0150.16.08 B SINKAMAT UF (engl.). - ACO Haustechnik

0150.16.08 B SINKAMAT UF (engl.). - ACO Haustechnik

0150.16.08 B SINKAMAT UF (engl.). - ACO Haustechnik

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Installation, Operating<br />

and Maintenance Manual<br />

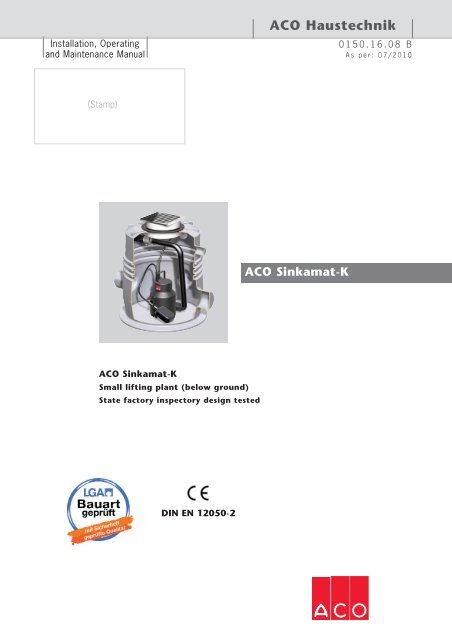

<strong>ACO</strong> Sinkamat-K<br />

Small lifting plant (below ground)<br />

State factory inspectory design tested<br />

DIN EN 12050-2<br />

<strong>ACO</strong> <strong>Haustechnik</strong><br />

<strong>ACO</strong> Sinkamat-K<br />

<strong>0150.16.08</strong> B<br />

As per: 07/2010

Contents<br />

Chapter Page<br />

1 Product identification<br />

1.1 Addresses 3<br />

1.2 Product identification 3<br />

1.3 Conformity Declaration 4<br />

2 Field of application<br />

2.1 Field of application 5<br />

2.2 General notes 5<br />

2.3 Basic principles/lifting plant fitting 5<br />

2.4 Product and functional description 6<br />

2.5 Technical data 7<br />

3 Safety notes<br />

3.1 - 3.8 Safety notes/staff/operator 8<br />

4 Operating instructions<br />

4.1 Scope of supply/individual components 9<br />

5 Installation<br />

5.1 - 5.7 Fitting 10 - 13<br />

5.8 Commissioning 14<br />

6 Operation<br />

6.1 - 6.2 Correct intended use/Likely misuse 15<br />

6.2 Operation 15<br />

7 Inspection and maintenance<br />

7.1 - 7.2 Regular maintenance works 16<br />

7.3 Faults; cause and remedy 16<br />

7.4 Spare parts list 16<br />

7.5 Service partners 17<br />

7.6 Excerpt from the Sales Terms and Delivery Conditions <strong>ACO</strong> Passavant GmbH 17<br />

8 Suggested installations 18 - 19<br />

9 Maintenance and functional check 20 - 23<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

2

1.1 Addresses<br />

Name and address of manufacturer<br />

<strong>ACO</strong> Passavant GmbH<br />

Postfach 11 62<br />

36267 Philippsthal<br />

Ulsterstraße 3<br />

36269 Philippsthal After-sales service<br />

Tel. ++49 (0) 66 20/ 77- 0 Service tel. ++49 (0) 3 69 65 - 819 - 444<br />

Fax ++49 (0) 66 20/77- 52 Service fax ++49 (0) 3 69 65 - 819 - 367<br />

Name and address of supplier<br />

_________________________<br />

_________________________<br />

_________________________<br />

_________________________<br />

After-sales service<br />

Tel. _____________________ __________________________<br />

Fax ____________________ __________________________<br />

1.2 Product identification<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

3<br />

<strong>ACO</strong> <strong>Haustechnik</strong><br />

Name and address of electrician<br />

<strong>0150.16.08</strong> B<br />

_________________________<br />

_________________________<br />

_________________________<br />

_________________________<br />

After-sales service<br />

Tel. _____________________ __________________________<br />

Fax ____________________ __________________________<br />

Name and address of plumber<br />

Type: Sinkamat-K<br />

Small lifting plant (below ground)<br />

Serial number<br />

Housing:<br />

Serial number<br />

Pump:<br />

Year built:<br />

Art.-Nr.: 620387<br />

Pump 50/1-K<br />

Art.-Nr.: 620490<br />

Pump 50/2-K<br />

_________________________<br />

_________________________<br />

_________________________<br />

_________________________<br />

After-sales service<br />

Tel. _____________________ __________________________<br />

Fax ____________________ __________________________

1.3 EC Conformity Declaration<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

4

2 Field of application<br />

2.1 Field of application of installation, operating and<br />

maintenance manual<br />

This manual is effective for the AC0 Sinkamat-K (below ground)<br />

small lifting plant.<br />

The manual is used for installation, commissioning, operation, maintenance,<br />

