The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

The Locomotive - Lighthouse Survival Blog

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

68 THE LOCOMOTIVE. [May,<br />

diameter of the dome, and we proceed to consider the objections to the seven-inch hole<br />

and the series of three-quarter-inch holes. <strong>The</strong> most obvious objection to tliese is, that<br />

in such cases the interior of the dome is quite inaccessible for inspection and repairs.<br />

We hold that the best solution of the dome-opening problem is to make the opening<br />

elliptical, 11" x 15", and to securely rivet to it a manhole frame (see Fig. 1). This makes<br />

the interior of the dome quite accessible, preserves a considerable portion of the shell,<br />

and so stiffens what remains as to materially increase its efficiency.<br />

In old boilers where the dome is of considerable size compared with the shell, say<br />

30" in diameter on a 48'' cylinder, one or two stay bolts may be put across it as shown in<br />

Fig. 3. This construction is not recommended for new boilers, but it is often serviceable<br />

where the dome of a boiler already in use gives trouble by leakage along the joint where<br />

it is riveted to the boiler. <strong>The</strong> same object may likewise be attained by the construction<br />

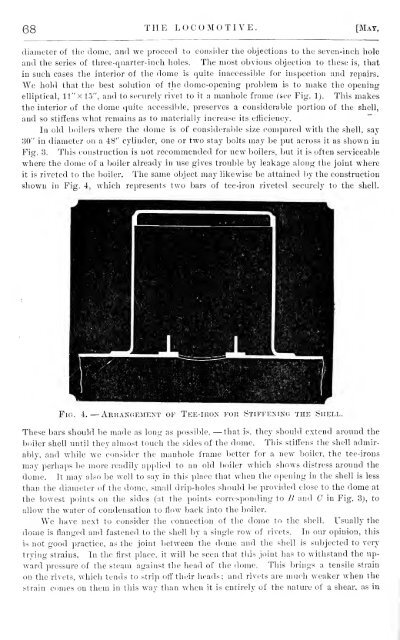

shown in Fig. 4, which represents two bars of tee-iron riveted securely to the shell.<br />

Fig. 4. — Arrangement of Tee-iron for Stiffening the Shell.<br />

<strong>The</strong>se bars should be made as long as possible, — that is, they should extend around the<br />

boiler shell until they almost touch the sides of the dome. This stiffens the shell admir-<br />

ably, and while we consider the manhole frame better for a new^ boiler, the tee-irons<br />

may perhaps be more readily applied to an old boiler which shows distress around the<br />

dome. It may also be well to say in this place that when the opening in the shell is less<br />

than the diameter of the dome, small drip-holes should be provided close to the dome at<br />

the lowest points on the sides (at the points corresponding to B and C in Fig. 3), to<br />

allow the water of condensation to flow back into the boiler.<br />

We have next to consider the connection of the dome to the shell. Usually the<br />

dome is flanged and fastened to the shell by a single row of rivets. In our ojDinion, this<br />

is not good practice, as the joint between the dome and the shell is subjected to very<br />

trying strains. In the first place, it will be seen that this joint has to withstand the upward<br />

pressure of the steam against the head of the dome. This brings a tensile .strain<br />

on the rivets, which tends to strip off their heads; and rivets are much weaker when the<br />

strain comes on them in this way than when it is entirely of the nature of a shear, as in<br />

""