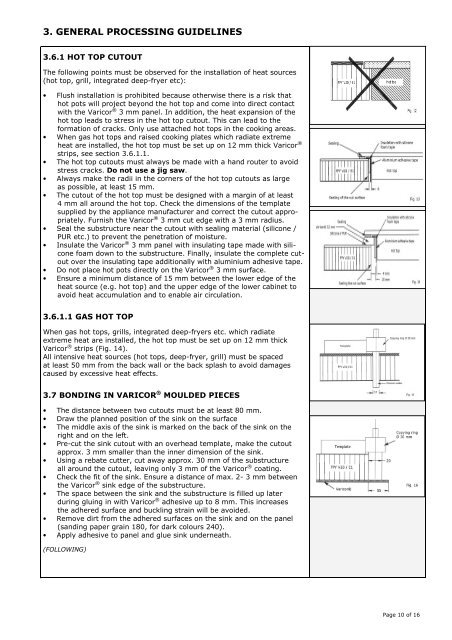

3.6.1 HOT TOP CUTOUT<br />

The following points must be observed <strong>for</strong> the installation of heat sources<br />

(hot top, grill, integrated deep-fryer etc):<br />

• Flush installation is prohibited because otherwise there is a risk that<br />

hot pots will project beyond the hot top and come into direct contact<br />

with the <strong>Varicor</strong> ® 3 <strong>mm</strong> panel. In addition, the heat expansion of the<br />

hot top leads to stress in the hot top cutout. This can lead to the<br />

<strong>for</strong>mation of cracks. Only use attached hot tops in the cooking areas.<br />

• When gas hot tops and raised cooking plates which radiate extreme<br />

heat are installed, the hot top must be set up on 12 <strong>mm</strong> thick <strong>Varicor</strong> ®<br />

strips, see section 3.6.1.1.<br />

• The hot top cutouts must always be made with a hand router to avoid<br />

stress cracks. Do not use a jig saw.<br />

• Always make the radii in the corners of the hot top cutouts as large<br />

as possible, at least 15 <strong>mm</strong>.<br />

• The cutout of the hot top must be designed with a margin of at least<br />

4 <strong>mm</strong> all around the hot top. Check the dimensions of the template<br />

supplied by the appliance manufacturer and correct the cutout appro-<br />

priately. Furnish the <strong>Varicor</strong> ® 3 <strong>mm</strong> cut edge with a 3 <strong>mm</strong> radius.<br />

• Seal the substructure near the cutout with sealing material (silicone /<br />

PUR etc.) to prevent the penetration of moisture.<br />

• Insulate the <strong>Varicor</strong> ® 3 <strong>mm</strong> panel with insulating tape made with sili-<br />

cone foam down to the substructure. Finally, insulate the complete cut-<br />

out over the insulating tape additionally with aluminium adhesive tape.<br />

• Do not place hot pots directly on the <strong>Varicor</strong> ® 3 <strong>mm</strong> surface.<br />

• Ensure a minimum distance of 15 <strong>mm</strong> between the lower edge of the<br />

heat source (e.g. hot top) and the upper edge of the lower cabinet to<br />

avoid heat accumulation and to enable air circulation.<br />

3.6.1.1 GAS HOT TOP<br />

When gas hot tops, grills, integrated deep-fryers etc. which radiate<br />

extreme heat are installed, the hot top must be set up on 12 <strong>mm</strong> thick<br />

<strong>Varicor</strong> ® strips (Fig. 14).<br />

All intensive heat sources (hot tops, deep-fryer, grill) must be spaced<br />

at least 50 <strong>mm</strong> from the back wall or the back splash to avoid damages<br />

caused by excessive heat effects.<br />

3.7 BONDING IN VARICOR ® MOULDED PIECES<br />

• The distance between two cutouts must be at least 80 <strong>mm</strong>.<br />

• Draw the planned position of the sink on the surface<br />

• The middle axis of the sink is marked on the back of the sink on the<br />

right and on the left.<br />

• Pre-cut the sink cutout with an overhead template, make the cutout<br />

approx. 3 <strong>mm</strong> smaller than the inner dimension of the sink.<br />

• Using a rebate cutter, cut away approx. 30 <strong>mm</strong> of the substructure<br />

all around the cutout, leaving only 3 <strong>mm</strong> of the <strong>Varicor</strong> ® coating.<br />

• Check the fit of the sink. Ensure a distance of max. 2- 3 <strong>mm</strong> between<br />

the <strong>Varicor</strong> ® sink edge of the substructure.<br />

• The space between the sink and the substructure is filled up later<br />

during gluing in with <strong>Varicor</strong> ® adhesive up to 8 <strong>mm</strong>. This increases<br />

the adhered surface and buckling strain will be avoided.<br />

• Remove dirt from the adhered surfaces on the sink and on the panel<br />

(sanding paper grain 180, <strong>for</strong> dark colours 240).<br />

• Apply adhesive to panel and glue sink underneath.<br />

(FOLLOWING)<br />

Page 10 of 16