repair and decommissioning. The operator must keep the<br />

manual at a safe place.<br />

Indications on possible standards, test signs, quality symbols and<br />

trademarks are state-of-the-art at the printing date of this manual.<br />

Deviations with illustrations, dimensions and weights are possible.<br />

We reserve the right to carry out amendments and improvements<br />

without prior notice to keep up with technical progress.<br />

Date of installation, operating and maintenance manual:<br />

January 2008<br />

2.3 Basic principles/lifting plant fitting<br />

where - why - for which reason<br />

What causes backflow?<br />

Wastewater can backflow into buildings whenever wastewater can<br />

no longer drain off optimally into the public sewers. The dimensioning<br />

of drainage installations today takes into consideration economic<br />

aspects and self-cleaning effects based on average rainfall<br />

events.<br />

However, heavy rainfall which exceeds the reference rainfall level<br />

can also occur. This means that the drainage installations can be<br />

overloaded at any time.<br />

In addition to periods of heavy rainfall, wastewater can also be prevented<br />

from draining off as quickly as required by unwanted reductions<br />

in pipe cross sections caused by deposits or blockages in<br />

sewer pipes, not to mention cracked pipes, pump failures in public<br />

sewers, and floods – all can lead to sewage backflowing into a building.<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

5<br />

2.2 General notes<br />

<strong>ACO</strong> <strong>Haustechnik</strong><br />

<strong>0150.16.08</strong> B<br />

Safety-conscious working<br />

These operating instructions contain fundamental information and precautionary<br />

notes. Please read the manual thoroughly prior to installation<br />

of unit, connection to power supply and commissioning. It is imperative<br />

to comply with all other operating instructions referring to components<br />

of this plant. The mentioned safety notes, the pertinent national accident<br />

prevention regulations as well as possible internal working-, operating<br />

and safety regulations of the operator have to be observed. The<br />

safety notes which could lead to danger for people in the case of their<br />

non-observance as well as in the case of warning of electric voltage,<br />

are marked with the general safety marks.<br />

Safety (from: VDMA information sheet 24292)<br />

This operating manual contains basic information which must be<br />

observed during installation, operation and maintenance. Therefore,<br />

this operating manual must be read by the fitter as well as the<br />

competent personnel / operator prior to assembly and commissioning<br />

and must always be available at location of plant.<br />

Supplements<br />

The operator of the plant must supplement the operating manual<br />

with instructions on existing national regulations for accident prevention<br />

and environmental protection.<br />

Besides the operating manual and the binding regulations for accident<br />

prevention valid in the user country and at the point of use, the<br />

approved expert regulations for safe and professional working have<br />

to be observed.<br />

Copyright<br />

<strong>ACO</strong> Passavant GmbH holds the copyright for these operating<br />

instructions. These operating instructions are meant for the assembly,<br />

operating, maintenance and supervisory staff. They contain regulations<br />

and technical drawings whose complete or partial reproduction,<br />

dissemination or use for competitive purposes, or passing on<br />

to third parties, is not permitted.

The backflow level<br />

The backflow level is the highest level (water level) to which wastewater<br />

can rise in a drainage installation. The backflow level is defined<br />

by the local authority (local bylaws). In the absence of any specific<br />

definition, the backflow level is usually taken as the level of the<br />

road above the sewer connections (fig. 1).<br />

All drainage installations below this level are at risk of backflow and<br />

should therefore be protected by implementing the appropriate<br />

measures.<br />

The backflow safety valve<br />

Protection against backflow is basically carried out by wastewater<br />

lifting plants.<br />

2.4 Product and functional description<br />

2.4.1 Product description/field of application<br />

The Sinkamat-K is a small lifting plant for below ground installation in<br />

frostproof premises below the backflow level. It delivers domestic grey<br />

water which is free of faeces from washing machines, showers, washstands,<br />

saunas, fitness and hobby rooms (cellar drainage) etc. The<br />

size of the suspended matter may not exceed the grain size mentioned<br />

in para 2.5.<br />

Caution !<br />

Do not feed any faeces, stones, lacquer, paint or acids!<br />

The small lifting plant is tested in accordance with DIN EN 12050-2.<br />

The housing consists of a high-quality PE with several connection<br />

options DN 100. A grey water submerged pump with solenoid float<br />

switch is integrated.<br />

The pump is equipped with a robust AC motor; sealing of pump housing<br />

to motor is carried out by a rotating mechanical seal.<br />

The pump housing and the impeller are of plastic, the motor housing<br />

and the shaft of stainless steel. The pressure line feedthrough<br />

AG R 1 1/2” with integrated non-return flap is defined. The DN 50 connection<br />

serves as inlet or for container ventilation. The pump is equipped<br />

with a 10 m connecting cable with safety plug (230 V, 50 Hz AC).<br />

Wastewater enters the lifting plant via one or more lateral inlet sockets<br />

up to DN 100. If water level rises and float switch floats upwards, the<br />

pump switches on. The submerged pump delivers the wastewater<br />

through the backflow preventer into the pressure line to the sewers<br />

until the water level again is thus low that float switches off pump<br />

again. The pressure line connection is a transition socket nipple<br />

PVC-U; 50-40-1 1/4” (internal diameter 40 mm).<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

6<br />

Fig. 1<br />

Fig. 2<br />

Fig. 3<br />

Backflow level

2.5 Technical data Performance diagram:<br />

Designation Parameter<br />

Pressure line connection Transition socket nipple<br />

as per EN ISO 15493 PVC-U; 50-40-1 1/4”<br />

(internal Ø 40 mm)<br />

Max. grain size 10 mm<br />

Voltage 230 V<br />

Frequency 50 Hz<br />

Rated input P1 350 W (50/1-K)/650 W (50/2-K)<br />

Charging rate 1.8 A (50/1-K) / 3.7 A (50/2-K)<br />

Revolutions 2800 min -1<br />

Mains connection line 10 m, 3x1 mm2 Float switch yes<br />

Max. delivery capacity 5.8 m3 /h (50/1-K) / 8.3 m3 (50/2-K)<br />

Max. delivery head 7.2 m (50/1-K) / 11.4 m (50/2-K)<br />

Total weight 12 kg<br />

Useable volume 15 l<br />

Container capacity 70 l<br />

The permissible delivery temperature is 40°C, up to 90°C for a<br />

short time.<br />

Water leaking from a bore in the pump housing of the Sinkamat-K<br />

pumps is construction-conditioned and ventilates the pump housing<br />

- no defect!<br />

max. installation depth<br />

Hmax<br />

Ø 520<br />

670<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

Hmin.<br />

DN 70<br />

541<br />

443<br />

158<br />

7<br />

75 +0,4<br />

0<br />

Ø 110 +0,4<br />

0<br />

[m] 12<br />

Total delivery head H<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

<strong>ACO</strong> <strong>Haustechnik</strong><br />

<strong>0150.16.08</strong> B<br />

Tolerances ISO 2548/C<br />

n = 2800 r.p.m.<br />

0<br />

0 0,5 1,0 1,5 2,0 2,5<br />

0<br />

Sinkamat-K 50/1 K<br />

Min. delivery flow DN 40<br />

Min. delivery flow DN 50<br />

Sinkamat-K 50/2 K<br />

1 2 3 4 5 6 7 8 9<br />

.<br />

Delivery flow Q<br />

Type Motor- Nom. current<br />

perform.<br />

(kW)<br />

P1 P2<br />

IN<br />

(A)<br />

(UST) 50/1-K 0,35 0,2 1,8<br />

(UST) 50/2-K 0,65 0,35 3,7<br />

Delivery<br />

flow<br />

(Q)<br />

3<br />

m /h<br />

l/s<br />

3<br />

m /h<br />

l/s<br />

Ø 60<br />

[l/s]<br />

[ ]<br />

Total delivery head<br />

H in (mm)<br />

2 3 4 5 6 7 8 9<br />

5,8 4,7 3,6<br />

1,6 1,3 1,0<br />

8,3 7,9 6,8 6,3 5,4 4,5 3,4<br />

2,3 2,2 1,9 1,75 1,5 1,25 0,95<br />

262<br />

40 40<br />

270<br />

372

3 Safety notes<br />

3.1 Safety notes<br />

The safety notes which could lead to danger to people in the case of<br />

their non-observance as well as in the case of warning of electric voltage<br />

are marked with the general safety marks (according to DIN 4844 .<br />

W8/9).<br />

General<br />

risk symbol<br />

If risks for the appliance and its performance persist in the case of nonobservance<br />

of safety notes, this is emphasized by the word<br />

Caution !<br />

Notes attached directly to the appliance, as e. g.<br />

■ sense of rotation arrow<br />

■ marking of fluid connections<br />

must be observed and kept in completely legible condition.<br />

3.2 Staff qualification and training<br />

The operations, servicing, inspection and assembly staff must have the<br />

appropriate qualifications to carry out the work. The operator must precisely<br />

specify and regulate the department responsible for management,<br />

the accountabilities and the supervision of the staff. If staff do<br />

not have the necessary qualifications, they must be trained and instructed<br />

accordingly. If required, this can be carried out by manufacturer/<br />

supplier on behalf of the pump operator. The operator must also ensure<br />

that the contents of the operating instruction manual are completely<br />

understood by the staff.<br />

3.3 Endangering in the case of non-observance of safety notes<br />

Non-observance of safety notes may lead to endangering persons as<br />

well as the pump. No damage claims are accepted in the case of nonobservance<br />

of safety notes. Here some examples of hazards which<br />

may occur:<br />

■ Breakdown of vital pump functions.<br />

■ Omission of required maintenance and servicing methods.<br />

■ Endangering of staff by electrical, mechanical and chemical effects.<br />

■ Endangering of environment by leakage of dangerous substances.<br />

3.4 Electrical safety<br />

The electrical installation of equipment and components must comply<br />

with the stipulations laid down by European standards EN 1012 Section<br />

1 and EN 60 204 Section 1, and must also where necessary comply<br />

with the local regulations laid down by the electrical utility. The local<br />

potential equalisation must also be observed.<br />

Work on the electrical equipment of the lifting plant must only be carried<br />

out by a properly qualified electrician or by properly instructed persons<br />

working under the instruction or supervision of a properly qualified<br />

electrician in accordance with the electrical regulations.<br />

Before any work is carried out on the electrical equipment, it is essential<br />

for the following measures to be implemented in the following order:<br />

1. All-pole disconnection (switching off the main switch or pull out mains<br />

plug).<br />

2. Securing the electrical equipment against accidental switching on.<br />

3. Checking that the system is not connected to the circuit.<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

Beware of<br />

electrical voltage<br />

8<br />

3.5 Safety notes for the operator/user<br />

■ If hot or cold machine parts are hazardous, these must be<br />

protected on site against contact.<br />

■ The pumps are equipped with a thermal winding protection,<br />

pump starts up automatically if motor cools down. In the<br />

case of repair or maintenance works, the appliance has to be<br />

unplugged!<br />

■ Contact protection for moving parts (e. g. coupling); may not<br />

be removed as long as machine is in operation.<br />

■ Leakages (e. g. of shaft seal) of hazardous delivery media<br />

(e. g. explosive, toxic, hot) must be handled in such a way<br />

that human beings and environment are not endangered;<br />

observe legal regulations.<br />

■ Endangering by electrical energy has to be ruled out (for<br />

details, refer to regulations of VDE (Association of German<br />

Electricians) and local power utilities).<br />

3.6 Notes for the operator<br />

The operator has to make sure that all maintenance, inspection and<br />

assembly works are carried out by authorised and qualified skilled personnel<br />

who have read instructions of this manual thoroughly.<br />

Original spare parts may be used only!<br />

Basically, all works at pump are to be carried out during stillstand<br />

periods only.<br />

Pumps or components delivering health-hazardous media must be<br />

decontaminated. Directly following finishing of works, all safety and<br />

protection devices have to be re-assembled and made operable.<br />

3.7 Arbitrary alteration and spare parts use<br />

If this operating manual is not observed<br />

- if safety notes are neglected in particular - or if the appliance<br />

is modified arbitrarily or non-original spare parts are fitted, no<br />

damage claims are accepted. The manufacturer is not liable for<br />

defects resulting from this non-observance!<br />

3.8 Improper operating methods<br />

The operational safety of the supplied machine is guaranteed only if<br />

machine is used properly and in accordance with section 1 of operating<br />

manual - General notes. The limit values indicated in the data<br />

sheet may by no means be exceeded!

4 Operating instructions<br />

4.1 Scope of supply/individual components<br />

9<br />

<strong>ACO</strong> <strong>Haustechnik</strong><br />

<strong>0150.16.08</strong> B<br />

Part number Designation Illustration Quantity<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

PE housing 1<br />

Protective cover during construction period 1<br />

Transition socket 1<br />

Sealing for transition socket 1<br />

Threaded socket 1<br />

Non-return flap for threaded socket 1<br />

Brass reducer 1<br />

Rapid connection plug 1<br />

Spigot nut 1<br />

Spiral hose 1<br />

Hose clamp 2<br />

Pump 1<br />

Rapid coupling 1<br />

PP top section 1

5 Installation<br />

5.1 Fitting in the base plate<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

1<br />

Fig. 4<br />

Set up housing, inlet connections<br />

Insert housing in flow direction and align horizontally. Saw off<br />

inlet connections as required and connect KG pipe(s) in accordance<br />

with DIN 19522 (fig. 4).<br />

Continue granular sub-grade course above upper edge of pipe.<br />

10<br />

2<br />

1<br />

Fig. 5<br />

In case of need:<br />

Place sealing flange (art. no. 620382) against pressurised water<br />

onto housing. Sealing flange can be attached stepwise to the<br />

different grooves (fig. 5). (For flange height-adjustability refer to<br />

installation or dimensional drawing on page 7).<br />

Protect pump shaft against soiling during construction<br />

works by means of the protective cover.

5.2 Installation of the pressure socket<br />

■ Bore for pressure socket<br />

■ Bore feed line at given marking (fig. 6).<br />

■ Bore for pressure socket to be carried out with drill 43 mm (fig. 7).<br />

■ Art. no. of drill: 0150.14.80<br />

■ Art. no. of drill adapter: 0150.14.81<br />

■ Deburr edges (fig. 8).<br />

4<br />

3<br />

■ Transition socket from 1 ¼“ to 50 mm bonded socket joint<br />

Apply sealing to threaded side (fig. 9).<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

1<br />

1<br />

Fig. 6 Fig. 7 Fig. 8<br />

Fig. 9 Fig. 10<br />

■ Transition socket outside<br />

■ Bolt brass reducer with threaded socket (fig. 11).<br />

■ Connect thread with container internal side and with threaded<br />

socket (in non-return flap seat) (fig. 12).<br />

13<br />

5<br />

7<br />

11<br />

3 + 4<br />

11<br />

<strong>ACO</strong> <strong>Haustechnik</strong><br />

6<br />

5<br />

1<br />

<strong>0150.16.08</strong> B<br />

■ Insert non-return flap in threaded socket (in longer thread, flap opening<br />

towards the outside) (fig. 10).<br />

5 + 7<br />

Fig. 11 Fig. 12 Fig. 13<br />

■ Mount rapid coupling with spiral hose and spigot nut with hose<br />

clamps (fig. 14). Only when exchanging spare parts or during<br />

cleaning.<br />

10<br />

11<br />

9<br />

Fig. 14<br />

8<br />

■ Bolt rapid connection plug wih brass reducer (fig. 13).

5.3 Shortening the top section<br />

■ The top section must be applied to the housing. By cutting it, it is<br />

continuously height-adjustable. Do not push into housing! (fig. 19)<br />

Cut top section.<br />

Deburr cut socket.<br />

(For height-adjustability of top section, refer to installation or dimensional<br />

drawing on page 7, dimensions in table below).<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

Fig. 19<br />

Height-adjustability of top section<br />

Art. no. Designation Hmax Hmin<br />

in mm in mm<br />

5084.71.00 PP top section, screwed 150 30<br />

5084.87.00 PP top section 150 30<br />

5084.81.00 MEKU top section 155 35<br />

Extended designs<br />

5084.71.01 PP top section, screwed 270 30<br />

5084.87.01 PP top section 270 30<br />

5084.81.01 MEKU top section 275 35<br />

Caution !<br />

Depending on design, the extended version may restrain maintenance of internal<br />

fittings. Please check locally.<br />

max. installation depth<br />

Hmax<br />

14<br />

Ø 520<br />

670<br />

Hmin.<br />

DN 70<br />

541<br />

443<br />

158<br />

12<br />

1<br />

14<br />

Fig. 20<br />

■ Inserting the top section (fig. 20)<br />

Press top section into groove in housing.<br />

Protect top section against shifting during flooring works<br />

Protect pump shaft against pollution during construction<br />

works.<br />

75 +0,4<br />

0<br />

Ø 110 +0,4<br />

0<br />

Ø 60<br />

262<br />

40 40<br />

270<br />

372

5.4 Pump installation<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

1<br />

Fig. 15<br />

■ Insert pump with float pointing upwards through the top section into<br />

the container (fig. 15).<br />

1<br />

12<br />

9 - 13<br />

Fig. 17<br />

■ Saw off connection of empty conduit for cable feedthrough. Connect<br />

pipe (DN 70) and lay.<br />

13<br />

<strong>ACO</strong> <strong>Haustechnik</strong><br />

13<br />

1<br />

<strong>0150.16.08</strong> B<br />

Fig. 16<br />

■ Connect pump (fig. 12)<br />

■ Fix hose end with spigot nut to pump in such a way that angle<br />

points upwards by 90°.<br />

■ Fix hose end with rapid coupling to connection plug, operate<br />

lever.<br />

■ Position pump in the centre.<br />

1<br />

12<br />

9<br />

10<br />

Fig. 18<br />

■ Draw cable through empty conduit.<br />

Caution !<br />

The cable supplied is 10 m long. When laying the empty conduit up to<br />

the power socket, pay attention that as much cable remains in the shaft<br />

as is needed to lift out the pump through the top section and place it<br />

right beside in case of maintenance works or exchange of pump.

5.5 Commissioning<br />

Works at the electrical plant may only be<br />

carried out by an electrician.<br />

Observe safety notes on page 8!<br />

The pump is equipped with a robust AC motor; sealing of pump housing<br />

to motor is carried out with a rotating mechanical seal. The electrical<br />

connection is done with a 10 m long connecting cable with safety<br />

plug (230 V, 50 Hz AC).<br />

■ Check pump for possible damages prior to commissioning<br />

(e. g. transport damages) in order to prevent accidents with<br />

electricity.<br />

■ The pump must be connected to a power socket with earthing.<br />

■ Never carry pump at cable, let into water at cable or pull out<br />

of water at cable.<br />

■ If current supply is not obligatorily carried out via a ground<br />

fault circuit interruptor with max. 30 mA error current, the<br />

pump must be connected to the power socket via a separate<br />

ground fault circuit interruptor.<br />

■ Float performance can be checked by lifting and lowering it.<br />

For proper working of the pump, a min. water level of<br />

120 mm is required. Suction is carried out up to a water level<br />

of 25 mm (fig. 21).<br />

■ The inlet sieve may not be blocked by sludge and/or fibrous<br />

media. The float switch attached to the pump must be able to<br />

move freely (see 5.4 float position).<br />

■ In order to avoid damaging of the rotating mechanical seal,<br />

the pump may not run dry.<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

On 120 mm<br />

Off 25 mm<br />

Fig. 21<br />

14

6 Operation<br />

The plant may only be operated, maintained and<br />

commissioned by persons who are familiar with<br />

the operating manual, the instructions contained<br />

therein and the pertinent regulations for job<br />

safety and accident prevention!<br />

6.1 Correct intended use<br />

The Sinkamat-K is a small lifting plant for below ground installation in<br />

frostproof premises below the backflow level. It has to be used for<br />

delivery of wastewater or grey water from hand washbasins, sinks,<br />

washing machines etc.<br />

6.1.2 Likely misuse<br />

The Sinkamat-K small lifting plant may not be used for delivery of<br />

wastewater containing faeces or fats.<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

15<br />

6.2 Operation<br />

<strong>ACO</strong> <strong>Haustechnik</strong><br />

<strong>0150.16.08</strong> B<br />

The Sinkamat-K small lifting plant works fully automatically. The only<br />

regular works which have to be carried out at the plant are maintenance<br />

works, which are described in chapter 7.

7 Inspection and maintenance<br />

7.1 Regular maintenance works:<br />

Once a month ■ by the operator<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

16<br />

■ Check plant for serviceability and tightness by observing a<br />

switching cycle.<br />

Every 3 months ■ Check visible connections for tightness by searching the peri-<br />

■ by a properly qualified technician/by<br />

<strong>ACO</strong> <strong>Haustechnik</strong><br />

Service (recommendation)<br />

■ Every 3 months with plants in commercial establishments.<br />

■ Every 6 months with plants in apartment buildings.<br />

■ Once a year with plants in single-family houses<br />

(recommendation).<br />

7.2 Maintenance of submerged pump<br />

Prior to all works at the pump, pull out<br />

mains plug and protect from unauthorised<br />

re-insertion!<br />

Maintenance consists of checking and cleaning the pump housing.<br />

In order to do this, remove the four recessed head screws. Remove<br />

and clean inlet sieve and base plate. Then re-assemble all parts in<br />

correct order.<br />

7.3 Faults; cause and remedy<br />

Fault Cause Remedy<br />

phery, the plant itself and the fittings.<br />

■ Operate the valve (if any). Check for easy movement, adjust<br />

and grease, if required.<br />

■ Open and clean the backflow preventer.<br />

■ Clean the submerged pump (see special instructions) and the<br />

directly adjacent line area.<br />

■ Clean collecting container internally (in case of need or as per<br />

special requirements).<br />

■ Check condition of collecting container.<br />

■ Check electrical parts of plant.<br />

■ Check centrifugal pump in accordance with information from<br />

product operating manual.<br />

Caution !<br />

In the case of wear of impeller (e. g. by abrasive media), wear of the<br />

rotating mechanical seal is also possible. Check of rotating mechanical<br />

seal and motor as well as exchange of the electrical connecting line<br />

should only be carried out by authorised after-sales service personnel<br />

or by the manufacturer itself.<br />

1. Motor does not turn - No or incorrect mains voltage - Check power supply<br />

- Faulty connection - Correct connection<br />

- Defective mains cable - Exchange (by after-sales service)<br />

- Impeller blocked - Clean<br />

- Activated motor protection (excessive heat, blockage, - Check, inform after-sales service<br />

voltage fault or other defect)<br />

- Float stuck - Place pump in such a way that float<br />

can work freely<br />

- Motor defective - Exchange (by after-sales service)<br />

2. Motor turns, however, - Impeller blocked or worn - Clean/exchange<br />

does not deliver - Pressure line blocked/hose bent - Clean/remove kink<br />

- Aspiration port blocked - Clean<br />

3. Delivery capacity too low - Pump not correctly ventilated (air bubbles in the - Ventilate pressure line of pump with initial commissiohousing)<br />

ning to allow water to enter the pump housing<br />

- Layout of pressure line too small - At least 25 mm (1”) diameter<br />

4. Leaking water - Pump ventilates itself - Construction-conditioned! No defect!<br />

7.4 Spare parts list Sinkamat-K below ground<br />

Art. no. Designation Components contained in this article<br />

0175.07.99 Pump<br />

0154.26.52 Internal fittings (spiral hose) Spiral hose, rapid coupling socket, wire hose clamps, hose connection elbow,<br />

spigot nut<br />

0154.23.89 Internal fittings (pressure line Reducer, threaded socket, non-return flap, flat sealing, transition socket,<br />

connection) rapid coupling plug

7.5 Service partners<br />

Our service partners are listed under:<br />

www.aco-haustechnik.de/servicepartner<br />

7.6 Excerpt from the Sales Terms and Delivery Conditions <strong>ACO</strong> Passavant GmbH<br />

1. General<br />

2. Price and payment<br />

3. Time of delivery, delivery delays<br />

4. Dispatch, transfer of risk, acceptance<br />

5. Retention of title<br />

6. Warranty<br />

Supplier shall be liable for property damage and deficiency in title with<br />

any further claims excluded, with the reservation of paragraph 7 and<br />

irrespective of sections 478, 479 German Civil Code as specified<br />

hereinafter:<br />

1. Any and all of those parts included in the delivery, that after delivery<br />

turn out to be unusable or not irrelevantly impaired in their serviceability,<br />

the cause of which lies prior to passage of risk, shall be repaired or<br />

supplied again at no cost for Purchaser. Supplier may choose between<br />

repair and substitute delivery. Purchaser shall be entitled to reduction of<br />

the purchase price or withdrawal from contract after the second unsuccessful<br />

attempt of repair or replacement or should repair or replacement<br />

be unacceptable. For the rest, Supplier shall be liable for damages<br />

only in the scope of the following section 7. Supplier shall be informed<br />

immediately of detected defects. Irrespective of the statutory merchants'<br />

requirement of examination and requirement to give notice of<br />

defects, written notice of evident defects shall be given to Supplier not<br />

later than 14 days upon delivery, otherwise the warranty shall cease.<br />

Replaced parts shall become Supplier's property.<br />

2. Upon consultation with Supplier, Purchaser shall grant Supplier sufficient<br />

time and opportunity for performing repairs and replacements considered<br />

necessary by Supplier, otherwise Supplier shall be released<br />

from liability for consequential damages. Purchaser shall be entitled to<br />

repair the defect himself or to having the defect repaired by any third<br />

party and to demand reimbursement of incurred costs from Supplier<br />

only in urgent cases of risk of improper operational safety and/or for<br />

preventing unreasonably large damage or should Supplier be in default<br />

with the elimination of defect. In such cases, Supplier shall be informed<br />

immediately.<br />

1 In order to guarantee proper operation of the lifting plant, all lifting plants should<br />

be serviced regularly. If no servicing is carried out as per DIN EN 12056-4 regulations,<br />

the warranty claim expires. For detailed information on DIN EN 12056-4<br />

regulations, please refer to the chapter „Inspection and Maintenance“. As main-<br />

7. Liability of supplier for compensation<br />

8. Excluding a redemption<br />

9. Use of software<br />

10. Applicable law, jurisdiction<br />

For complete Sales Terms and Delivery Conditions of <strong>ACO</strong> Passavant<br />

GmbH, please refer to:<br />

www.aco-haustechnik.de/unternehmen<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

17<br />

<strong>ACO</strong> <strong>Haustechnik</strong><br />

<strong>0150.16.08</strong> B<br />

3. Repair and/or replacement costs to be borne by Supplier – as far as<br />

the objection is justified – shall include costs for the replaced part including<br />

inland shipping costs as well as reasonable costs for removal and<br />

installation, and furthermore, if reasonably demandable in the individual<br />

case, costs for possible provision of its fitters and assistants.<br />

4. In particular, no warranty shall be granted in the following cases:<br />

Unsuitable or improper use, faulty assembly and/or putting into operation<br />

by Purchaser or any third party, natural wear and tear, faulty or<br />

negligent usage, improper maintenance 1, unsuitable operating means,<br />

defective construction works, unsuitable construction ground, chemical,<br />

electrochemical or electrical impacts – as far as such impacts are not<br />

due to Supplier's intention or negligence.<br />

5. Supplier shall not be responsible for consequences resulting from<br />

Purchaser's or any third Party's improper repairs. This provision shall<br />

apply also to alterations made to the object of delivery without Supplier's<br />

prior consent.<br />

6. The claims as fixed under section 6 – except of those resulting from<br />

section 478, 479, 438 subsection 1 no. 2, 634a subsection 1 no. 2<br />

German Civil Code – shall expire by limitation one year after delivery.<br />

tenance works have to be carried out by properly qualified staff, the closing of a<br />

maintenance contract covering the complete drainage plant is strongly recommended.

8 Suggested installations<br />

Sinkamat-K for below ground installation in frostproof premises below the backflow level, without insulation<br />

Tiles<br />

Base plate<br />

Soil<br />

Sinkamat-K for below ground installation in frostproof premises below the backflow level, without insulation, with sealing flange<br />

Tiles<br />

Base plate<br />

Soil<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

18<br />

Pump cable<br />

<strong>ACO</strong> small lifting plant<br />

Sinkamat-K<br />

for ground installation in<br />

frostproof premises below<br />

the backflow level<br />

Top section<br />

Pump cable<br />

Sealing flange<br />

<strong>ACO</strong> small lifting plant<br />

Sinkamat-K<br />

for ground installation in<br />

frostproof premises below<br />

the backflow level,<br />

with sealing flange

19<br />

<strong>ACO</strong> <strong>Haustechnik</strong><br />

Sinkamat-K for below ground installation in frostproof premises below the backflow level, with insulation<br />

Tiles<br />

Thermal insulation<br />

Base plate<br />

Soil<br />

<strong>0150.16.08</strong> B<br />

Pump cable<br />

<strong>ACO</strong> small lifting plant<br />

Sinkamat-K<br />

for ground installation in<br />

frostproof premises below<br />

the backflow level<br />

Sinkamat-K for below ground installation in frostproof premises below the backflow level, with insulation, with sealing flange<br />

Tiles<br />

Thermal insulation<br />

Base plate<br />

Soil<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

Top section<br />

Pump cable<br />

Sealing flange<br />

<strong>ACO</strong> small lifting plant<br />

Sinkamat-K<br />

for ground installation in<br />

frostproof premises below<br />

the backflow level,<br />

with sealing flange

9 Maintenance and functional check<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

20<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

21<br />

<strong>ACO</strong> <strong>Haustechnik</strong><br />

<strong>0150.16.08</strong> B<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

22<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Service-Line Tel. +49 (0) 36965 819–0<br />

Fax +49 (0) 36965 819–361<br />

23<br />

<strong>ACO</strong> <strong>Haustechnik</strong><br />

<strong>0150.16.08</strong> B<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

Maintenance and functional check<br />

of plant carried out as per installation and operating manual on:<br />

1. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:<br />

2. Maintenance:<br />

Date:<br />

Company:<br />

Telephone:

<strong>ACO</strong> Passavant GmbH<br />

Im Gewerbepark 11c<br />

D-36457 Stadtlengsfeld<br />

Tel. ++49 (0) 36965 819–0<br />

Fax ++49 (0) 36965 819–361<br />

www.aco-haustechnik.de<br />

The <strong>ACO</strong> Group. A strong family you can build on.<br />

Installation notes<br />

As per: 07/2010<br />

Origin: German manual<br />

Subject no. <strong>0150.16.08</strong> B<br />

HT 540E/07/2010 ● As per: 04/2010 LTC ● Subject no. <strong>0150.16.08</strong> B<br />

Origin: German manual ● Subject to technical alterations!